AMS 2175 28NOV2011

-

Upload

osmin-diaz -

Category

Documents

-

view

376 -

download

13

Transcript of AMS 2175 28NOV2011

-

8/2/2019 AMS 2175 28NOV2011

1/21

e.~A. , I I I i iMerOSpaceAn SAE I nt er na tI on al G r ou p

_ AMS2175AEROSPACEMATERIALSPECIFICATION

Issued JUL 2003

Cas tin gs, C la ssifica tio n a nd In sp ectio n o f

1. SCOPE:1.1 Purpose:

T his s pe cific atio n e sta blish es n on de stru ctiv e te stin g meth od s, s amplin g fre qu en cy , a nda cc ep ta nc e c rite ria fo r th e In sp ec tio n o f m e ta l ca stin gs .1.2 A pp lica tio n:

T his specification has been used typically for structura l castings, but usage is not lim ited to suchapplications.1.2.1 C asting M ethods: This specification is intended to apply to all casting m ethods except highpre ssu re d ie ca stin gs (se e 8 .3 ).1.2.2 C asting Alloys: This specification Is intended to apply to all casting alloys covered in Tables 6through 14. Other alloys m ay be inspected to th is standard as described in 3.4.3.2 usingc rite ria s pe cifie d b y th e c og niz an t e ng in ee rin g o rg an iz atio n.1 .3 C la ss ific atio n:

C astings that are inspected in accordance w ith th is specification are designated by classes andapplicable grades. The "C asting C lass" governs the frequency of inspection (see 3.1 and 4.3),w hile the "C asting G rade" contro ls the acceptance criteria (see 3.1 and 3.4).1.3.1 C lasses:

C lass 1 - A casting, the single fa ilure of w hich w ould endanger the lives of operatingpersonnel, or cause the loss of a m issile, aircraft, or other vehicle.

Superseding AMS-STD-2175

SAE Tec lllic al s ta nd ar ds B oa rd R ule s p ro vid e th at: 'T his r ep or t Is p ub lis he d b y SAE to a dv an ce t he s ta te o f te ch nic al a nd e ng in ee rin g s cie nc es . T he u se o f t his r ep ort Is e nt ire lyvo lu nta ry. a nd Its a pplica bility a nd suitab ility fo r an y p artlo ula r u se , Inc lu ding a ny p aten t Infrin gem en t a risin g th erefro m, Is to e so le re sp on sib ility of the use r.' :;SAE r ev ie ws e ac h te ch nic al r ep or t a t le as t e ve ry fiv e y ea rs a t wh ic h t im e It m ay be r ea ff irm ed , re vis ed , o r c an ce lle d. SAE I nv it es y ou r w ritte n c omments a nd s ug ge sllo ns . : :COPYrighl2003 SAE Internstional .'A ll r ig ht s r es er ved. No per t o f t his pub li ca ti on may be r ep roduced, s to red I na r et rie va l s ys tem o r t ra nsmi tt ed , I n an y f orm o r b y any means , e le ct ro nl o, ' Il 1eChenl ca l, p ho tooopy ln g,r eoor dl ~ o r o th erwi se , w it hout t he p rio r w ri tt en permis si on o f SAE.TO PLACEA DOCUMENTORDER: Tel: 877-606-7323 (Inside US A and Canada)Tel: 724-776-4970(outside USA)Fax: 724-77800780Email: cUltsvclae.orghttp://www.sae.orgM~,~tDDRE5S:by I HS U l " "t o n ae " " , h SA E>o du ct io o ' " n et oO Id ng p . .. .. . Ued wtthout IIcens. to m ltiS Uoen , . . . CunmIn, EnAiM Co k lc lI 23 25 0 21 0 0. U s er -; on e 1uk.N ot lor Re s. ' a , 05l ' . lOl2OO710:45:31 MDT

http://www.sae.org/http://www.sae.org/ -

8/2/2019 AMS 2175 28NOV2011

2/21

AMS 2175 SAE AMS 2175

1.3.1 (Continued):Class 2 - A casting, the single failure of which would resuH in a significant operational

penalty. In the case of missiles, aircraft, and other vehicles, this includes loss ofmajor components, unintentional release or inability to release armament stores, orfailure of weapon installation components.

Class 3 - Castings not included in Class 1 or Class 2 and having a margin of safety of 200percent or less.

Class 4 - Castings not included in Class 1 or Class 2 and having a margin of safety greaterthan 200 percent.

1.3.2 Grades: Castings, or sections of a casting, shall be of the following grades:Grade A - The highest quality grade of casting, or area of a casting, with minimum allowable

discontinuities and very difficult to produce except in local areas.Grade B - The second highest quality grade of casting, or area of a casting, which allows

slightly more discontinuities than Grade A, and difficult to produce, except in localareas.

Grade C - A high quality grade of casting, or area of a casting, that can be consistentlyproduced.

Grade D - The lowest quality grade of a casting, or area of a casting, that is easily producedand is used primarily for low stress or noncritical areas adjacent to the highergraded areas.

2. APPLICABLE DOCUMENTS:The issue of the following documents in effect on the date of the purchase order forms a part ofthis specification to the extent specified herein. The supplier may work to a subsequent revisionof a document unless a specific document issue is specified. When the referenced document hasbeen canceled and no superseding document has been specified, the last published issue of thatdocument shall apply.

2.1 ASTM Publications:Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959 orwww.astm.org.ASTM E 155 Reference Radiographs for Inspection of Aluminum and Magnesium

CastingsReference Radiographs for Heavy-Walled (2 to 4.5-in. (51 to 114-mmSteel CastingsReference Radiographs of Investment Steel Castings for AerospaceApplications

ASTM E 186ASTM E 192

.... ' ..BAl i I Il l emo t iona lb y I HS uo'1d lcens" _ BAE

l du ct im o r networking permlUed without l icense to m 1!-iS IJcensee=CoomIns E n Q I n e co II lcl12J2502111O.User=jones.""No l for R e 'a i o .1 J5 I 'J 0I 20 07 10 :4 S ;3 ' M [ )T

http://www.astm.org./http://www.astm.org./ -

8/2/2019 AMS 2175 28NOV2011

3/21

AMS2175

2.1 (Continued):ASTM E272ASTM E280ASTM E 310ASTM E446ASTM E 1255ASTM E 1320ASTM E 1417ASTM E 1444ASTM E 1742

2.2 NAS Publications

SAE AMS2175

Reference Radiographs of High-Strength Copper-Base and Nickel-Copper Alloy CastingsReference Radiographs for Heavy-Walled (4.5 to 12-in. (114 to 305-mmSteel CastingsReference Radiographs for Tin Bronze CastingsReference Radiographs for steel Castings up to 2 in. (51 mm) inThicknessRadioscopyReference Radiographs for Titanium CastingsLiquid Penetrant ExaminationMagnetic Particle ExaminationRadiographic Examination

Available fromAlA, 1000Wilson Boulevard, Suite 1700, Arlington, VA 22209-3901 orwww.aia-aerospace.org.NAS410 Certification and Qualification of Nondestructive Test Personnel

3. TECHNICAL REQUIREMENTS:3.1 Classification of Castings:3.1.1 Determination of Classes and Grades: The cognizant engineering organization shall establishthe class and grade(s) for each casting design (see 1.3). Sections of a casting may be ofvarying grades depending on the applied stresses to that portion of the casting. Particular

attention should be given to areas that contain, or will eventually contain, stress risers aftermachining (such as sharp internal corners, holes, or notches).3.1.1.1 If the grade of casting is not indicated on the drawing or other contractual document,Grade C shall apply, except for Class 4 castings, where Grade D shall apply.3.1.1.2 Class 1 Casting Requirements: All areas of Class 1 castings shall be of a quality equivalentto, or better than, Grade C, except that all highly stressed areas of a Class 1 casting shallbe of a quality equivalent to, or better than, Grade B.3.2 Inspection Sequence:

It is the responsibility of the vendor to perform appropriate inspections as necessary and in theproper sequence during processing to assure freedom from harmful discontinuities in the finalproduct. The intent of Inspections during processing is to detect flaws that would be detrimentalto the final product at the earliest stage in processing so as to minimize the cost of rejected orscrapped castings. The sequence for penetrant, magnetic particle, and radiographicinspections shall be as specified in ASTM E 1417, ASTM E 1444, and ASTM E 1742,respectively, or as otherwise specified by the cognizant engineering organization .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .- 3-SAE IntemadonalO>dby IHS under irense with SA EP"onIUed wHhout licensefnlm IHS Llcensee=Cunmlns EngIne Co Incl12325021 00, User= jones, lukeNo t lor Resale , 05I31 l12OO710:45:31 MDT

http://www.aia-aerospace.org./http://www.aia-aerospace.org./ -

8/2/2019 AMS 2175 28NOV2011

4/21

AMS 2175 AMS 2175AE

3.3 Personnel Qualification:Personnel performing penetrant, magnetic particle or radiographic inspections shall be qualifiedand certified in accordance with NAS 410 for the applicable method.

3.4 Inspection Methods and Acceptance Criteria:3.4.1 Visual Inspection: Visual inspection shall be performed in areas with adequate lighting.

Ambient lighting should not be less than 75 foot-candles. Castings shall be free of foreignmaterials, and shall not contain cracks, hot tears, cold shuts, and negative core seams (alsocalled parting line below flush). In addition, castings shall conform to the criteria specified onthe engineering drawing, specification, or agreed upon observational standards (see 8.4).The following criteria shall also apply:

3.4.1.1 Surface Roughness: Surface roughness shall conform to the engineering drawingrequirements. Surface roughness requirements specified on the engineering drawing(Le., 63 Ra, 125 RMS, etc.) do not preclude the presence of acceptable liquid penetrant ormagnetic particle indications. Visual and tactile comparison with commercially availableobservational standards may be used to determine conformance to surface roughnessrequirements.

3.4.1.2 Gate, Riser, and Parting Line Projections: If allowance limits for gate, riser, or parting lineprojections are not specified on the engineering drawing or casting (materief) specification,then the maximum limit for gates, risers and parting lines shall be in accordance withTable 3.

3.4.1.3 Surface Pits and Raised Metal: Allowable surface pits and raised metal (also called positivemetal), other than gates, risers and parting lines, that are not specifically controlled by theengineering drawing or agreed upon observational standards shall be allowed as specifiedin 3.4.1.3.1 and 3.4.1.3.2.

3.4.1.3.1 For sand castings, surface pits are acceptable if they have smooth rounded contours anddo not cause the casting to fall outside the dimensional requirements of the engineeringdrawing. Raised metal that has a jagged or irregular surface, or which causes the castingto fall outside of the dimensional requirements of the engineering drawing, shall beremoved or blended to conform to the dimensional and surface roughness requirements ofthe engineering drawing.

3.4.1.3.2 For investment and permanent mold castings, random raised metal shall be limited to aheight of 0.015 to 0.030 inch (0.38 to 0.76 mm) in an area 0.125 x 0.125 inch (3.2 x 3.2mm) and no more than one per square inch (650 mrrr), Random surface pits shall belimited to 0.030 to 0.060 inch (0.76 to 1.5 mm) in diameter and 0.030 inch (0.76 mm) indepth and no more than one per square inch (650 mrrr), Surface pits less than 0.030 inch(0.76 mm) deep or raised metal less than 0.015 inch (0.38 mm) in height may be present.

............................. -4-SA E intemationaled byIHSunder iceose";'h SAEl f 't ) du c ti cn o r ne two rk in g pennl t le d witilotA license (rom IHS Ucensee=CurmIns EngIneCo 1nc11232502100 .Use t = jones , l uk eNot for Resale. 0 5 13 0 12 0 07 1 0 ;4 5 ;3 1 MOT

-

8/2/2019 AMS 2175 28NOV2011

5/21

AMS2175 AMS2175AE

3.4.2 Magnetic Particle and Penetrant Inspection:3.4.2.1 Inspection Method for Ferromagnetic Materials: The method for inspection of ferromagneticmaterials shall be in accordance with ASTM E 1444. When approved by purchaser,penetrant inspection may be performed in lieu of magnetic particle inspection (e.g., castingsize or complex shape prevent adequate magnetic particle inspection). All precipitationhardening stainless steels shall be penetrant inspected in accordance with 3.4.2.2, unlessotherwise specified by the purchaser.3.4.2.2 Inspection Method for Nonferromagnetic Materials: The method for inspection ofnonferromagentic materials shall be in accordance with ASTM E 1417. The cognizantengineering organization may specify the sensitivity level of the penetrant materials to beused. If no sensitivity level is specified, the inspection facility shall use Sensitivity Level 1 orbetter.3.4.2.3 Magnetic Particle and Penetrant Acceptance Criteria: Ifthe magnetic particle or penetrantacceptance criteria are not specified, the surface quality shall conform to Table 4.3.4.3 Radiographic Inspection:3.4.3.1 Radiographic Inspection Method: The method for inspection shall be in accordance withASTM E 1742. The use of nonfilm radiographic techniques (Le., radioscopy, digitalradiography, etc.) is permitted provided the method used is sufficiently sensitive to resolvethe required radiographic quality level. Radioscopic inspection shall be conducted inaccordance with ASTM E 1255; however, prior approval shall be obtained from thecognizant engineering organization on the detailed inspection, evaluation, documentation,and quality control procedures.3.4.3.2 Radiographic Reference Standards: Radiographic standards shall be as required in ASTME 155, ASTM E 186, ASTM E 192, ASTM E 272, ASTM E 280, ASTM E 310, ASTM E 446,and ASTM E 1320. For alloy types where reference radiographs are specifically covered,the reference radiographic shall be of the same alloy family as the casting. For alloys notspecifically included in the alloy family covered by the ASTM reference radiographicstandards, the coqnlzant engineering organization shall either specify an ASTM standardrepresentative of the quality required, or develop its own radiographic standards containingdetails comparable to an ASTM standard.3.4.3.3 Radiographic Acceptance Criteria: The cognizant engineering organization shall specify theradiographic grade(s) for Class 1,2 and 3 casting designs. Radiographic grade(s) may bespecified for Class 4 castings. Castings shall meet the requirements for the applicablegrade(s) as shown in Tables 6 through 14. The maximum permissible radiographic severity

levels for graded titanium castings shall be specified by the cognizant engineeringorganization.

-5-SAE ln temaUona Iby(HS under icen.. with SAEtion or _ngpenr;tted without license tom (HS Llcl!nsee=O.mnlns IiO!(Ine Co (nci1232502100. Usor=jones._Not fo r Resalo. 05l30I200710:45:31 M O T

-

8/2/2019 AMS 2175 28NOV2011

6/21

AMS 2175 SAE AMS 2175

4. QUAL IT Y A SSURANCE PROV IS IO NS4 .1 Re spon sib ility fo r In sp ec tio n:

The vendo r o f c as tin gs sha ll s up ply a ll s amp le s fo r v en do r's te sts a nd sha ll b e re sp on sib le fo rth e p erfo rmance o f a ll re qu ire d te sts . A ll te stin g sha ll b e p erfo rmed a t fa cilitie s a ccep ta ble top urc ha se r. P urc ha se r re se rv es th e rig ht to s amp le a nd to p erfo rm any con firma to ry te stin gdeemed necessa ry to ensure tha t t he cas tings con fo rm to specifie d requ irements .4 .2 C la ss ific atio n o f T es ts :4 .2 .1 A ccep ta nce Tes ts : In sp ec tio n fo r v is ua l (3 .4 .1 ), magnetic p artic le o r p enetra nt (3 .4 .2 ), a nd ,when specifie d (see 4 .3 .3 ), r ad iogr aphic (3 .4 .3 ) soundness a re accep tance te st s and sha ll bep erfo rmed on each lo t.4 .2 .1 .1 In sp ec tio n L ot: A n in sp ec tio n lo t, fo r th e p urp oses o f v is ua l, p en etra nt, magnetic p artic le ,

and rad iographic in spec tion sha ll be as def ined in the cas ting (materia l) specln ca tlon,e ng in ee rin g d rawin g, o r p urc ha se o rd er. If n ot s pe cifie d in a ny o f th e a bo ve documents , a nin sp ec tio n lo t s ha ll b e d efin ed a s a ll c as tin gs o f th e s ame p art n umbe r a nd th e s ame a llo y,p roduced using the same p rocess ing parame te rs o f the cas ting p rocedure , and subm it tedfo r in sp ec tio n a s a s in gle g ro up .4.3 S am pling and T esting:

Shall be in accordance w it h the follow ing:4 .3 .1 V is ua l in sp ec tio n: E ac h c as tin g s ha ll b e 1 00% v is ua lly e xamin ed .4 .3 .2 Magnetic p artic le a nd penetra nt in sp ec tio n: E ach cas tin g sha ll b e sub je cte d to e ith ermagnet ic part ic le o r pene tr an t in spec tion, a s app ropr ia te (see 3 .4 .2 ), e xcep t t ha t C la ss 4cas tin gs sha ll b e samp le in sp ec te d in a ccord an ce w ith Tab le 1 o r g re ate r, u nle ss a fre quen cyo f 1 0 0 p erc en t is s pe cifie d.4 .3 .3 Radio gra ph ic in sp ec tio n: S amp lin g in sp ec tio n a nd in sp ec tio n covera ge sha ll b e a s in dic ate dbelow:

C la ss 1 cas tin gs - E ach cas tin g sha ll b e comp le te ly e xam in ed .C la ss 2 cas tin gs - Ca stin gs sha ll b e sele cte d in a ccord an ce w ith Tab le 1 and comp le te lyexamined.

C la ss 3 cas tin gs - Cas tin gs sha ll b e sele cte d in a ccord an ce w ith Tab le 2 and comp le te lyexamined.C la ss 4 cas tings - Rad iograph ic exam ination is not r equir ed unle ss o therw ise specifie d.

-6-8AE Intemodonolb y I HS u nd er l IO en se w it h S A Ero duCliM o r ne two lt dng penr lt te d wtthout I rcen. el rorn I llS L I c en s .. .. c .. rm " '. E nAk teCo k t c It 2 32 5 02 tOO . US I IP 'j o ne> . lu k eNo t l o r R e so le . 0 5 l3 0l 20 0 7 1 0: 45 :3 1 MDT

-

8/2/2019 AMS 2175 28NOV2011

7/21

AMS2175 SAE AMS2175

4.3.3.1 If radiographic examination is specified and no sampling is specified, Table 2 shall apply.4.3.3.2 When approved by purchaser, a statistically based continuous sampling plan may be used

instead of lot sampling.4.4 Reports:

The vendor of castings shall furnish with each shipment a report showing the results ofinspections for visual, magnetic particle or penetrant, and, when specified, radiographicsoundness of each lot of castings. This report shall include the purchase order number, meltand heat treat lot numbers, AMS 2175, casting part number, quantity, and, when applicable,casting serial number(s).4.5 Resampling and Retesting:4.5.1 Reinspection of Rejected Lots: When an inspection lot is rejected on the basis of a sampling

plan, regardless of the inspection method, it may be resubmitted for 100 percent inspectionand unacceptable castings removed from the lot per 4.5.2. For lots rejected by a radiographicinspection sampling plan, the radiographic views where the unacceptable discontinuities werefound shall be inspected on the balance of the castings in the lot.4.5.2 Individual Casting Rejection: Individual casting rejection shall apply in those instances whereall castings in the lot are inspected and any individual casting is found unacceptable to visual,penetrant, magnetic particle, or radiographic Inspection requirements. Only unacceptablecastings need to be rejected, and individual castings meeting the requirements of thisstandard may be accepted.4.5.3 Discontinuity Removal: If it is determined that rejectable discontinuities shall subsequently beremoved by machining on machining stock surfaces, or by blending on as-cast surfaces, thenthose discontinuities shall not be cause for rejection provided reinspection is performed afterthe material removal to verify that the discontinuity was removed and the dimensionaltolerance requirements of the casting are satisfied.5. PREPARATION FOR DELIVERY:

Not applicable6. ACKNOWLEDGEMENT:

A vendor shall mention this specification number and Its revision letter in all quotations and whenacknowledging purchaser orders.7. REJECTIONS:

Castings not conforming to this specification, or to modifications authorized by purchaser, will besubject to rejection.

, - -7-SAE .,.ematiOMIby IHS under . .. .. .. with SAE

ductim 0( n etwo f1dng pennt ted without l ic en se kom IHS UcenseeoQmnJns Enj JJ ne Co I nc ll 232502100, Use r= jo ne s, U teNo l for ResaJe, 05/3(J/2007 10:45 :3 1 MOT

-

8/2/2019 AMS 2175 28NOV2011

8/21

AMS2175 SAE AMS2175

8. N OTES:8.1 A change bar (I ) lo ca te d in th e le ft ma rg in is fo r th e con venie nce o f t h e u se r in lo ca tin g a re as

where te ch nic al re vis io ns , n ot e dito ria l c ha nges , h ave been made to th e p re vio us is su e o f aspe cific atio n. A n (R ) s ymbol to th e le ft o f th e d ocument title in dic ate s a comp le te re vis io n o f th especificat ion, in cluding te chnical r ev is ion. Change bar s and (R ) a re not u sed in o rig inalpub lica tions, no r in spec if ica ti ons tha t contain ed itor ia l changes on ly .8 .2 D imens io ns a nd p ro pe rtie s in in ch /p ound units a nd th e Fah re nheit tempe ra tu re s a re p rima ry ;d imens io ns a nd p ro pe rtie s in S I u nits a nd th e Cels iu s tempe ra tu re s a re shown a s app ro xima teequ ivalent s o f t he p rima ry unit s and a re p resented only f or in fo rma tion.:~ .3 Intended U se:i: Th is s tandard p rescr ibes accep tance cri te ria for su rface inspec tions and rad iog raphicin sp ec tio ns a pp lie d to me ta l c as tin gs . This s ta ndard is n ot in te nd ed to a pp ly to h ig h p re ssure

d ie cas tin gs . A ccep ta nce c rite ria fo r d ie c as tin gs may be based on s ta ndard s a nd guid elin esd evelo ped b y th e Americ an Soc ie ty fo r Tes tin g a nd Ma te ria ls (ASTM ), a nd th e No rth Americ anD ie Cas tin g A ssoc ia tio n (fo rme rly th e Americ an D ie Cas tin g In stitu te (ADC I . E xample s a reASTM B 5 0 5 a nd ADCI "Q ", "E ", a nd "M " s erie s s ta nd ard s.8 .4 Ob se rv atio na l S ta ndard s:

Obse rvat iona l s tanda rds for v isua l in spec tion may in clude samp le cas tings w ith knownd iscontinuit ie s. Assis tance w it h the v isua l in spec tion c rite ria f or s teel cas tings may be obtainedby reference to MSS SP-5 5 and A STM A 80 2. MSS SP-5 5 ("Q uality S tandard for S te elCas tin gs fo r Valv es , F la ng es , a nd F ittin gs a nd o th er P ip in g Componen ts - V is ua l Me th od "ava ilable fr om the Manu factu re r's S tandardizat ion Socie ty o f t he Va lve and F itt in gs Indus tr y,127 Pa rk S treet , N .E ., V ienna, VA 22180 ) con ta in s r efe rence pho tographs tha t illu st ra te variousty pe s and deg re es o f s urfa ce d is co ntin uitie s, while ASTM A 802 ("S te el Cas tin gs , S urfa ceAccep tance Standards , V isua l Examina tion ") contains p la tes tha t mode l ac tua l d iscon tinu it iesand su rface roughness .8 .5 P roducib ilit y Cons idera tions :

The c la ss a nd g ra de a ss ig ned to th e cas tin gs should re pre se nt a re alis tic v alu e fo r th efu nc tio na l re qu iremen ts (e .g ., C la ss 1 cas tin gs should n ot b e spe cifie d fo r a C la ss 2app lication). Casting des ign coupled w ith found ry p ractice can make ove rly severe soundnessrequir ements imp ractical f or a manu factu re r t o satis fy . Consult atio n w it h the p roducing found ryo r experienced cas ting des ign per sonnel is re commended befo re specif ying the cas ting g rade .(See 1 .3 .)

-8-SAe lnIomllfonaibyIHS underlloonoe withSAe Uoen. . . . CUnvnIns E O A N Co 1nc11232502100 ,UsoP jon , lu k eNOIIorR e . . I8, 05l30l2007 10 :45 ;31 MDT

-

8/2/2019 AMS 2175 28NOV2011

9/21

AMS2175 AMS2175AE

8.6 Radiographic quality grades for machined areas:Castings that have been found acceptable per the ASTM radiographic standards may haveinternal discontinuities (such as shrinkage, porosity, and inclusions) that become exposed bymachining. One method of alleviating this problem is quantifying (in terms of size) the ASTMreference radiographic discontinuities so that their size on the surface may be approximated.Once this has been performed, the cognizant engineering organization should be able todetermine if the discontinuities allowed in the radiographic grade will be permissible on thesurface. If they are not permissible, the area that is machined should be zoned to a morestringent radiographic grade.

8.7 Ultrasonic Inspection of Thick Castings:Class 1 and Class 2 castings that have a section thickness of 4.50 inches and greater shouldalso be inspected by ultrasonic methods due to the loss of radiographic sensitivity in the thickersections. It should be noted that ultrasonic examination may not be practical for a" castingconfigurations. Because ultrasonic inspection and radiographic inspection require different testmethod standards and different acceptance standards, the cognizant engineering organizationwill need to specify the appropriate document for performing ultrasonic inspection along with theappropriate quality level of acceptance criteria contained within that document.

8.8 Terms used in AMS are clarified in ARP1917 and defined as follows:8.8.1 Chaplet: Metal core support that is used in the mold cavity and fuses into the casting.8.8.2 Cold Shut: An imperfect junction between two flows of metal in a mold caused by the surfaceof the streams of molten metal chilling too rapidly such that complete fusion does not occur.This discontinuity may have the appearance of a crack or lap with smooth or rounded edges.8.8.3 Core Shift: Movement of a casting core such that a change in position can be discerned.Cores are portions of the mold that may create internal passageways or other castingfeatures.8.8.4 Crack: A separation (rupture or fracture) of metal that was once joined in the solid state andproduces a linear indication observed during nondestructive testing. See "cold shut" and "hottear" for examples of other discontinuities that also produce linear indications.8.8.5 Defect: A discontinuity or condition that exceeds allowable limits. Defects are, by definition,unacceptable.8.8.6 Discontinuity: An interruption in the normal physical structure or configuration of a part such

as a crack, inclusion, or porosity, which mayor may not affect the usability of the part.

. . - - - .-9-SAE Intemationoled by IHS under icenso wnh SAEro duc tl cn o r ne two f 1dngpenrltted without l i cen se f rDm IHS Ucens ee=C lmnln9 Eng In e Co 1n< 'J 1232502100 . Use r- jo ne s. lu keNot for Resale, 0 51 30 12 00 7 1 0: 45 :3 1 M DT

-

8/2/2019 AMS 2175 28NOV2011

10/21

AMS 2175 SAE AMS 2175

8.8.7 Foreign Material: Material other than the specified metal alloy, typically sand, slag, oxide,dross, or metal of different density. Indications of foreign material appear as isolated,irregular, or elongated variations of radiographic film density In radiographic inspection whereacceptance criteria exists for both foreign material and inclusions, the distinguishing factor isthat the foreign material indications usually occur over a larger area while the inclusionindications are usually singular indications of a few discrete inclusions.

8.8.8 Gas Holes: Round or elongated, smooth-edged voids occurring individually, in clusters, ordistributed throughout the casting. They are generally caused by trapped air or gases evolvedfrom the metal during solidif ication.

8.8.9 Gas Porosity: Tiny voids distributed throughout the entire casting or a portion of the casting.They are generally caused by trapped air or gases rejected from the metal or mold materialduring solidification.

8.8.10 Hot Tear: A fracture that forms upon sOlidification of the moHen metal, often resulting fromabrupt changes in section thickness that cause nonuniform cooling contraction. Radiographicimages of hot tears appear as ragged dark lines of variable width and with no definite line ofcontinuity. Hot tears may exist in groups and generally start at the surface.

8.8.11 Inclusions: Particles of foreign material such as mold sand or shell and slag or dross that areembedded in the casting.

8.8.12 Insert: A piece of metal preplaced within the mold cavity and used to locally increase the rateof heat removal during solidification. It fuses to the final casting and is also called an internalchill.

8.8.13 Misruns: The failure of the molten metal to completely fill the mold. A misrun appears on theradiograph as prominent darkened areas of variable dimensions with a definite and smoothoutline.

8.8.14 Penetrameter or Image Quality Indicator (IQI): A strip of metal that is radiographically similarto the metal being tested, representing a percentage of object thickness and provided with acombination of steps, holes, or wires. When placed between the radiation source and film, itsimage provides a check on the radiographic technique employed.

8.8.15 Radiographic Quality Level: The ability of the radiographic procedure to demonstrate acertain IQI sensitivity based on the detection of the IQI holes or wires.

8.8.16 Segregation: A concentration of alloying elements in specific regions of the casting, usuallythe result of the primary crystallization of one phase with the subsequent concentration ofother elements in the remaining liquid.

- 10-SAE In temadono lby IH S unde

-

8/2/2019 AMS 2175 28NOV2011

11/21

AMS 2175 SAE AMS 2175

8 .8 .1 7 S hrin ka ge : T he te rm s hrin ka ge , a s u se d in th is sta nd ard , re fe rs to a n etw ork o f sma ll v oid sfo rm in g due to g ra in b oundary s olid ific atio n p henomena. A la rg er a nd s in gu la r v oid cau sed b ysolid ific atio n shrin ka ge on a la rg e s ca le , a s d efin ed in 8 .8 .1 8 is c alle d a shrin ka ge cav ity .Sh rin kage is typically catego rized as dendr it ic , f ilamen ta ry , f ea thery , o r sponge. Sh rin kage isu su ally c on centra te d below th e surfa ce but may e xte nd to th e surfa ce . In ra dio gra ph icI nspection, depending on the category , shrin kage may appea r as dar k irr egula r patches, a sd ark fe ath ery s tre ak s, o r a s a la cy o r a h oney combed dark ened a re a w ith a d iffu se outlin e.Rad iographic re fe rence s tandards p rovide v isua l e xamples o f each subca tego ry o f shrin kage.In pene tran t inspec tion , dendrit ic sh rinkage (sometimes ca lled "mic roshr inkage" ) and spongeshrin ka ge a re o fte n in dis tin gu is ha ble from each o th er a nd appea r a s a sponge-lik e c lu ste r o ftin y p inho le s o r spo tt y irr egula r a reas w it h fea ther y outlin es . In magnet ic part ic le in spec tionshrin ka ge , ma y appea r a s a ja gged a re a o r irre gu la r p atc h o f magnetic p artic le s.

8 .8 .1 8 Shrin ka ge Cavity : A d is cre te v oid w ith in a sec tio n o f th e cas tin g cau sed b y in su ffic ie nt fe ed in go f mo lt en me ta l dur ing solid ification and volume reduct ion o f the me ta l a s it solid if ie s.Sh rin kage cav itie s appea r on the radiograph as dark a reas that a re indis tin ct ly ou tlin ed andhave i rregu lar d imensions.

8 .8 .19 Su rface I rr egula rit ie s: Any anomoly , e ither pos itive ( ra ised ) o r negat ive ( depressed ) f rom thenorma l c as t s urfa ce . The se a re b es t o bserv ed b y v is ua l in sp ec tio n, b ut ma y p ro du ceind ica tions in magnet ic pa rt ic le , pene tran t, o r rad iog raphic inspec tion .8 .8 .2 0 V is ua l In sp ec tio n: In sp ec tio n o f c as tin g surfa ce s to d ete rm in e con fo rmance to th erequ iremen ts for su rface roughness , su rface ir regular it ies , d imens ions, o r any v is ib le su rfacediscontinuities.8.9 C ross R eference:

The c la ss o f cas tings defined in 1 .3 cor re sponds to p revious des igna tions o f t his speC if icat ionas fol lows :AMS2175 M IL -STD -2175AMS-STD -2175 MIL -C-6021H MIL -C-6021GC lass 1 Class 1 Class 1, C lass 1AClass 2 Class 2 C lass 1, C lass 1BClass 3 C lass 3 C la ss 2 , C la ss 2 AC lass 4 Class 4 C la ss 2 , C la ss 2 B

PR EPAR ED U NDER TH E JU R ISD IC TIO N O F AMS COMMITTEE uB "

- 11 -S A E I n le m aU om Iby IH S oodet IIoon8e w it h S A El 0

-

8/2/2019 AMS 2175 28NOV2011

12/21

AMS2175 SAE AMS 2175

TABLE 1 - Samp lin g, Radio gra ph ic In sp ec tio n o f C la ss 2 Cas tin gs , a ndMagnetic Pa rtic le and Pene trant I nspect ion o f C la ss 4 CastingsLo t S ize [1] Samp le S ize [2] Lo t S ize [1] Samp le S ize [2]2- 5 All 27- 36 106- 8 5 37- 51 119-11 6 52- 82 1212-15 7 83-162 1316-20 8 163- 971 1421-26 9 972 and o ve r 15

Notes:[1] See 4.2.1.1 f or lo t defin it io n. When app roved by purchase r, a s ta tis ticallyb ased con tin uo us samplin g p la n may be u sed in ste ad o f lo t s amplin g.[2] Accep ta nce number is O .

TABLE 2 .- S amplin g, Radio gra ph ic In sp ec tio n o f C la ss 3 Cas tin gsLo t S ize [1] Sample Size [2] Lo t S ize [1] Sample Size [2]2- 4 All 18-27 75- 6 4 28-48 87 -11 5 49 and ove r 912-17 6

Notes:[1] See 4.2.1.1 f or lo t defin itio n. When app roved by purchase r, a s ta tis ticallyb ased con tin uo us samp lin g p la n may be u sed in ste ad o f lo t s amplin g.r21 Accep ta nce number is O .

8AE In l em0 1l " " ,, 1b y I HS oodet loon... y , ft h 8AEnor_ngpennlUOdwfthOUIlicen fromIHS

- 12-u o en s . .. C lm n m EfllIIoo Co 1nd1232502100,lJserojonel,1ukeN o l l or Resa l e , 0 5 13 0 12 00 1 10 :4 8 :3 1 MD T

-

8/2/2019 AMS 2175 28NOV2011

13/21

AMS2175 SAE AMS 2175

T AB LE 3 - M ax im um A llo wab le G ate , R is er, a nd P artin g L in e P ro jec tio ns

C as tin g We ig ht, P ounds N onmac hin ed S urfac e, In ch es M ach in ed S urfa ce , In ch es(Kg) (mm ) (mm )Up to 10 0.031 0.062(U p to 4.5 ) (0.79) (1 .57)

Over 10 thru 25 0.047 0.062(O ve r 4.5 th ru 11 .3 ) (1.19) (1.57)Over 25 thru 50 0.062 0.094

(Over 11.3 thru 22.7) (1 .57) (2.39)Over 50 0.125 0.188

(Over 22.7) (3.18) (4 .78)

-13 -SAE "" .maVor a ib v I HS u nd o' 1Icens. YAthSAE0,_nge n r jl l 8 d w l t h oU l l 1o e n t a from IH S L l o o n . . . . .c.mnn. EnAm Co 1noI1232502100. U . . . -. ; o n . Iuk.Noliot Resale. 0513012007 1 0: 45 :3 1 MOT

-

8/2/2019 AMS 2175 28NOV2011

14/21

~MS2175 SAE

TABLE 4 - Maximum Allowable Discontinuity Size and Distribution in Inchesfor Magnetic Particle and Penetrant Inspection [1] [2] [3] [4] [9]Discontinuity Type Grade A Grade B Grade C Grade DRandom Individual Discontinuities 1/4 T orthe 1/3 T or the 1/3 T or the 1/2 T or the(Gas Holes, Inclusions, Discrete sizes sizes sizes sizesShrinkage Cavities), Nonlinear shown shown shown shown[5] [6] below, below, below, below,whichever whichever whichever whicheverSurface .................................. is less: is less: is less: is less:Subsurface (Magnetic Particle only) 0.03 dia 0.05dia 0.09 dia 0.12dia0.05dia 0.09 dia 0.12 dia 0.15 dlaCracks, Hot Tears, Cold Shuts, or None None None NoneThrough-Wall DiscontinuitiesMicroshrinkage or Shrinkage 0 0.12 dia 0.38 dia 0.75 diaSponge, Nonlinear [7]Microshrinkage or Shrinkage 0 0 0.12 0.25Sponge, Linear [1] [4]Number of Random Individual 2 3 4 4Discontinuities Discontinuities [8]Allowed Within a 2 Microshrinkage or 0 1 1 1x 2 Inch Area Shrinkage SpongeNotes:[1] Linear discontinuities (length to width rat io of 3 to 1 or greater) are not allowed except under thefollowing circumstances:

a) Linear dendritic shrinkage or linear shrinkage sponge indications shall be evaluated inaccordance with this table and shall not be allowed to break over an edge, extend through a wall,or be located in internal comers of fillet radii.b) In magnetic particle inspection, discontinuities 0.030 inches or less in length need not beevaluated for linearity. In penetrant inspection, discontinuities 0.015 inches or less in lengthneed not be evaluated for linearity.

[2] Discontinuities that are visible under white light without the use of penetrant or magnetio particlesmay be evaluated to the criteria of this table.[3] Size limits shown are for actual discontinuity size as opposed to bleed out from penetrant inspection.Indications may be inspected by measuring their size after wiping with a solvent dampened cloth,cotton swab, or brush. Immediately evaluate the discontinuity for size as soon as the solvent hasevaporated.[4] For rounded indications exhibiting excessive bleedout, or doubtful indications of microshrinkage orsponge shrinkage, disposition may be based on the radiographic acceptance criteria afterradiographing the part. Linear microshrinkage or linear sponge shrinkage shall only be acceptableafter verification by radiography.[5] For random individual discontinuities, the minimum resolvable size shall be 0.030 inches for magneticparticle inspection and 0.015 inches for penetrant inspection. Discontinuities smaller than thesesizes shall be considered non-interpretable.[6] For Grade A, any tw o random individual discontinuities shall be separated by a distance of at leastthree times the maximum dimension of the larger discontinuity. For Grades B, C, and D, randomindividual discontinuities shall be separated by a distance equal to twice the maximum dimension ofthe larger discontinuity. However, if the total length of the discontinuities that violate this spacingrequirement does not exceed the maximum length permitted for a single discontinuity, then thesediscontinuities shall be considered as one and shall not be cause for rejection.[7] Microshrinkage is also called dendritic shrinkage.[8] The limits for random individual discontinuities do not apply if the discontinuities are smaller than one-half their maximum allowable size and they meet the minimum spacing requirement of Note [6].[9] "T" is the casting section thickness.

8AE internationalby tHS under Icen.a Yo4Ih8AEn or nOlWOrtdng penrittad wI1hout lleens. to m IHS

- 14-L lo o n. ao o Cu rn n ln s E I1 !I N Co 1n

-

8/2/2019 AMS 2175 28NOV2011

15/21

AMS2175 SAE

TAB LE 5 - N otes for Tables 6 through 14

[1 ] A n a re a o f lik e s iz e to th e re fe re nc e ra dio gra ph s ha ll b e th e u nit a re a b y whic h th ep roduction radiograph is eva luated. If th e p roduct ion r ad iogr aph shows ad is co ntin uity th at is e qual to o r b ette r th an th e severity le ve l o f th e re fe re ncera dio gra ph , th e cas tin g sha ll b e a ccep ta ble . If th e p ro du ctio n ra dio gra ph shows ad iscontinuit y o f g reater sever it y t han the refe rence rad iogr aph, t he cas ting sha ll berejected.[2 ] W h en tw o o r more ty pe s o f d is co ntin uitie s a re p re se nt (in a n a re a e qu al to th er efe rence radiograph ic p la te a rea) t o an extent equal t o the maximum perm issib lesever it y le ve l fo r each t ype, t he cas ting sha ll be r eje cted .[3 ] N umb ers in th e ta ble a re ASTM ra dio gra ph ic p la te n umbe rs fo r a p artic ula r ty pe a ndsever it y o f d is cont inuit y. A low number indicate s fewer, smalle r d is cont inuitie s wh ilea h igher number ind ica tes more numerous, l arge r d iscon tinu it ies .[4 ] T he m in imum re so lv ab le ra dio gra ph ic in dic atio n s iz e sha ll b e 0 .0 1 5 In ch es .Ind ica tions sma lle r than thi s s ize shall be cons ide red non- in te rp re tab le .[5 ] Ga s hole s, s an d spo ts , a nd in clu sio ns a llowed b y th ese ta ble s (e ve n th ose smalle rth an th e maximum a llowab le s iz e) s ha ll b e cau se fo r re je ctio n when c lo se r th an tw ic eth eir m ax im um d imen sio n to a n e dg e. E xc ep tio ns to th is n ote b as ed o n th e C la ssa nd G ra de o f th e c as tin g a re sh own b elow:

C lass 1 - N o exceptions from N ote [5 ].C lass 2 - N o exceptions from N ote [5 ] for G rade A and G rade B areas, or oth er areasth at a re spe cifie d c ritic al o r h ig hly s tre ssed . O th erw is e, th e No te [5 ]d is co ntin uitie s a re a ccep ta ble if th ey a re separa te d from th e edge b y ad is tance equal to o r g reater t han the d iscont inuity 's maximum d imension.C la ss 3 - G as h ole s, s an d s po ts , a nd in clu sio ns o f th e max im um s iz e a llo we d b yth ese ta ble s sha ll b e cau se fo r re je ctio n if th ey a re c lo se r th an oned iame te r o f th eir m axim um d imen sio n to a n e dg e. T his d oe s n ot a pp ly tog as hole s, s an d spo ts , a nd in clu sio ns smalle r th an th e maximum a llowablesize.C la ss 4 - Edge o f p art d is co ntin uitie s a re a ccep ta ble if th ey a re n ot c ra ck -lik e, lin ea r,o r round wi th p ro trud ing l inear ind ica tions.The te rm "e dge" re fe rs to th e oute r b oundary o f th e ra dio gra ph ic image o f th ecas tin g. This in te rp re ta tio n n eed only b e made in th e s ta ndard e xp osure s (v iews )def ined by the app roved rad iogr aphic t echn ique . Additio na l r ad iogr aphic exposuresto d ete rm in e th e d is ta nce from th e surfa ce o f e ach gas hole , s an d spo t, o r in clu sio nin o ther o rienta tions a re not requ ired.

[6 ] "N o ne ", a s u se d in th es e ta ble s, m ea ns th at th e d is co ntin uity is n ot a llo we d.

-15 -" BA E I n le m at io n o ld by IH S u n d e r " ' e Y d th B A EltJ< Iu otio n o r n _n g p en rlt to d Y dth ou lllo en se lm m IH S LIoen.ee=Cunvnm E n R I n e Co 1noI1232502100. U8ePjonos. "" 'eNOIIor Re . . . .. 05 f .I 0 I2 0 0 7 10 :46 :31 MDT

AMS2175

-

8/2/2019 AMS 2175 28NOV2011

16/21

AMS2175 SAE

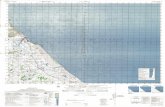

TABLE 6 - Maximum Permissible Radiographic Severity Levels for Discontinuities inAluminum Castings per ASTM E 155 [3] [4] [5]

AMS 2175

Discontinuity

Cracks [1]

Gas HolesGas Porosity, RoundGas Porosity, ElongatedShrinkage Cavity

Grade A Grade B Grade C Grade DInch Inch Inch Inch

1/4 3/4 1/4 3/4 1/4 3/4 1/4 3/4None None 1 1 2 2 5 5None None 1 1 3 3 7 7None None 1 2 3 4 5 5None None 1 NA 2 NA [2] 3 NA [2][2}None None 1 1 2 2 4 3None None 1 1 2 2 4 4None None 1 1 2 1 4 3

Shrinkage SpongeForeign Material, Less DenseForeign Material, More Dense

Cold Shuts [1]----------------------------------- None ----------------------------------------------------------------- None -----------------------------------

Surface Irregularity [1] ------------------- Not to exceed drawing tolerance ---------------Core Shift [1] -------------------- Not to exceed drawing tolerance -----------------Notes:[1] Reference radiographic plates are not available for this type of discontinuity.[2] A 3/4 inch shrinkage cavity plate is not available in ASTM E 155. For section thicknessesgreater than 1/2 inch, use the 1/4 Inch shrinkage cavity plate and the following limits:Grade A = none, Grade B = 3, Grade C = 4, Grade D = 5.[3] Use ASTM E 155 Volume I reference radiographic plates.[4] For feature thicknesses greater than two inches, the 3/4 inch reference radiographic platesmay be used.[5] See Table 5 for additional notes that apply to this table.

r t >18AE ln te rneU" ,, " ,b y I H S u nd or l lc en s. w it h S AEto

-

8/2/2019 AMS 2175 28NOV2011

17/21

AMS 2175 SAE

TABLE 7 - Maximum Permissible Radiographic Severity Levels for Discontinuities inMagnesium Castings per ASTM E 155 [3] [4] [5]

AMS2175

Grade AInch

(b) Pipe Shrink Type

Discontinuity1 /4 3 /4

Grade BInch1 /4 3 /4

Grade CInch1 /4 3 /4

Grade DInch1 /4 3 /4

Gas Holes None NoneMicroshrinkage, Feathery None NoneMlcroshrinkage, Sponge None NoneForeign Material, Less Dense None None

1 11 11 12 2

3 24 43 43 3

4 47 77 84 4

Reacted Sand Inclusions [6] 1Foreign Material, More Dense None None

Gravity Segregation [6] 1Eutectic Segregation [6](a) Microshrinkage Type None

None

None(c) Hot Tear Type

1 132

4None

Same as sizeon plate

2 243

5None

Same as sizeon plate

3 3

1 /3 of sizeon plateTwice sizeon plate

64

6

Oxide Inclusions [6] NoneEutectic Depletion, Flow Line [6] NoneCracks [1]

1 /3 of sizeon plate 1 /2 of sizeon plateSame assizeon plate

Same as size Twice size Any lengthon plate on plate [2]------------------------------- None -------------------------------------------------- None --------------------------old Shuts [1]--------------------- Not to exceed drawing tolerance -------------urface Irregularity [1]------------------- Not to exceed drawing tolerance -----------ore Shift [1]

Notes:[1] Reference radiographic plates are not available for this type of discontinuity.[2] No other types of discontinuities are allowed to be contained with it in an area of like size tothe reference radiographic plate.[3] Use ASTM E 155 Volume I and II reference radiograph numbers.[4] For feature thicknesses greater than two inches, the 3 /4 inch reference radiographic platesmay be used.[5] See Table 5 for additional notes tha~~ppIY to this table.16 1 Applicable to all casting section thicknesses.

SAE In t.m01 l on o lby tH S unde r loons. ith SA Eo du ct io n o r_ng p en ri tt ed w lt ho ut l te en s. fr om t HS

I- 17- - ,L lc o ns . .. . C Ummm En!Ine Co m l I 2325021 !JO ; lJsepjon Iuk.Not 10 < Resal 05130/2007 1 0 :4 5: 31 MD T

/

-

8/2/2019 AMS 2175 28NOV2011

18/21

AMS 2175AMS2175 SAE

co

co M

co Q)5z. , . . . . co (0 Q)coZ (0

10 10 (0

(0

(0

10Q)coZ

2 !oZ (0 co

. e : : .ocaf(J)"0~(!)

10

. , . . . .

. , . . . .

Q)coZ. , . . . .

Q)coZQ)coZQ)coZ2 !oZ

. , . . . .

. . . . .

. . . . .

. , . . . .

. . . . .

2 !oZ

Q)coZQ)coZQ)coZ2 !oZ

10

. , . . . .

. . . . .

10

. , . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SAEInlernotl_by IHS under I oo ns e w it h SAEr ep ro duc Um or n_ ng p en nm ed w lth ou ilic on sor rom IH S

.S1/) ......~~'~N:;;0>e: ......8w.!!! :? !01-" ' 0 0021/)'"Q)~ii; I/)...II/)~~c ...(1)0>-(1)-CI)~.~-- aEl! ECl-.:t:01.0:c~C U . c :0 : : : ( , )(l)e::0-.~:;._ ClE.S" ' 1 ; )~ C UEO::J(I)E.!.~~:?!5iIE001;;W g , !...Ie:~-I-

Q)CoZ

(J)C)c8 .CJ)oiEc'c. e : : .CJ)

. , . . . . . , . . . .

o~- g(J)ooiC). ! l !c.;::. e : : .CJ)

Q)CoZ. , . . . . . , . . . .

- 18-

(J) (J)g : 5z zI II I

. . . .o. . . .(IIt!'0I'5-s:CJ)"0'0o

c2. ! 1 2:!:

.9'0z

(J)C):2c ::"0'0:!:. . . .o~s:CJ)~oo

.9'0z.9" 0z

.9'0z

I

LtoenseeoO.mntna Engine Co tncI1232502100, Us8Pjones. lukeNo t iltResole . 0 6 I3 0 IZ l 0 7 10 :45 :31 MDT

-

8/2/2019 AMS 2175 28NOV2011

19/21

AMS 2175 SAE AMS 2175

TABLE 9 - Maximum Permissible Radiographic Severity Levels for Discontinuities inHeavy-Walled Steel Castings 2 to 4.5 Inch (51 to 114 mm) in Thicknessper ASTM E 186 [1]

Code or Category Discontinuity Grade A Grade B Grade C Grade DA Gas Porosity None 1 2 3B Sand and Slag Inclusions None 1 2 4C Shrinkage, Type 1 None 2 3 5C Shrinkage, Type 2 None 2 3 4C Shrink~ge, Type 3 None 2 3 4D Crack ---------------------- None ------------------E Hot Tear ---------------------- None ------------------F Insert ---------------------- None ------------------

Notes:[1] See Table 5 for additional notes that apply to this table.

TABLE 10- Maximum Permissible Radiographic Severity Levels for Discontinuities inSteel Castings up to 2 Inch (51 mm) in Thickness per ASTM E 446 [2]Code or Category Discontinuity Grade A Grade B Grade C Grade D

A Gas Porosity None 1 2 3B Sand and Slag Inclusions None 1 2 3CA Shrinkage, Type CA None 1 2 3CB Shrinkage, Type CB None 1 2 3CC Shrinkage, Type CC None 1 2 3CD Shrinkage Type CD None 1 2 3D Crack None None None NoneE Hot Tear None None None NoneF Insert None None [1] [1]G Mottling --- Not to exceed drawing tolerance ---

Notes:[1] Not to exceed drawing tolerance.[2] See Table 5 for additional notes that apply to this table.

- 19-8AE Inl"""'l_by IHSunder I I oensa with SAEo n or_011penriHOdwfthouiliamolmm IHS L I o on . o o- C u rrmm E f lA InOCo k l< :I 1232502100 .l J se p j on e s ." .Nailor R o s ol o . 0 5t .I 0I 20 07 1 0: 46 :3 1 MD T

-

8/2/2019 AMS 2175 28NOV2011

20/21

AMS2175 AMS2175AE

TABLE 11 - Maxim um Perm issib le R adiographic S everity L eve ls for D isco ntin uitie s inHeavy-Walled 4.5 to 12 Inch (114 to 305 mm) Steel Castings per ASTM E 280 [1]

Gas Por os ity 3 Grade Dode or Category D iscontinuity Grade A Grade B Grade CA 1 2S an d a nd S lag Inclusions 1 2 3Shrin kage , T ype 1 2 31Shrink age, Type 2 1 2 3

C S hrink age, Type 3 1 2 3D Crack ---- - -- - -- - -- - -- - -- - -- - None ---- -- - -- - -- - -- - -- -E H ot T ea r --- - -- - -- - -- - -- - -- - -- - - None ---- -- - -- - -- - -- - -- -F Insert - -- - -- - -- - -- - -- - -- - -- - - None ---- - -- - -- - -- - -- - --

Notes:[1] See Table 5 for additional notes that apply to this table.

TABLE 12 - Maxim um Perm issible R adio grap hic S everity L evels fo r D iscontinuities inH igh-S tre ngth C op per-B ase and N ick el-C oppe r A llo y C astingsup to 2 Inches (51 mm) in Thickness per ASTM E 272 [3]Code or Category D iscontinuity [2] Grade A Grade B Grade C Grade D

A Gas Porosity None 1 2 3Ba Sand Inclusions None 1 2 3Bb Dross Inc lusions None 1 2 3Ca Shrinkage, L inear NA[1) NA[1) NA[1) NA[1)Cd Shrinkage, Feathery N one 1 2 3Cd Shrin ka ge Spo ng y NA[1) NA[1) NA[1) NA[1)

Notes:[1] Reference radiographic plates are not available for this type of discontinuity.[2] Cracks, hot tears, and inserts are not allowed.[ 3 ] See Table 5 for additional notes that apply to this table.

- 20-SAE I n temavomlby100Uderloonsewith SAE< l d u C t I . . .. .. . n_ng ponTi.ed_lIcense tom 100 Lk:enseeoCtmnln. EngM Co 1nc/12321Rl2100. U.OPjone 1 u k aN ot " " Resale. 0 5/ 30 12 00 71 0: 45 :3 1 MDT

44444

-

8/2/2019 AMS 2175 28NOV2011

21/21

AMS2175 AMS 2175AE

TABLE 13- Maximum Permissible Radiographic Severity Levels for Discontinuities inHigh-Strength Copper-Base and Nickel-Copper Alloy Castings2 to 6 Inches (51to 153mm) in Thickness per ASTM E 272 [3]

Code or Category Discontinuity [2] Grade A Grade B Grade C Grade DA Gas Porosity None 1 2 3Ba Sand Inclusions None 1 2 3Bb Dross Inclusions None 1 2 3Ca Shrinkage, Linear None 1 2 3Cd Shrinkage, Feathery NA[1] NA[1] NA[1] NA[1]Cd Shrinkage Spongy None 1 2 3

Notes:[1] Reference radiographic plates are not available for this type of discontinuity.[2] Cracks, hot tears, and inserts are not allowed.[3] See Table 5 for additional notes that apply to this table.

TABLE 14 - Maximum Permissible Radiographic Severity Levels for Discontinuities inTin Bronze Castings up to 2 Inches (51mm) in Thickness per ASTM E 310 [2]

Grade Discontinuity [1]ode or CategoryA Gas Porosity

Grade A Grade B Grade CNone 1 2None 1 2None 1 2None 1 2

B Sand InclusionsCa Shrinkage, LinearCd Shrinkage, Feathery orSpongyOa Hot Tear --------------------------- None -----------------------Eb Inserts, Chaplets --------------------------- None -----------------------

Notes:[1] Cracks are not allowed.[2] See Table 5 for additional notes that apply to this table.

- 21 -SAE k l tema 1 lo n a lby IHS "'-Ioense vdth SAE Llcensee=Cunmils EnQile Co Incl1232502100,lJsepjones,1uke

3333