3mE Keuzevakken 2010 En

-

Upload

quynh-nguyen -

Category

Documents

-

view

217 -

download

0

Transcript of 3mE Keuzevakken 2010 En

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 1/186

Program overview04-Sep-2013 10:53

Year 2010/2011

Organization Mechanical, Maritime and Materials Engineering

Education 3mE Keuzevakken

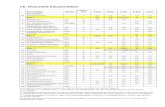

Code Omschrijving ECTS p1 p2 p3 p4 p5

3mE Keuzevakken 2010 3mE Electives 2010BM1100 Orthopaedic Implants and Technology 3BM1210 Medical Instruments A: Clinical Challenges and Engineering Solutions 3

ME1100 Automotive Crash Safety; Active & Passive Safety Systems 3

ME1110 Medical Device Prototyping 6ME1120 Space Robotics 4ME1400 Sustainability in Transportation Engineering 3ME1590CH Separation Processes, Design & Operation 6

ME1591CH Thermodynamics for Designers 3

ME1592CH Process Intensification 6ME1600 Reliability and Uncertainty Models in Engineering Mechanics 2ME1610-10 Tissue Biomechanics of Bone, Cartilage and Tendon 4

ME1615 Micro-Assembly, Packaging and Test 3MS3011 Semiconductor Principles and Devices 3

MS3021 Metals Science 4MS3031 Computational Materials Science 4MS3221 History of Materials Production and Usage 3MS3252 Materials Degradation and Countermeasures 3

MS3401 Primary Metals Production 3

MS3412 Processing of Metals 4MS3421 Developments in Production and Processing 2MS3432 Determination of Microstructure 4MS3442 Relation between Properties and Microstructure 4

MS3452 Total Performance Approach: Case Studies 3

MS3461 Corrosion and Protection against Corrosion 3MS3471 Modern Analysis Techniques & Authenticity Research 4MS4011 Mechanical Properties 3

MS4021 Structure Characterisation 5MS4031 Waves 3

MS4041 Structure of Materials 5MS4051 Physics of Materials 6MS4061 Thermodynamics and Kinetics 4MS4071 Materials in Art and Design 3

MS4081 Mechanics of Materials 4

MS4091 Material Connections 4MS4101 From Ore to Plate: Production of Materials 3MS4111 Thin Film Materials 3MS4121 Practicals Materials Science 4

MS4131NS Solid State Physics 2 3

MS4141TU Fracture Mechanics 3MS4151 Recycling Engineering Materials 3MS4161 Engineering with Materials 10

MS4171 Lifetime Performance of Materials 3MS4181 New Trends in Materials 3

MS4191 Materials for Conventional Energy Production 2MS4201 Art History and Archaeology 4MS4211 Materials at High Temperature 3MS4221 Materials for the Hydrogen Economy 2

MS4232-09 Biomaterials 6

MT113 Design of Advanced Marine Vehicles 3MT1401 Law for MT 3MT213 Marine Engineering C 2MT216 Introduction Combustion Engines 3

MT218 Mechatronics in MT 5

MT313 Shipping Management 3MT514 Ship Movements and Steering 3 3MT515 Resistance and Propulsion 3 3

MT523 Numerical Methods for MT 4MT524 Hydromechanics of Special Ship Types 3

MT525 Marine Propulsion Systems 2MT724 Shipfinance 3MT725 Inland Shipping 2MT727 Shipyard Process, Simulation and Strategy 4

3

Page 1 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 2/186

MT728 SalvageMT729 Maritime Business Game 3MT815 Construction and Strength, Special Subjects 2MT816 Composit Materials 2MT830 Applications of the Finite Element Method 3

MT835 Hydro Elasticity 3

OE4601 Survey of Offshore Engineering Lectures 3OE4603 Introduction to Offshore Structures 3OE4610 Survey of Offshore Engineering Projects 8OE4623 Drive System Design Principles 3

OE4624 Offshore Soil Mechanics 3

OE4625 Dredge Pumps and Slurry Transport 4OE4626 Dredging Processes 4OE4630 Offshore Hydromechanics 8

OE4630 D1 Offshore Hydromechanics, Part 1 1,5

OE4630 D2 Offshore Hydromechanics, Part 2 2

OE4630 D3 Offshore Hydromechanics, Part 3 3

OE4630 D4 Offshore Hydromechanics, Part 4 1,5

OE4651 Bottom Founded Structures 6OE4652 Floating Structures 4

OE4653 Marine Pipelines 4

OE4654 Sub Sea Engineering 4OE5662 Offshore Wind Farm Design 4OE5663 Dynamic Positioning 3OE5664 Offshore Moorings 3

OE5665 Offshore Wind Support Structures 3

OE5670-11 Integrating Exercise 11OE5671 Dredging Equipment Design 4OE5672 Dredging Laboratory 4SC4010 Introduction Project SC 3

SC4025 Control Theory 6

SC4026 Control System Design 3SC4032 Physical Modelling for Systems and Control 4SC4040 Filtering & Identification 6SC4050 Integration Project SC 5

SC4060 Model Predictive Control 4

SC4070 Control Systems Lab 4SC4081-10 Knowledge Based Control Systems 4

SC4081-10 D1 Knowledge Based Control Systems, Exam 3

SC4081-10 D2 Knowledge Based Control Systems, Literature 0,5

SC4081-10 D3 Knowledge Based Control Systems, Matlab0,5

SC4091 Optimization in Systems and Control 4SC4110 System Identification 5SC4120 Special Topics in Signals, Systems & Control 3SC4150 Fuzzy Logic and Engineering Applications 3

SC4160 Modeling and Control of Hybrid Systems 3

SC4170AP Inverse Problems & Statistical Signal Processing 3SC4180ES Modeling and Control 6SC4190CH Process Dynamics and Control 6SC4210 Vehicle Mechatronics 4

WB1310 Multibody Dynamics A 3

WB1405A Stability of Thin-Walled Structures 1 4WB1406-07 Experimental Dynamics 3WB1408A Shell Structures - Introductory Course 3WB1408B Shell Structures - Advanced Course 5

WB1409 Theory of Elasticity 3WB1412 Linear & Non-lineair Vibrations in Mechanical Systems 3WB1413-04 Multibody Dynamics B 4WB1416 Numerical Methods for Dynamics 3WB1417-05 Fluid-Structures Interaction 4

WB1418-07 Engineering Dynamics 4

WB1422ATU Advanced Fluid Dynamics A 6WB1424BTU Race Car Aerodynamics 3WB1427-03 Advanced Fluid Dynamics A 5WB1428-3 Computational Fluid Dynamics 3

WB1429-03 Microfluidics 3

WB1433-04 Thermomechanical Modelling & Charact.of Polymers 3WB1440 Eng. Optimization: Concept & Applications 3WB1441 Engineering Optimization 2 3WB1443 Matlab in Engineering Mechanics 2

WB1444-07 Advanced Micro Electronic Packaging 3WB1445-05 Mechanics of Micro Electronics and Microsystems 3WB1450-05 Mechanical Analysis for Engineering 4WB1451-05 Engineering Mechanics Fundamentals 4WB1481LR Dynamics and Control Space Systems 4

WB2301-5 System Identification and Parameter Estimation 7

WB2303-10 Measurement in Engineering 3

Page 2 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 3/186

WB2305 Digital Control 3

WB2306 The Human Controller 3WB2308 Biomedical Engineering Design 4WB2404 Man-machine systems 4WB2408 Physiological Systems 3

WB2414-09 Mechatronic System Design 4

WB2415 Robust Control 6WB2421 Multivariable Control Systems 6WB2427 Predictive Modelling 3WB2428-03 Mechanical Design in Mechatronics 5

WB2432 Bio Mechatronics 4

WB2433-03 Humanoid Robots 3WB2436-05 Bio-Inspired Design 3WB2454-07 Multiphysics Modelling using COMSOL 4WB2601OE Strenght of Materials 1

WB3404A Vehicle Dynamics A 3

WB3415-03 Adams Course 3WB3416-03 Design with the Finite Element Method 3WB3417-04 Discrete Systems: MPSC 5WB3419-03 Characterization and Handling of Bulk Solid Materials 6

WB3420-03 Introduction Transport Engineering and Logistics 5

WB3421-04 Automation and Control of Transport and Production Systems 6WB3422-03 Design of Transport Equipment 5WB3423-04 The Delft Systems Approach 3WB3424-08 Production Organisation Principles 3

WB3425-04 Production Engineering Practical 5

WB4300B Fundamentals of Fluid Machinery 2WB4302 Energy Conversion 4WB4400-03 World of Process & Energy Technologies 1WB4402 Project Engineering 6

WB4403 Advanced Reaction & Separation Systems 4

WB4405 Fuel Conversion 3WB4408A Diesel Engines A 4WB4408B Diesel Engines B 4WB4410A Refrigeration 3

WB4416 Nuclear Engineering 3

WB4420 Gas Turbines 3WB4421 Gas Turbine Simulation/Application 3WB4422 Thermal Power Plants 4WB4425-09TU Fuel Cell Systems 3

WB4426 Indoor Climate Control Fundamentals3

WB4427 Refrigeration Technology and Applications 4WB4429-03 Thermodynamics for Process & Energy 3WB4431-05 Modeling of Process and Energy Systems 4WB4432-05 Process Dynamics and Control 3

WB4433-05 Conceptual Process Design and Optimization 4

WB4435-05 Equipment for Heat Transfer 3WB4436-05 Equipment for Mass Transfer 3WB4438-05 Technology and Sustainability 3WB5400-08 Mechatronic System Design 2 4

WB5414-08 Design of Machines and Mechanisms 4

WB5430-05 Engineering Informatics 3WB5431-05 Life Cycle Engineering 3WB5435-05 Machine Intelligence 3WB5451-05 Student colloquia and events PME 1

WBP202 Haptic Experiment Design 4

Page 3 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 4/186

Year 2010/2011

Organization Mechanical, Maritime and Materials Engineering

Education 3mE Keuzevakken

3mE Keuzevakken 2010

Responsible ProgramEmployee

E.P. van Luik

Page 4 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 5/186

BM1100 Orthopaedic Implants and Technology 3

Responsible Instructor Prof.dr.ir. E.R. Valstar

Instructor Dr.ir. R. Happee

Contact Hours / Weekx/x/x/x

0/4/0/0

Education Period 2

Start Education 2

Exam Period Different, to be announced

Course Language English

Course Contents Most people have first hand experience with the limitations and impact of trauma of the musculo-skeletal system: a sprainedankle severely limits your mobility and causes severe pain, but will heal without too many residual complaints.

However, diseases such as osteoarthritis and rheumatoid arthritis - irreversibly destroy joints, and cause severe limitation of thepatients mobility and produce pain. Today, 600 million people worldwide are suffering from the limitations and pain that arecaused by arthritis.

In the end, these affected joints will often be replaced surgically with an artificial joint. Worldwide 1.5 million hips and 750,000knees are replaced with a joint prosthesis annually. After a joint replacement, patients are normally pain free again and gain inmobility. A joint replacement is one of the most rewarding surgical procedures.

Ten years post-operatively, 5 to 10% of these prostheses annually 150.000 cases - have failed and need to be replaced in ademanding revision operation. For total shoulder replacement these numbers are much higher: up to 44% of the implants havefailed at ten years follow-up.

In this course you will learn to analyse, evaluate, and judge joint replacement prostheses with respect to their influence on thehost bone, their function, fixation, and longevity based on the scientific state-of-the art knowledge.

Study Goals Main intended learning outcomeThe student should be able to analyse, evaluate, and judge joint replacement prostheses with respect to their influence on the hostbone, their function, fixation, and longevity based on the scientific state-of-the art knowledge.

Sub intended learning objectivesThe student should be able to:LO1: Describe the function, role and organisation of the main constituents of bone tissue, and explain the bone remodellingprocessLO2: Describe the hip, the knee, and the shoulder from a structural and functional perspective.LO3: Describe the effects of osteoporosis, osteoarthritis, rheumatoid arthritis on the human body, understand the problems thatpatients experience.LO4: Analyse, evaluate, and judge the design of orthopaedic implants, based on design rationales, peer-reviewed scientificarticles, and national registers.

Education Method This course will be taught in a number of highly interactive sessions and a mini-symposium. In addition to that, there is a visit tothe Department of Anatomy at Leiden University Medical Center (LUMC) and a one-on-one meeting with an orthopaedicsurgeon from the LUMC.

One of the class sessions is a hands on session in which you are going to place a real prosthesis in an artificial bone. The courseis finished in a mini-symposium in which students will present the results of their assignments and there will be extensivediscussions with the students and a basic researcher and an orthopaedic surgeon.

The class sessions will have a highly interactive nature and will have to be prepared thoroughly by the students. All assignmentsare carried out by groups of three students. For several sessions there will be an assignment that the students need to hand inbefore the session takes place.In a larger assignment, which forms the basis for the presentations and discussions in the mini-symposium, students will focuson different controversies that still exist in orthopaedics.

Course Relations This course partially replaces WB2431 Bone Mechanics & implants which was last given in 2007-2008.Participation in the course ME1610, Bone and Cartilage is recommended but not required.

Assessment You are assessed based on assignments that you hand in. All assignments are carried out by groups of three students. Studentscan pass this course only if all assignments have been handed in on time.

There is no additional examination.

Department 3mE Department Biomechanical Engineering

Page 5 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 6/186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 7/186

ME1100 Automotive Crash Safety; Active & Passive Safety Systems 3

Responsible Instructor Dr.ir. R. Happee

Contact Hours / Weekx/x/x/x

0/0/0/4

Education Period 4

Start Education 4

Exam Period 45

Course Language English

Expected prior knowledge WB3404A Vehicle Dynamics A can be followed in parallel (recommended).Summary Automotive Safety technologies are covered with a focus on potential benefits, test procedures, sensing, control and human

machine interfacing.

Course Contents Contents as stated below may be adapted based on the interests of students and time constraints

Course ContentsContinuation

1.The road safety problemReview of fatalities, injuries and vehicle damage in a national and international perspective. Outlook on safety in first, secondand third world countries.Comparison of safety of different transport modes. Breakdown into injuries of car occupants, pedestrians, cyclists, motorcyclistsand others. Breakdown of costs into life years lost, medical and rehabilitation costs, vehicle damage and congestion due toaccidents.

Road safety countermeasure overview: Pre-crash, In-crash and Post-crash measures (Haddon Matrix). Vehicle safetytechnologies, road infrastructure, enforcement of speed, alcohol and other regulations, education.

2.Accident causationIntroduction of aspects like perception of speed, direction and distance, awareness, reaction times & failure to act.Illustration of loss of control due to wheel slip etc.

3.Active Safety 1Vision and Visibility.Obstacle & vehicle detection technologies.Vehicle to vehicle communication and vehicle to infrastructure communication.Driver assistance systems.

4.Active Safety 2The role of tyre, suspension, steering and braking system.Antilock Braking Systems (ABS) and Electronic Stability Programs (ESP).

5.Crash dummies & Injury CriteriaDevelopment and validation of crash test dummies using cadaver testing for high severity and volunteer testing for low severityloading.- Mathematical human body models.- Injury severity scales (AIS, MAIS, )- Injury criteria and tolerances and their derivation from cadaver testing and real accidents.

6.Passive Safety 1 frontal impact

Frontal car impact will be used to explain how occupant safety is enhanced by the deformable vehicle front structure, theprotective vehicle compartment, belt system, airbag and seat. The mechanical interaction will be illustrated quantitativelyincluding some practical calculation assignments.- Injuries to car occupants in Frontal Impact.- Demonstrated benefits of belts and airbags.- Full vehicle front overlap versus partial overlap impact.- Compatibility of vehicle shape and stiffness across the diversifying car fleet.- Triggering of belt pretensioner and airbag(s)- Adaptation of belt and airbag operation towards crash conditions and occupant size and position. Potential benefits of real timecontrol of belt and airbag.

7.Passive Safety 2 other impact modesOther impact modes will be reviewed in a global manner:SIDE IMPACT: Injuries. Test procedures & dummies. Protection offered by the protective vehicle compartment, airbags andvehicle interior padding.ROLLOVER: Injuries and ejection. Test procedures & dummies. Effectiveness of curtain airbags and belts to prevent ejection.REAR IMPACT: Injuries. Test procedures & dummies. Passive and active seat systems for rear impact.PEDESTRIANS AND CYCLISTS impacted by vehicle fronts: Injuries. Test procedures & dummy subsystems representingbody parts. Deformable vehicle front and bonnet structures. Compromises between pedestrian, frontal impact, durability andrepair costs for marginal accidents (parking).

8.Safety from a sensing & control perspectiveReview of safety systems described in previous chapters in terms of:- Sensing, identification and state estimation.- Human machine interfacing.

9.Safety test proceduresReview of regulated test procedures, consumer test procedures and best practice for active and passive safety as introduced inprevious chapters.- Safety in the vehicle development process.- Subsystem versus full system testing.- Hardware versus virtual testing.- Gaps where accident types and injury types are not well covered.- Gaps where innovative safety systems are not well covered.- Discussion of political and financial forces driving safety enhancement including: Governments, Car manufacturers, Suppliers,Vehicle and health Insurance companies.

Study Goals The student must be able to analyse the potential benefits of current or future active and/or passive safety systems

Education Method Lectures (4 hours per week)Plus Self-study & Exercises

Assessment Written exam

Enrolment / Application Register on Blackboard and mail [email protected]

Percentage of Design 10%

Page 7 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 8/186

Department 3mE Department Biomechanical Engineering

ME1110 Medical Device Prototyping 6

Responsible Instructor Dr. J.J. van den Dobbelsteen

Instructor Dr.ir. J.L. Herder

Instructor Dr.ir. D.H. Plettenburg

Instructor Dr.ir. G.J.M. Tuijthof

Contact Hours / Week

x/x/x/x

0/0/2/2

Education Period 34

Start Education 3

Exam Period Exam by appointment

Course Language English

Expected prior knowledge Previous participation in WB2436-05, WB5414-03, WB2308, WB2428-03 is considered as a pre.

Course Contents In the course Medical Device Design students develop and produce a sound solution to a problem in the medical field incollaboration with their supervisor, clinicians, instrument makers and production companies. The course offers students to workon a design assignment that encompasses the complete design cycle from problem analysis to actual production of the prototype.Each group has a budget of 3000 Euro for production of the prototype. The course is a logical follow-up of the courseBiomedical design engineering WB2308.

Students will select a design assignment from a number of options proposed by clinicians (e.g. surgeons, rehabilitation doctors).A conceptual design previously developed in WB2308 could also serve as a base for the development of a physical prototype.The students work in groups of two under close supervision of an instructor on the assignment, to end up with a working

prototype. The course is finalized with a public presentation for clinicians and companies and a report.

In weekly meetings of the instructors with all participating groups students are expected to present and discuss the progress intheir project in an informal setting.

Study Goals The student must be able to:1. Employ a design task with a multidisciplinary team to solve a real technical problem in a medical environment:translate the clinical problem as presented in the assignment into a practical, technical solution, i.e. do a problem analysis,specify design requirements, come up with a conceptual design, create a cardboard model;obtain feedback on the clinical feasibility of the concept from the medical assignor to further detail the design.2. Realize the fabrication of a prototype medical device in collaboration with instrument makers and production companies:

define economical demands;create detailed drawings, CAD model;formulate a production plan.3. Evaluate the performance of the new prototype:test the technical functionality of the device and/or the clinical applicability of the device in a medical setting;reflect on previously made design choices based on the performance of the prototype.4. Present the design to a multidisciplinary audience of technicians, clinicians and (medical) companies.

Education Method Design project

Assessment Prototype, report and final presentation

Percentage of Design 100%

Design Content Specification of technical, economical and fabrication demands, development and selection of conceptual designs, CAD,Fabrication of prototype.

Department 3mE Department Biomechanical Engineering

Page 8 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 9/186

ME1120 Space Robotics 4

Responsible Instructor Dr.ing. A. Schiele

Contact Hours / Weekx/x/x/x

0/0/0/2

Education Period 4

Start Education 4

Exam Period Different, to be announced

Course Language English

Course Contents Overview to space robotics systems, design and requirements. This course will set the foundation to design space robotic

systems and to understand the requirements specifically imposed on robots by application in non-terrestrial environments. Thelecture provides an overview to some relevant basics about robotic manipulators in general and then prepares the students toconsider particular constraints posed by temp., radiation and space robotic systems. Focus will lie on manipulator type of roboticapplications, but also typical mobile robotics scenarios will be outlined.

Lect. 1:IntroductionRobots in space;Manipulators, Mobile robotics;Purpose, goals, difference w.r.t. terrestrial robotic systems

Lect. 2:Basics I: Homogeneous coordinatesConcept of homogeneous transformations, linear & rotational transforms(Euler angles, quaternions), Denavit-Hertenberg Convention, 6 DOF forward and inverse kinematics (Assignment)

Lect. 3:Basics II: Link velocityLink velocity and velocity propagation, Jacobians (analytical, geometrical, numerical,), construction of Jacobian,

Lect. 4:Basics III: Link forces & RedundancyLink force propagation, force transformations

Manipulator redundancy, Manipulator & operational space, null space, redundancy resolution strategies, redundant inversekinematics

Lect. 5:Exercises (Basics I-III)

Lect. 6:Space environmental effectsTemperature Environment (effects on mechanical Systems), radiation environment (effects on electronic systems), launch andlanding environments (examples), planetary surface environments

Lect. 7:Tribology in spaceBasic effects, overview of models, selection of appropriate lubricants

Lect. 8:Robotic actuators in spaceDC, stepper and brushless motors, bearing and bushing modification, qualified motors, selection of actuators.

Lect. 9:Sensors for manipulators in spacePosition/Velocity Sensing, force sensors, strain gauges (layout and design), sensor electronics,

Lect. 10:Testing for space mechatronicsIntroduction to applicable standards, mechanical, thermal and electrical testing. (I/F load calculation, thermal modelingapproaches, EMC)

Lect. 11:Applications I: Robotic planetary missionsMission operation, examples about mission control (MER, Nanokhod)

Lect. 12:Applications II: Orbital roboticsOperational modes: human-machine interfaces, examples of ERA/SSRMS, introduction to Telecontrol and Tele-operationconcepts

Lect. 13/14:Lab assignment (TBC):A: SRMS/SSRMS interfaces joystick (trl. Of 7 dof. Manipulators (PA.10, LBR4)B: Nullspace motion, resolution of 7 dof redundancy on LBR4(A+B = final assignment)

Study Goals The students are capable:* To identify, define and analyse problems of robots, vehicles and other mechanical systems in space* To design and produce a sound solution to typical space robotics problems

The following exit qualifications serve to realise this goal:

The students meet the following qualifications:* Basic knowledge of the problems of mechanical systems in space, i.e. related to tribology, actuators, mechatronics, sensors,thermodynamics, etc.* Ability to set up motion equations for 3D mechanisms applicable in space and in general, calculation of kinematics anddynamics using most often used methods.* Knowledge about particular space environment requirements and testing methods.* Knowledge about the space mission operations and human interfacing requirements.* Analyze some basic problems in space robotic missions, and synthesize an adequate solution.

Education Method 14 lectures, 2 assignment

Prerequisites Basic understanding of: linear algebra, physics, analog electronics, digital & analog signal processing, mechanics (statics,kinetics, dynamics), linear control theory, Matlab, C.

Assessment Assignment

Department 3mE Department Biomechanical Engineering

Page 9 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 10/186

ME1400 Sustainability in Transportation Engineering 3

Responsible Instructor Ir. J.H. Welink

Contact Hours / Weekx/x/x/x

0/0/2/0

Education Period 3

Start Education 3

Exam Period 34

Course Language English

Course Contents Subject of the course is the sustainability in the transportation and production engineering and logistics. The course covers:Use of material and energy resourcesEnergy production and storageEfficiency of transport systems: Transport loss factor, effect kinetic energy, energy recuperation and transmissionProduct life cycle and sustainable product designSustainable processes and supply chainsEconomical aspects of sustainability

Study Goals The student must be able to⢠Describe and explain issues with (non-)sustainable materials and energy⢠Calculate the use of energy resources and emissions for different uses of energy sources⢠Devise, propose, explain and/or evaluate more energy efficient transport systems⢠Demonstrate, analyse and evaluate life cycle analyses and devise, explain, analyse and evaluate sustainable design in relationto the life cycle of a product⢠Explain, devise, propose, analyse and evaluate and/or explain more sustainable production processes⢠Calculate the costs of the environmental impact of the transportation and production engineering and logistics, and theaccounting of environmental costs and calculate economics for (sustainable) investments

Education Method Lectures (2 hours per week)

Assessment Written exam (80% of mark) and assignment (20% of mark)Department 3mE Department Maritime & Transport Technology

ME1590CH Separation Processes, Design & Operation 6

Responsible Instructor Dr.ir. J.H. ter Horst

Contact Hours / Weekx/x/x/x

0/4/0/0

Education Period 2

Start Education 2

Exam Period 2

Course Language English

Course Contents Separation processes are very important in all sectors of modern process industry. A reaction section in a chemical plant istypically surrounded by 3-6 separation units, which perform a variety of functions (e.g. feed concentration, product purification,solvent-recycling, off-gas treatment and water-recovery). Separation processes consume approximately 40% of the energyconsumption and 75% of the investment cost in the process industry. Consequently, you are likely to come across the designand/or operation of separation units in your future career.Focus is given on the conceptual design of the main separation processes in the chemical industry: distillation, absorption,extraction, crystallization, adsorption and membrane separations. The main features of these processes are highlighted andillustrated with examples from industrial practice.

Study Goals Students are taught to select industrial separation units, to master various design methodologies and to recognize their potentialsand limitations. Hands-on experience with computer-aided design is developed through instructions and homework assignments.

Education Method Lectures, class assignments

Books Separation Process Principles, J.D.Seader & E.J.Henley, John Wiley & Sons, 2nd Ed., 2006

Assessment The developed knowledge and acquired skills are tested by means of homework assignments, which can be worked out in groupsof two students. An oral examination of the groups about the obtained separation technology knowledge finalizes the course.

Department 3mE Department Process & Energy

ME1591CH Thermodynamics for Designers 3Responsible Instructor Dr.ir. T.W. de Loos

Contact Hours / Weekx/x/x/x

0/0/0/0/x

Education Period Summer Holidays

Start Education 5

Exam Period 5

Course Language English

Course Contents Data retrieval. Intermolecular forces. Prediction of ideal gas properties. Equations of state. Thermodynamics properties of non-ideal fluids. Vapour pressure and latent heat. G-excess models. UNIFAC methods. G-excess mixing rules for equations of state.Algorithms to calculate phase equilibria and complex chemical equilibria. Examples. Data banks, data generators, flowsheeting.

Study Goals Overview of state of the art thermodynamic models used in process design, allowing the participant to make a motivated choicebetween models used in flowsheet programms

Education Method intensive course (1 week)

Assessment assignments

Department 3mE Department Process & Energy

Page 10 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 11/186

ME1592CH Process Intensification 6

Responsible Instructor Prof.dr.ir. A.I. Stankiewicz

Contact Hours / Weekx/x/x/x

0/4/0/0

Education Period 2

Start Education 2

Exam Period 2

Course Language English

Course Contents 1.

Introduction to Process Intensification(PI):- sustainability-related issues in process industry- defnitions of Process Intensification- fundamental principles and approaches of PI

2.How to design a sustainable, inherently safer processing plant - presentation of PI case study assignments.

3.PI Approaches:- STRUCTURE - PI approach in spatial domain (incl. "FOCUS ON" guest lecture)- ENERGY - PI approach in thermodynamic domain (incl. "FOCUS ON" guest lecture)- SYNERGY - PI approach in functional domain (incl. "FOCUS ON" guest lecture)- TIME - PI approach in temporal domain (incl. "FOCUS ON" guest lecture)

4.Team work on case studies - intermediate reporting, consultancy.

Study Goals Basic knowledge and conceptual process design experience in Process Intensification.

Education Method Lectures, group projectLiterature and StudyMaterials

1.Lecture notes via Blackboard.

2.Book "Re-Enegineering the Chemical Processing Plant: Process Intensification" by A. Stankiewicz and J. A. Moulijn (MarcelDekker, 2004), also available for on-line reading via the Library of TU Delft.

3.Recommended papers via Blackboard

4."Process Intensification Information Sheets" via Blackboard

Assessment The examination on Process Intensification course lasts 2.5 hours and is divided into two parts:

Part 1: Written examination, lasting 1.5 hour.Part 2: Presentation and discussion of the case-study assignment results by project groups (1 hour)

Department 3mE Department Process & Energy

ME1600 Reliability and Uncertainty Models in Engineering Mechanics 2

Responsible Instructor Prof.dr.ir. M.A. Gutierrez De La Merced

Contact Hours / Weekx/x/x/x

0/0/0/2

Education Period 4

Start Education 4

Exam Period Different, to be announced

Course Language English

Course Contents This course provides an introduction to the most common computational techniques to study the influence of parameteruncertainty in the performance of mechanical systems. Rather than modelling the problem by means of stochastic differentialequations, advantage is taken of existing numerical techniques for deterministic problems in order to characterise the stochastic

response. The focus is in modelling the spatial variability of material and geometric properties by means of random fields andstudying how this randomness propagates to the response field. The preferential techniques for this purpose belong to the familyof Stochastic Finite Element Methods and are presented in this course for the purpose of both uncertainty and reliability analysis.In the former attention is paid to how characteristics of the random parameters such as the expectation and the covariancepropagate to those of the response. In the latter the focus is on approximating the probability distribution of any characteristic of the structural performance.

Study Goals To get acquainted with the most common techniques for random field modelling and stochastic finite elements, including theirrange of applicability, limitations and accuracy.

Education Method Lecture

Assessment Assignment and oral discussion

Department 3mE Department Precision & Microsystems Engineering

Page 11 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 12/186

ME1610-10 Tissue Biomechanics of Bone, Cartilage and Tendon 4

Responsible Instructor Prof.dr.ir. H.H. Weinans

Instructor Dr. A.A. Zadpoor

Instructor Dr.ir. R. Happee

Contact Hours / Weekx/x/x/x

2/0/0/0

Education Period 1

Start Education 1

Exam Period 1

2Course Language English

Course Contents The healing process of bone is a beautiful example of adaptive repair in a living tissue.The tissues of the musculoskeletal system such as bone, cartilage and tendon/ligament are able to adapt their architecture tochanges in external loads and to repair damage. Astronauts lose bone mass during spaceflight, as their skeleton adapts to the lowgravity environment. Tennis players have stronger bones in their dominant arm and high resistance training, likeweight-lifting, increases bone mass.

During this lecture series, a number of topics related to musculoskeletal tissues will be discussed.We will give an introduction to the development of the skeletal system, bone and cartilagebiology and the remodeling and repair processes that are important during life.In addition the most important skeletal diseases will be discussed, such as osteoporosis (reduced bone mass that increasesfracture risk) and osteoarthritis (degeneration of the joints). The course will also cover diagnostic methods, imaging andcomputer analyses that can be used to obtain information on the skeleton from novel imaging modalities.

Study Goals 1. know the function and role of the main constituents of bone, cartilage and tendon tissueand the organisation of these tissues at the different hierarchies2. be able to describe the development, remodeling and repair processes of bone cartilage and tendon tissue and its response to

mechanical load. Understand these concepts in terms of growth, aging and degeneration.3. know the structure, function of bone cartilage and tendon and understand the mechanical properties of these tissues, such ase.g. anisotropy and visco-elasticity.4. describe the effects of the major diseases of the skeletal system such as osteoporosis, osteoarthritis, rheumatoid arthritis andtendinopathy and understand the concept behind different treatment options.5. know the principles of tissue engineering, be able to describe the tissue engineering process in the laboratory and knowadvantages and disadvantages of natural and synthetic tissue6. describe clinical study set-ups: prospective, retrospective,randomised, non-randomised; clinical scoring systems, radiologicalassessment techniques, national registries and explain the advantagesand disadvantages of each aforementioned item

Education Method Lectures

Assessment written exam

Department 3mE Department Biomechanical Engineering

Page 12 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 13/186

ME1615 Micro-Assembly, Packaging and Test 3

Responsible Instructor Dr.ir. M. Tichem

Course Coordinator Ir. J.J.L. Neve

Contact Hours / Weekx/x/x/x

0/0/4/0

Education Period 3

Start Education 3

Exam Period 35

Course Language EnglishRequired for Micro and Nano Engineering (specialisation within the MSc Mechanical Engineering variant PME)

-NOTE:This course will not be given during the study year 2010/2011.Students of the specialisation PME-MNE who want to finish their courses this studyyear can choose an extra elective of 3 EC tocompensate for this course.As a replacment course WB1444-7 "Advanced Micro-electronic packaging" is advised. This course is also given in Educationperiod 3.-

Summary Assembly and packaging processes are very important for the realisation of microsysems, and determine to a high degree theirtechnical and economic performance. The course teaches the basic principles of and technology for micro-assembly andpackaging processes.

Course Contents The course explains the basic principles of as well as the technology for the assembly and packaging of miniaturisedproducts/systems. The products focused on originate both from the micro-mechanical engineering domain and from thesemiconductor domain (complex microelectronics and microsystems/ MEMS).

More specifically, the course addresses the following topics: example microproducts and microsystems and their integrationchallenges; trends and roadmaps; scaling laws and the consequences for assembly; micro-part gripping; accurate part alignment;precision and micro-robots; haptic assembly; self-assembly and batch assembly; micro-assembly systems, design; generalpackaging flows for IC packaging and MEMS packaging; packaging architectures (including SoC, MCM, SiP); materials andprocesses; thermal management; hermeticity; packaging-induced failures; reliability and test.

Study Goals The course enables students to research, to design and to implement micro-assembly and packaging processes. More specifically,students- Gain understanding of the state-of-the-art in industrial assembly and packaging processes, as well as knowledge on the state-of-the-art in research in the domain;- Gain knowledge and skills to develop innovative micro-assembly and packaging processes.

Education Method A variety of methods will be used: lectures, guest lectures, analysis of scientific and technical papers/ mini-workshop,exercises/case studies during the lectures/ the course period.

Literature and StudyMaterials

Lecture notes Micro-assembly, most recent version available upon start of the course.Scientific papers, made available during the course.Handouts with presentation slides.

Assessment Written examAssignments

Percentage of Design 25%

Department 3mE Department Precision & Microsystems Engineering

Page 13 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 14/186

MS3011 Semiconductor Principles and Devices 3

Responsible Instructor Prof.dr. B.J. Thijsse

Contact Hours / Weekx/x/x/x

0/0/4/0

Education Period 3

Start Education 3

Exam Period 34

Course Language English

Required for MS3031 Computational Materials Science, MS4111 Thin Film Materials, MS4131NS Solid State Physics II.Expected prior knowledge Introductory classical mechanics and electromagnetism.

Basic quantum mechanics (particle-wave dualism, one-dimensional Schrödinger equation, hydrogen atom, chemical bond, freeelectron theory, band theory).Crystal dynamics.Elements of statistical physics (Maxwell-Boltzmann, Fermi-Dirac, Bose-Einstein distributions, phonons, photons).

Summary Basic semiconductor physics, principles of semiconductor devices, low-dimensional systems.

Course Contents Following up on the free electron and band theories of solids, the course focuses on the properties of electrons and holes insemiconductors and on the different ways in which semiconductor materials can be engineered into devices. Examples arediodes, transistors, leds, lasers, and solar cells. Special subjects are low-dimensional systems and the question why electronsbehave independently.

Study Goals The student is able to use quantum mechanical models to explain the properties and behavior of electrons and holes insemiconductors and of their roles in basic electronic, and optoelectronic devices.

More specifically, the student is able to:1.Explain the band model for electron and hole energies in semiconductors.2.Apply Fermi-Dirac statistics to calculate the number of carrier electrons and holes in conductors and semiconductors.

3.Formulate the combined roles of electron scattering and electric field on the electrical conductivity of materials in variousmaterials.4.Indicate the main fundamental and application-oriented differences between elemental, III-V, and II-VI semiconductors.5.Demonstrate the effects of doping, composition, and size on energy gaps and Fermi energies.6.Explain the biased and unbiased p-n junction, the tunnel diode, the field effect transistor, and high-mobility electron devices.7.Formulate the operation of lasers and leds.8.Show how and why heterostructure semiconductor lasers are built and operated.9.Explain light detectors and photovoltaic cells as examples of optoelectronics.10.Identify the main materials engineering aspects of device fabrication.11.Demonstrate the role of diffusion, annihilation, and creation of electrons and holes on the dynamic behavior of semiconductors.12.Explain the effects of low-dimensionality on device properties.13.Identify the main materials engineering aspects of device fabrication.14.Explain why electrons behave independently, in spite of their Coulomb interaction.15.Apply all of the above in problems representing simplified and real cases.

Education Method Lectures

Literature and StudyMaterials

Course material:"Solid State Physics", 2nd edition, by J.R. Hook and H.E. Hall (Wiley, 2006).Statistical mechanics survival guide", version 24 Sep 2007, by B.J. Thijsse, available through Blackboard.Exercises and useful links on Blackboard.Making your own notes during class is highly recommended.

Prerequisites MS4031 Waves, MS4041 Structure of Materials, MS4051 Physics of Materials, or equivalent courses.

Assessment Written exam, open book

Remarks Oral examination possible only in special circumstances (after two seriously attempted written exams).

Department 3mE Department Materials Science & Engineering

Page 14 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 15/186

MS3021 Metals Science 4

Responsible Instructor Prof.dr.ir. L.A.I. Kestens

Instructor Ir. N. Geerlofs

Instructor Dr.ir. W.G. Sloof

Instructor Prof.dr. J.H.W. de Wit

Contact Hours / Weekx/x/x/x

0/0/4/0

Education Period 3

Start Education 3

Exam Period 34

Course Language English

Required for Specialisation Course Metals Science & Technology:- MS3412 Processing of Metals,- MS3442 Relation between Properties & Microstructure,- MS3461 Corrosion & Protection against Corrosion,- MS3452 Total Performance Approach: Case Studies

Summary Microstructure, Nucleation, Growth, Interfaces, Solid-State Transformations, Crystallographic Texture, Solidification, Diffusion,Segregation, Grain Boundary, Dislocation, Hardening, Hall-Petch Relation, Constitutional Undercooling, Precipitation.

Course Contents Metals represent a vital class of materials for a technological society. This course examines the structure and properties of metalsacross a range of length scales, addressing issues of microstructural changes and phase transformations, metals productiontechniques and the behaviour of metals in generic applications.

The course covers microstructures, mechanical properties in relation to microstructures and solidification. In additionintroductions are given to the influence of welding on microstructures and properties and on the susceptibility of metals to

corrosion.Microstructural aspects include:1)the essential characteristics of different types of interface between either grains of the same phase or

grains of different phases, the formation of metastable phases, and orientation relations.2)the classical nucleation theory for phase transformations in the solid state, and the relation to

experimental observations on nucleation.3)the basic features of phase-transformation models for diffusion-controlled, interface-controlled, and

mixed-mode transformations, and the relation to experimental results.4)diffusionless / martensitic phase transformations occurring under either thermal or mechanical driving

force.5)the origin of crystallographic texture in metallic microstructures, the representation of texture and the

experimental techniques to measure texture on a macro- or microscopic scale.6)the characteristics of the microstructure of a range of commercial steels, aluminium alloys, titanium

alloys and magnesium alloys, the main features of the technological processing of these alloys and themain application areas.

Mechanical properties of metals in relation with their microstructure include descriptions of dislocations, slip systems,movement of dislocations, interactions between dislocations, lattice defects and precipitates. Concepts of dislocation generation

and multiplication are discussed. Strength of metals is considered including temperature and strain rate dependence of the flowstress. Strengthening mechanisms such as solute and precipitation hardening, work hardening and grain size refinement aredescribed. The relation between strength and grain size i.e. the Hall-Petch relation is discussed.

Solidification and melting describe transformations between crystallographic and non-crystallographic states of a metal or alloy.Basic phenomena during solidification are explained including: nucleation and growth, heat flow and micro segregation. Theeffects of major process parameters on these phenomena are described, as well as their effect on as-cast microstructures.

Study Goals The student is able to describe the characteristic features of metals, explain the dominant structures and mechanisms responsiblefor their physical and mechanical properties and describe the temperature dependence of these structures and mechanisms.

More specifically, the student is able to:1. distinguish the different types of interfaces and their characteristic properties.2. identify the microstructural parameters that play a critical role in the nucleation behaviour of various

solid-state transformation processes based on thermodynamic principles,.3. differentiate between the different types of growth modes, to make the link with the kinetic features of

the transformation, and to derive the relevance for the microstructural features.4. identify the mechanism, including the crystallographic features, of a diffusionless transformation.5. quantitatively describe the crystallographic texture of metals and understands the importance of the

crystallographic texture with regard to the anisotropic behaviour of metals.6. identify and read the microstructures of various common metallic systems, relate the microstructures tothe corresponding phase diagram and interpret these microstructural features in terms of a selectedgroup of material properties.

7. describe dislocations, dislocation movement, dislocation interactions with other dislocations, lattice (e.g.solute atoms, grain boundaries) defects and precipitates in fundamental terms.

8. explain plastic deformation of metals using dislocation theory.9. illustrate the origin and multiplication of dislocations10. describe the strengthening mechanisms for metals: solute and precipitation strengthening, work

hardening, grain size effect (Hall-Petch relation)11. explain the difference between nucleation and growth during solidification.12. explain the different growth modes13. formulate the effect of cooling rate on the phase transformation and the resulting microstructure.14. explain and apply the principle of constitutional undercooling to actual solidification situations.15. formulate the occurrence of segregation during solidification.16. formulate the different heat transfer modes during solidification.17. explain the occurrence of different morphologies by applying principles of heat and mass flow.18. identify the main materials engineering aspects of solidification and casting.19. appraise the influence of the welding thermal cycle on material structure and properties20. recognise corrosion mechanisms and their dependence on microstructures.21. apply all of the above in problems representing simplified and real cases.

Education Method Lectures

Literature and StudyMaterials

Course material:D.A. Porter and K.E. Easterling Phase Transformations in Metals and Alloys, Chapman and Hall, 2nd Edition, 1992.D. Hull and D.J.Bacon Introduction to Dislocations, 4th Edition, Butterworth-Heinemann, 2001.G. den Ouden Lastechnologie, Delftse Uitgevers Maatschappij, 3rd Edition, 1993. (English translation in progress). Chapter 5 &

Page 15 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 16/186

6D.A. Jones Principles and Prevention of Corrosion, Prentice Hall,1996J. Beddies and M.J. Bibby, Principles of Metal Manufacturing Processes, Arnold, 1999.

Prerequisites - MS4041 Structure of Materials,- MS4021 Structure Characterisation,- MS4061 Thermodynamics and Kinetics

Assessment Written exam

Special Information Laboratory project(s): 2 x 1/2 days, Casting / Solidification (5th and 6th week)

Remarks 3 hours examination, closed book

Department 3mE Department Materials Science & Engineering

MS3031 Computational Materials Science 4

Responsible Instructor Dr. M.H.F. Sluiter

Instructor Dr. A.J. Bottger

Instructor Prof.dr.ir. J. Sietsma

Contact Hours / Weekx/x/x/x

0/0/0/4

Education Period 4

Start Education 4

Exam Period 45

Course Language English

Required for MS4131NS Solid State Physics IIExpected prior knowledge Undergraduate physics, mathematics, and thermodynamics. Basic familiarity with fluid dynamics and some materials science

(atomic structure, defects).

Summary Computer modeling of materials. Length and time scales. Modern modeling techniques. Simulation of materials structure,change, and properties. Student computer projects.

Course Contents 1. Introduction to materials modeling.2. Phase field methods.3. Background statistical mechanics.4. Quantum-level modeling.5. Molecular dynamics.6. Ising model, Cluster Variation Method, Monte Carlo techniques.7. Finite volume methods.8. Discrete dislocation dynamics.9. Computer lab classes.

Study Goals The student is able to differentiate between the possibilities of the principal computer modeling techniques in materials science,and design and execute a modeling strategy for a given problem.

More specifically, the student is able to:1.recognize that the properties and behavior of materials are determined by interrelated phenomena on widely different time,length, and energy scales2.explain why and how different modeling approaches (ab initio methods, molecular dynamics, Monte Carlo methods, clustervariation method, phase field modeling, discrete dislocation dynamics, finite volume methods) each have their strengths over adifferent subrange of these scales3.formulate criteria for selecting the most appropriate method for a given problem4.indicate what type of information can be obtained from the different techniques and how these pieces of information canpossibly be combined5.explain the main algorithms and the underlying theories of the different techniques6.use these algorithms and theories to predict the behavior of modeling methods for different cases7.implement small parts of self-designed code in an existing or new program8.apply a number of modeling techniques to small but realistic materials problems, by executing different computer simulationprojects9.critically analyze the simulation results and give written and oral presentations of the results

Education Method Lectures, computer projects.

Literature and StudyMaterials

Extensive lecture notes are available on Blackboard.

Prerequisites MS4031 Waves, MS4041 Structure of Materials, MS4051 Physics of Materials, MS4061 Thermodynamics and Kinetics,MS4081 Properties of Materials, MS4101 Production of Materials, MS3011 Semiconductor Devices and Magnetism, orequivalent courses.

Assessment Written exam + project presentation.

Remarks In addition to the written examination, short written reports of the computer projects are required. Also, a mini-conference willbe held at which the students present the results of one of their computer projects in more detail.

Design Content Students should design modelling plans.

Department 3mE Department Materials Science & Engineering

Page 16 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 17/186

MS3221 History of Materials Production and Usage 3

Responsible Instructor Prof.dr. J. Dik

Instructor Drs. N.C.F. Groot

Contact Hours / Weekx/x/x/x

x/0/0/0

Education Period 1

Start Education 1

Exam Period Different, to be announced

Course Language English

Summary Culture, art, archaeology, history, materialsCourse Contents This course studies the development of materials and production techniques in the visual arts. From the early stone age to the

contemporary art, artists and craftsmen have been on a continuous quest for new materials and innovative production techniquesto realize artistic concepts. The main focus of this course is the relation between the introduction of new materials on one handand immaterial developments in the form of stylistic changes in the visual arts.

Study Goals The student is able to:- give a general overview of materials in art and archaeology; he can describe the timeline of materials used from 9000BC tillpresent- relate between material innovation on one side and economical, social and cultural changes on the other

Education Method Lecture

Literature and StudyMaterials

yet to be defined

Assessment Written exam

Department 3mE Department Materials Science & Engineering

MS3252 Materials Degradation and Countermeasures 3

Responsible Instructor Prof.dr. J. Dik

Contact Hours / Weekx/x/x/x

x/0/0/0

Education Period 1

Start Education 1

Exam Period Different, to be announced

Course Language English

Summary Culture, art, archaeology, history, materials, degradation

Course Contents Precious historical artefacts are subject to degradation through time. This course studies the effect of various degradation factorson artworks, including temperature changes, moisture and UV radiation. The course has a focus on the diagnosis of degradationphenomena through materials analysis. It also includes a range of (passive and active) countermeasures that can be undertaken.

Study Goals The student is able to:- give an overview of important inorganic degradation mechanisms on artworks- describe degradation mechanisms that have already occured but can also outline possible future threats to the artwork- relate between degration phenomena and environmental influences- formulate countermeasures and discuss and their pros and cons

Education Method Lecture

Literature and StudyMaterials

Literature

Assessment Yet to be defined

Department 3mE Department Materials Science & Engineering

Page 17 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 18/186

MS3401 Primary Metals Production 3

Responsible Instructor Prof.dr. R. Boom

Instructor Dr. Y. Yang

Assistent J.A. Woelders-van der Burg

Contact Hours / Weekx/x/x/x

0/0/0/2

Education Period 4

Start Education 4

Exam Period 4

5Course Language English

Summary Primary metals production, primary metals refining and recycling

Course Contents Extractive metallurgy, production, refining and recycling of the primary metals iron and steel, aluminium, magnesium andtitanium.

Study Goals The student is able to describe the characteristic features of production from ore and secondary sources (scrap) for the followinggroup of technically important metals: iron and steel, aluminium, magnesium and titanium. The student can reproduce the mostcommonly used production methods for these metals and understands why these are industrially applied. what technologies areinvolved, which developments are ongoing, and what impact these processes have on energy consumption and environment.

More specifically, the student is able to reproduce:- the thermodynamics of extractive metallurgy;- the chemical reactions relevant for the metals extraction from ore or scrap;- the mass and thermal balances of the most common production processes;-the slag/metal equilibria as a function of composition and temperature of slag and liquid metal;

- the material flow in the iron and steel production chain;- the kinetics of steelmaking in the basic oxygen furnace (BOF);

- the process control modelling of steelmaking;- the dynamic measurement of process progress in the BOF;- the removal of sulphur from liquid iron by CaO and Mg;- slag formation in the BOF and its relevance for dephosphorisation and refractory lining life;- gas/metal mixing and homogenisation by gas injection and stirring;- the secondary metallurgy of steelmaking (deoxidation, vacuum degassing, desulphurisation, calcium injection);- the electric arc furnace (EAF) process for steel scrap melting and refining;- the Hall-Heroult process of primary aluiminium production;- the important parameters for aluminium recycling;- the Pidgeon and EMF production processes for magnesium;- the Kroll process for tiatanium production;- the Fray/Cambridge development to produce titanium, aluminium and magnesium.

Education Method Lecture

Computer Use The student will be explained and demonstrated how to use the webbased learning methods of the International Iron and SteelInstitute (steeluniversity.org) in which TU Delft is being involved.

Literature and StudyMaterials

Brahma Deo and Rob Boom, Fundamentals of Steelmaking Metallurgy, avilable from the lecturerHandouts of the lectures in the form of powerpoint presentations

Assessment Oral exam

Remarks A plant visit to a production site for iron and steel or aluminium in The Netherlands is part of the course.

Department 3mE Department Materials Science & Engineering

MS3412 Processing of Metals 4

Responsible Instructor Dr.ir. M.J.M. Hermans

Contact Hours / Weekx/x/x/x

4/0/0/0

Education Period 1

Start Education 1

Exam Period 12

Course Language EnglishRequired for MS4101 - Production of Materials, MS3031 - Computational Materials Science

Summary heat flow, fluid flow, dimensional analysis, boundary conditions

Course Contents Subjects covered include transport phenomena in metals processing. The module will focus on quantitative descriptions of processes using physical and material models in terms of fundamental and essential building blocks. Numerical approximationmethods are discussed to obtain quantitative results and are related to process conditions and process performance.Microstructural evolution models are also included. These concepts are illustrated with selected case studies.

Study Goals The student is able to understand and to apply general principles of metals processes.

More specifically the student is able to:- analyse metal process problems- apply (transport) equations to practical cases and problems- formulate a process problem in terms of mathematical equations- solve simplified problems in materials processing

Education Method Lecture

Literature and StudyMaterials Course Material: D.R. Poirier and G.H.Geiger, Transport Phenomena in Materials Processing, TMS Warrendale USA, ISBN 0-87339-272-8: Chapters 2,3,4,7,8,10.

References from literature: numerous books on Transport Phenomena

Prerequisites MS3021 - Metals Science

Assessment 50 % Written examination with problems (open book), 50 % course work, students have to pass both parts to pass the course

Department 3mE Department Materials Science & Engineering

Page 18 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 19/186

MS3421 Developments in Production and Processing 2

Responsible Instructor Dr. J. Zhou

Instructor Dr. J. Duszczyk

Contact Hours / Weekx/x/x/x

3/0/0/0

Education Period 1

Start Education 1

Exam Period 12

Course Language EnglishSummary Particular materials production, rapid solidification, compaction, sintering, powder injection moulding, full-density processing,

and porous materials for biomedical applications.

Course Contents The course concerns the fundamentals of the non-conventional materials production and processing technology to prepareparticular metals and alloys of almost any compositions and to consolidate these materials into near-net-shape products forengineering applications or control the porosity of sintered materials for the bio-functionality of implants in the human body. Itintroduces the methods to produce advanced materials through atomisation, melt-spinning or spray deposition, thecharacterization of the initial materials such as particle size, size distribution, morphology and density, and the methods toconvert the initial materials into engineered shapes such as compaction and powder injection moulding and to provide structuralintegration such as sintering. It details the mechanisms operating during full-density processing to enhance mechanical propertiessuch as extrusion and isostatic pressing. It also explains the techniques to control porosity to tailor the physical and mechanicalproperties and allow tissues to grow into the porous implant. Qua materials, it covers a wide range of metals and alloys forengineering and medical applications.

Study Goals Upon satisfactory completion of the course, students should be able to:

1. recognise the capabilities and limitations of the advanced materials processing technology in comparison with the

conventional technology;2. select processing routes and process parameters for the end product meeting the specific performance requirements forengineering or medical applications;3. predict microstructural evolution and dimensional changes occurring during each processing step and the performance of theproduct at the end of the processing chain, on the basis of a fundamental understanding of process physics and relatedmetallurgy;4. identify the faults as a result of improper material selection and processing and to propose solutions to the problem;5. evaluate the gains in product performance against processing complexity.

Education Method Lectures, plus a case study and plant tour

Literature and StudyMaterials

Dictaat MS3421, lecture notes and recommended research articles

Prerequisites MS3021 - Metals Science, MS4011 - Mechanical Properties, MS4101 - Production of Materials

Assessment Closed-book written examination

Department 3mE Department Materials Science & Engineering

Page 19 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 20/186

MS3432 Determination of Microstructure 4

Responsible Instructor Dr.ir. W.G. Sloof

Contact Hours / Weekx/x/x/x

0/0/2/2

Education Period 34

Start Education 3

Exam Period Different, to be announced

Course Language English

Summary Electron Back Scatter Diffraction, EBSD, Orientation Imaging Microscopy, Kikuchi diffraction patterns, Scanning ElectronMicroscopy, Texture, Misorientation, Coincidence site lattices, Grain boundaries, Sterographic projection, Pole figures,Orientation Distribution Functions.

Course Contents A modern technique to determine the microstructure of crystalline materials is Orientation Imaging Microscopy which is basedon Electron Back Scatter Diffraction in a Scanning Electron Microscope. This technique enables to determine the microstuctureof materials quantitatively in terms of: (i) spatial distribution of phases, (ii) size, shape and orientation of crystallite grains, (iii)misorientation between neighbouring grains, and (iv) texture. The course covers fundamental aspects of EBSD measurements,evaluation of collected data and analysis of results.The principles of Electron Back Scatter Diffraction and the generation of Kikuchi patterns. Methods of indexing the diffractionpatterns and the determination of crystal orientation. Definitions of coordinate systems and their relation with Euler angles andspace. Stereographic projection and representation of crystal orientations in pole figures. Construction of phase and Euler maps.Representation of grain orientions in Rodrgues-Frank space. Determination of misorientation between neighbouring grains.Special orientation relations: coincidence site lattice. Methods to determine grain size and shape, and texture.

Study Goals The student is able to use the physical principles of Electron Back Scatter Diffraction (EBSD) to explain quantitativedetermintion of materials microstructures.

More specifically, the student is able to:Explain the principles of EBSD and the formation of Kikuchi patterens.

Show how electron microscopes equipped with EBSD are built and operated.Describe how diffraction patterns are sampled, indexed and processed to crystal orientation images.Formulate how texture of materials is reperesented using pole figures.Explain the use of Euler angles and Euler space to characterize crystal orientations.Compute misorientations and orientation relations between neighboring grains.Illustrate the representation of EBSD data with the Rodrigues vector in Rodrigues-Frank space.Describe how orientation maps are constructed and how grain size and shapes are quantifiedShow how electron microscopes equipped with EBSD diffractometers are built and operated.Apply all the above to analyse the microstructure of a material from an EBSD measurement.

Education Method Lecture and laboratory project.

Computer Use Operation of an electron microscope equipped with EBSD. Processing and analysis of EBSD measurement data.

Literature and StudyMaterials

Instructions and guides are available on blackboard.

References from literature: V. Randle, Microtexture Determination and its applications, 2nd edition, Maney Publishing, London,2003; ISBN 1-902653-83-1.

Assessment Oral exam (project, written report and oral exam).

Remarks Hours per week: 2 lectures.Other hours: self study, lab project and report writing.

The course includes a laboratory project (2 EC) involving an EBSD measurement of a material. Next, a set of diffraction patternsis collected. Then, the data are processed and analysed to determination the microstructure with great detail. The results of thisproject are presented in a written report and discussed at the oral examination. The assignments can be found on blackboard.

Department 3mE Department Materials Science & Engineering

Page 20 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 21/186

MS3442 Relation between Properties and Microstructure 4

Responsible Instructor Prof.dr.ir. J. Sietsma

Instructor Dr.ir. M. Janssen

Contact Hours / Weekx/x/x/x

4/0/0/0

Education Period 1

Start Education 1

Exam Period 12

Course Language EnglishSummary microstructure, mechanical properties, fatigue, magnetic properties

Course Contents The module consists of two parts: mechanical properties and magnetic properties. In the mechanical part a selection will beconsidered of properties such as strength, (fracture) toughness, fatigue and creep.

The magnetic properties concern the following subjects: magnetic moments in materials, magnetic measurements, ferro-, para-and diamagnetism, hysteresis, Barkhausen effect, magnetostriction, domains, domain walls, kinetics of domain-wall processes,soft and hard magnetic materials, magnetic recording, magnetic methods in materials evaluation.

Study Goals The student is able to explain the effects of various different microstructural parameters on the mechanical and magneticproperties of metals.

More specifically with respect to mechanical properties, the student is able to:- describe how microstructural barriers affect the growth of short fatigue cracks and categorise the effect of crack length onfatigue limit- identify initiation sites for fatigue cracks: locations, loading conditions and development- identify the different stages in short fatigue crack growth and indicate effects of the microstructural unit size (e.g. grain size),corrosive environments and notches

- illustrate the complexity of multiaxial fatigue in comparison with uniaxial fatigue and the effect of loading order on damageaccumulation during mixed mode loading- explain different models for analysing short fatigue crack growth- elaborate on the significance of short fatigue cracks for lifetime predictions- explain the role of the deformation character (i.e. wavy or planar slip) on the fatigue limit and the consequences this has forvarious ultra fine-grained metals and metal alloys- elaborate on the microstructure of metals subjected to severe plastic deformation and on the subsequent effect of cyclicdeformation (i.e. softening and hardening)- explain the nature of stress-strain hysteresis loops for ultra fine-grained metals on the basis of friction stresses and back stresses- identify the development of fatigue damage in ultra fine-grained metals, both on a macro-scopic and on a microscopic scale,and methods to delay this damage- describe current models for fatigue mechanisms in ultra fine-grained metals- interpret results from scientific journal papers, which means extracting principal ideas from extensive texts while dealing withincomplete and sometimes conflicting information

More specifically with respect to magnetic properties, the student is able to:- describe the character of magenitisation of materials- explain the background and mechanism of magnetic measurements- identify the main types of magnetism

- describe the magnetic processes determining the hysteresis loop and identify the main parameters describing the hysteresis loop- explain the occurrence of the Barkhausen effect- explain the characteristics of ferromagnetic domains, domain walls, and domain-wall motion- describe the most important charateristics of soft- and hard-magnetic materials, and the main applications- explain the mechanisms used for magnetic recording and storage- explain the mechanisms underlying the application of magnetic methods in materials research and characterisation

Education Method Lecture

Literature and StudyMaterials

Course material:- Mechanical properties: Review articles provided on demand- Magnetic properties: D. Jiles, Introduction to Magnetism and Magnetic Materials, ed. Chapman & Hall, 2nd edition, 1998,chapters 2.3-2.5, 3-8, 12-15

Prerequisites MS4041 - Structure of Materials, MS4081 - Mechanics of Materials, MS4011 - Mechanical Properties, MS3021 - MetalsScience.

Assessment Oral exam for the part on mechanical properties; written exam, open book, for the part on magnetic properties;

Department 3mE Department Materials Science & Engineering

Page 21 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 22/186

MS3452 Total Performance Approach: Case Studies 3

Responsible Instructor Dr.ir. J.M.C. Mol

Contact Hours / Weekx/x/x/x

2/0/0/0

Education Period 1

Start Education 2

Exam Period 12

Course Language English

Required for MS4161 (Designing (with) Materials)Summary Materials in Design, Materials Processing in Design, Materials Selection, Process Selection case studies, Materials Processing,

Materials Engineering.

Course Contents Materials in Design - Evolution of engineering materials - The design process - Engineering materials and their properties -Materials selection charts-Materials selection: case studies; Materials processing and design - Materials Processing SelectionCharts - Case studies: process selection - Data sources.

Study Goals The student is able to develop a systematic procedure for selecting materials and processes with best matches the requirements of a design

More specifically, the student is able to:Integrate materials selection with other aspects of designDevelop materials indices and/ or value functions to model design requirementsIdentify the main materials engineering aspects of materials and process selection.Apply all of the above in case studies representing simplified and real designs.

Education Method Lecture

Computer Use Cambridge Engineering Selector (CES) Software Package

Literature and StudyMaterials

Materials Selection in Mechanical Design, Michael F. Ashby, Butterworth-Heinemann ISBN 0 7506 4357 9Lecture notes made available through Blackboard after class

Prerequisites MS3021 (Metals Science); CH4011MS (Polymer science); CH4021MS (Ceramic Science); MS4011 (Mechanical Properties)

Assessment - Presentation- Written report on 2 case studies (assignments)- Oral feedback session

Design Content Materials and Process selection

Department 3mE Department Materials Science & Engineering

Page 22 of 186

7/22/2019 3mE Keuzevakken 2010 En

http://slidepdf.com/reader/full/3me-keuzevakken-2010-en 23/186

MS3461 Corrosion and Protection against Corrosion 3

Responsible Instructor Dr.ir. J.M.C. Mol

Instructor Prof.dr. J.H.W. de Wit

Contact Hours / Weekx/x/x/x

4/0/0/0

Education Period 1

Start Education 1

Exam Period 12

Course Language EnglishSummary corrosion, protection against corrosion, corrosion principles, corrosion prevention, galvanic corrosion, intergranular corrosion,

pitting corrosion, crevice corrosion, coatings, surface layers

Course Contents - Relevance of corrosion, costs to society- Definitions and electrochemical character of corrosion- General corrosion vs local forms of corrosion- Electrochemical Thermodynamics- Electrochemical Kinetics- Passivity- Galvanic Corrosion and intergranular corrosion- Pitting and Crevice Corrosion- Protection against corrosion

Study Goals The student is able to describe the electrochemical nature of corrosion processes, in his professional life to understand the riskshazards and costs due to corrosion phenomena and act upon it in making decisions on metals applications and to make anargumentative selection of materials classes ( steel, stainless steel, aluminium alloys, copper alloys) for given applications.

More specifically, the student is able to:

1.derive and produce qualitative and semiquantitative polarisation diagrams for a corroding metal from a1.simple set of data2.compose polarisation diagrams for galvanic corrosion and for passive materials from a set of data3.compose and use Pourbaix diagrams in making decisions on metals applications4.calculate the corrosion current density of metals from quantitative polarisation diagrams5.transform the corrosion current density into practical corrosion rates like mm/year6.list the most important corrosion localised phenomena7.describe the mechanisms of the most important localised corrosion phenomena8.criticize a given description of a corrosion mechanism9.select the technical best protection measures to prevent attack of metals in a given surrounding10.criticize and judge a given materials application11.discuss in a balanced way applied protective measures taking into account, risks for health, environment and costs

Education Method Lectures

Literature and StudyMaterials

Principles and Prevention of Corrosion, Second Edition 1996, van Denny A. Jones, ISBN 0-13-359993-0

Assessment Written exam

Remarks In case of too few participants the written exam will be replaced by an oral exam.

Department 3mE Department Materials Science & Engineering

MS3471 Modern Analysis Techniques & Authenticity Research 4

Responsible Instructor Prof.dr. J. Dik

Contact Hours / Weekx/x/x/x

x/0/0/0

Education Period 1

Start Education 1

Exam Period Different, to be announced

Course Language English

Summary Authenticity research, art objects, historical artefacts, materials analysis

Course Contents Precious historical artefacts have always been the subject of falsification. Forgeries can be identified as such by analysis of the

materials used. This course studies the proces of materials analysis of artworks, including the sampling of the object, theanalytical identififcation of materials and the historical interpretation of analysis results. The course has a highly practicalorientation and usually includes a questioned art object from the art world.