Thesis Wijshoff

-

Upload

herb-endricott -

Category

Documents

-

view

33 -

download

8

Transcript of Thesis Wijshoff

Structure- and fluid-dynamics in piezo inkjet

printheads

Samenstelling promotiecommissie:

Prof. dr. ir. L. van Wijngaarden, voorzitter Universiteit TwenteProf. dr. rer. nat. D. Lohse, promotor Universiteit TwenteProf. dr. rer. nat. F. G. Mugele Universiteit TwenteProf. dr. ir. H. Tijdeman Universiteit TwenteProf. dr. ir. J. Huetink Universiteit TwenteProf. dr. ir. M. E. H. van Dongen Technische Universiteit EindhovenProf. dr. F. Toschi Technische Universiteit EindhovenProf. dr. ir. D. J. Rixen Technische Universiteit DelftIr. H. Reinten, referent Oce Technologies B.V.

The research described in this thesis was carried out at the Research and Devel-opment department of Oce Technologies B.V.

Nederlandse titel:Dynamica van constructies en vloeistoffen in piezo inkjet printkoppen

Publisher:Herman Wijshoff, Oce Technologies B.V., Venlo,P.O. Box 101, 5900 MA Venlo, The Netherlandswww.oce.comCover design: Herman WijshoffBackground cover illustration: A MEMS-based printhead structure, the future.Front cover illustration: The models describing the complete printhead operation,the upper two represent the solid mechanics and the lower two the fluid mechanicspart of the thesis.Back cover illustration: Cover of the oldest publication in this field, anno 1749.Print: Gilde Print B.V., Enschede

c© Herman Wijshoff, Venlo, The Netherlands 2008

No part of this work may be reproduced by printphotocopy or any other means without the permissionin writing from the publisher.ISBN 978-90-365-2582-4

Structure- and fluid-dynamics in piezo inkjet

printheads

PROEFSCHRIFT

ter verkrijging vande graad van doctor aan de Universiteit Twente,

op gezag van de rector magnificus,prof. dr. W. H. M. Zijm,

volgens besluit van het College voor Promotiesin het openbaar te verdedigen

op vrijdag 25 januari 2008 om 16.45 uur

door

Herman Wijshoffgeboren op 3 september 1961

te Grevenbicht

Dit proefschrift is goedgekeurd door de promotor:

prof. dr. rer. nat. Detlef Lohse

Contents

1 Introduction 1

1.1 Historical overview on inkjet technology . . . . . . . . . . . . . . . 1

1.2 Printing principles . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Printhead operation . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Working principle . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Printhead testing . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Guide through the thesis . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Structure dynamics 19

2.1 Actuating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.1 Piezoelectricity . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.2 Bump mode actuation . . . . . . . . . . . . . . . . . . . . . 22

2.1.3 Actuation efficiency . . . . . . . . . . . . . . . . . . . . . . 26

2.2 Local cross-talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2.1 Electrical cross-talk . . . . . . . . . . . . . . . . . . . . . . 27

2.2.2 Direct cross-talk . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2.3 Pressure-induced cross-talk . . . . . . . . . . . . . . . . . . 31

2.3 Printhead dynamics . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.1 Modeling setup . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3.2 Structural resonances . . . . . . . . . . . . . . . . . . . . . 35

2.4 Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3 Channel acoustics 41

3.1 Narrow channel theory . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.1.1 Governing equations . . . . . . . . . . . . . . . . . . . . . . 41

3.1.2 Frequency characteristics . . . . . . . . . . . . . . . . . . . 44

3.1.3 Traveling wave principle . . . . . . . . . . . . . . . . . . . . 48

3.2 Nozzle boundary . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.1 Nozzle pressure . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2.2 Drop size and speed . . . . . . . . . . . . . . . . . . . . . . 54

3.3 Cross-talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.3.1 Local cross-talk . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.3.2 Printhead resonances . . . . . . . . . . . . . . . . . . . . . . 59

i

ii CONTENTS

3.3.3 Acoustic cross-talk . . . . . . . . . . . . . . . . . . . . . . . 62

3.4 Residual vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.4.1 Refill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.4.2 Drop on demand frequency oscillations . . . . . . . . . . . . 68

3.4.3 Interaction with local cross-talk . . . . . . . . . . . . . . . . 70

3.5 Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4 Drop dynamics 73

4.1 Drop formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.1.1 Drop shape and properties . . . . . . . . . . . . . . . . . . 73

4.1.2 Impact on acoustics . . . . . . . . . . . . . . . . . . . . . . 77

4.2 Break-off mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.2.1 Impact of ink properties . . . . . . . . . . . . . . . . . . . . 81

4.2.2 Secondary tail . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.2.3 Tail-end speed . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.3 Satellite drop formation . . . . . . . . . . . . . . . . . . . . . . . . 87

4.3.1 Mist of droplets . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.3.2 Rayleigh breakup . . . . . . . . . . . . . . . . . . . . . . . . 89

4.3.3 Fast satellites . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.3.4 Slow satellites . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4.4 Drop size modulation . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.4.1 Pulse width and fill-before-fire-level . . . . . . . . . . . . . 94

4.4.2 Acoustic resonances . . . . . . . . . . . . . . . . . . . . . . 96

4.4.3 Break pulses . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.4.4 Meniscus and drop formation oscillations . . . . . . . . . . 99

4.5 Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5 Wetting dynamics 103

5.1 Wetting of the nozzle plate . . . . . . . . . . . . . . . . . . . . . . 103

5.1.1 Origin of wetting . . . . . . . . . . . . . . . . . . . . . . . . 103

5.1.2 Wetting regimes and visualization . . . . . . . . . . . . . . 106

5.2 A wetted nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.2.1 Jetting nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.2.2 Non-jetting nozzle . . . . . . . . . . . . . . . . . . . . . . . 111

5.3 A wetted nozzle plate . . . . . . . . . . . . . . . . . . . . . . . . . 114

5.3.1 Long-range phenomena . . . . . . . . . . . . . . . . . . . . 114

5.3.2 Driving mechanisms . . . . . . . . . . . . . . . . . . . . . . 115

5.3.3 Complete wetting . . . . . . . . . . . . . . . . . . . . . . . . 118

5.3.4 Marangoni flow . . . . . . . . . . . . . . . . . . . . . . . . . 120

5.4 Impact on drop formation . . . . . . . . . . . . . . . . . . . . . . . 121

5.4.1 Drop properties . . . . . . . . . . . . . . . . . . . . . . . . . 121

5.4.2 Channel acoustics . . . . . . . . . . . . . . . . . . . . . . . 122

5.5 Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . 123

CONTENTS iii

6 Bubble dynamics 1256.1 Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

6.1.1 Dirt and air entrapment . . . . . . . . . . . . . . . . . . . . 1256.1.2 Acoustic detection of air bubbles . . . . . . . . . . . . . . . 126

6.2 Air entrainment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1286.2.1 Wetting layer . . . . . . . . . . . . . . . . . . . . . . . . . . 1286.2.2 Small dirt particles . . . . . . . . . . . . . . . . . . . . . . . 129

6.3 The oscillating bubble . . . . . . . . . . . . . . . . . . . . . . . . . 1346.3.1 Size dynamics . . . . . . . . . . . . . . . . . . . . . . . . . . 1346.3.2 Impact on channel acoustics . . . . . . . . . . . . . . . . . . 1346.3.3 Impact on drop formation . . . . . . . . . . . . . . . . . . . 136

6.4 The moving bubble . . . . . . . . . . . . . . . . . . . . . . . . . . . 1396.4.1 Balance of forces . . . . . . . . . . . . . . . . . . . . . . . . 1396.4.2 Net displacements . . . . . . . . . . . . . . . . . . . . . . . 140

6.5 The growing bubble . . . . . . . . . . . . . . . . . . . . . . . . . . 1416.5.1 Rectified diffusion and dissolution . . . . . . . . . . . . . . 1416.5.2 Influence of the actuation . . . . . . . . . . . . . . . . . . . 1436.5.3 Impact on channel acoustics . . . . . . . . . . . . . . . . . . 1456.5.4 Impact on drop formation . . . . . . . . . . . . . . . . . . . 146

6.6 Concluding remarks . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7 Conclusions 149

References 153

Summary 165

Samenvatting 169

Acknowledgements 173

List of publications 175

About the author 177

iv CONTENTS

Chapter 1

Introduction

In this chapter an overview is presented of the main inkjet developments to clarifythe importance of inkjet technology as key-technology for today’s industry. Besidesprinting onto paper, many other application have emerged the last years. The re-quirements to meet the needs in many areas justify the intensive research program.The basic printing principles are outlined and the main printhead operation issuesare presented. Finally a guide through the chapters of this thesis is given.

1.1 Historical overview on inkjet technology

Inkjet printing is an important technology in color document production [133].The rapid development of inkjet technology started off around the late fifties.Since then, many inkjet devices have seen the light of day. In this overview, theattention is mainly restricted to the development towards the most importantinkjet concepts of today, namely continuous, piezoelectric, and thermal inkjet.

The first inkjet-like recording device, using electrostatic forces, was inventedby William Thomson, later Lord Kelvin, in 1858. This was the Siphon recorder asshown in figure 1.1. The apparatus was used for automatic recordings of telegraphmessages and was patented in 1867 (UK Patent 2147/1867). A siphon produces acontinuous stream of ink onto a moving web of paper and a driving signal movesthe siphon horizontally back and forth. The first experiments on manipulating astream of droplets even goes back to 1749. That year, Abbe Nollet published hisinvestigations on the effects of static electricity on a drop stream [122, 123].

In 1822 the equations to describe the motion of fluids were formulated bythe French engineer and physicist Claude Navier [121], seventy years after Eulerhad published his equation for ideal liquids without viscosity [53]. Navier alsoformulated the general theory of elasticity in a mathematically usable form in1821. George Stokes introduced his equations for the motion of liquids in 1845[145]. Hence the name Navier-Stokes equations for the application of classicalmechanics to a continuum under the assumption of a stress that is linear with thestrain rate.

1

2 CHAPTER 1. INTRODUCTION

(a) (b)

Figure 1.1: (a) The Siphon recorder is the first practical continuous inkjet de-vice. It was used for automatic recordings of telegraph messages and invented byWilliam Thomson in 1858 (UK Patent 2147/1867). (b) An illustration from AbbeNollet showing the first experiments on the effect of static electricity on a dropstream, published in 1749 [122].

The foundation of modern inkjet technology is attributed to the Belgian physi-cist Joseph Plateau and English physicist Lord Rayleigh. Plateau was the veryfirst to publish on this field with his article On the recent theories of the consti-tution of jets of liquid issuing from circular orifices in 1856 [132]. He derived therelationship of jet diameter to drop size in 1865. Lord Rayleigh published a seriesof founding papers starting with Instability of jets in 1878 [136]. The experimentalfoundation of this work started in 1833, when Savart published his observationson drop break-up [138]. He was the first one who recognized that the break-upof liquid jets is governed by laws, independent of the circumstance under whichthe jet is produced. He used acoustic energy to form uniform drops. What wasmissing in his work was the realization that surface tension is the driving forcebehind drop break-up. The groundwork for the description of the role of surfacetension forces was laid by Young in 1804 [172] and Laplace in 1805 [96].

Still, it took many decades before applications of the physical principles ofdrop formation were used in commercial working devices. In 1951, Elmqvist of theSiemens-Elema company patented the first practical continuous inkjet device (USPatent 2,566,433), which was based on the Rayleigh breakup [97]. This resulted

1.1. HISTORICAL OVERVIEW ON INKJET TECHNOLOGY 3

in the Mingograph, which was released in 1952. Instead of being an inkjet printer,it was merely a medical voltage recorder (e.g. for ECG and EEG). The deflectingof the drops was driven through analog voltages from a sensor, quite similar tocurrent seismic apparatus.

In the early 1960s Sweet of Stanford University demonstrated that, by apply-ing a pressure wave pattern to an orifice, the ink stream could be broken intodroplets of uniform size and spacing [147]. When the drop break-up mechanismwas controlled, the drops could be charged selectively and reliably as they emergedout of the continuous ink stream. The charged drops were deflected, when pass-ing through an electric field, to form an image on the substrate. The unchargeddrops were captured by the gutter and re-circulated in the system. This versionof the printing process is known as the Continuous Inkjet (CIJ) printing process(US Patent 3,596,275), with the Inkjet Oscillograph as first device. This devicewas elaborated for use by the Stanford Research Institute (SRI) for inkjet bar cod-ing work for Recognition Equipment Incorporated (REI). The A.B. Dick Companyelaborated Sweets invention to be used for character printing. With their Videojet9600 in 1968, it was the first commercial CIJ printing product.

Figure 1.2: Classification of inkjet printing technologies, adapted from [97].

The binary deflection was further developed, not only for bar code printing, butalso for advertising purposes, with the so-called DIJIT printer, introduced in 1973by the Mead company. Developments were boosted by the huge research effortsof IBM in the 1970s, which resulted in 1976 in the IBM 6640, a word processinghardcopy-output peripheral application [27]. Two companies were involved inthe multiple drop deflection, the Sharp and the Applicon company. The formerreleased their Jetpoint in 1973, the latter their color image printer in 1977. Inthe same period Hertz of the Lund University of Technology in Sweden developed

4 CHAPTER 1. INTRODUCTION

several continuous inkjet techniques, which enabled gray-scale printing by varyingthe number of drops per pixel. His methods were adopted by Iris Graphics andStork to produce high-quality color images for the prepress color hardcopy market[69].

Instead of continuously firing drops it is also possible to create drops only whenan actuation pulse is provided: drop-on-demand. Major advantages of drop-on-demand (DOD) printers over CIJ printers include the fact that there is no needfor break-off synchronization, charging electrodes, deflection electrodes, guttering,and re-circulation systems, high pressure ink-supplies and complex electronic cir-cuitry. The first pioneering work in that direction was performed in the late 1940sby Hansell of the Radio Corporation of America (RCA), who invented the firstdrop-on-demand device as shown in figure 1.3. By means of a piezoelectric disc,pressure waves could be generated that caused a spray of ink drops. However, thisinvention, intended for use as a writing mechanism in a pioneering RCA facsimileconcept, was never developed into a commercial product [133].

Figure 1.3: Drawing of the first drop-on-demand piezo inkjet device, which waspatented in 1950 but not further developed into a commercial product (US Patent2,512,743). A piezoelectric disc (5) generates pressure waves in the solid cone (1),which cause a spray of ink drop from the nozzle (2).

The first DOD technique, that really emerged, was the electrostatic pull inkjetin the 1960s. The basic working principle comprises the following. Conductiveink is held in a nozzle by negative pressure. By application of a high voltagepulse to an electrode located outside the nozzle, a charged droplet of ink is pulledout. By application of the appropriate deflection field, the droplet can be locatedon the substrate. Companies developing electrostatic pull inkjet devices were theCasio, Teletype, and Paillard company. The Inktronic Teletype machine in thelate 1960s was marketed by the Teletype company. With the model 500 Typuter,the Casio company released a printer of this type in 1971. In the 1970s, the

1.1. HISTORICAL OVERVIEW ON INKJET TECHNOLOGY 5

DOD electrostatic pull principle was abandoned due to poor printing quality andreliability, although research activities continues until today [153, 154].

Generally, the basis of piezoelectric inkjet (PIJ) printers is attributed to threepatents in the 1970s. Common denominator of these three patents is the use ofa piezoelectrical unit to convert an electrical driving voltage into a mechanicaldeformation of a ink chamber, which generates the pressure required for the dropformation from a nozzle. The first one is that of Zoltan of the Clevite company in1972 (US Patent 3,683,212), proposing a squeeze mode of operation [28]. In thismode, a hollow tube of piezoelectric material is used. When a voltage is appliedon the piezoelectric material, the ink chamber is squeezed and a drop is forced outof a nozzle.

Figure 1.4: Classification of piezo inkjet (PIJ) printhead technologies by the de-formation mode used to generate the drops.

The second patent of Stemme of the Chalmers University in 1973 (US Patent3,747,120) utilizes the bend mode of piezoelectric operation. In this mode, thebending of a wall of the ink chamber is used to eject a drop. The third patentof Kyser and Sears of the Silonics company in 1976 (US Patent 3,946,398) alsoused the bend mode operation. Both bend-mode patents were filed in the sameyear. The minor difference between the two is that Stemme used a flat disc ofpiezoelectric material to deform a rear wall of an ink chamber and that Kyser andSears used a rectangular plate to deform the roof of an ink chamber. The firstPIJ printer to reach the market was in 1977 with the Siemens PT-80, which usedthe squeeze mode. Silonics was the second company to introduce a piezoelectric

6 CHAPTER 1. INTRODUCTION

DOD printer, namely the Quietype in 1978, which used the bend mode The bendmode is also referred to as bimorph or unimorph mode. Obviously, the maindiscriminator between the PIJ patents is the used dominating deformation modeof the piezoelectric material, together with the geometry of the ink channels.

The patent of Stuart Howkins (US Patent 4,459,601) of the Exxon company in1984, describing the push mode version, and the patent of Fischbeck (US Patent4,584,590), who proposed the shear mode, completed the now commonly adaptedcategorization of printhead configurations. With the push mode, also referredto as bump mode, a piezo electric element pushes against an ink chamber wallto deform the ink chamber. In the shear mode the strong shear deformationcomponent in piezo electric materials is used to deform a ink chamber wall. So ingeneral, four types of PIJ printheads are distinguished, the squeeze, push, bend,and shear mode, see figure 1.4.

With sudden steam printing, figure 1.5, a researcher from the Sperry RandCompany basically invented another DOD technique, thermal inkjet printing, inthe 1960s. By boiling aqueous ink at certain time instances, a drop of ink could begenerated. The strength of this design clearly was not immediately acknowledged,since the company did not elaborate this idea into a commercial product. Theidea was abandoned until the late 1970s when Canon and Hewlett Packard (HP)picked it up.

Figure 1.5: Sudden steam printing, the first drop-on-demand thermal inkjet de-vice, which was patented in 1965, but not further developed into a commercialproduct (US Patent 3,179,042). An electric current from the electrodes (102 and104) passes through a portion of the ink (116). The ink is preheated (132) nearlyto its boiling temperature and the extra heat from electric current generates thesteam that ejects the drops form the nozzle.

In 1979 Endo and Hara of the Canon company re-invented the drop-on-demandprintheads actuated by a water vapor bubble, called bubblejet, with the firstprinter launched in 1981. In the same period also HP developed their thermalinkjet technology leading to the first successfull low-cost inkjet printer in 1984.

1.1. HISTORICAL OVERVIEW ON INKJET TECHNOLOGY 7

The invention of thermal inkjet (TIJ) fundamentally changed inkjet research. Bythe replacement of the piezoelectric by a thermal transducer, the main bottle-neck concerning miniaturization was resolved. The thermal transducer became asimple, small, and cheap resistor, figure 1.6.

Figure 1.6: Side view of HP’s SPT printhead, showing the state of the art tech-nology in thermal inkjet printing [8]. The outlet diameter of the nozzle is 18 µm,the ink chamber height is 18 µm. The nozzle pitch in a single row is 42.3 µm andboth nozzle rows are shifted a half nozzle pitch with respect to each other. Thisresults in a nozzle resolution of 1200 npi.

TIJ can be manufactured using mass-production based on IC manufacturingtechnologies. This made the cost per nozzle much lower than the cost per nozzle ofa piezoelectric printhead. Both the fact that inkjet printers now could be minia-turized and its low cost of manufacturing made TIJ the superior inkjet technologyat that time. HP solved the reliability problem of the thermal drop on demandprintheads by the concept of disposable heads and increased the performance oftheir thermal printheads continuously as shown in figure 1.7. HP claims that TIJjets everything that nucleates like toluene, silver suspensions, and even functionalproteins. Currently thermal inkjet, with top-shooters of HP, Canon, Lexmarkand Olivetti and side-shooters of Canon (the first series) and Xerox, dominatesthe low-end home/office color printer market. Oce also applies thermal drop-on-demand inkjet in its wide format color printing systems with printheads of variousmanufacturers.

After the introduction and immense success of TIJ, PIJ research efforts werelargely diminished. However, critical in TIJ is the spreading and intercolor bleed-ing of water based inks. This requires special coatings on the media surface. Athigh productivity cockling and drying of the media is another problem. Therefore,solid inks (hot-melt or phase-change ink), which require piezo actuation, remainedimportant.

Only a few companies continued their research into PIJ. New initiatives witha bump-mode design were taken in 1984 by Howtek and Exxon, later acquired by

8 CHAPTER 1. INTRODUCTION

Figure 1.7: HP Moores law: inkjet printhead performance as printhead drops persecond (the number of nozzles times the maximum drop-on-demand frequency)doubles every 18 months for the past 20 years. It started with 12 nozzles in asingle color glass chip in 1984. Via different printer series (the different markers),this evolved into the 3900 nozzles in a six color single silicon chip in 2006, theScalable Printhead Technology (SPT).

Dataproducts. Now the bump mode actuation is used by Hitachi (which acquiredDataproducts), Trident, Brother and Epson [155]. The bend mode is used byTektronix (acquired by Xerox), Brother/Kyocera and Epson [119, 175]. The shear-mode design came into the field in 1984 with Spectra, a with Xerox licenses formedcompany, and later with Brother. Spectra is acquired by Markem, later by Dimatixand finally by FujiFilm [114, 118]. A special version of the shear mode is the sharedwall design of Xaar. This company started in 1990 for commercializing the workof the Cambridge researchers [15, 95, 109, 111, 173, 174]. Other companies whichuse this concept are Brother/Kodak, ToshibaTEC and MicroFab [3].

At present, both TIJ and PIJ printing have evolved into the two most impor-tant technologies when it comes to printing. The initial advantages of TIJ over PIJhave been leveled over the years by further development of the PIJ technology. Afundamental strength of the PIJ technology is its ability to deposit a wide varietyof materials on various substrates in well-defined patterns. Recently many otherapplications than printing onto paper emerged [13, 106, 116, 140, 142, 167, 168].

In the display market, inkjet technology is used to manufacture Flat PanelDisplays (FDP), Liquid Crystal Displays (LCD), color filters (a part of LCDs),Polymer Light Emitting Diodes (PLED), and flexible displays. The accompanyingperformance criteria are among the major driving forces behind much research anddevelopment efforts [11, 67]. Within the chemical market, the inkjet technology ismainly used as tool for research purposes. The unique capacity of the technologyfor dispensing small doses of liquids makes it very useful for this market. Appli-cations include material and substrate development as well as coating purposes[92, 120, 127].

1.2. PRINTING PRINCIPLES 9

In the electronic market, inkjet printheads are used to create functional electri-cal traces using conductive fluids on both rigid and flexible substrates. One of thefirst applications of inkjet technology within this field was that for the productionof Printed Circuit Boards (PCB). Other applications include the fabrication ofelectric components and circuits such as Radio Frequency Identification (RFID)tags, wearable electronics, solar cells, fuel cells, and batteries. Challenges for theinkjet technology within this field include the spreading of the ink and the requiredguarantees of continuity of the jetted lines [68, 91, 99, 148].

Three-dimensional mechanical printing claims the inkjet technology as tool forrapid prototyping, small volume production, and the production of small sensors[158, 160, 170]. Jetting of UV-curable optical polymers is a key technology forthe cost-effective production of micro-lenses. These tiny lenses are used in devicesfrom fiber optic collimators to medical systems. The ability of inkjet technology toprecisely jet spheres in variable, but consistent, drop sizes provides opportunitiesfor the cost reduction of existing optical components and innovative new designs[16, 36, 41].

The life science market is rapidly expanding with new requirements for precisedispensing of DNA and protein substances [6]. The high costs of these fluids makeinkjet technology with its precision placement and tight flow control an excellentdispensing tool. Applications include the use for DNA research, various medicalpurposes such as dosing of drugs, and food science. A quite futuristic applicationis the use of inkjet printing for the fabrication of living tissue [31, 32, 40, 79, 135].

1.2 Printing principles

The graphic printing applications require certain performance criteria to be met.For an inkjet printhead, an important set of requirements is related to the resultingdrop properties, namely:

• Drop-speed: the resulting droplets are required to have a certain speed,typically several m/s. A high drop speed results in a short time of flight. Thesensitivity for disturbing influences like variations in the printhead-substratedistance will be less, thus the dot position errors will be smaller.

• Drop-volume: depending on the application under consideration, the per-formance requirement concerning volume typically varies now from 2 to 32picoliter. For some applications, it is required that the drop-size can be var-ied during operation. For example, for large areas that need to be coveredlarge drops are desired, whereas for high resolution printing small drops aredesirable. This is referred to as drop-size modulation.

• Drop speed and volume consistency: the variations in drop volume and speedmust stay within a certain percentage band, typically around 2 percent. Thisis to avoid irregularities in the printed object.

10 CHAPTER 1. INTRODUCTION

• Drop-shape: the shape of the dots on a substrate is negatively influenced bythe formation of tails or satellite drops. These are highly undesirable for thequality of the print.

• Jet straightness: the droplets have to be deposed in a straight line towardsthe substrate, typically within 10 mrad accuracy.

Productivity and stability are important requirements, which are closely re-lated to the jetting process. The productivity of an inkjet printhead is mainlydetermined by the jetting frequency, defined as the number of drops that a chan-nel jets within a certain time fdod, and by the number of nozzles Nnoz, definedby the integration density or nozzles per inch and the printhead width. A highintegration density has a lot of consequences for the functionality and the pro-ducibility. For the productivity of an inkjet printer, the firing power Pjet of theprintheads is the key number. The productivity in m2/s is given by:

Pjet =Nnozfdod

dpi2× (24.4 · 10−3)2 (1.1)

with dpi the number of dots per inch [2]. This results in a print time tprint for anarea Aprint of a printer of:

tprint =Aprint

ηPjet(1.2)

with η the efficiency of the printer, which plays a very important role in a scanningsystem. Most inkjet printers use a carriage with several printheads which movesover the full width of the paper. Between the strokes of the carriage, or printswaths, the paper is transported over a certain distance to cover the full area.At higher frequencies the carriage turn-time and the paper step give more andmore limitations. These limitations result in an optimum DOD-frequency for theproductivity of scanning printer systems [26]. For productivity the maximumapplicable DOD-frequency for 600 dpi prints in most scanning printer concepts is30 − 40 kHz.

High productivity single pass printing requires a page-wide array with thou-sands of nozzles as explored by Spectra [152, 179] and Brother-Kyocera [75], andused by Xerox/Tektronix in their Phaser printer series. Another way to increasethe number of nozzles is to use multiple nozzles per channel as explored by Trident[180].

The number of dots per inch is important for print cost and print quality. Printcost is directly related to the thickness of the ink layer or amount of ink/m2. Asa first order approximation, the required drop volume for a 600 dpi dot is about32 pl and for a 1200 dpi dot about 4 pl, since volume scales as the third powerof the spatial resolution. The total volume for a 600 dpi dot with four 1200 dpidrops becomes 16 pl instead of 32 pl with a single 600 dpi drop. Print quality isbetter with smaller dots at a high resolution. Finer detail can be represented andalso the graininess of the print is much less with small dots. For water based inks

1.3. PRINTHEAD OPERATION 11

the less amount of ink with smaller drops results in shorter drying time, anotherdrive to move towards smaller drops. So there is a trade-off between productivityand print quality/cost. Drop size modulation is a way to meet both requirements.The small drops are used for achieving a high print quality and the large dropsfor productivity.

Stability of the jetting process is one of the most important performance re-quirements for inkjet printheads. Typically, it is required that at most one failureoccurs per certain number of jetted drops. For printing onto paper this is typicalone billion, but in some industrial applications no failure at all is allowed.

Additional, more general, requirements include the lifespan of the printhead(typically more than ten billion actuations per channel, a fundamental strengthof PIJ over TIJ), the materials compatibility (a wide variety of inks must bedeposable (again a strength of PIJ over TIJ), the maintainability, and the cost ofproduction and manufacturability of the printhead (a weakness of PIJ).

1.3 Printhead operation

1.3.1 Working principle

The final goal of the printhead operation is firing billions of drops. Before a dropis fired, a lot of processes must take place. In the case of hotmelt inks it startswith the melting of the ink in the melting unit (a), figure 1.8. This unit musthave enough capacity. A good heat transfer and draining of the melted ink at agiven maximum temperature like 135 C is necessary, taking into account someovershoot and time delay. Another task is filtering (b) the ink. The next unit is thereservoir (c), which must have enough volume, while keeping the total printheaddimensions within certain limits. Important aspects concerning the reservoir are:

• filtering with non-woven filters with high dirt holding capacity

• removal of air bubbles

• temperature control

• closing static pressure, for example supplied with hose (d)

• ink-level sensing.

The lower part of the printhead is the central part (e) where drop formationtakes place. This part is the subject of this thesis and is shown in more detail infigure 1.9. The main components in the central part are:

• a last filter (k), to remove the dirt particles from the ink

• the channel block (h), in which the ink channels (l) are made

• the nozzle plate (g), where the drops are formed

12 CHAPTER 1. INTRODUCTION

Figure 1.8: 3D CAD drawing of a printhead prototype showing (a) the meltingunit, (b) the filter units, (c) the reservoir, (d) the static pressure hose, (e) thecentral part, and (f) the electronic driving supply.

• the actuator foil (i), which covers the ink channels in the channel block. Thefoil is also connected to:

• the actuator plate with piezo elements and substrate (j). Here the drivingforce for the drop formation process is generated. The required electricvoltage is supplied by the electronic flex (f), figure 1.8.

The ink path from the reservoir and last filter to the nozzle can be dividedinto a supply channel, a pressure channel and a connection channel. The actuationtakes place in the pressure channel, which is shown in figure 1.9 in a front view ofa channel. When a voltage is applied on a piezo element, this element will changeits shape. This deforms the ink channel, which generates the pressure waves tofire a drop. The reaction force is supplied by the substrate, which is connected tothe channel block via passive piezo elements.

Typical dimensions are length 5−20 mm for the total ink channel with a cross-section of 0.01 − 0.05 mm2. The channel block material is graphite with shapedchannels, or a metal like brass or silicon with etched channels. The actuator foil hasa thickness of 5−50 µm and we use poly-imide, metal, glass, or silicon as material.The actuator plate is a piezo-ceramic material with a height of typical 500 µmwith diced elements. In most cases we use a substrate to support the elementstructure. The substrate is several millimeter longer than the piezo elements, to

1.3. PRINTHEAD OPERATION 13

Figure 1.9: Side view of channel structure and front view with actuation principleas explained in section 2.1.2., with (c) the reservoir, (g) the nozzle plate, (h) thechannel block, (i) the actuator foil, (j) the actuator with piezo elements and thesubstrate, (k) a last filter, and (l) the ink channel.

enable the connection of the electronic flex. The nozzle plate thickness rangesfrom 30− 125 µm and nozzle diameters from 18− 50 µm. Different nozzle shapesare made in nozzle plates of nickel, tantalum, poly-imide or silicon.

A long ink channel with a nozzle at the right side and a large reservoir atthe left side is the simplified geometry of the inkjet device like in [17], figure1.10. A piezo actuator element drives each channel. To fire a droplet, an electricvoltage is applied and the channel cross-section will be deformed by the inversepiezo-electric effect. This results in a negative pressure wave inside the channel.The pressure waves propagates in the channel direction and will be reflected whenthe characteristic acoustic impedance Z of the channel changes. The acousticimpedance of the channel depends on the size of the channel cross-section A andthe speed of sound c as:

Z =ρc

A(1.3)

with ρ the density of the ink. The speed of sound is influenced by the complianceof the channel cross-section, see section 3.1.3. The reflection and transmissioncoefficients at the interface between domain 1 and domain 2 are:

R =Z2 − Z1

Z1 + Z2T =

2Z2

Z1 + Z2(1.4)

When the compliance does not change, the following relationship holds:

R =A1 − A2

A1 + A2T =

2A1

A1 + A2(1.5)

At the large reservoir (A2 ≫ A1) the transmission coefficient is zero and the reflec-tion coefficient equals −1. This means that the pressure wave will be completelyreflected and the amplitude of the wave will change from a negative to a positivepressure wave.

14 CHAPTER 1. INTRODUCTION

Figure 1.10: Schematic drawing of the actuation principle. An electric voltage ona piezo element enlarges the channel and a negative pressure is generated. Afterreflection at the reservoir this becomes a positive pressure pressure wave. Thepositive pressure wave is amplified by the second slope of the driving waveform toget a large positive pressure peak at the nozzle, which fires a drop.

The charging of the piezo element (a) enlarges the channel cross-section andthe resulting negative pressure wave will be reflected at the reservoir at the left (b).The large reservoir acts as an open-end and the acoustic wave returns as a positivepressure wave (c). The de-charging of the piezo element reduces the channel cross-section to its original size. This will amplify the positive pressure wave when tunedto the travel time of this acoustic wave (d). The channel structure and drivingpulse are designed to get a large incoming positive pressure peak at the nozzle(e), which drives the ink through the nozzle. Acceleration of the ink movement inthe small cross-section of the nozzle (conservation of mass and incompressibility)results in drop formation.

1.3.2 Printhead testing

Droplets are measured by means of optical methods [1] like stroboscopic illumi-nation at drop formation rate and high-speed camera recordings up to 160,000images/sec with a Phantom V7 camera from Vision Research or up to 1 millionimages/sec with a Shimadzu HPV-1 camera. The basic setup for the optical mea-surements is outlined in figure 1.11. The setup can be divided into a part whichcontrols the printhead and a part to visualize the droplets.

The required reference temperature is reached by a PID controller (Eurotherm2408), which measures the temperature of the printhead with thermocouples andcontrols the input voltages for the heating elements. The printhead is mountedin vertical direction with the nozzles faced down, similar to its position in aninkjet printer. To avoid that the ink simply flows out of the nozzles under theinfluence of gravity, an air pressure unit (TS 9150G) makes sure that the pressure

1.3. PRINTHEAD OPERATION 15

in the ink reservoir remains 8 mbar below the ambient pressure. The setup isconnected to a personal computer that is equipped with National InstrumentsIMAQ PCI 1409 and PCI GPIB cards for image capturing and processing and forcommunication, respectively. A Newport MM3000 motion controller is used forautomatic positioning of the printheads in the measuring positions with Newportxy-tables.

Figure 1.11: Outline of experimental setup with printhead control, driving elec-tronics and optical recording equipment.

We use Labview software to control the measurements and the measuring re-sults can be directly exported to for example Excel for further analysis. Afterdefining the actuation signal, it is sent to an arbitrary waveform generator (PhilipsPM 5150/Wavetek 75A). The waveform generator sends the signal to an amplifier(Krohn-Hite 7602). From the amplifier, the signal is fed to a so-called switch-board. The switch-board is controlled by the personal computer and determineswhich channels are provided with the appropriate actuation signals.

We use a standard CCD-camera (for example Sony SSC-M370CE or WatekLCL902K) to capture the images from an Olympus SZH-10 microscope of thedrop formation with a frame rate 25 images/sec. A led produces flashes of 100 nsand the strobe frequency is the same as the drop repetition rate or DOD-frequency.We will only see the reproducible part of the drop formation, because the imagesare integrated over many (depending on the DOD-frequency up to several hun-dred) droplets. Drop properties can be derived very easily from these images. Thedrop speed is calculated from the distance of adjacent drops and the known repe-tition time. The drop size is calculated from the number of pixels, or by weightinga certain number of captured drops. Drop direction is calculated from the cen-ters of mass. To capture non-reproducible phenomena we use high-speed camerarecordings. In a certain time frame (up to typical 1 s) all drops are recorded with

16 CHAPTER 1. INTRODUCTION

1-10 µs time intervals, using a trigger signal to read back the relevant time frame.

With laser-Doppler interferometry (Ono Sokki laser vibrometer LV1500) werecord meniscus movements without drop formation. The measuring principle isbased on mixing an undisturbed and a Doppler-shifted laser beam. The Dopplereffect, the frequency shift ∆f , of the reflected beam is given by:

f =2v

cf0 =

2v

λ(1.6)

with f0 the frequency of the undisturbed laser beam, λ the wavelength of the laserbeam, c the speed of light, and v the normal speed of the surface which reflectsthe laser beam. The meniscus speed is derived from the interference pattern ofthe reflected beam with the reference beam and the frequency characteristics arerecorded with a HP 3585A spectrum analyzer. With laser-Doppler it is also possi-ble to measure actuator displacements with an accuracy of 20 nm [178]. Anothersetup for the latter is a speckle interferometer.

All these measurements give details on the ink flow outside the printheadand the deformations of the exterior of the printhead. The phenomena inside thechannels are difficult to measure. Only when using special transparent printheads,e.g. channels in or covered by a glass plate, and flow tracing particles the flowinside can be measured [117]. The only suitable method for the opaque heads usesthe actuator also as a sensor. As generally known, a piezo can be used as actuatoror as sensor, see e.g. [159]. For that, one uses the piezos inverse (actuator) anddirect (sensor) piezo-electric effect. The former comprises the following. If anelectrical voltage V is applied to the piezo unit, a displacement y of the piezo unitresults. The latter refers to the following phenomenon. If a force F is appliedto a piezos surface, an electric charge Q results. Together, this behavior can bedescribed as:

[

yQ

]

=

[

d 1/kC d

] [

VF

]

(1.7)

with C the capacity, d the piezoelectric charge constant, and k the stiffness of thepiezo, see chapter 2 for more details.

Switching the piezo elements from the electronic driving circuit to a measuringcircuit gives an accurate recording of the average pressure inside the ink channel,which we from now on call the ”Paint” signal (Piezo-Acoustic sensing of INkchannels in the Time domain), figure 1.12. First the driving waveform is applied,which takes 5 − 20 µs. After that the current from the piezo element can bemeasured until the next actuation cycle starts. The piezo must be completelyde-charged before the acoustic measurement starts. The problem for this setupis that the amplitude of the Paint signal is only 0.1 mA, while the current forcharging and de-charging the piezo is about 10 mA. The acoustic measurementalso enables monitoring of jetting stability [85] and feed-forward control of thedriving waveform [65].

1.4. GUIDE THROUGH THE THESIS 17

from the piezo however.

Paint-signalPiezo-finger

Actuation puls

dt

dFdz

dt

dp

piezo

Figure 1.12: Outline of Paint measurement. Switching the piezo elements betweenan electronic driving circuit and a measuring circuit enables both. The actuationof the channels and the measurement of the pressure variation inside the channels.

1.4 Guide through the thesis

The aim of the research described is this thesis is to explore the processes whichlead to the final goal, the stable and reproducible formation of billions of drops.We need more information on the phenomena preceding the drop formation fora better understanding of the operating principles of the piezo printhead. Thisenables a faster and better development of new printheads [166].

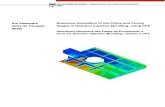

The first step is the actuation. The transformation of an electric voltage toa deformation of the ink channels is described in chapter 2. The deformationsinside the printhead cannot be measured and modeling with the commercial finiteelement code Ansys plays an important role [162]. The deformation of the channelcross-section results in pressure waves.

The acoustic properties of the ink channels are the subject of chapter 3. Thepressure waves play a central role in the printhead operation. They connect theelectrical/mechanical domain of the actuator to the fluid dynamic domain in andoutside the nozzles. Measurements are done with the laser-Doppler setup and theacoustic measurement. Details on ink flow and acoustic pressure waves inside theink channel are available through modeling. The acousto-elastic interaction playsan important role in the ”narrow-channel” model. Acoustic modeling with Ansysgives the details of the interactions with the structure dynamics of the printhead.

Another approach, modeling the complete printhead operation with one modelin a multi-physics approach [177], leads to a very long calculation time and is notconsidered in this thesis.

The drop formation is the final goal of the printhead operation. The pressurewaves in the ink channels are the driving force behind the drop formation process.In chapter 4 the details of the drop formation process are described. Opticalmeasurements and modeling provide the information we need. For the modelingof the free surface flow with surface tension, and its impact on channel acoustics,we use the commercial volume of fluid code Flow3D, an approach used also byDimatix/Spectra [113] and other competitors.

18 CHAPTER 1. INTRODUCTION

Also the flow phenomena on the nozzle plate are important. Wetting of thenozzle plate can influence the drop formation process. The material interactions,which determine the wetting properties, are not known in detail. Therefore, anexperimental study of the wetting phenomena is performed. This is described inchapter 5.

Wetting can also result in air entrainment. Air bubbles play an importantrole in the jetting stability. The theoretical and experimental research on thegeneration and the behavior of air bubbles and their impact on the printheadperformance is the subject of chapter 6. The acoustic measurement is an indirectmeasuring tool for the existence of air bubbles. Transparent heads are developedfor direct visual measurements. Modeling is done with different numerical models.

In the last chapter the results are summarized, conclusions are drawn and anoutlook on further developments is presented.

The experiments are done with printheads developed at Oce Technologies B.V.For the research described in this thesis a transparent test ink is used with aviscosity of about 10 mPa.s at the jetting temperature of 130 C, a surface tensionof 30 mN/m, a density of 1000 kg/m2 and a speed of sound of 1250 m/s.

Chapter 2

Structure dynamics

In this chapter the driving force in piezoelectric printheads is discussed. The actu-ator design for the printhead will be presented, which is based on the bump modeactuation. The deformation of the channels to generate the pressure waves forfiring droplets from the nozzles can also result in local cross-talk effects, like thedirect and the pressure induced cross-talk effect, as will be shown with numericalsimulations. Exciting many channels at the same time excites also resonances inthe printhead structure.

2.1 Actuating

2.1.1 Piezoelectricity

The driving force to fire a droplet with a piezo inkjet printhead is generated bythe actuator, which deforms the structure through the inverse piezo-electric effect.

The piezoelectric effect (electricity from an applied mechanical stress) was firstdiscovered by Pierre and Jacques Curie in 1880. Their experimental demonstrationconsisted of a conclusive measurement of surface charges appearing on speciallyprepared crystals, which were subjected to mechanical stress. In 1881, Lippmanndeduced mathematically the inverse piezoelectric effect (stress in response to anapplied electric field). The Curie brothers immediately confirmed the existenceof this property [25]. In the following years, the twenty natural crystal classes inwhich piezoelectric effects occur and all possible macroscopic piezoelectric coeffi-cients were defined [5].

Barium titanate (BaTiO3), the first piezoelectric ceramic with a perovskitestructure (a tetragonal/rhombohedral structure very close to cubic), was foundaround 1943. S. Roberts detected the piezoelectric effect in BaTiO3 in 1947. In1954, the discovery of the piezoelectric ceramic Pb(ZrxT i1−x)O3, lead zirconatetitanate (PZT), was reported by B. Jaffe (US Patent 2,708,244). In the followingyears PZT became the main industrial product in piezoelectric ceramic materials.

Ceramic perovskites have a cubic structure that is stable at temperatures abovetheir Curie temperature, as seen in figure 2.1. When the temperature decreases

19

20 CHAPTER 2. STRUCTURE DYNAMICS

Figure 2.1: The elementary cell of PZT (a) above the Curie temperature and (b)below the Curie temperature. At a high temperature, the electric charges coincidein a cubic structure and there is no piezo-electricity. Below the Curie-temperaturethe electric charges do not coincide anymore. This results in a piezoelectric effect.

and falls below the Curie temperature, the structure changes and in the caseof PZT, the O2− and the Pb2+ -ions are moved from their cubic positions andthe T i4+ and Zr4+ ions are moved from the center of the cube. The positiveand negative charge sites do not coincide anymore, which results in a dipole anda structure that is no longer cubic but rather tetragonal. An electric field willtherefore tend to deform the structure and this results in the inverse piezo-electriceffect.

In general, a uniform alignment of the electric dipoles only occurs in certainregions of a crystal, while in other regions the polarization may be in the reversedirection. Such regions are called ferroelectric domains. When a ferroelectric ce-ramic is produced, it shows no piezoelectricity. Because of the random orientationof the different domains, there is no net polarization. In order for the material tobecome piezoelectric it has to be poled. Poling is the imposition of a DC-voltageacross the material. The ferroelectric domains align to the field resulting in anet piezoelectric effect. Not all the domains become exactly aligned. Some ofthem align only partially and some do not align at all. The number of domainsthat do align depends upon the electric poling field, the temperature, and thetime the electric field is held on the material. During poling the material perma-nently increases in dimension between the poling electrodes. The material can bede-poled by reversing the poling voltage, increasing the temperature beyond theCurie temperature or by inducing a large mechanical stress.

A ferroelectric hysteresis loop for a piezoelectric ceramic is a plot of the polar-ization P developed against the field E applied to that device at a given frequency.A typical hysteresis loop is shown in figure 2.2. Applying a small electric field,we only get the linear relationship between P and E (1→2), because the field isnot large enough to switch any domain and the sample will behave as a normal

2.1. ACTUATING 21

Figure 2.2: P-E hysteresis loop for a ferroelectric material. A plot of the polariza-tion P developed against the field E applied to that device at a given frequency.(1-2) A small electric field does not align the domains but (3-4) a large electricswitches the domain in one direction resulting in (5) a net polarization of the ma-terial. (6) A large electric field in the opposite direction de-polarizes the materialand (7-8) can even reverse the polarization.

dielectric material. As the electric field strength increases (2→3), a number ofthe negative domains (which have a polarization opposite to the direction of thefield) will be switched over in the positive direction and the polarization will in-crease rapidly until all domains are aligned in the positive direction (4). As thefield strength decreases, the polarization will generally decrease but not returnback to zero. When the field is reduced to zero (5), some of the domains willremain aligned in the positive direction, and the ferroelectric sample will exhibita remnant polarization Pr.

The remnant polarization Pr in a ferroelectric sample cannot be removed untilthe applied field in the opposite (negative) direction reaches a certain value. Thestrength of the field required to reduce the polarization P to zero (6) is called thecoercive field strength Ec. Further increasing of the field in the negative directionwill cause a complete alignment of the dipoles in this direction (7). Reversingthe field direction once again can complete the hysteresis cycle. The piezoelectricPIC251 material has a Curie temperature of 200 C. The coercive field strengthat room temperature is 1.2 kV/m and only the half at an operating temperatureof 130 C.

Balance of angular momentum requires that the stress tensor is symmetric andthe six remaining components of the stress matrix are written as a vector with sixcomponents, T = (τxx, τyy, τzz, τyz , τzx, τxy)T . The same is done for the strainmatrix. We use linear relationships for describing the piezoelectric effect. Thematrices with the piezoelectric coefficients d for the piezoelectric and the inverse

22 CHAPTER 2. STRUCTURE DYNAMICS

piezoelectric effect are equal:

S = d E D = dT T (2.1)

in which D is the electric displacement field (or the charge density), and E is theapplied electrical field. Combining the piezoelectric equations with the equationsdescribing dielectric relation with ε the matrix with the dielectric constants:

D = ε E (2.2)

and the elastic equation with s the compliance matrix:

S = s T (2.3)

we get the matrix equations describing the complete electromechanical behaviorof a material:

S = s T + d E (2.4)

D = dT T + ε E (2.5)

2.1.2 Bump mode actuation

The actuator of the printhead is a bump mode actuator. A side view and a frontview is already given in figure 1.9. The actuation movement is directed along thepolarization of the piezo material and the corresponding axis along the height hp

of the piezo element is the y-axis as shown in figure 2.3. The z-direction is takenin the direction of the channel and the length lp of the piezo element.

2 (=z)

1 (=x)

3 (=y)

1 (=x)

hp

bp

lp

hs

V

Figure 2.3: Configuration of the bump mode actuator with definition of the x-,y- and z-directions. The y-direction is the actuation and polarization direction ofa piezo element with height hp, width bp and length lp, supported by a substratewith thickness hs.

To identify the directions in a piezoelectric ceramic element, the orthogonalaxes are termed 1, 2 and 3. The 3 axis is taken parallel to the direction of

2.1. ACTUATING 23

polarization within the ceramic. For the orthotropic PZT-material the matriceswith the polarization in the y-direction become:

s =

s11 s13 s12 0 0 0s13 s33 s13 0 0 0s12 s13 s11 0 0 00 0 0 s44 0 00 0 0 0 s66 00 0 0 0 0 s44

(2.6)

d =

0 d13 00 d33 00 d13 00 0 d15

0 0 0d15 0 0

ε =

ε11 0 00 ε22 00 0 ε33

(2.7)

The displacement of a free piezo element with height hp, that is without anymechanical stresses, in the y-direction is:

∆y

hp= d33E3 = d33

V

hp(2.8)

with V the driving voltage. So the free displacement is ∆y = d33V see also equa-tion 1.7. With d33 about 400 pm/V for most PZT materials, the displacement ofthe piezo element is 0.4 nm/V . As we will see in chapter 3 the volume displace-ment of the actuator should be about twice the drop volume. To fire a drop of25 pl with a channel of 10 mm length and a width of 250 µm, the displacementof the piezo element should be 20 nm. This requires a driving voltage of 80 V .

For driving electronics, a driving voltage of less than 40 V is preferred. Asimple way to reduce the required driving voltage is to use a multi-layer stackas shown in figure 2.3. The piezo element is divided in n layers with thicknessdlayer = hp/n. So the free displacement is ∆y = nd33V . The required drivingvoltage in the previous example becomes now 80/n.

A limitation is the maximum electric current Imax, which has to be suppliedduring the charging time tp by the driving electronics:

Imax =Q

tp(2.9)

A faster charging of the piezo element, i.e. a smaller tp, is only possible when thetotal charge Q at the electrodes of the piezo element remains within certain limits.The total charge of a free piezo element is:

Q = lp · bp D = ApD = ε33ApE3 =ε33Ap

hpV = CV (2.10)

24 CHAPTER 2. STRUCTURE DYNAMICS

see also equation 1.7. With n layers the total area of the electrodes becomes nAp

and the electric field E3 becomes nV/hp. So the total capacitance of the piezoelement becomes:

C =n2ε33Ap

hp(2.11)

With equations 2.9, 2.10, 2.11, and the fact that the required driving voltage scaleswith 1/n we can see that the maximum electric current increases with n. Thislimits the maximum applicable number of layers within a piezo element.

In order to be capable of deforming an ink channel, the piezo elements haveto be supported by a substrate, which supplies the reaction force. An importantconsequence of this is that mechanical stresses will be generated, which influencethe piezoelectric behavior of the piezo element. The stresses result from the d13 de-formation mode of the piezoelectric material. With a d13 coefficient of -180 pm/V(which is a typical value for many PZT materials), a 10 mm long piezo elementwould have an increase in length of 400 nm, while the actuation displacement isonly 20 nm. Connected to a substrate this elongation will be counteracted.

As a first order approximation we assume that the support by a substrate re-sults in homogeneous mechanical stresses T1 and T2 in the x- and z-direction, re-spectively, throughout the complete piezo element, so the strain in the y-directionbecomes:

S3 = s13T1 + s13T2 + d33E3 = deffE3 (2.12)

Assuming isotropic material properties in the x- and z-directions in the piezoelement and the substrate, T1 = T2, we get for the strain in the x- and z-directionin the piezo element:

S1 = S2 = s11T1 + s12T2 + d13E3 = (s11 + s12)T1 + d13E3 (2.13)

For the strain in the substrate in the x- or z-direction we get with the isotropiccompliances s11 = ss and s12 = −νss of the substrate material:

Ss = ssTs − νsTs = ss(1 − νs)Ts (2.14)

with ν the Poisson ratio of the substrate material. Both materials are connected,so the strain in the x- and z-direction in the piezo element and the substrate areequal. The forces in the piezo element are opposite to the forces in the substrate.For the x-direction this results in:

∑

F1 = 0 = hpT1 + hsTs (2.15)

Substituting equation 2.15 in equation 2.14 we get:

Ss = S1 = −ss(1 − νs)

hshpTs (2.16)

2.1. ACTUATING 25

With equations 2.13 and 2.12 this results in the following equation for the effectivepiezo electric constant:

deff = d33

(

1 − 2d13s13/d33

s11 + s12 + ss(1−νs)hs

hp

)

(2.17)

The substrate is 1 mm thick and the material(AlOx) has an E-modulus of 110 GPaand a Poisson ratio of 0.35. With PZT as piezo material with an E-modulus of60 GPa this results in a loss of about 50 % for the effective piezoelectric constant.This is shown in figure 2.4.

Figure 2.4: Ratio between deff and d33 as function of substrate thickness. Themechanical constraints from the substrate reduce the effective piezo electricity bya factor of two.

One way to reduce the loss in effective piezoelectricity is to make use of theshape factor. At least one dimension in the x- or z-direction of the piezo ele-ment should be much less than the height of the element. Then, the mechanicalconstraints from the substrate only extend over a similar small part of the piezoelement height and the loss in effective piezoelectricity will be much less. The mostextreme version of this approach is used by Trident in their PixelPro printhead[37]. Also Epson uses in their MLP printheads [149] a high aspect ration betweenthe height and the length and width of the piezo elements. In the printheads ofOce the piezo height is 500 µm, the width less than 100 µm and the length sev-eral millimeters to actuate ink channels of the same length. The loss in effectivepiezoelectricity is reduced to 30 %.

The strain in the piezo element is now inhomogeneous and we use finite elementsimulations to solve the complex behavior. To include all structural details likeglue menisci, without getting very large CPU times, we use static linear analysiswith a two-dimensional plain strain model in the x- and y-directions. The com-mercial finite element code Ansys is used with standard full structural PLANE82elements and piezo-electric PLANE13 elements, which solve the above mentionedequations 2.4 and 2.5. The parametric models are written in APDL (Ansys Para-metric Design Language).

26 CHAPTER 2. STRUCTURE DYNAMICS

2.1.3 Actuation efficiency

The efficiency is defined as the volume displacement in the ink chamber per voltdriving amplitude on the electrodes of the piezo element. The volume displace-ment per volt must be as high as possible. The effective piezo electric coefficientgives the change in channel height as function of the electric voltage, equation2.17. Mechanical constraints result not only from the substrate but also fromthe channels, which are covered with a foil. Some basic actuator design rulescan be derived with simple formulas for the stiffness in the actuation direction ofblock-shaped components with height h0, width b0 and length l0. The equationsfor the elongation ke, bending kb and shear stiffness ks in the y-direction of thecomponents with elasticity modulus E and Poisson ratio ν are:

ke =Eb0l0

h0kb =

Eh30l0

b30

ks =Gh0l0

b0(2.18)

with the shear modulus G = E/2(1 + ν). The elongation stiffness is importantfor the piezo elements . The stiffness increases proportional to the piezo width bp

and varies from 100-200 MN/m for 85-170 µm piezo width of an element of 500µm height and 10 mm length.

For the 25 µm tantalum foil between the actuating piezo and the channel wall,see figure 2.5a, the bending stiffness and the shear stiffness are both important.The bending and shear stiffness can be considered as two springs acting in series.The width of the foil between the piezo element and the channel spacing is bf =(bch − bp)/2. The bending stiffness is the lowest for a large distance between thepiezo element and channel wall. The bending stiffness determines mainly the totalstiffness, which varies therefore with the third power of the piezo width. For asmall foil width (bf <

√2(1 + ν)hf ) the shear stiffness is the lowest. The total

stiffness is mainly determined by the shear stiffness, which varies proportional tothe piezo width. For a 220 µm wide channel the stiffness of the foil varies from100 MN/m to 500 MN/m, with the bending stiffness the lowest with a 85 µmwide piezo element and the shear stiffness the lowest with a 170 µm wide piezoelement. For a 270 µm wide channel the foil stiffness varies from 40 MN/m to150 MN/m.

The stiffness of the piezo element and the foil increases with the width of thepiezo element. For a large displacement the stiffness of the foil must be low andthe stiffness of the piezo element must be high. This means that there will be anoptimum in piezo width for the efficiency as shown in figure 2.5b. The calculatedvolume displacement in a 10 mm long channel is shown as function of piezo elementwidth for a double layer PZT element. For a 220 µm wide channel the optimumpiezo element width is about 90 µm and for a 270 µm wide channel about 150 µm.The efficiency is not the only criterion. The influence on neighboring channels isanother important design criterion. The will be discussed in the next subsection.

2.2. LOCAL CROSS-TALK 27

(a)

0.3

0.35

0.4

0.45

0.5

0.55

0.6

0.65

20 70 120 170 220 270

Piezo width [um]

Dis

pla

ce

me

nt

[pl/

V]

220 channel

270 channel

(b)

Figure 2.5: (a) Drawing of a single piezo element supported by a substrate andconnected via a foil to an ink channel. (b) Calculated volume displacement in a220 µm and a 270 µm wide channel, covered with a 25 µm tantalum foil. Thechannel length is 10 mm. The double-layer piezo element height is 500 µm. Theresults of the Ansys calculations show the optimum piezo element width.

2.2 Local cross-talk

2.2.1 Electrical cross-talk

The use of a passive support reduces the effective piezoelectric constant in thebump mode actuator. A high aspect ratio between the height of the piezo elementsand the other dimensions reduces this loss. Another way to reduce the loss ineffective piezoelectricity is to use a substrate of the same piezoelectric material.The external electrodes are the ground electrodes to prevent electrical effects inthe other parts of the printhead. The voltage is applied to the inner electrodeon the interface between the two piezo layers, figure 2.6. The strain from the d13

mode is the same in both piezo layers so no mechanical stresses are generated inthe xz-plane. There will be no loss in effective piezoelectricity.

The calculated distribution of the electric field and the resulting deformationare shown in figure 2.6. A voltage of 100 V is applied on the inner electrode ofthe piezo element in the middle. All outer electrodes and the inner electrodesof the other piezo element are kept at 0 V . 100 V on one element of PZT59material results in a contraction of that piezo element in the y-direction of 54 nm.The height of the piezo elements is 500 µm, diced to get distinct elements, on a1000 µm piezo layer, which acts as the substrate.

The electric field is not restricted to one element. As a consequence also thesubstrate and the neighboring piezo elements will deform because of the inversepiezoelectric effect and this results in a large cross-talk effect. The substrateand the neighboring elements are lifted 10 nm in the y-direction, opposite to

28 CHAPTER 2. STRUCTURE DYNAMICS

(a) V (b) uy

Figure 2.6: (a) Calculated electric potential in the xy-plane of an actuator withpiezo material as substrate and 75 elements per inch (element width and spacingis 169 µm, which results in a pitch of 338 µm). (b) The resulting displacementin the y-direction uy. The electric voltage is applied on the electrode betweenthe central element and the substrate. The electric field is not restricted to oneelement and this results in a large cross-talk effect.

the actuation direction. The remaining displacement of the foil of the actuatedchannel is reduced to 44 nm. This loss in net actuation displacement and the largecross-talk effect of 23% on both neighboring elements are the reason that for thesubstrate a passive material is used.

The expansion of the electric field towards the neighboring elements via theferroelectric substrate is just one example of electrical cross-talk. Other electricalcross-talk effects from for example parasitic capacitances in the electronic drivingcircuit have to be avoided too.

2.2.2 Direct cross-talk

To prevent electrical cross-talk an actuator is used with 500 µm high PZT elementson a 1 mm AlOx substrate. The actuator is attached to a channel block withchannels at the same resolution as the piezo elements. With a resolution of 75channels per inch the reasonable channel width bch varies between 170 µm and270 µm. The stiffness of a 25 µm tantalum foil, which covers a 220 µm widechannel, is 150 MN/m for a 10 mm long channel. This foil has to be displacedover several tens of nanometers.

With the 169 µm wide piezo elements supported by a substrate, the reactionforce of the substrate will be guided to the non-actuated elements. The channelsthat are not actuated will deform too, as shown in figure 2.7a. for a 120 µm highchannel, made in brass. This results in a direct cross-talk effect.

The resulting deformation of the neighboring channels is opposite to the de-

2.2. LOCAL CROSS-TALK 29

formation which is necessary for firing a drop. In figure 2.7a the actuation resultsin a displacement of 27 nm of the foil of the actuated channel, but the foil inthe first neighboring channels lifted over 13 nm in the opposite direction, whichmeans a cross-talk effect of almost 50%. The drop speed will be lower when aneighboring channels is actuated simultaneously. This is shown in figure 2.7b fora 270 µm wide channel. The resulting measured drop-speed of channel zero isdepicted when in turn neighboring channels are actuated. When the neighboringchannel at the right of channel zero is actuated, the drop-speed of channel zerodrops from 5 to 2.2 m/s.

A thin substrate results in an even larger cross-talk effect on the first neigh-boring channels, but the cross-talk effect is now restricted to only a few channels.The total stiffness (bending and shear) of a 1 mm thick substrate with a lengthof 10 mm over a distance of eight elements (2.7 mm), as calculated with equa-tions 2.18, is about 150 MN/m. This is of the same order as the stiffness of thefoil, which covers the channel. The stiffness of a 0.5 mm substrate is the sameover a distance of 4 elements. So the range of the direct cross-talk effect can beestimated by the balance between the stiffness of the substrate and the stiffnessof the foil. The total cross-talk effect is about the same with a thin or a thicksubstrate. Actuating all channels simultaneously would results in a complete fallout of the drop formation.

(a)

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

-5 -4 -3 -2 -1 0 1 2 3 4 5Neighbouring channel nr.

Dro

p s

pe

ed

[m

/s]

1.0 mm substrate

0.5 mm substrate

(b)

Figure 2.7: (a) Front view of the channel structure and the calculated deformationof the channel structure. The color scale light→dark is 13 nm → −27 nm, thedeformation is magnified 2000 times in the plot of the deform ed structure. Thereaction force of the substrate is guided to the neighboring elements and thisresults in an opposite deformation of the neighboring channels. (b) The measuredresulting lowering of the drop speed for a 1 mm and a 0.5 mm thick substrate. Athin substrate results in a more localized cross-talk effect.

The reaction force of the substrate has to be guided to another part of theprinthead to suppress the direct cross-talk effect. A simple way is to use thechannel spacings. With 220 µm wide channels there is enough space for doubling

30 CHAPTER 2. STRUCTURE DYNAMICS

the piezo element resolution. The number of piezo elements is doubled by reducingthe piezo element width and spacing from 169 µm to 84.5 µm. One half of thepiezo elements is used as actuators and the other half as supports against thechannel walls. This creates a force loop as already shown in figure 1.9.

The stiffness of the force loop must be much higher than the stiffness of thechannel structure, which has to be deformed. With 220 µm wide channels made ingraphite, which has an E-modulus of 14 GPa, the stiffness of the channel spacingsbecomes comparable with the stiffness of the piezo elements. This results in astiffness of the force loop of 100 MN/m. The distance between the piezo elementsand the channel spacing is 68 µm. The stiffness of a 25 µm tantalum foil isof the same order as the stiffness of force loop. The resulting lowering in dropspeed when a neighboring channel is actuated simultaneously is shown in figure2.8a. The stiffness of a 50 µm silicon foil is 200 MN/m and the stiffness of a20 µm poly-imide foil, which has an E-modulus of only 9 GPa, is 10 MN/m. Theconsequences for the lowering in the drop speed are also shown in figure 2.8a.

With a 10 µm thin polyimide foil the stiffness of the foil in the actuationdirection becomes less than 1 MN/m and the direct cross-talk effect can even beeliminated. This is shown in figure 2.8b. The actuation of piezo element resultsin 40 nm displacement of the foil of the actuated channel. The displacements inthe neighboring channels are less than 1 nm.

2

2.5

3

3.5

4

4.5

5

5.5

6

-5 -4 -3 -2 -1 0 1 2 3 4 5Neighbouring channel nr.

Dro

p s

pe

ed

[m

/s]

20 µm PI

25 µm Ta

50 µm Si

(a) (b)

Figure 2.8: (a) The resulting lowering of the drop speed with a double piezo el-ement resolution for a 50 µm silicon foil, a 25 µm tantalum foil, and a 20 µmpoly-imide foil. (b) Front view of the channel structure and the calculated defor-mation, of 220 µm wide channels in graphite, covered with a 10 µm poly-imidefoil. The color scale corresponds to a displacement range of 0 nm to 60 nm. Thedeformations are in the plot magnified 2000x. The reaction force of the substrateis guided to the channel walls and this eliminates the direct cross-talk effect.

2.2. LOCAL CROSS-TALK 31

2.2.3 Pressure-induced cross-talk

The actuation of a channel results in pressure waves with an amplitude of 1-2 baras we will see in chapter 3. These pressure waves deform the structure, too. Infigure 2.9a, the deformation is shown of 220 µm wide channels in graphite, coveredwith a 25 µm tantalum foil. A positive pressure inside the actuated channel resultsin a deformation of all channels, which is called the pressure induced cross-talkeffect.

The deformation of the channels has two main components, an elongationand a bending component. The actuator is pushed away from the channels, anaction, which is counteracted by the piezo elements, which are connected to thechannel walls. The elongation stiffness in the y-direction of this force loop is about100 MN/m with 10 mm long channels. The elongation component of the channeldeformation results in an enlargement of all channels, thus in a lowering of thechannel pressure and the drop speed is lowered for all channels.

(a)

6.8

6.9

7

7.1

7.2

7.3

7.4

7.5

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6Neighbouring channel nr.

Dro

p s

pe

ed

[m

/s]

160 µm

120 µm

(b)

Figure 2.9: (a) Front view of the channel structure and the calculated deforma-tion, magnified 10000 times, of 220 µm wide channels in graphite covered with a25 µm tantalum foil. The pressure in the middle channel is 1 bar. The resultingdisplacement of the foil in the y-direction is about 2 nm/bar. (b) The measuredresulting lowering of the drop speed with a 10 µm poly-imide foil for a channelheight of 120 µm and 160 µm. The bending of a high channel walls in the firstneighboring channels can compensate for the elongation of the channel spacing.This results in an increase of the drop speed with 160 µm high channels.

The amount of elongation depends on the stiffness in the y-direction of thefoil between the piezo elements and the channel spacings. A 25 µm tantalum foilhas a stiffness comparable to the elongation stiffness of the piezo elements and thechannel spacings. The channel spacings and piezo elements will be deformed a lotas shown in figure 2.9a. With a 10 µm poly-imide foil, the stiffness of the foil ismuch lower. The pressure waves will deform mainly the foil of the channel itself.The resulting lowering of the drop speed is only 0.1− 0.2 m/s, as shown in figure

32 CHAPTER 2. STRUCTURE DYNAMICS

2.9b.

The deformation of the thin flexible poly-imide foil is large and this results ina very compliant channel cross-section. For the actuated channels the complianceof the channel has a large impact on the channel acoustics as we will see in chapter3. The efficiency will be reduced and the effective speed of sound in the ink willbe much lower.

For the pressure induced cross-talk effect the bending stiffness in the x-directionof the channel wall is important too. The bending stiffness in the x-direction ofthe piezo elements is negligible. For a channel spacing of 120x120 µm the bendingstiffness is about 70 MN/m. This bending component reduces the cross-sectionof the first neighboring channel and can compensate the effect of the elongationdeformation component as shown in figure 2.9b for a 160 µm high channel. Thebending component has a larger effect in the first neighboring channel than theelongation component and this results in an increase of the drop speed, when thefirst neighboring channel is actuated at the same time.

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

-10 -5 0 5 10Neighbouring channel nr.

Dro

p s

peed

[m

/s]

single

cumulative

(a)

2 5.84 4.52 7.26 7.11 4.57

5 5.38 3.86 6.6 6.6 3.91

6 5.79 4.47 7.21 7.06 4.57

7 5.94 4.57 7.32 7.16 4.62