Newcom intelligence center oktober 2013 #newcomresearch - Inventarisatie Keuzeproces Energiemarkt

Ministerie van Economische Zaken Directie Energiemarkt T.a.v. - … · Ministerie van Economische...

Transcript of Ministerie van Economische Zaken Directie Energiemarkt T.a.v. - … · Ministerie van Economische...

-

Ministerie van Economische Zaken

Directoraat-generaal Energie, Telecom & Mededinging

Directie Energiemarkt

T.a.v.

Postbus 20401

2500 EK DEN HAAG

Cc Staatstoezicht op de Mijnen

T.a.v.

Postbus 24037

2490 AA DEN HAAG

Nedmag Industries

Mining & Manufacturing B.V.

BiUitonweg 1

9641 KZ Veendam

RO. Box 241

9640 AE Veendam

The Netherlands

T +31 598 651 911

F +31 598 551 226

E infoiinedmag.nl

I www.nedmag.com

Uw kenmerk

Telefoon

Betreft

Datum

DGETM-EM/14135221

(0598)-651260

Winningsplan Nedmag Industries

Veendam, 30 oktober 2015

Geachte

OJ

OJ

OJ

O a

Conform artikel 6 van het instemmingsbesluit (3 oktober 2014) van het Ministerie van

Economische Zaken aangaande het gewijzigde winningsplan, dient Nedmag een nadere

studie uit te voeren naar het verschil tussen het squeezevolume uit de materiaalbalans en

het volume uit de inversie, en de invloed daarvan op de onzekerheid in de

bodemdalingsvoorspelling.

In mijn brief van 23 juni 2015 heb ik u gevraagd om het onderzoek later te mogen indienen.

In het bijgevoegd rapport is een gedetailleerde studie weergegeven naar de invloeden van

de kritische parameters op de massabalans van Nedmag's zoutwinning. Naast het gevraagde

squeezevolume is ook het ondergrondse pekelvolume berekend.

Bij de opzet van de studie is van het bedrijf NG-Consulting uit

Sondershausen geconsulteerd over de wijze waarop de diverse oplosprocessen verlopen. De

heeft namelijk een uitgebreide expertise op het gebied van

"zoutchemie".

Trade register Groningen 02331543 VAT HD. IML 0049270B4B01

NedMag is ISO 9001. ISO 14001 150 22000 and GMP+ certified

-

O

Het bijgevoegde rapport geeft het volgende aan:

• Het huidige BDS (Brine Data System) model geeft een onvolledige berekening van

het squeeze- en ondergronds volume omdat de geproduceerde magnesiumchloride

pekel artificieel wordt gesplitst in de componenten carnallitische en bischofitische

pekel, en water. Daarnaast is het model opgezet voor berekeningen per individuele

caverne waardoor het squeezevolume onjuist berekend wordt wanneer individuele

cavernes met elkaar verbonden raken.

• Om een separate controle op het BDS model te kunnen uitvoeren is een nieuw

massabalansmodel (MB) opgezet.

• In dit massabalansmodel zijn alle productiedata vanaf 1972 op maandbasis ingevoerd

en zijn onjuiste loogfasen, die in het verleden in BDS zijn gehanteerd, gecorrigeerd

(MB revised).

• acht het zeer waarschijnlijk dat in loogfase 3 het

bischofietvoorkomen direct oplost in plaats indirect. De indirecte oplosroute zou

inhouden dat eerst carnallitische pekel wordt gevormd welke zich daarna omzet tot

bischofitische pekel. Gezien de zeer hoge oplossnelheid van bischofiet zout is een

indirecte oplosroute ergonwaarschijnlijk. De massabalans is hiervoor gecorrigeerd

(MB revised LF 3->2).

• Het model is tot slot aangepast om het effect van clustering van cavernes te bepalen

(MB cluster). Op het moment dat cavernes verbonden raken is er vanuit gegaan dat

het zeer oplosbare bischofiet rond het injectiepunt reeds is opgelost. Door de

verdere loging wordt de gevormde carnallitische pekel onderweg naar de cq in de

producerende caverne omgezet in bischofitische pekel. Dit is dan de indirecte

oplosroute.

Dit laatste model (MB cluster) geeft de beste benadering weer van de ondergrondse

oplosprocessen en de hierbij ontstane squeezevolumes van de Nedmag

magnesiumchloridewinning.

De belangrijkste conclusies uit dit rapport zijn dat:

• Het berekende squeezevolume 3 % groter is in vergelijking met het huidige BDS

model.

• Het ondergrondse pekelvolume met 11 % is toegenomen in vergelijking met het

huidige BDS model.

Nedmag heeft gevraagd om bijgevoegd rapport inclusief de

massabalansberekeningen te toetsen. Nedmag heeft, op dit moment, nog geen bevestiging

gekregen dat hij deze opdracht wil uitvoeren.

-

De invloed van het toegenomen squeeze- en ondergronds volume op de huidige en

toekomstige bodemdaling is beperkt gezien de bovengenoemde beperkte afwijkingen ten

opzichte van de huidige waarden in BDS. Voordat wij hieraan verdere conclusies verbinden

stellen wij voor om eerst de onderstaande lopende acties af te wachten zodat er een totaal

beeld ontstaat van alle huidige en toekomstige effecten van onze zoutwinning. Eveneens

vinden wij het belangrijk om een reactie van Staatstoezicht op de Mijnen te krijgen op dit

rapport.

Lopende acties

Aangezien het squeezevolume bepalend is voor de optredende bodemdaling hebben wij het

volume uit de ontstane bodemdalingskom over de periode eind 2003 t/m medio 2010 laten

bepalen met behulp van de INSAR techniek. Deze pilot study is ingediend bij het

Staatstoezicht op de Mijnen (21 augustus 2015) en op 20 oktober 2015 besproken met

Als vervolg op deze pilot study wil Nedmag de

bodemdaling over de gehele squeezeperiode 1993 t/m 2015 door SkyGeo laten bepalen.

Zoals met het Staatstoezicht op de Mijnen is besproken op 20 oktober is het van belang dat

de INSAR meetdata goed worden geïnterpreteerd en verwerkt. Hiervoor is nog een nadere

bespreking nodig tussen het Staatstoezicht op de Mijnen, Nedmag en SkyGeo. Indien alle

partijen het eens zijn over een goede verwerking en interpretatie van de INSAR meetdata zal

Nedmag deze studie laten uitvoeren. Het voordeel van deze INSAR analyse is dat ook het

komvolume berekend kan worden en vergeleken kan worden met de resultaten uit het

bijgevoegde rapport voor de periode 1993 t/m 2015. Een belangrijk punt van dit onderzoek

is de wijze waarop de correctie wordt gemaakt voor de bodemdaling door gaswinning welke

rond de zoutwinning Nedmag optreedt.

Staatstoezicht op de Mijnen laat de door Nedmag uitgevoerde abandonneringsstudie (onze

brief van 2 april 2015) reviewen. De verwachting is dat deze review in het voorjaar van 2016

gereed is. Deze abandonneringsstudie en de review zullen antwoord geven op de vraag welk

effect het ondergrondse pekelvolume heeft op de toekomstige bodemdaling na

abandonnering van de cavernes.

Samenvattend

In het tweede kwartaal van 2016 zal zowel de review van Staatstoezicht op de Mijnen als

ook de bovenstaande acties zijn afgerond. Met de uitkomst hiervan en de genoemde

conclusies uit de massabalans studies kunnen effecten van de huidige en toekomstige

zoutwinning bepaald worden. Deze resultaten zullen met het Staatstoezicht op de mijnen

worden besproken.

Hopende u hiermee voldoende te hebben geïnformeerd.

Hoogachtend,

NEDMAG INDUSTRIES

turing B.V.

Algemeen directeur

-

OUIAIQBN

-

Mass balance study of the Nedmag caverns

Modelling of magnesium salt dissolution and calculated squeeze volumes

NEDMAG

Author

Version

Date

1

30-10-2015

-

ni NEDMAG Mass balance of the Nedmag caverns v1

1. INTRODUCTION

On 26 March 2013 NEDMAG Industries Mining & Manufacturing B.V. in Veendam

(Nedmag) has requested the Minister of Economic Affairs for approval of a modified

production plan for potassium and magnesium salts. The plan announces a study into

best practices to abandon the caverns after final production stop ^\

On 3 October 2014 the Minister of Economic Affairs has approved of the modified plan

under certain conditions, among others article 6, stating that Nedmag will investigate the

discrepancy between the squeeze volume calculated on basis of a mass balance and the

volume derived from inversion of the soil subsidence and the influence on soil subsidence

predictions.

After pre-feasibility study and discussions with magnesium salt solution mining expert

a study proposal was presented to State Supervision of Mines and

TNO-Utrecht on 25 March 2015. The proposal was to do a history match of the Nedmag

brine field from 1972 with the aim to improve the accuracy of the calculated squeeze

volume. The study includes the following:

A mass balance model will be developed and expanded with the salt lithology to

quantify the amount of inert material and bulking effects.

- The existing BDS model will be scrutinized with respect used leaching phase and

other assumptions.

The effect of direct versus indirect dissolution of bischofite will be studied.

- The effects of connectivity of caverns will be incorporated.

This note describes the results of these investigations followed by conclusions regarding

the accuracy of calculated squeeze volumes.

Page 2

-

ni NEDMAG

Mass balance of the Nedmag cavems v1

2. THE NEDMAG SOLUTION MINING PROCESS AND ITS MODELLING

2.1 The Nedmag solut ion mining process

Nedmag produces magnesium brine by solution mining of magnesium at a depth of

1300 to 1800 m in the Zechstein II formation. The first four caverns VE-1 to 4 have

been developed from WHC-1, the caverns TR-1 to 9 were developed from WHC-2.

Process water or dilute brine is injected into the bischofite/carnallite containing ZE-I

l b layer. In the early years also salt was produced from the carnallite containing ZE-I

2b/3b layer.

' I l l

1 n i l j r /

MOB n K . i j l

D lOOOm I r i n

I « M B

_ .

IMOm

Z3 =J I I I

Vtfm II

1

VWH),,,

1

/..».!

Kkt

Metfcl

I I . l l l l I

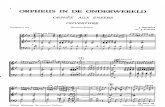

Figure 1: Typical salt lithology of a Nedmag cavern

In the development of the caverns the following 6 leaching phases are distinguished:

Page 3

-

ni NEDMAG Mass balance of the Nedmag cavems v1

Cluster operation

Figure 2: Leaching phases of Nedmag caverns

In leaching phase 1 water or dilute brine is directly injected into the carnallite layer

underlying the bischofite salt. In this phase a sump is prepared and a carnallitic (KCI-

rich) brine is produced while sylvite precipitates. To prevent uncontrolled upward

leaching the top of the cavern is protected with an oil blanket.

The leaching paths can be represented below by line OPC in the thermodynamic

phase diagram (Figure 3). From O to P carnallite dissolves congruently, thereafter

from P to C more carnallite dissolves while sylvite precipitates.

Page 4

-

ni NEDMAG Mass balance of the Nedmag cavems v1

Figure 3: The MgCla/KCI phase diagram

After the desired sump volume is obtained the oil blanket and/or the injection level

are raised and the upper lying bischofite salt is contacted and leaching phase 2 sets in.

In leaching phase 2 the injection fluid contacts the bischofite salt and bischofitic brine

is directly formed along direct path OQB. In addition the carnallitic brine present in

the sump is displaced by more dense bischofitic brine and also enriches to bischofitic

brine.

After further upward displacement of the oil blanket and/or injection point in leaching

phase 3 the injection fluid first contacts the overlying carnallite salt and carnallitic

brine is formed and sylvite precipitates. The carnallitic brine "floats" on top of the

denser bischofitic brine. Since the volume of the formed carnallitic brine exceeds the

volume of the formed cavity the excess carnallitic brine is pushed into the bischofitic

area and further enriches towards bischofitic brine. As a result secondary carnallite,

kieserite and halite precipitate. In leaching phase 3 the dissolution path OPCOB is

followed and bischofitic brine is formed indirectly. The specific volume effects of

indirect formation of bischofitic brine are significantly smaller than for direct

formation as described in leaching phase 2.

One major assumption in the BDS model (section 2.2.1) in leaching phase 3 is that

insoluble tailings fall to the bottom of the cavern as well as part of the formed sylvite.

Page 5

-

ni NEDMAG Mass balance of the Nedmag cavems v1

As a resuit a larger cavity is created in the overlying carnallite giving less carnallitic

brine overflows to the lb bischofite section.

AV p r o d u c t l o n A

fall

AV in ject ion

Sylvite •

Inert Halite, Kieserite

Precipitates Seconday carnallite, halite, kieserite 9

Figure 4: Schematic fall-out of inert material and sylvite in leaching phase 3

In leaching phase 4 the injection point and oil blanket are raised to the lower 2b

carnallite layer. The carnallitic brine formed moves through the borehole to the top of

the lb section and transforms to bischofitic brine as in leaching phase 3 with indirect

formation of bischofitic brine.

In leaching phase 5 the injection point and oil blanket are raised to the upper 3b

carnallite layer and the production is raised to the lower 2b carnallite layer. In this

phase carnallitic brine is produced according to the same dissolution path as in

leaching phase 1.

Until the year 1993 the caverns were operated close to litho-static pressures with a

"room and pillar" solution mining approach. After successful demonstration of the

squeeze concept between 1993 and 1995 the TR wells, except TR-9, are producing

under 60 - 80 bar sub-lithostatic conditions

Soon after start-up in October 1982 a pressure connection was found to be between

TR-1 and TR-2. In the period from November 1996 onwards more TR caverns gradually

interconnected into one large cluster. In September 2009 VE-4 also connected to the

TR cluster. During the last VE-3 workover in November 2006 a connection with VE-2

was noticed.

Currently the Nedmag caverns consist of two clusters and two separate caverns:

Page 6

-

ni NEDMAG Mass balance of the Nedmag cavems v1

- The TR cluster consisting of TR-1/2/3/4/5/6/7/8 & VE-4.

- The VE cluster consisting of VE-2 & VE-3.

VE-1 developed in the 2b/3b section only.

- TR-9 in development since May 2012.

In the cluster operation which is currently applied to the TR cluster water or brine

typically are injected into the shallower l b sections, the carnallitic brine formed

migrates through connections within the l b bischofite layer to a deeper l b cavern.

During its migration towards the production point the carnallitic brine contacts

bischofite salt and enriches into a bischofitic brine.

2.2 Nedmag mass balance models

2.2.1 The BDS model

The Brine Data System (BDS) model was developed in 1995 and is in use to

monitor the development of the various volumes due to the Nedmag solution

mining process since 1972. It is primarily based on a mass balance with inputs of

measured: injection and production brine volumes and concentrations per cavern.

At a given leaching phase BDS calculates the quantities of dissolved salt, and

precipitate as well as the squeeze volume and the total underground brine

volume. The squeeze volume is defined as the volume of brine coming to surface

in excess to what could be expected from the injection fluid without cavern

convergence.

One characteristic BDS feature is that it assumes that all brine compositions can

be represented by a mixture of the three components: saturated bischofitic brine,

saturated carnallitic brine and water. In addition it is assumed that the caverns are

filled by a two phase system of saturated carnallitic brine floating on top of a

saturated bischofitic brine with compositions independent on depth. In case of the

production under-saturated brine it is assumed that part of the injection water

shortcuts directly to the brine production flow.

The BDS calculations are set-up for a single cavern operation. The interconnection

of caverns creates a mismatch between injection fluid and brine production per

cavern. Therefor realistic squeeze volumes and underground brine volume can

only be obtained by summating the values of the individual caverns.

The accuracy of the BDS model calculations for the total underground brine

volume has been estimated by Renier His main findings were that the selected

leaching phases were not always correct and that the choice for indirect or direct

formation of bischofitic brine has a significant effect on the volumes calculated.

Renier recommended to study the following:

Page 7

-

ni NEDMAG

Mass balance of the Nedmag cavems v1

o

o

The effect of depth (temperature) on saturated brine compositions and

densities. A variation analysis for the total height difference between the

caverns showed that this introduces an inaccuracy of 4 % of the calculated

squeeze volume. This result has been reported by Nedmag in 2012

The effect of pressure, depth and shape on cavern convergence. This is

part of the Nedmag Abandonment study .

The effect of brine exchange between interconnected caverns, which is

part of this study.

2.2.2 The mass balance model

Since BDS relies on the physically incorrect assumption that all brine compositions

can be split into: saturated carnallitic and bischofitic brine and water a more exact

mass balance model was prepared. In this model it is assumed that the undiluted

brine composition is representative for the entire cavern content. This avoids the

use of a standard bischofitic brine composition. However the use of standard

saturated carnallitic brine remains necessary in the case of indirect dissolution in

leaching phases 3 and 4. The model equations are given in Appendix I and have

been described previously

3. MODEL CALCULATIONS

3.1 BDS and mass balance model with the same input data and assumptions

Using the same monthly based input data-set for the period of 1972 till June 2015 the

volume calculations were repeated with the mass balance model. All leaching phases

as well as fall out of tailings/sylvite in leaching phase 3 were kept identical to the ones

used in the original BDS calculations. The summated volumes for the two single

caverns and the two clusters are reported below.

Cavern/Cluster Squeeze volume, m^ Total underground brine volume, m^

BDS MB BDS MB

VE-1 21,646 31,115 197,531 165,637

TR-9 56,426 138,493 192,560 132,637

VE-2/3 219,954 424,544 684,396 665,202

TR-1/8, VE-4 5,696,586 6,389,158 4,747,297 4,317,038

Total 5,994,612 6,983,311 5,821,784 5,280,514

It is shown that the improved mass balance produces 16 % more squeeze volume and

9 % less total underground brine volume than BDS. This is besides imperfections in

the BDS mass balance, which is not closed because of brine splitting, mainly due to

the large negative squeeze contributions that arise in BDS when in case of injection

into a cavern without brine production.

Page 8

-

ni NEDMAG

Mass balance of the Nedmag cavems v1

3.2 Mass balance model with revised leaching phases

The designation of leaching phases in the BDS data was checked against the actual

injection depth as reported in historical monthly reports in relation to the salt

lithology per cavern. It was found that there were a number of months in which was

injected into the lb bischofite (leaching phase 2) instead of the overlying lb carnallite

(leaching phase 3) as used in BDS. This means that there has been more direct

production of bischofitic brine than accounted for in the original BDS calculation. After

revision of the leaching phases for this (MB revised) the following volumes were

calculated:

Cavern/Cluster Squeeze volume, m^ Total underground brine volume, m^ Cavern/Cluster

MB original MB revised MB original MB revised

VE-1 31,115 31,115 165,637 165,637

TR-9 138,493 36,361 132,637 327,345

VE-2/3 424,544 226,705 665,202 986,054

TR-1/8, VE-4 6,389,158 5,914,734 4,317,038 5,005,945

Total 6,983,311 6,208,914 5,280,514 6,484,981

Because in direct dissolution mode of bischofite more brine is formed than by indirect

dissolution the non-squeeze contribution to the production flow is increased. As a

result the squeeze contribution reduces by 0.78 Mm^ and the total underground brine

volume increases by 1.20 Mm^.

3.3 Mass balance model with revised leaching phases and direct dissolution from lb

only

In the view of consultant Norbert Grüschow complete indirect dissolution of

bischofite in leaching phase 3 for a single cavern is highly unlikely. This is mainly due

to the mixed nature of the overlying bischofite and carnallite salt and the brine

convections flows. To quantify the effect of direct bischofite dissolution the

calculations with revised leaching phases were repeated with all leaching phases 3

replaced by leaching phase 2.

Cavern/Cluster Squeeze volume, m^ Total underground brine volume, m^ Cavern/Cluster

MB revised MB revised LF 3 - > 2 MB revised MB revised LF 3 - > 2

VE-1 31,115 31,115 165,637 165,637

TR-9 36,361 36,361 327,345 327,345

VE-2/3 226,705 197,875 986,054 1,021,098

TR-1/8, VE-4 5,914,734 5,470,444 5,005,945 5,802,750

Total 6,208,914 5,735,795 6,484,981 7,316,829

Page 9

-

\i NEDMAG

Mass balance of the Nedmag cavems v1

In the extreme situation of direct bischofite dissolution only when injected and

produced from the lb section the squeeze volume drops by 0.47 Mm^ and the total

underground brine volume increases by 0.83 Mm^.

3.4 Mass balance model with revised leaching phases and clustering

The general conception is that inter-cavern connections arise in the continuous more

soluble bischofite layers. Caverns are assumed to be connected when their pressures

start to correlate. However pressure communication gives no clue about volumetric

exchange between caverns. This can only be deduced by comparing volumetric

balances of injection and production per cavern. Unfortunately the balances are also

affected by squeeze flows which are not known for the individual caverns. However in

practice the connections in the TR cluster are actively used with in general injection

into the more shallow lb caverns and production from the deepest l b caverns, but

the actual flow paths are uncertain.

The mass balance model was used to determine the effect of a cluster operation on

the calculated volumes. It was assumed that up to the point of connection caverns

can be treated as single caverns using revised leaching phases and the assumption

that there is only direct dissolution when injected and produced from the lb section.

From the onset of connection the connected caverns are represented by one big

cavern with mixed injection and mixed production flows.

In the cavern development over time the following 9 clusters can be defined:

Figure 5: Time development of connections between the Nedmag caverns

For the connected cluster it is assumed that all bischofite in the injection zone already

has been consumed in the pre-connection period and that additional injection results

in the formation of carnallitic brine. The carnallitic brine migrates through the cluster

and somewhere contacts bischofite to form bischofitic brine. This type of leaching can

be described by leaching phase 4.

Page 10

-

ni NEDMAG

Mass balance of the Nedmag cavems v1

Cavern/cluster Squeeze volume m^ Total underground brine volume, m' Cavern/cluster

MB revised LF 3 - > 2 Cluster MB revised LF 3 --> 2 Cluster

VE-1 31,115 31,115 165,637 165,637

TR-9 36,361 36,361 327,345 327,345

VE 2/3- 197,875 218,891 1,021,098 449,516

TR 1-8/VE-4 5,470,444 1,621,421 5,802,750 1,828,331

Cluster 1-9 4,270,717 3,703,218

Totaal 5,735,795 6,178,504 7,316,829 6,474,046

As a resuit of an increased indirect dissolution contribution in the cluster approach

the squeeze volume increase by I

total underground brine volume.

the squeeze volume increase by 0.44 Mm^ with an associated decrease of 0.84 Mm^ in

4. DISCUSSION

In 2011 an inversion study was carried out by TNO '̂ on the subsidence measurements

for the period of 1993 till 2010. From this study a mismatch of about 15 % was found

between the BDS calculated squeeze volume and the squeeze volume as determined

by inversion. According to TNO this discrepancy can be due to either an error in the

geomechanical model or a positive structural error in the determination of the total

squeeze volume from production data.

In the table below the calculated squeeze and underground brine volumes are

summarised.

Case Squeeze Underground

volume brine volume

3

m m^

BDS 5,994,612 5,821,784

MB 6,983,311 5,280,514

MB revised LF's 6,208,914 6,484,981

MB revised, LF 3 - > 2 5,735,795 7,316,829

MB cluster approach 6,178,504 6,474,046

Under the assumption of a constant factor of 85 % for the whole production period of

1972 till June 2015 an inversion volume of 5.09 Mm^ is expected on basis of the BDS

squeeze volume. In none of the above calculations with the mass balance model such

a low value is approximated even with direct bischofite dissolution giving a minimum

value of 5.74 Mm^.

Page 11

-

I i ; NEDMAG Mass balance of the Nedmag cavems v1

Since the cluster approach gives a more realistic representation of the multiple cavern

operation a squeeze volume of 6.18 Mm^ is considered to the more likely value with

an associated total underground brine volume of 6.47 Mm^.

5. CONCLUSIONS

Mass balance calculations for the Nedmag caverns incorporating revised leaching

phases and the effects of cavern connections gives a most likely squeeze volume of

6.18 Mm^ and a total underground brine volume of 6.47 Mm^ for the period 1972 till

June 2015. This squeeze volume is only 3 % higher than the 5.99 Mm^ found with the

current BDS model. Since this disagreement is far less than the accuracy of

subsidence measurements a correction on soil subsidence predictions is not

reasonable.

However a squeeze volume of 6.18 Mm^ is 21 % higher than the expected inversion

squeeze volume of 5.09 Mm^ for the same period. This discrepancy cannot be

explained by the physical solution chemistry and the followed leaching paths of

dissolving carnallite and bischofite but must be due to inaccuracies in the subsidence

measurements or geomechanical effects that prevent part of the underground

volume reduction to come to surface.

REFERENCES

1. Winningsplan kalium- en magnesiumzoutwinning 2013, Nedmag Industries Mining &

Manufacturing B.V., Winningsvergunning Veendam, 26 maart 2013.

2. Gedrag van Magnesiumzouten tijdens de Winning in de Concessie van Nedmag te

Veendam en een daaruit volgende volumebepaling van het Complex van Cavernes van

WHC-2. MSc Thesis TU Delft, 1 september 2006.

3. Het ondergronds pekelvolume en onzekerheidsanalyse hiervan bij de Nedmag

zoutwinning. Interne Nedmag notitie, Veendam, 25 april 2012.

4. Abandonment study Nedmag caverns. Cavern squeeze modelling and geophysical

analysis of brine permeation and containment. Well Engineering Partners B.V.,

, Hoogeveen 31-3-2015.

5. Nauwkeurigheidsanalyse BDS modelberekeningen. Interne Nedmag Notitie, ,

Veendam, januari 2013.

6. Nedmag Veendam inversie bodemdaling TNO-rapport (060-UT-2011-00687).

, Utrecht, 8 april 2011.

Page 12

-

ni N E D M A G Mass balance of the Nedmag cavems vi

APPENDIX I

Leaching phase 1

The development of a cavern starts with the creation of an undercut in the lower section of

the l b carnallite salt. Dissolution of the overlying bischofite salt is prevented by installing an

oil blanket. In phase 1 water or diluted brine (Mi) is injected and the salts: carnallite (C),

halite (H), kieserite (K) go into solution forming brine (M). Due to the incongruent

dissolution behaviour of carnallite the sylvite {Si) precipitates simultaneously. Typically a

carnallitic brine is formed typically wi th: 27 % MgCb, 5.2 % KCl, 2 % NaCl and 1.3 % MgSOa

and a density of 1.33 t /m^ (PCB) at saturation.

For phase 1 the following mass balance equations are valid:

Total mass M i + C + H + K = M + S| (1)

Magnesium chloride m i M i + mcC = mM (2)

Potassium chloride SiMi + ScC= sM + Sj (3)

Sodium chloride balance h i M i + H = hM (4)

Kieserite balance k i M i + kkK = kM (5)

The symbols: m, s, h and k represent the dissolved mass concentrations of MgCb, KCl, NaCl

and MgS04 in the injection fluid (subscript 1) or of the brine formed. The symbols mc, Sc and

kk represent the MgCIa content in carnallite, the KCl content in carnallite and the MgS04

content in kieserite respectively.

Combination of eqn's (2), (3), (4) and (5) and substitution in eqn. (1) yields:

M = M l (1-mi/mc - h i - k M / ( I - m/mc - h - k/k^) (6)

Insertion of known mass of injected water or brine and measured concentrations of injection

and product brine allows the calculation of the mass of brine (M) formed. Insertion of M in

eqn's (2) till (5) quantifies the mass of the dissolved salts: C, H, K and precipitate SJ..

The net volume of the carnallite cavity for litho-static pressure conditions, i.e. in the absence

of cavern convergence, is calculated using the respective salt densities through:

AV ccav = C/pc + H/PH + K/PK - Si/psy (7)

Finally the volume of brine produced under litho-static conditions is calculated through:

AVprod = M / PCB - AVc,cav (8)

Page 13

-

\i NEDMAG

Mass balance of the Nedmag caverns vl

Carnallite Bischofite Kieserite Halite Sylvite

p, t /m3 1.60 1.60 2.57 2.14 1.99

MgCl2,% 34.28 46.86

KCl, % 26.84

NaCl, %

MgS04, % 86.98

Leaching phase 2

After an undercut has been developed the oil blanket is withdrawn allowing contact of the

injected water or brine with bischofite salt. As a result bischofite dissolves (B) from the l b

section and a bischofitic brine is produced typically containing: 36.8 % MgCb, 0.32 % KCl, 0.48

% NaCl and 0.45 % MgS04 and a density of 1.38 t /m^ (PBB) at saturation.

For this phase the following mass balance equations are valid:

Total mass

Magnesium chloride

Potassium chloride

Sodium chloride

Kieserite

M i + C + B + H + K = M

m i M i + mcC + mBB= mM

SiMi + ScC= sM

h iMi+ H = hM

k iM i + kkK = kM

(9)

(10)

(11)

(12)

(13)

The symbols: m, s, h and k represent the mass concentrations of MgCl2, KCl, NaCl and MgS04

in the injection fluid (subscript 1) or in the brine formed. The symbol mg represent the MgCb

content of bischofite salt.

Combination of eqn's (2), (3), (4) and (5) and substitution in eqn. (1) yields:

M = M l (1- Si/sc*(l-mc/mB)- mi/mg - h i - ki/kk) / ( 1 - s/sc*(l-mc/mB)m/mB - h - k/kk) (14)

Insertion of the known mass of injected water or brine and measured concentrations of

injection and product brine allows the calculation of the mass of brine (M) formed. Insertion

of M in eqn's (10) till (13) allows the calculation of mass of the dissolves salts: B, C, H, K.

The net volume of the cavity without for litho-static pressure condition convergence, is

calculated using the respective salt densities through:

AV B.cav = C/pc + B/PB + H/PH + K/PK (15)

Finally the volume of brine produced under litho-static conditions is calculated through:

AVprod = M/PBB - AVB.CSV (16)

Page 14

-

ni NEDMAG Mass balance of the Nedmag caverns vi

Leaching phases 3 and 4

After the bischofitic cavern had reached its optimum diameter the injection point was raised

either into the l b carnallite layer above the bischofite salt (phase 3) or the 2b/3b carnallite

layer (phase 4). As a result the injected water or brine initially forms a carnallitic brine in a

carnallite cavity. The carnallite dissolution process is identical to phase 1 described by eqn's:

(1) to (7). The part of the carnallitic brine that doesn't fit into the carnallitic cavity overflows

to the underlying l b bischofite cavity according to:

AVoverf low = M / pCB " A V c ,( (17)

In the bischofite cavity the carnallitic brine (M i = AVoverfiow * PCB) dissolves bischofite salt and

a bischofitic brine is produced. As a result of the increased MgCb concentration part of the

carnallite (C|), kieserite (K|) and halite (H|) precipitate. The effects of the carnallitic brine

transformation can be described by:

Total mass balance:

Magnesium chloride balance:

Potassium chloride balance

Sodium chloride balance

Kieserite balance

M i + B = M + Ci + Ki + H i (18)

m i M i + mBB= mM + mcCi (19)

SiMi = sM + ScCi (20)

h i M i = h M + H i (21)

k iM i = kM + kkKi (22)

After some manipulation of eqn's (19), (20), (21) and (22) followed by substitution in eqn.

(18) gives:

M = M l (1- Si/sc*{l-mc/mB)- mi/mg - h i - k M / ( I - s/sc*(l-mc/mB)m/mB - h - k/kk) (23)

This equation is identical to equation (14).

Insertion of known mass of injected water or brine and measured concentrations of injection

brine allows the calculation of the mass of the overflow AVoverfiow The underlying assumption

is that a saturated carnallitic brine. Inserting the overflow as M i allows the calculation of the

bischofite brine formed (M). With eqn's (19) till (22) the mass of the dissolved B and

precipitates: C|, H i , K l is calculated.

Leaching phase 5

The volume effects resulting from production of carnallitic brine though injection and

production from the 2b/3b layer can be fully described are identical to the ones derived for

leaching phase 1.

Calculation of squeeze volume

The net volume of the cavity without for litho-static pressure condition convergence for the

l b bischofite section is calculated using the respective salt densities through:

AVB.cav = B/PB - Ci/pc - Hi/pH - Ki/pK

Page 15

-

ni N E D M A G Mass balance of the Nedmag cavems vi

The volume of brine produced that would be produced under litho-static conditions is

calculated through:

AVprod = M / PBB - AVB,cav

The squeeze volume is defined as the excess of brine coming to surface over the calculated

litho-static contribution:

AVsqueeze ~ AVjurface " AVprod

Page 16

-

f \ 1