dudeL KR Editeddd

-

Upload

melvinkuri -

Category

Documents

-

view

221 -

download

0

Transcript of dudeL KR Editeddd

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 1/27

SRM University | Chemical Engineering | December 13, 2013

A Brief Overview of the

Refining Process & ColumnInternals

IN-PLANT TRAINING REPORT

Bharat Petroleum Corporation Ltd., Kochi Refinery

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 2/27

1

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 3/27

2

CERTIFICATE

This is to certify that the report that the report titled “A Brief Overview of

the Refining Process & Column Internals is an authentic record of the in-

plant training course completed by AVINASH K.V., Reg. No. 1071110019,

of SRM University, Kattankulathur, during the period December 2 to

December 13, 2013 under my supervision and guidance.

Guide:

Date:

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 4/27

3

ACKNOWLEDGEMENT

Having been a part of a prestigious organization like BPCL-Kochi Refinery,

I would like to acknowledge all those who made my tenure here a great

learning experience.

First of all, I would express my gratitude to the management for letting me

be part of this organization. Next, I take this opportunity to express my

profound gratitude to Mrs. Rajeswari D, for her guidance and monitoring

throughout the training period. I also thank Mr. Jose Jacob for his guidance.

I am deeply indebted to the apprentice trainees, especially, George Naveen

and colleagues who lend their valuable time as well as thoughts in enabling

this endeavor to be very educative and enjoyable. I also extend my gratitude

to all the staff members of BPCL-KRL, Ambalamugal for their support.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 5/27

4

DECLARATION

I, hereby, declare that this project report entitled “A Brief Overview of the

Refining Process & Column Internals” has been prepared by me under the

supervision of Mrs. Rajeswari D., Engineer (P.E), BPCL-Kochi Refinery.

I also declare that this dissertation has not been submitted by me fully or

partly for the award of any degree, diploma, title or recognition earlier.

Avinash K.V.

Reg. No. 1071110019

Dept. of Chemical Engineering

SRM University, Kattankulathur

Tamil Nadu

Place:

Date:

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 6/27

5

CONTENTS

Chapter Title Page #

1 Certificate i

2 Acknowledgement ii

3 Declaration iii

4 Profile of BPCL-KR 5

5 Units and Products 8

6 CDU-2 Shutdown – A study of Column

Internals & Equipment

16

7 Conclusion 23

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 7/27

6

CHAPTER 1

Profile of BPCL – KR

Kochi Refinery, a unit of Bharat Petroleum Corporation Limited (BPCL), embarked on

its journey in 1966 with a capacity of 50,000 barrels per day. Formerly known as Cochin

Refineries Limited and later renamed as Kochi Refineries Limited, the refinery was

originally established as a joint venture in collaboration with Phillips Petroleum

Corporation, USA. Today it is a frontline entity as a unit of the Fortune 500 Company,

BPCL.

Kochi Refinery, located at Ambalmugal near the city of Kochi in Kerala, is one of the

two Refineries of BPCL, presently having a crude oil refining capacity of 9.5 Million

Metric Ton per Annum (MMTPA). The product portfolio of the 190,000 barrels per day

refinery today includes petrochemical feedstock and specialty products in addition to its

range of quality fuels.

Fuel products of this fuel based refinery includes Liquefied Petroleum Gas, Naphtha,

Motor Spirit, Kerosene, Aviation Turbine Fuel, High Speed Diesel, Fuel Oils and

Asphalt. Specialty products for the domestic markets include Benzene, Toluene,

Propylene, Special Boiling Point Spirit, Poly Isobutene and sulfur.

The refinery has implemented world class technology and systems for operations and

enterprise resource planning. It is an ISO 14001 Environmental Management Systems

(EMS) and ISO 9001:2000 Quality Management System (QMS) accredited company and

has also obtained the ISO 17025 (Testing Methods in Quality Control) certification from

NABL (National Accreditation Board for testing & Calibration of Laboratories). The

refinery has successfully implemented the Occupational Health and Safety Management

System (OHSAS) 18001:2007 in the year 2009.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 8/27

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 9/27

8

Kochi Refinery is situated in Kochi, the most happening city in Kerala that is rightly

called God’s own country. The refinery has a unique bond with its environment which is

evident in the green blanket so carefully nourished right around it. The refinery has been

blessed with a fine topography and the entire complex, spreading across over thousand

two hundred acres has been so constructed as to blend naturally with it. Upcoming

expansions and developments would also adhere to this philosophy of blending with

nature. The most recent addition to the refinery architecture is the rainwater harvesting

pond and eco-park that has been converted to a must-see spot with sprawling landscaped

lawns and thatched canopies for conferences and get-togethers. Year after year the

refinery has been bagging accolades for its commitment to the environment; for the all-

round care for the environment, the judicious storage, use and reuse of water, theefficiency in managing solid wastes and effluents and the care taken to keep the

atmosphere clean.

The recent achievement of 24 million accident free man-hours stands testimony to the

fact that the prime focus of Kochi Refinery is on safety in everything we do. From

training to retraining, and adhering to international standards in safety practices, both,

offsite and onsite, Kochi Refinery has taken it as a mission to make safe living and

working a natural mantra of its employees, contract workers, customers and the general

public. Several awareness programmes have been successfully conducted to this effect

with the results for all to see.

As a socially responsible corporate citizen, the community welfare initiatives of the

refinery concentrate on developing the weaker sections of society, particularly, the

scheduled castes and scheduled tribes and people below the poverty line in important

sectors like health, education, housing and women empowerment.

Thus, apart from maintaining its world class standards in operational excellence, the

singular objective of Kochi Refinery is to uphold the BPCL vision of energizing lives by

continued excellence in all round performance with new ideas, added vigor and sustained

commitment to its social, cultural, organizational and natural environment.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 10/27

9

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 11/27

10

CHAPTER 2

Units and Products

The different units in the refinery are considered a part of manufacturing department, and

are:

1. Crude Distillation Unit (CDU – 1)

2. Crude Distillation Unit (CDU – 2)

3. Fluidized Catalytic Cracking Unit (FCCU)

4. Diesel Hydro Desulphurization Unit (DHDS)

1. Crude Distil lation Uni t (CDU – 1)

The design of CDU-1 is a primary unit and mainly meant for preventing

LPG components which was going to fuel gas header along with the crude

column overhead gas. Other features include optimization of heat recovery

system, qualitative improvement of products from the crude atmospheric column

and increase in crude output.

The crude after desalting process is heated to a required temperature in the

heater and is fed to the prefractioner. The overhead product obtained is the

naphtha. It is fed to LPG recovery unit in naphtha stabilizer; light naphtha from

the crude prefractioner contains lighter components such as LPG and fuel gas.

This naphtha as such cannot be routed to store due to its high vapour pressure.

The naphtha is stabilized by separating out and recovering the LPG component in

the LPG recovery unit.

The preheated crude from the prefractioner column bottom is sent to crude

column after being heated in the crude preheat train in the crude change heater for

further distillation process. The distilled products are drawn from the different

sections of the columns depending upon their boiling range. Heavy naphtha, kero-

1, kero-2 and diesel are the side products. The remaining portion of the crude is

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 12/27

11

drawn from the column bottom and reduced crude oil (RCO) are routed to FCCU

block for further separation.

2. Crude Distil lation Uni t (CDU – 2)

The installed capacity of CDU-2 is MMTPA. The plant is designed to

process 362.20 TPH of BH crude with light ends at 2.2 wt.% or Arabian mix

crude. Crude from the storage is pumped through a feed preheat train and

preheated to 135 °C. Stripped water from the sour water strips unit is injected into

the crude and the mixed crude is sent to desalter for removing salts. A high

voltage electric field in the desalter brakes the emulsion and the brine water isseparated.

The desalted crude is pumped through another preheat exchanger and then

split into two streams for further preheating in the second and third chains of

preheat train. The preheat crude is finally heated in the charge furnace to 360°C

and introduced into the flash zone of the atmospheric column.

The atmospheric column overhead vapours are condensed and received in

an accumulator and over heat stream is sent to naphtha stabilizer. A small quality

of fuel gas is generated which is burned off in the crude heater.

Heavy Gas Oil (HGO), light gas oil (LGO), kerosene and heavy naphtha

are withdrawn as side streams and are stream stripped in stripper columns. Heavy

naphtha is cooled and routed to gas oil stream. Provision is also given to route

heavy naphtha along with stabilized naphtha. Kerosene after stream stripping is

cooled and routed to storage.

HGO, LGO streams are mixed after cooling and the gas oil streams is

further cooled and it is routed to storage and vacuum diesel from VDU joins gas

oil at battery limit. Provision is given to blend kerosene and LVGO also with gas

oil. Gas oil along with other blend streams goes to the diesel pool as combined

diesel stream.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 13/27

12

RCO from the crude column bottom is sent to VDU. Apart from top reflex

cooling and condensation of vapours at various stages of the column is achieved

by means of the pump around streams of kerosene, LGO and HGO. The heat

content of the pump around streams are mostly recovered in crude preheat trains.

LGO is used as heating medium for stabilizer reboiler.

3. F lu idized Catalytic Cracking Uni t (FCCU)

The FCCU was commissioned in 1985 with the design capacity of 1

MMTPA. Feed preparation unit (FPU) is a main unit in the FCCU block. The

purpose of the feed preparation unit is to make feed of required quality to be

proposed in FCCU. In this unit RCO is distilled under vacuum into four differentcuts namely vacuum diesel oil (VDO), Light vacuum gas oil (LVGO), heavy

vacuum gas oil (HVGO) and vacuum residence. The VDO cut is normally routed

to diesel pool. LVGO and HVGO combined having boiler range approximately

between 360°C and 555°C is the feed of FCCU

By maintaining the endpoint VGO below 550°C, the metal content like Ni,

Vanadium etc. and carbon residue are reduced to an acceptable level. The metals

if present in VGO are poisons to the FCC catalysts. FCCU converts VGO into

higher value products such as LPG, gasoline, and diesel by cracking of heavier

hydrocarbon molecules of VGO to lighter components. Silica-alumina catalyst in

powder form is used for promoting the cracking reactions. Reaction takes place at

higher temperature and at pressure about atmospheric pressure

During cracking, heavy hydrocarbon molecule of VGO are converted to

lower molecular weight components such as LPG, gasoline etc., coke is formed as

side product. The entire coke formed is deposited on the catalyst surface, using

exothermic reaction and regenerate the catalyst H2S

Present in the LPG is removed by absorbing di-ethanol amine in an absorption

column in the amine unit.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 14/27

13

4. Diesel H ydro Desulphur ization Unit (DHDS)

DHDS is designed to de-sulphurise the diesel blend stock and reduce the

sulphur content less than 0.05 wt. %. This is achieved by passing a pre heated

diesel steam along with hydrogen over two reactors in series containing beds of

Nickel-Molybdenum catalyst. Any unsaturated hydrogen in the feed stock also get

saturated which helps in improving the quality of diesel.

The sulphur recovery converts and separate H2S contained in the sour gas

and until and amine regeneration unit in the form of stripping units function is to

treat sour water generated from DHDS units.

List of Process, Flow Control & Equipment

1. Atmospheric Section

Feed and Crude Preheat Train I A/B

Desalter

Crude Preheat Train II A/B

Prefractionator

Crude Preheat Train III A/B

Atmospheric heater & Balancing Atmospheric heater

Fuel System for Atmospheric heaters

Combustion Air System

Atmospheric Distillation Column

Atmospheric Column Overhead Circuit

Heavy Naphtha Section

Kerosene & Circulating Reflux Section

Light Gas Oil & Circulating Reflux Section

Heavy Gas Oil & Circulating Reflux Section

Bottom Stripping Section

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 15/27

14

Heavy Naphtha Product Circuit

Kerosene Product Circuit (ATF/MTO)

LGO Product Circuit

HGO Product Circuit

Atmospheric Overhead Naphtha Caustic Wash

ATF Caustic Wash

2. Vacuum Section

Vacuum Heater

Air Preheating Circuit

Vacuum Column

Vacuum Column Overhead Circuit

Vacuum Diesel Circuit

LGO Circuit

HGO Circuit

Slop distillation

Vacuum residue circuit

Water System

Steam Generation System

Chemical Injection facility

Demulsifier Injection

PRODUCTS

The 150,000 barrels per day Kochi Refinery is a fuel based refinery producing all

petroleum fuel products such as:

Liquefied Petroleum Gas(LPG) and Superior Kerosene Oil (SKO) for households

and industrial uses

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 16/27

15

Motor Spirit (MS/Petrol) and Hi-Speed Diesel (HSD) for automobiles

Naphtha, the major raw material for fertilizer and petrochemical industries

Furnace Oil (FO), Light Diesel Oil (LDO) and Low Sulphur Heavy Stock (LSHS)

as fuel for industries.

Aviation Turbine Fuel(ATF) for aircrafts

SPECIALITY PRODUCTS

Kochi Refinery makes Specialty products for domestic markets viz., Benzene, Toluene,

White Spirit, Poly Isobutene and sulfur.

Kochi Refinery offers supplies of any grade Fuel Oil (both 180 cst and 380 cst) and Low

Aromatic Naphtha (high Paraffinic) to the international market.

KR also produces specialty grade bitumen products like Natural Rubber Modified

Bitumen, Bitumen Emulsion etc.

The Fuel Oil has been bench marked in the Singapore and Dubai Fuel Oil markets.

EXCLUSIVE PRODUCTS

Natural Rubber Modified Bitumen: It is one of KRs premier products that

revolutionized road development. NRMB has been on a fast track since its introduction in

1999. This NMRB is a product was developed by the Engineers of R&D department of

Kochi Refinery as in-house innovative product. This was tested and was lauded by IIT,

Delhi and Ministry of Petroleum & Natural gas with awards and appreciations.

Bitumen, which is derived from petroleum is a critical component in road building.

Polymer added to Bitumen enhances both quality and longevity of roads.KR in

association with leading research institutes made an in-depth study on feasibility of using

natural rubber available in abundance in Kerala, to develop the premier product, NRMB.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 17/27

16

NRMB has improved many roads throughout the region. Its success track is evident from

the smooth Seaport-Airport road in Cochin. NRMB is a superior mix of bitumen and

natural rubber latex.

Improved skid resistance and more service life are the booster effects along with prime

factors like save fuel, reduces traffic pollution and atmospheric pollution. All this sums

up to reduced road maintenance cost.

The most important property of Rubberized Bitumen is its elastic recovery. The elastic

nature prevents rutting (permanent deformation due to the load over the road)

BITUMEN EMULSION

This eco-friendly product was launched by the refinery in June 2005.Bitumen in different

grades is used for road maintenance and construction. Bitumen requires heating for the

temporary reduction of viscosity. With Bitumen emulsion, which is a ready to use

product, there is no need for the preliminary hearing. Reduced road maintenance cost,

energy savers, and economics, longer service life for roads and reduced atmospheric

pollution during road laying /maintenance are some of the advantages of Bitumen

emulsion.

DIESEL ADDITIVE

After years of pure and applied research, KR hit upon the formula for high performing

Diesel. KRs Diesel Additive is an indigenous product successfully tested in laboratories

both locally and globally. Trials at various stages in various types of vehicles have also

been completed. When used along with diesel in a specified proportion, it improves the

combustion inside engine cylinder, thereby reducing harmful exhaust emissions and

assuring better fuel efficiency.

Diesel Additive is suitable for all engines, which use diesel as fuel like automobiles,

boats. It helps enhancing the engine efficiency through faster rate of heat release. It also

keeps the cylinder peak pressure to the optimum level, which means the system requires

less energy to maintain relatively low pressure and thus allowing the engine to run

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 18/27

17

smoothly. Immediate results on these changes in combustion pattern are reduction in

engine noise level and smooth drive. In the long run, this effect improves engine life and

longer change period of engine oil.

Diesel Additive is a petroleum product, which burns out completely along with diesel

fuel and hence will not foul the injector nozzle tip by clogging even at high pressure.

INNOVATIONS

BPCL – Kochi Refinery is an ever growing organization which has its own R & D

department, wherein knowledgeable and experienced engineers and experts are untiringly

working on innovative processes, loss control measures, and damage control measures,

and improved quality products, environmental-friendly fuels continuously and constantly.

India has already established a respectable position amongst Petroleum processing

industries globally and will be improving its position in coming years, as assured by the

Petroleum experts of BPCL – Kochi Refinery.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 19/27

18

CHAPTER 3

CDU-2 Shutdown – A Study of Column Internals &

Equipment

As part of the shutdown operations, the internals of a few columns and equipment

like Atmospheric Column, Naphtha Splitter Unit-2 (NSU-2), DHDS Stripper, Desalter

and heat exchangers were studied. A brief overview of the study has been given below.

Column Internals:

Trays and Plates

Common types of tray designs are given below:

Bubble cap trays

A bubble cap tray has riser or chimney fitted over each hole, and a cap that covers

the riser. The cap is mounted so that there is a space between riser and cap to allow the

passage of vapor. Vapor rises through the chimney and is directed downward by the cap,

finally discharging through slots in the cap, and finally bubbling through the liquid the

liquid on the tray.

Valve tray

In valve trays, perforations are covered by lift-able caps. Vapor flows lifts the

caps, thus self-creating a flow area for the passage of vapor. The lifting cap directs the

vapor to flow horizontally into the liquid, thus providing better mixing than is possible in

sieve trays.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 20/27

19

Sieve trays

Sieve trays are simply metal plates with holes in them. Vapor passes straight

upward through the liquid on the plate. The arrangement, number and size of the holes

are design parameters.

Because of their efficiency, wide operating range, ease of maintenance and cost factors,

sieve and valve trays have replaced bubble cap trays in many applications.

During the internal checking, valve trays were found to be used in NSU-2 and

Atmospheric Distillation Column.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 21/27

20

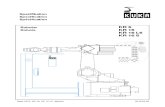

L iquid and Vapor F low in a Tray Column

The figure below show the direction of vapor and liquid flow across a tray, and across a

column.

Each tray has two conduits, one on each side, called downcomers. Liquid falls through

the downcomers by gravity from one tray to the below it. The flow across each plate is

shown in the above diagram.

A wier on the tray ensures that there is always some liquid (holdup) on the tray and is

designed such that the holdup is at a suitable height.

Being lighter, vapor flows up the column and is forced to pass through the liquid, via the

openings on each tray. The area allowed for the passage of vapor on each tray is called

the active tray area .

As the hotter vapor passes through the liquid on the tray above, it transfers heat to the

liquid. In doing so, some of the vapor condenses adding to the liquid on the tray. The

condensate, however, is richer in the less volatile components than is in the vapor.

Additionally, because of the heat input from the vapor, the liquid on tray boils, generating

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 22/27

21

more vapor. This vapor, which moves up to the next tray in the column, is richer in the

more volatile components. This continuous contacting between vapor and liquid occurs

on each tray in the column and brings about the separation between low boiling point

components and those with higher boiling points.

Tray Designs

A tray essentially acts as a mini-column, each accomplishing a fraction of the separation

of the separation task. From this we can deduce that the more the trays there are, the

better the degree of separation and that overall separation efficiency will depend

significantly on the design of the tray. Trays are designed to maximize the vapor-liquid

contact by considering the

Liquid distribution and

Vapour distribution

on the tray. This is because better vapor-liquid contact means better separation at each

tray, translating to better column performance. Less trays will be required to achieve the

same degree of separation. Attendant benefits include less energy usage and lower

construction costs.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 23/27

22

Naphtha Splitter Unit (NSU)

The naphtha stream obtained from the distillation tower is unstable naphtha, i.e., naphtha

along with more volatile components – mainly LPG. To stabilize the naphtha stream,

these gaseous components have to be removed. This operation is called naphtha

stabilization.

After stabilization, the naphtha stream is split into three streams based on their boiling

ranges. This, again, is a distillation operation.

The naphtha stream will consist of compounds from five carbon atom chain to those that

boil at around 140-160 ºC. The three streams obtained will be:

o Top product – 5-60 ºC

o

Side product – 60-110 ºC

o Bottom product – 110-160 ºC

The side stream and top product can be used for petrol blending. However, it will have a

low octane number (around 65). If the pour point of the bottom product is less than 10 ºC,

it can be used for diesel blending.

Another option is to redirect the bottom product to FCCU to make higher octane number

naphtha.

Desalter

Desalter is used to eliminate salts, water, sediment, and suspended solid. We need to have

desalter for some reasons, as follows:

1. To avoid corrosion (effected by salts) – it is usually main target of desalter

operation.

2. To avoid fouling and coking (effected by salts, sediment, and suspended solid).

3. To avoid erosion inside piping/equipment (effected by sediment).

4.

To avoid high energy consumption (effected by salts, water, sediment, and

suspended solid).

5. To avoid catalyst poisoning (effected by salts).

6. To avoid high cost of chemical used for handling fouling and corrosion (effected

by salts, sediment, and suspended solid).

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 24/27

23

Factors influencing emulsion stability of liquid inside of the desalter:

Crude density

Crude inlet temperature

Electrical grid of desalter

Wash water injection rate

pH of Wash water injection

Pressure drop (dP) of mixing valve

Interface level of desalter

Desalter pressure

Demulsifier

Heat Exchangers

Most heat exchangers used in the refinery are Shell and Tube type. Often, multiple shell

and tube heat exchangers, referred to as heating trains are used to bring about the required

heating effect.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 25/27

24

For maximum heat recovery, the heating trains are designed to use the feed as the cooling

fluid and a product stream as the heating fluid. For instance, in the crude distillation units,the feed is preheated in the pre-heat trains by the diesel stream exiting from the

fractionator. Since heat exchangers handle high temperature, ample provision for thermal

expansion must be provided. Hence, most shell and tube heat exchangers are designed as

floating head exchangers.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 26/27

25

Conclusion

The training period at the refinery has helped me understand the foundation

and functioning of the organization. Through the course of my training, I

managed to improve my knowledge and understanding of the concepts and

theories which were only subjective to me till date. I have also been

educated about the shutdown procedures and was given an opportunity to

study internals of a few columns and equipment.

I am happy to conclude that this training has given me the much needed

exposure to the petroleum industry and hope it holds me in good stead for

the future.

Avinash K.V.

8/10/2019 dudeL KR Editeddd

http://slidepdf.com/reader/full/dudel-kr-editeddd 27/27

Bibliography:

Operating Manual for CDU-II

Petroleum Refining Process - Meyers

Factstaff.cbu.edu