Swagelok®

Transcript of Swagelok®

::i-r(M^·

Replenishing system designed by Denny Harr is , Photographer, Cleveland, Ohio

Swagelok® Tube Fittings Provide Leakproof Connections for Corrosive Chemicals

T h e chemica l replenishing sys tem

for t h i s c o l o r p r o c e s s m a c h i n e

n e e d e d S W A G E L O K . M o r e t h a n

8 0 S W A G E L O K Tube Fit t ings in a

var ie ty of shapes and sizes provid

ed easy i n s t a l l a t i o n of l e a k p r o o f

connect ions f r o m : Glass to plastic

t u b i n g , p las t ic to plastic tub ing and

glass to glass tub ing .

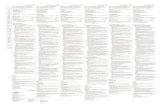

This chemical replenishing system is fast in operation, neat in appearance and has no leaks. Plastic and glass had to be used for this system because the replenishing chemicals cor

rode stainless steel and other metals. SWAGELOK Plastic Tube Fittings and NUPRQ* plastic Valves were utilized with plastic and glass tubing to provide an all plastic and glass system.

It was very important that the mixture of these chemicals be precise and free from any foreign matter. Plastic SWAGELOK Tube Fittings provided vacuum tight tubing connections to protect the chemicals and provide longer usage.

The tube fittings and valves control seven different chemicals which replenish the processing tanks

é"% V \ 'c' through 3/8" O.D. Polyethylene tubing. This entire ma-^ ^ ^ * . V * C V f V O \ Î P ^ ^ - chine can be completely replenished within 3 minutes.

^ ^ ^ ^ F ^ W * ^ J|| * Registered Trademark Q n i W r e ν Π Ι ί α DOPlDI ΓΑΛΟ Nuclear Products Company, Cleveland ΙΟ. Ohio b U L V U . Y U U H r K U b L t l V l b @ 1 9 6 1 b y C r a w f o r d Fitting company, all rights reserved.

Crawford Fitting Company, 884 E. 140th St., Cleveland 10, Ohio · Crawford Fittings ?Canada) Ltd., Niagara Falls, Ontario, Canada Circle No. 3 on Readers' Service Card