Pin Dang 2

Transcript of Pin Dang 2

-

8/6/2019 Pin Dang 2

1/6

PergamonEnergy Convers. Mgmt Vol. 38, No. 10-13, pp. 1219-1224, 1997 1997 Elsevier Science LtdAll rights reserved. Printed in G reat B ritain

PH : S0 19 6-8 90 4(9 6)0 01 51 -3 0196-8904/97 $17.00 + 0 .00

R E D U C T I O N O F S P E C I F I C F U E L C O N S U M P T I O N I N G A ST U R B I N E P O W E R P L A N T S

W E N - J E I Y A N GD e p a r t m e n t o f M e c h a n i c a l E n g i n e e r i n g a n d A p p l i e d M e c h a n i c s , U n i v e r s i t y o f M i c h i g a n , A n n A r b o r ,MI 48109, U .S .A .

A l ~ t r ~ e t - - T h i s p a p e r p r e s e n ts a b r i e f r e vi e w o n r e c e n t a d v a n c e s in g a s t u r b i n e t e c h n o l o g y a n d v a r i o u sm e a ns for r e duc t ion in spe c i f i c fue l c onsum pt ion . A n in te rc oole d r e c upe ra t ive c om bine d c yc le , w i thc lose d- loop s t e a m c oo l ing bre a ks the 6 0% ba r r i e r in the rm a l ef fi ci enc y. A n innov a t ive c he m ic a l ga s tu rb inei s in de ve lopm e nt to a c h ie ve a the rm a l e f f i c i e nc y of ove r 60%. V a r ious m e a ns for r e duc t ion in spe c i f i cfue l c on sum pt io n a re d i s cus se d . 1997 E lse v ie r Sc ie nc e L td .

G a s tu rb in e t e c hnolog y In te rc oole d- re c upe ra t ive c om bine d c ycle The rm a l e ff ic ie ncy Spe ci fi cf u e l c o n s u m p t i o n

I N T R O D U C T I O NIn recen t years , a rap id increase in demand for energy has promoted a need for gas tu rb ines toincrease in thermal ef f i c iency , thus to lower fuel consumpt ion and cos t . The u l t imate goal i s toexceed a lower heat ing value p lan t ef f ic iency of 60% which has bee n cons idered the barr i er inthermal ef f i c iency . A new requi rement i s tha t indus t r i a l gas tu rb ines mus t be envi ronmenta l ly safeby lower ing N Ox emiss ions . A b r ief survey ind icates tha t a natura l gas - f i red , in tercooledrecupera t ive combined cycle wi th c losed- loop s team cool ing sys tem has ach ieved the ob ject . Inaddi t ion , an innovat ive new chemical com bined cycle i s curren t ly under d evelop men t which seemsto be very promis ing . There are severa l major fac tors which have been iden t i f i ed to af fec t powerp lan t ef fi ciency. This p ape r p resen t s a b r ief rev iew of recen t advan ces in gas tu rb ine t ech nologyand d i scuss ion of some majo r fac tors enhancing thermal ef fi ciency.

R E C E N T A D V A N C E S I N G A S T U R B I N E T E C H N O L O G YFive types of advance d gas tu rb ine cycles are p resen ted : in tercooled recupera t ive com bined cycle ,

in tercooled thermochemical recupera t ive s ing le cycle , chemical combined cycle , in tercooledrecupera t ive s ing le cycle and veh icu lar gas tu rb ine .lntercooled recuperative combined cycle

T w o w o r l d -g i an t p o w er g as t u rb i n e m an u fac t u re r s , G en e ra l E l ec t r i c C o m p an y an dW es t i n g h o u s e E l ec tr i c C o rp o ra t i o n h av e b een co m p e t i n g t o ach i eve a l o w er h ea ti n g v a l u e (L H V )p l an t e f fi ciency o f g r ea t e r t h an 6 0 %: w i t h t h e ad v an ced H . t u rb i n e t ech n o l o g y d ev e l o p ed b y G E[1 ] an d t h e ad v an ced t u rb i n e s y s t em (A T S) p ro g ram o f Wes t i n g h o u s e [2] . B o t h co m p an i e s p ro p o s e dan in tercooled recupera t ive combine cycle , wi th c losed- loop s team cool ing sys tem. Figure 1 showst h e p ro p o s ed r e f e r en ce s y s t em o f Wes t i n g h o u s e .

In tercool ing u t i l i zes an in tercooler w hich ex t rac t s heat f rom ai r l eav ing a com presso r sec t ion andt rans fers i t to cool ing water . This i s ca l l ed evap orat ive in tercool ing where the t em peratur e o f a i rl eavi n g a co m p re s s o r s ec t io n i s r ed u ced b y ev ap o ra t i o n o f w a t e r i n t o t h e a i r s t ream . T h e u n i t m ayuse one in tercooler ins ta l l ed between low-pressure (LP) and h igh-pressure (HP) compressors , o rt w o i n t e r co o l e r s b e t w een L P , i n t e rm ed i a t e -p re s s u re an d H P co m p res s o r s , o r co n t i n u o u sevap orat ive c ool ing in a ll s t ages of a s ing le com pressor .

R ecu p e ra t i o n u s es a r ecu p e ra t o r t o ex t r ac t h ea t f ro m t u rb in e ex h au s t t o b o t h h ea t an d ev ap o ra t e1219

-

8/6/2019 Pin Dang 2

2/6

1 22 0 W E N - J E I Y A N G : F U E L C O N S U M P T I O N I N G A S T U R B I N E P O W E R P L A N T S

wa t e r i n t o H P c om pr e sso r d e l ive r y a i r. T he p r oc e ss i s r e f e rr e d t o a s e va p or a t i ve r e c upe r a t ion . The r ei s a no t h e r f o r m o f re c upe r a t i on . I t i s c he m i c a l re c upe r a t i on , whe r e by t u r b i ne - e xh a us t e ne r gy wo u l dbe t r a nsm i t t e d ba c k i n t o t he t u r b i ne t h r ough a r e f o r m e d na t u r a l ga s f ue l . M or e de t a i l s a r epresented in the succeeding sec t ion.

C l ose d - l oop s t e a m c oo l i ng is t o use s t e a m t o c oo l a ga s t u r b i ne . T h i s i nvo l ve s d i r e c ti ng a po r t i onof t he d r y s t e a m i n the he a t r e c ove r y st e a m ge ne r a t o r ( H R S G ) t h r ough t he wa l ls o f ho t - e ndc om pone n t s , suc h a s va ne s , c om bus t o r ba ske t s a nd t r a ns i t i ons , p r i o r t o e xpa nd i ng i t t h r ough t hes t e a m t u r b ine . T he s t e a m i s supe r he a t e d a s it re m ov e s he a t r a d i a te d a nd c o nve c t e d f r om t he ho tga s pa t h .

The i m pa c t o f c l ose d - l oop s t e a m c oo l i ng ( o f s t a t i ona r y pa r t s ) i nc lude s :( i ) Wi t h t he r o t o r i n l e t t e m pe r a t u r e ( R I T) m a i n t a i ne d c ons t a n t , r e p l a c i ng a i r c oo l i ng wi t h

bo t t om i ng c yc l e s t e a m r e su l ts i n a s i gn if ic a n t d r op i n t e m pe r a t u r e s i n t he c om bus t i on r e a c t i onbe c a use m uc h m or e a i r be c om e s a va i l a b le t o bu r n t he sa m e qua n t i t y o f fue l. C onse que n t l y , t hep r e m i x l e a n - bur n d r y l ow- NO x c om bus t i on be c o m e s e ve n m o r e l e an , r e su lt ing i n a r e duc t i on i nemiss ions .

W i t h t he use o f TC B a nd i m pi nge m e n t c oo l i ng t o s t r e ng the n t e m pe r a t u r e r e s is t anc e , the GE 7ECc om bus t i on sys t e m i s f ue l e d wi t h na t u r a l ga s , r e fi ne ry a nd p r oc e ss ga se s . I t is de s i gne d t o a c h i e veNOx e m i ss i on o f a s l ow a s se ve n pa r t s p e r m i l li on , t he l owe s t i n t he pow e r ge ne r a t i on i ndu s t r yf o r ga s t u r b i ne s o f t ha t s iz e. The G ETE C ga s t u r b i ne ha s t h r e e c oo l i ng t u r b i ne s t a ge s. The m a t e r ia l suse d a r e w i t h supe r i o r t e m pe r a t u r e r e s is t a nc e a nd r e s i s ta nc e t o c r e ep , ho t c o r r os i on a nd ox i da t i onc oo l i ng t e c hn i que s . A va c uum p l a sm a sp r a y c oa t i ng i s a dde d t o f u r t he r ox i da t i on a nd c o r r os i onresistance.( ii) I n t he a bse nc e o f m o m e nt um m i x i ng l os s be t we e n c oo l i ng a i r a nd m a i n - s tr e a m ga s f low, thetota l pressure ava i l able a t t he f i r s t ro tor in l e t for expanding through the turbine wi l l be higher ,r e su l t i ng i n e x t r a powe r p r oduc t i on by t he ga s t u r b i ne .

( ii i) The requ i reme nt o f m uch l ess AT/T r e duc e s t he ho t spo t t e m pe r a t u r e f r om e a c h b r a c ke t ,r e su lt ing i n a r e duc t i on i n t he c oo l i ng r e qu i r e m e n t s i n t he f i r s t- r ow va ne s a nd b l a de s . C onse qu e n t l y ,

s t e a mt u r b i n e(

c o o l i n g

c o n d e n s e r

a ir

~e r

n I~ n a t ; S ~ _ i =L 4 ,c o m b u s to r C

_ _ ~ m p r e s s o r s

I / I in t e r -~ q

, c o o l i n gw a te r n

g a st u r b i n e

- I t

~ = w a t e r

h e a te x c h a n g e r

~.F .

p u m p: r a t o r

! h e a t e c o v e ry( d r u m t y p e )

F i g . 1 . I n t e r c o o l e d r e c u p e r a t i v e c o m b i n e d c y c l e .

-

8/6/2019 Pin Dang 2

3/6

W E N - J E I Y A N G : F U E L C O N S U M P T I O N I N G A S T U R B I N E P O W E R P L A N T S 1221

AIR ~ I N T E R ~ .COOLER

COOLINGWATER

B.F. WATERCO+Hz

COMBUSTOR METHANEFUEL

AIR

REGENERATOR GAS REFORMER HEA T RECOVERYSTEAMGENERAROR

Fig. 2. Inter coo led thermochem ical recuperative single cycle.

addi t ional power wi l l be produced in the s team turb ine f rom the h igher- temperature s t eamex p an d i n g t h ro u g h t h e s t eam t u rb i n e .In s u m m ary , c l o s ed - l o o p s t eam co o l i n g co n t r i b u t e s t o r ed u c t i o n i n em i s s i o n s an d ex t r a p o w erg en e ra t i o n b y b o t h g as t u rb i n e an d s t eam t u rb i n e .Intercooled thermochemical recuperative single cycle

In co n t r a s t t o ev ap o ra t i v e r ecu p e ra t i o n b e i n g ad o p t ed i n a co m b i n ed cy c l e , t h e rm o ch em i ca lrecupe ra t ion of gas tu rb ine exha us t energy i s opera ted on a s ingle cycle , as i llus t ra ted in Fig . 2 .H ere , o n l y t h e g as t u rb i n e p ro d u ces p o w er b y b u rn i n g r e fo rm ed r ecu p e ra t ed fu e l . M e t h an e an dsuffic ien t s t eam w i th the a id of a ca ta lys t a t an app ropr ia te t emp erature and pressure wi ll reformin to a fuel cons i s t ing o f H2, CO and C H 4 . Si nce n o l a t en t h ea t o f v ap o r i za t i o n o f s team g en e ra t edin the H R S G i s los t to the cycle , ef fi cien t exhaus t energy recu pera t ion i s poss ib le . An H 2-rich fuelh as g rea t e r f l am m ab i l it y t h an C H 4 an d t h u s s u p p o r t s co m b u s t i o n a t a l o w er f lam e t em p era t u re ,resu l t ing in a reduct ion of NOx format ion .Chemica l combined cyc le

Arai [3 ] and h i s associa tes p roposed an innovat ive chemical gas tu rb ine concept as i l lus t ra tedin Fig. 3. Special features of this gas turbine system include: (1) the fi rs t -s tage gas turbine is drivenby lean-burn dry low NOx gas produced in the h igh- temperature , h igh-pressure ex t ra- r i ch fuelcombus tor . A C/C compos i te mater ia l i s used as a i r fo i l mater ia l to p revent mater ia l de ter io ra t ionfrom oxid iza t ion react ion . (2) The refo rme d fuel cons i s t ing of CO, H2 and o thers i s exha us ted f romthe f i r s t -s t age gas tu rb ine and en ters in to the fuel -a i r heater to cool fuel and compressed a i r f romthe a i r compressor . I t then en ters the f i r s t reheated to heat s t eam, i s compressed by the fuelco m p res s o r an d t h en i s m i x ed w i t h co m p res s ed a i r f ro m t h e a i r co m p res s o r t o b u rn i n t h e l eanfu e l co m b u s t o r . N o t e t h a t b o t h t h e fu e l - a i r h ea t e r an d t h e s t eam h ea t e r ac t l i k e an i n t e r co o l e r .Af ter d r iv ing the second-s tage tu rb ine , the exhaus t gas en ters another reheater to heat the s team.T h e s u p e rh ea t ed s t eam t h en d r i v es t h e s t eam t u rb in e . T h e s eco n d r eh ea te r p e r fo rm s t h e fu n c t i o nof a recupera tor . (3 ) He at loss f rom the exhaus t gas can be s ign if i can tly reduce d th rough a p rop erco m b i n a t i o n o f ex t ra - r ich fu e l co m b u s t i o n an d h i g h - tem p era t u re r eg en e ra ti o n t ech n o lo g y . In f ac t,there are th ree heat exchan gers in the cycle , two o f which ( fuel -a i r heater an d reh eater I ) per formthe du ty o f an in tercooler an d the th i rd one ( rehea ter I I ) as a recupera tor . T herefore , th i s cyclei s equ ivalen t to an in tercooled recu pera t ive com bined cycle wi th chemical energy in the reform edgases . I t is an t i c ipated that the chem ical gas tu rb ine cycle may a ch ieve thermal ef fi ciency exceeding60% . T he m ain th rus t o f th i s concep t i s to ef fec t ively u t il i ze re la t ively h igh chemical energy in thereform ed gases such as CO a nd H: in the second-s tage gas tu rb ine . T hus , the un i t i s ca l l ed chemicalgas tu rb ine by the developers [3 ] .

-

8/6/2019 Pin Dang 2

4/6

1222 WEN -JEI YA NG : FU EL CONSUMPTION IN GAS TURBINE POWER PLANTSa i r

a i r com pressor ~

fue lfuel-airheater

extra-r ich fuelco m b u s t o r 1 5 0 0 * C

a ir

fuelcompressor

lean-fuelco m b u s t o r

second-stageturbine

lean-burndry lowNO xgas

reheater Ic irculat ings team ' re h e a t e r II / ~ g a s/ ~ x h a u s t

s team tu rb ine

Fig. 3. Chemicalcombinecycle.

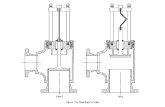

Intercooled recuperative single cycleT h e W es t i n g h o u s e / Ro l l s Ro y c e W R -2 1 , i n t e rco o l ed r ecu p e ra t ed ( ICR ) g as t u rb in e w i ll p o w er

U.S. warsh ips [4 ] . Th i s s ing le-cycle gas tu rb ine pow er p lan t i s show n in F ig . 4 [4 ] . I t i s equ ip pedwi th an in tercoo ler to coo l the a i r be tween the h igh-pressure and low-pressure compressors , thusr ed u c in g co m p res s i o n p o w er . A r ecu p e ra t o r r eco v e r s exces s en e rg y f ro m ex h au s t f r o m t h e p o w e rt u rb i n e fo r p r eh ea ti n g t h e co mp res s ed a i r p r io r t o en t e r i n g t h e co mb u s t o r ch am b er , t h u s i mp ro v i n gthe sys tem 's fuel efficiency. This turb ine a chieves a therm al efficiency of 43 % .Vehicular gas turbine

V o l v o ae ro t u rb i n e h as d ev e l o p ed a l o w -N O x t u rb i n e fo r a u t o mo b i l e s [ 5] . I t i s o p e ra t ed o n aregenera t ive gas tu rb ine cycle . Fuel and a i r en ter ing the tu rb ine 's combus tor are wel l mixed andv ap o r i zed p r i o r t o co mb u s t i o n . T h i s l o w er s t h e f l ame t emp era t u r e an d mi n i mi zes t h e fo rma t i o nof n i t rogen ox ides , NOx. The gas tu rb ine i s equ ip ped w i th a regenera t ive , o r ro tary , a i r hea terco n s is t in g o f a ce r ami c ro t o r p e r fo r a t ed w i t h man y p as s ag es fo r a lt e rn a t e f l o w o f h o t g a s e s an d

Exhaust

Airi n l e t

~ P ow e rV com presso r ru ~ t turomCturbincompressor turbineFig. 4. Intercooled ecuperativesingle cycle.

-

8/6/2019 Pin Dang 2

5/6

W E N - J E I Y A N G : F U E L C O N S U M P T I O N I N G A S T U R B I N E P O W E R P L A N T S 122 3

L )E

..=

1500140013001 2 0 011001000

90 08 007 0060 050 0 I I I I I

1940 1950 1960 1970 1980 1990Year

Fig. 5. Gas turbine inlet temperature (TIT) trend.

- I I I I I I

2 0 0 0

coo le r a i r. T urb ine ef fi ci ency i s thus b oos ted . Th i s un i t w as fue led by d iese l o il bu t can a l so burngaso l ine , methano l and natu ra l gas .

F A C T O R S A F F E C T I N G T H E R M A L E F F I C I EN C YSevera l major fac to rs af fec t thermal ef f i c i ency o r speci f i c fue l consumpt ion . An enhancement in

thermal ef f i c i ency impl ies a reduct ion in speci f i c fue l consumpt ion . Th i s can be ach ieved by thefo l lo w i n g m e t h o d s :

(1 ) increase in f i r ing t empera tu re , refer r ing to tu rb ine in le t t empera tu re (TIT) ;(2 ) reduce coo l ing a i r usage;(3 ) improve component ef f i c i encies ;(4 ) cycle enhance men t .Only the f i r s t two fac to rs are d i scussed in the fo l lowing .

Raising turbine inlet temperatureFigure 5 dep ic t s the genera l gas tu rb ine in le t tem pera tu re t rend [2 ] . The n orm al f i ring

tempera tu re can be ra i sed in th ree d i f feren t ways by u t i l i z ing :( i) aerode r iva t ive coo l ing t echn iques ;( ii ) therma l bar r i er coat ings (TCB);( i i i ) h igh per fo rmance mater i a l s fo r component s such as ro to rs , nozzles and bucket s which can

sus ta in a t empera tu re up to 1930C.A ero d e r i v a t i v e g as t u rb in e a r e ad ap t ed f ro m a i r c r a ft en g in es fo r u s e o n l an d i n p o w e r g en e ra ti o n

or on water as mar ine eng ines . Thei r use reduces cos t s by min imizing spare horsepower andred u c in g m a i n t en an ce d o w n t i me . M an y o f t h e d esi g n co m p o n en t s o f t h e G E H t u rb i n e w ereo b t a i n ed b y a i r c r a f t en g in e t ech n o l o g y . Fo r ex amp l e , an a i r c ra f t en g i ne co m p res s o r w as s ca l ed -u pfor the H tu rb ine co m pon ent to increase the p ressure ra t io and f low which in tu rn increases ou tpu tand eff ic iency [6 ] . Aero der iva t ive c oo l ing t echn iques th a t were deve loped fo r a i rcraf t eng ines area l s o i n co rp o ra t ed i n t o t h e co o l i n g o f g as t u rb i n es fo r u s e o n l an d an d w a t e r .

T BC s p ro v i d e t w o m a i n fu n c t i o n s. O n e i s t o r ed u ce me t a l t emp era t u r e a n d t h e o t h e r i s t o r ed u cet h e rma l s t r e ss e s o f t h e ma t e r i a l u n d e rn ea t h t h em. T h u s , t u rb i n e co m p o n e n t d u rab i l it y can b e

-

8/6/2019 Pin Dang 2

6/6

1 22 4 W E N - J EI Y A N G : F U E L C O N S U M P T I O N I N G A S T U R B I N E P O W E R P L A N T Si m p r o v e d . A n e x a m p l e o f T B C c o n si st s o f a 1 00 # m t h ic k , M C r A 1 Y b o n d c o a t ( ba s e) a n d a 3 0 0 # mt h i c k , Zr O 2- 7 ( w e i g h t p e r c e n t a g e ) Y 2 0 3 t o p c o a t . T h e e f f e ct s o f a p p l y i n g T B C s a r e a r e d u c t i o n i nc o o l i n g a i r u s a g e a n d a c h a n g e i n t u r b i n e b l a d e t i p - s h r o u d c l e a r a n c e s .Reduct ion in coo l ing a i r u sage

I t i s a r a t h e r c o m m o n p r a c t i c e t h a t t h e f i r st - st a g e v a n e c o o l i n g is a c c o m p l i s h e d b y a c o m b i n a t i o no f i m p i n g e m e n t , fi lm a n d c o n v e c t i v e c o o l i n g , w h i l e b l a d e c o o l i n g i n c o r p o r a t e s i n t e r n a l m e a n s u s i n gs e r p e n t i n e , r i b b e d a n d p i n p a s s a g e s w i t h e x t e r n a l f i l m . B o t h t h e i n t e r n a l a n d e x t e r n a l c o o l i n gs c h e m e s h a v e b e e n e x t e n s i v e l y s t u d i e d , b u t i s s t i l l i n t h e p r o c e s s o f f u r t h e r r e f i n e m e n t .Fu t u r e f i b e r d e v e l op m e n t

I n o r d e r t o m e e t t h e U . S . G o v e r n m e n t ' s g o a l o f d o u b l i n g t h e p r o p u l s i o n c a p a b i li t ie s o f g a st u r b i n e e n g i n e s b y t h e y e a r 2 0 05 , r e v o l u t i o n a r y i n c r e a s es i n e n g i n e p e r f o r m a n c e m u s t b e o b t a i n e d .A f i ve - y e ar in d u s t r y - g o v e r n m e n t c o l l a b o r a t i o n h a s b e e n f o r m e d t o d e v e l o p f ib e r s n e e d e d f o ri m p r o v e d g a s - t u r b i n e e n g i n e s : g o v e r n m e n t o r g a n i z a t i o n s , i n c l u d i n g t h e A d v a n c e d R e s e a r c hP r o j e c t s A g e n c y ( A R P A ) , U . S . A i r F o r c e , U . S . A r m y , U . S . N a v y a n d N A S A , w i t h i n d u s t r i a lm e m b e r s o f t h e I n t e g ra t e d H i g h P e r f o r m a n c e T u r b i n e E n g i n e T e c h n o l o g y ( I H P T E T ) F i b e rD e v e l o p m e n t C o n s o r t i u m i n c lu d i n g A l l is o n G a s T u r b i n e D i v is i on o f G e n e r a l M o t o r s , G a r r e ttE n g i n e D i v i s io n o f A l l i e d- S i g n al , G e n e r a l E l e c tr i c A i r c r a f t E n g i n e s , L y c o m i n g D i v i s io n o f T e x t r o n ,U n i t e d - T e c h n o l o g i e s - P r a t t a n d W h i t n e y , T e l e d y n e C A E , a n d W i l l i a m I n t e r n a t io n a l .T o a d v a n c e t h e g o a l o f d o u b l i n g t h e p r o p u l s i o n c a p a b i l i t i e s o f g a s t u r b i n e e n g i n e s , t h ec o n s o r t i u m c o m m u n i t y i d en t if ie d c o n t in u o u s l y -r e i n fo r c e d C e r a m i c M a t r ix C o m p o s i te s ( C M C s ) ,M e t a l M a t r ix C o m p o s i te s ( M M C s ) a n d I n t e r m e t a ll i c M a t r ix C o m p o s i t e s (I M C s ) a s en a b l in gt e c h n o l o g ie s w i t h t h e g r e a t e s t p r o m i s e . T h e y d i s p l a y h i g h e r s p e c if ic s t r e n g t h a n d d a m a g e t o l e r a n c ec o m p a r e d t o t h e i r m o n o l i t h i c c o u n t e r p a r t s . B e s id e s , C M C s a l lo w n e a r - s t o i c h i o m e t r i c f u e lc o m b u s t i o n f o r i n c r e a s e d t h r u s t a n d e l i m i n a t e t h e c o o l i n g a i r r e q u i r e m e n t p e n a l t i e s i n c u r r e d b yt h e u s e o f m e t a ll i c a n d i n t e rm e t a l l ic s t r u c tu r e s . T h e m a x i m u m o p e r a t i n g t e m p a t u r e s a r e : f o rc o n t i n u o u s l y - r e i n f o r c e d C M C s i n i ta l ly a t 1 37 0 C a n d l a t e r a t 1 5 3 8 C o r h i g h e r ; a n d f o rM M C / I M C c o m p o n e n t s a t 7 6 0 -1 0 9 3 C o r h i g he r . C u r re n t ly , t h e a re a s o f h ig h - t e m p e r a t u res t r e n g t h , s t i f f n e s s , o x i d a t i v e s t a b i l i t y a n d t h e r m a l - e x p a n s i o n c o m p a t i b i l i t y w i t h t h e m a t r i x a r el i m i t e d b y f i b e r t e c h n o l o g y .

R EMARK SA f t e r W o r l d W a r I I , b o t h G E a n d R o l l s R o y c e u se d c o m p o n e n t s f r o m a i r cr a f t e ng i n es to d e s ig n

a e r o d e r i v a ti v e g a s tu r b i n e s f o r u s e i n p o w e r g e n e r a t i o n a n d m a r i n e p r o p u l s i o n . C o m b i n e - c y c l e g a st u r b i n e s o f f e re d h i g h t h e r m a l e f fi ci e nc y a n d l o w f u e l c o st s f o r 1 5 0 - 20 0 M W a p p l i c a t io n s . T h e h i g hp r e s s u r e r a t i o s o f f e r e d b y a e r o d e r i v a t i v e c o o l i n g t e c h n i q u e s , t h e r m a l b a r r i e r c o a t i n g s a n dh i g h t e m p e r a t u r e m a t e r i a ls a r e u s e d b y G E , W e s t i n g h o u s e a n d K a w a s a k i H e a v y I n d u s t r i e s ( J a p a n )t o i m p r o v e t h e i r s im p l e - c yc l e t u r b i n e s i n lo w e r p o w e r o u t p u t ( 1 3 - 1 5 M W ) a p p l i c a ti o n s . I n t e r c o o l e dr e c u p e r a t e d ( I C R ) a e r o d e r i v a t iv e g a s t u rb i n e s w i t h u p t o 1 5 M W c a p a c i t y a r e u s e d i n o f f sh o r ep i p e li n e s a n d m a r i n e p r o p u l s i o n . W e s t i n g h o u s e a n d R o l l s R o y c e a r e i n t h e p r o c e s s o f d e v e l o p i n gt h e W R - 2 1 I C R t u r b i n e s to p r o p e l t h e f u t u r e n a v a l v e ss e ls o f b o t h t h e U . S . A . a n d U . K . T h e u s eo f c e r a m i c m a t e r i a l s b e c o m e s a t t r a c t i v e t o m e e t t h e t r e n d o f i n c r e a s i n g T I T .T h e c h a l l e n g e n o w i s th e m o s t e n e r g y - ef f ic i e n t g a s t u r b i n e m u s t a l so b e e n v i r o n m e n t a l l y su p e r i o rt h r o u g h e n h a n c i n g e m i s s i o n c o n t r o l s t o m e e t e v e r - i n c r e a s i n g s o c i a l d e m a n d s .

R E F ER EN C E S1. Valenti , M., Mech. Engng, 1995, 117, 86-89.2. B annister , R. L., Cheru vu, N. S., Lit tle , D. A. an d McQ uiggan, G., Mech. Engng, 1994, 116, 68-75.3. Arai , N., JSME J., 1994, 209.4. Valenti , M., Mech. Engng, 1995, 117, 70-73.5. Valenti , M., Mech. Engng, 1994, 1 16, 46--49.6. Valenti, M., Mech. Engng, 1994, 116, 52-56.