Pb i srtcartonfreezersandchillers 150dpi a4size 5c us tcm11 12231

description

Transcript of Pb i srtcartonfreezersandchillers 150dpi a4size 5c us tcm11 12231

engineering for a better world GEA Refrigeration Technologies

In touch with GEA Refrigeration Technologies –single retention time automated system

GEA I-SRT carton freezers & chillers

2

3

5

1

6

7

4

Food packed in cartons, plastic totes or shrink-wrapped; GEA I-

SRT (Single Retention Time) can handle all your products at once

coming in various sizes and types with first-in first-out

sequence. GEA I-SRT system off ers optimal fl exibility through

a wide range of food applications and full integration into your

in-line process.

In touch with our technology

1

2

3

5

6

7

4

GEA I-SRT carton freezer

GEA I-SRT provides automated system for product handling

from the production room to the freezer/chiller and on to the

palletizing area, while achieving:

• Optimum product quality through accurate

temperature control

• Full inventory control

• Minimum labor

• Cost eff ective chilling and freezing solution

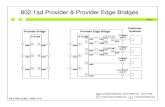

The SRT Process

1 Batches accumulate by product specifi cation or retention time on our fully

integrated material handling conveyors.

2 Load transfers to the SRT infeed conveyor and package tracking is initiated,

allowing total inventory control and data capture.

3 Optional step: Loadmoves to an accumulating table allowing internal

accumulation of product, streamlining production into the freezing environment.

4 After product is spaced for optimal airfl ow, a custom designed sweep arm gently

transfers product to an empty shelf. The carrier then indexes up one level and

the next batch of product loads.

5 When all shelves are full, the transfer elevator raises the carrier and inserts it

into the SRT rack.

6 Packages pass through the SRT rack system while powerful fans provide the

required velocity and end-fl ow air distribution to ensure effi cient heat transfer.

7 The carrier ejects from the rack to the transfer elevator. Product transfers to the

outfeed conveyor leaving the shelf empty to take on new product.

Capacities: 1,400 to 13,600 kg per hour

Enclosure footprint: 9 to 24.5 m L x 9 m W x 7.5 to 11 m H

Standard shelf sizes: 5.4 m W x 0.7 m L or 5.4 m W x 1.3 m L + custom specific

Packages processed: Cartons, Totes, Nestors, Shrink wrapped packages

Products: Poultry, Pork, Beef, Ice Cream, Cheese, Yogurt, Redi-meals, Soups, Bakery

Feed rates: Up to 15 units per minute (15 kg cartons )

Hours of operation: Up to 24 hours per day / up to 7 days per week

Carriers: 4 to 20 carriers long x 2 high + 1 on either the infeed / outfeed or transfer elevator

Shelves per carrier: Production specific – from 7 to 10 shelves per carrier

Shelf construction: Galvanized steel frame and corrugated galvanized steel decking.

Shelf loading: Loading patterns are custom configured, specific to carton sizes and weights, all to optimize freezing / chilling profiles and production rates. (units across x units deep)

Storage capacity: From 1,200 to 6,000 cartons at any one time within a SRT system = 280 to 1,400 square meters of storage capacity.

Air flow: Horizontal airflow - 6m/second over the top of all units. Airflow is baffled and controlled so that it insures even air flow and temperature to all products throughout the rack structure of the SRT system. Counter end air-flow.

Evaporators: Galvanized or stainless steel / aluminum. Coil banks are stacked, 2 to 4 high.

Fans: Fans are blow through design, 3 fans per bank. Fan sizes are production specific, ranging from 6 to 12 fans, each from 3.75 kW 11.19 kW.

Refrigeration: Pumped ammonia, freon or CO2 cascade system

Suction temperature: -1.1° C to -45.5° C, depending upon freezer or chiller requirements.

Defrost system: Typically one defrost cycle per week, predominantly with hot gas, and some with electric or water defrost.

SRT infeed system: One per SRT system – can be fed by up to two production / transport conveyors.

SRT discharge systems: One per SRT system at the same end as infeed

Platforms and ladders: Platforms and ladders are supplied within the SRT enclosure to access the in-feed and out-feed conveyors, as well as the upper elevators assemblies and other high level components.

Construction: Galvanized Steel – bolt together assembly

Safety: All moving parts within the SRT are painted yellow. Access into the SRT freezer enclosure is re-stricted such that the SRT must be isolated prior to personnel entry. Drives external to the SRT are guarded and a controlled shutdown of the SRT occurs whenever an access door is opened.

Electrical and control equipment: Each SRT system has its own dedicated Allen Bradley Processor or equivalent. Major operator controls will be accessed via SCADA screens. The operator Interface is an Allen Bradley Touchscreen PanelView 1000 plus or equivalent.

Drives & servos: SEW Eurodrive, hydraulics

Camera system: Cameras & monitoring system are included within each SRT control system.

Installation: Mechanical and electrical installation typically included in GEA Refrigeration Technologies scope.

GEA I-SRT System Typical Application Data

Excellence Passion Integrity Responsibility GEA-versity

GEA Group is a global engineering company with multi-billion euro sales and operations in more than 50 countries. Founded in 1881, the company is one of the largest providers of innovative equipment and process technology. GEA Group is listed in the STOXX Europe 600 Index.

© G

EA. A

ll ri

ghts

res

erve

d. 0

3/2

012

– RT

-002

-08

01-U

S-EU

– S

ubje

ct t

o m

odif

icat

ion

www.gearefrigeration.com