Module A1, Internal production control with · Module E1, Quality assurance for production,final...

Click here to load reader

-

Upload

dangnguyet -

Category

Documents

-

view

214 -

download

2

Transcript of Module A1, Internal production control with · Module E1, Quality assurance for production,final...

Hi Auke-Pieter

Ontwerpdruk PS:

"De maximaal toelaatbare druk". De door de fabrikant aangegeven maximale druk waarvoor de

apparatuur ontworpen is. Deze druk wordt bepaald op een door de fabrikant aangeven plaats, namelijk

daar waar de beveiligings- of veiligheidsinrichtingen zijn aangesloten of de bovenzijde van de

apparatuur, of, indien dat niet passend is, een andere aangegeven plaats;

PS=90bar

V<1 liter art 3 par. 3 Goed vakmanschap!

PS*V<200 1 liter < V < 2.22 liter categorie I module A

PS*V<1000 2.23 liter < V < 11.11 liter categorie II module A1, D1 , E1

PS*V<3000 11.12 liter < V < 33.33 liter categorie III module B1+D, B1+F, B+E, B+C1, H

PS*V>3000 V>33.34 liter categorie IV module B+D, B+F, G, H1

Verantwoordelijkheden producent verantwoordelijkheden notified body (Lloyds b.v.)

Module A , internal production control 1) Draw up technical documentation which must enable an

assessment to be made of the conformity of the pressure equipment with the requirements of the Directive which apply to it. It must, as far as is relevant to such assessment, cover the design, manufacture and operation of the pressure equipment and contain: * A general description of the pressure equipment * Conceptual design and manufacturing drawings * Descriptions and explanations necessary for an understanding of the drawings and the operation of the pressure equipment * A list of the harmonised standards and a description of the solutions adopted to meet the essential safety requirements where harmonised standards have not been applied * Results design calculations made, examinations carried out etc * Test reports 2) Ensure manufacturing process complies with technical documentation. 3) Affix CE marking. 4) Draw up written declaration of conformity. 5) Retain declaration of conformity and technical documentation for 10 years.

geen

Module A1, Internal production control with monitoring of final assessment, In addition to the requirements of Module A 1) Choose a Notified Body. 2) Affix Notified Body identification number to each item.

1) Monitor final assessment & monitor by unexpected visits.

2) Ensure manufacturer performs final assessment according to Section 3.2 of the essential safety requirements. 3) Take samples of pressure equipment at manufacturer or storage premises to conduct checks. 4) Assess number to sample and whether it is necessary to perform or have performed, all or part of final assessment on the samples. 5) Take appropriate action if items do not conform.

Module D1, Quality assurance for production,final inspection and testing 1) Draw up technical documentation covering design, manufacture and operation as described under Module A. 2) Operate an approved quality system for production, final inspection and testing (e.g. ISO 9002) which must ensure compliance of the pressure equipment with the requirements of the Directive which apply to is. 3) Lodge application for assessment of quality system with a Notified Body which includes: - relevant information on the pressure equipment concerned - documentation on the quality system including a description of - quality objectives and organisational structure - manufacturing, quality control and quality assurance techniques to be used - examinations and tests to be carried out - quality records, such as inspection reports and test data, calibration data, reports concerning the qualifications or approvals of the personnel concerned, particularly with permanent joining - means of monitoring quality and the quality system 4) Undertkae to fulfill obligations arising from the quality system. 5) Affix CE markering and identification number of Notified Body responsible for surveillance. 6) Draw up written declaration of conformity. 7) Inform the Notified Body of intended adjustments to the quality system. 8) Hold documentation for 10 years.

1) Assess quality system including an inspection visit to the manufacturers' premises. 2) Include in the auditing team at least one member with experience of assessing the pressure equipment technology. 3) Presume conformity in respect of the elements of the quality system which implement a relevant harmonised standard (e.g. ISO 9002). 4) Notify the manufacturer of assessment decision. 5) Carry out surveillance visits to ensure that the manufacturer fulfils the obligations arising from the approved quality system. 6) Carry out periodic audits such that a full re-assessment is carry out every 3 years. 7) Carry out unexpected visits to verify that the quality system is functioning correctly. 8) Assess proposed changes to the quality systems.

Module E1, Quality assurance for production,final inspection and testing 1) Draw up technical documentation covering design, manufacture and operation as described under Module A. 2) Operate an approved quality system for final inspection & testing (e.g. ISO 9003) under which each item of pressure equipment must be examined & appropriate tests carried out to ensure its conformity with the requirements of the Directive which apply to it. 3) Lodge application for assessment of quality system with a Notified Body which includes relevant information on the pressure equipment concerned documentation on the quality system including a description of: - Quality objectives and organisational structure; - Procedures for the permanent joining of parts; - Examinations and tests to be carried out after manufacture; - quality records, such as inspection reports and test data, calibration data, reports concerning the qualifications or approvals of the personnel concerned, particularly with permanent joining; - Means of monitoring quality and the quality system. 4) Undertake to discharge obligations arising from the quality system. 5) Affix CE marking and identification number of Notified Body responsible for surveillance. 6) Draw up written declaration of conformity. 7) Inform the Notified Body of intended adjustments to the quality system. 8) Hold documentation for 10 years.

1) Assess quality system including and inspection visit to the manufacturers' premises. 2) Include in the auditing team at least one member with experience of assessing the presume equipment technology. 3) Presume conformity in respect of the elements of the quality system which implement a relevant harmonised standard (e.g. ISO 9003). 4) Notify the manufacturer of assessment decision. 5) Carry out surveillance visits to ensure that the manufacturer fulfils the obligations arising from the approved quality system. 6) Carry out periodic audits such that a full assessment is carried out every 3 years. 7) Carry out unexpected visits to verify that the quality system is functioning correctly. 8) Assess proposed changes to the quality system.

Artikel 3

3. Pressure equipment and/or assemblies below or equal to the limits in sections 1.1, 1.2 and 1.3 and

section 2 respectively must be designed and manufactured in accordance with the sound engineering

practice of a Member State in order to ensure safe use. Pressure equipment and/or assemblies must be

accompanied by adequate instructions for use and must bear markings to permit identification of the

manufacturer or of his authorized representative established within the Community. Such equipment

and/or assemblies must not bear the CE marking referred to in Article 15.

Samengevat;

Voor een 90 bar vat V<1 liter is goed vakmanschap, gebruikers instructies en een indentificatieplaat

voldoende.

Voor het zelfde vat tot V<2.22 liter valt deze in categorie I van de PED en moet je aan de regels van

module A voldoen (zie hierboven)

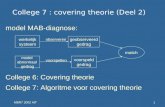

Voor het zelfde vat tot V<11.11 val je in categorie II en moet je voor een van de modules kiezen te

weten A1, D1 of E1

Deze regels moet je volgen voor het maken van een drukvat (accumulator), maar waar je bij DESY aan

moet denken is dat je een complete koelmachine gaat maken, ik heb nog niet verdiept aangaande de

regels voor een koelmachine volgens de Europese richtlijnen!

Groeten Ad