Model ZW4000 - American Fire Supply · 2017. 9. 1. · Zurn Industries, LLC | Wilkins 1747 Commerce...

Transcript of Model ZW4000 - American Fire Supply · 2017. 9. 1. · Zurn Industries, LLC | Wilkins 1747 Commerce...

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. D

Date: 10/15

Document No. FV-ZW4000

Product No. Model ZW4000

Model ZW4000

Pressure-Tru™ Fire Hose Valve

Page 1 of 5

ApplicationThe Pressure-Tru™ ZW4000 Series Pressure Reducing Valve

is listed as a standpipe valve for individual hose stations in

CLASS I and CLASS III systems. Regulates pressure under

both FLOW and NO-FLOW conditions.

Standards Compliance• �UL® Listed

• �C-UL® Listed

• �NYC MEA 325-06-E

• City of Los Angeles Approved

MaterialCastings/internals Cast bronze ASTM B 584

Elastomers Buna Nitrile (FDA approved)

EPDM (FDA approved)

FeaturesSizes: 2 1/2"

Maximum inlet pressure 400 psi

Inlet connection: (FNPT) or ANSI B1.20.1

(Grooved) AWWA C606

Outlet connection: Male Hose (NH) NFPA 1963

Factory Set

Tapped and plugged inlet and outlet for pressure gauge.

� � � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � !" � # $ $ $ % $ & ' ( ) & * % $ ) + # * % ' # % + , ) - ' # & $ - - ' % * ( % - % ' ) ( , % , ( � *" � # $ $ $ � � % % % ' ) ) , ) % $ % ' ) ) * & * % ' # % + , ) - ' ( * $ & % ' ) % , % ( - ' % * ) $ ( ) - % $ � #" � # $ $ $ � % % + ' % * ) ( & % $ & ' % * ) * + * % ' # % + , - + ' % * ( # - - ' % * ( % - % ' ) ( , % ( ( � %" � # $ $ $ � � � % % % ' ) ) , ) % $ % ' ) ) * & * % ' # % + , ) - ' ( * $ ( - ' # ) ) ) ( - ' % * ) $ ( ) - % $ � #" � # $ $ $ � . % $ & ' ( ) & * % $ ) + # * % ' # % + , ) - ' # & $ - % + ' % * % $ $ - % ' ) ( , % , ( � *

Options(Suffixes can be combined)

�c ZW4000 - angle type valve

�c IL - in-line (globe type) valve

�c G - with grooved inlet connection

�c SF - with San Francisco hose thread (3”)

�c ST - with specified hose thread

�c CC - with cap and chain

�c CH - with chrome finish

ZW4000 ZW4000G

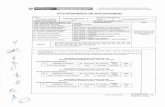

Dimensions & Weights (do not include pkg.)

AA

RADIUS

OF SWING

B

D

B

C

D

E

ERADIUS

OF SWING

C

A

RADIUS

OF SWING

B

C

D

E

A

B

D

ERADIUS

OF SWING

C

ZW4000G ZW4000ILG ZW4000 ZW4000IL

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 2 of 5

Residual Pressure ChartsFor Pressure-Tru® 2 1/2” Models: ZW4000, ZW4000G, ZW4004 & ZW4004G

Choosing The Correct SettingsIn designing a sprinkler system, a minimum of 20 psi pressure differential (the difference

between the inlet static pressure and the valve outlet set static pressure) is recommended

to assure a well regulated and efficient system. In choosing the correct setting for the

Pressure-Tru® valve, refer to the Residual Pressure Charts, Static Pressure Chart and the

following procedures:1. Determine the demand in gallons per minute required downstream of the valve.2. Determine the standpipe residual or “flow pressure” at the valve inlet.3. Locate the appropriate flow chart based on GPM required and body style.4. Locate the inlet residual pressure on the vertical axis of the chart and draw a horizontal line from this pressure across the chart.5. Locate the desired valve outlet residual pressure on the horizontal axis of the chart and draw a vertical line from this pressure.6. The curve nearest the intersection of the two lines drawn is the appropriate type for the valve.7. To determine the static outlet pressure, locate the static chart. Determine the valve inlet static pressure shown on the vertical axis and draw a horizontal line from that pressure to the appropriate curve determined above, then draw a vertical line down to the horizontal axis and read the static outlet pressure.

Maximum Rated Inlet PressureMaximum inlet pressure, to

assure a maximum outlet

pressure of 175 psi. Inlet side

of valves can be safely tested

up to 400 PSI during system

hydrostatic leak test./ 0 1 1 2 3 4 5 6 7 1 8 2 3 9 : 2 ; ; < : 2= > ? 2 ? ; @ A B ? 5 CD E F F A G H I F CJ E F F A G H I F C9 K L F A G E H I CM K N F A G N G I CO G P F A G F F F CQ G I F A N H G I C= G G I A N I I F CR G F F A N K H I C

ANGLE BODY (ALL)

50-200 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE BODY (ALL)

201-300 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE BODY (ALL)

301-400 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE BODY (ALL)

401-500 GPM

N O

P

QR

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (NPT)

201-300 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Residual Pressure ChartsFor Pressure-Tru® 2 1/2” Models: ZW4000IL & ZW4004IL

INLINE BODY (NPT)

50-100 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (NPT)301-400 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Inle

t R

esid

ua

l (p

si)

INLINE BODY (NPT)101-200 GPM

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

N O

P

Q

R

S

T

U

INLINE BODY (NPT)

401-500 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE & INLINE BODIES (ALL)

STATIC CHART

N O P

Q

R

S

T

U

Inle

t S

tatic (

psi)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Static (psi)

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 ! Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 ! Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 3 of 5

Residual Pressure ChartsFor Pressure-Tru® 2 1/2” Models: ZW4000ILG & ZW4004ILG

INLINE BODY (GROOVED)

50-100 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ua

l (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

101-200 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ua

l (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

201-300 GPM

N O

P

Q

R

S

TU

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

301-400 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

401-500 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Proper performance is dependent upon licensed, quali-

fied personnel performing regular, periodic testing ac-

cording to ZURN WILKINS' specifications and prevailing

governmental & industry standards and codes and upon

following these installation instructions. Failure to do so re-

leases ZURN WILKINS of any liability that it might otherwise

have with respect to that device. Such failure could also

result in an improperly functioning device.

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 " Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 " Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 4 of 5

S T U V V W X V Y X Z[ Y \ ] X ^ V _ ` a U b X c _ X _ d Y ] X e f g h i f j k V W X e U b X c _ l V m \ U n o p p q r s q r r t p u v w x qy U b V z X { { {| ] V } X ^ V _ ` | b V V ~ X _ d Y ] X e � j k V W X e U b X c _ � i y c � � y U c � Y � ] c e X _ { { {� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � � � � � � ¡ ¢ � � £ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ ¤ { {� � � � � � � � � � � S T U V V W X V Y X Z[ Y \ ] X ^ V _ ` a U b X c _ X _ ¥ Y _ W ¦ m � X b ~ � W V b ` ¦ � � e T U n o p p q r s q r r t p u v w x q§ V Y � e V b ¦ � � e T U ¨ V k c Y _ � U X X ] l V m \ U { { {| ] V } X ^ V _ ` | b V V ~ X _ ¥ Y _ W [ _ c � e X b ^ b c T © X e y c � � X _ ^ V Y Y X e y U b V z X � ] c e X _ { { {� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � ¡ � ª « £ � � ¡ « ¬ � £ ª � � � � � £ � £ � � ¬ ® ® � £ � « ¢ ® � ¬ ® � � ¯ { {° � ± � ¢ ¬ ² ª � ¢ ³ « � �´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´ ´

Exampleµ { ¶ · µ ¸ ¹ º » ¼ ¼ » � � ¢ � ½ � � ¢ ¾ � « « ¢ ¿ « ¢ « � À � � Á �  ¾ � � « ¢ � � � à S T U V V W X V Y X Z[ Y \ ] X ^ V _ ` a U b X c _ X _ ¥ Y _ W ¦ m � X b ~ � W V b ` ¦ � � e T U n o p p q r s q r r t p u v w x q§ V Y � e V b ¦ � � e T U ¨ V k c Y _ � U X X ] l V m \ U { { {| ] V } X ^ V _ ` | b V V ~ X _ ¥ Y _ W [ _ c � e X b ^ b c T © X e y c � � X _ ^ V Y Y X e y U b V z X � ] c e X _ { { {� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �Ä p r Å t Æ q Ç È É x Ê q r Å q x È Ë r p Ì É Í q Ë Î o Ì Ê Ï Í q Ð Ñ Ò Ó Ó Ò Ä Ô Õ s Ö × v { {

ZW4000 Series Fire Valve Part Number AssistantCheck off the boxes that match the choices you want. If the choice is blank, this is standard and you

add nothing to the part number. If there are letters after the check box, then you add those letters to the

part number in that order from left to right.

A bonnet setting has to be part of the part number since the ZW4000 series valves are factory set and not

field adjustable. The flow curves Must be used by the system designer to select the correct bonnet setting.

ü

ü

ü

ü

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 ! Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 ! Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. A

Date: 7/13

Document No. OF-ZW4000SERIES

Page 5 of 5

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. C

Date: 10/15

Document No. FV-ZW4004

Product No. Model ZW4004

Model ZW4004

Pressure-Tru ™ Automatic Fire Control Valve

Page 1 of 5

ApplicationThe Pressure-Tru™ ZW4004 Series Pressure Reducing Valve

is listed as a floor control valve, an indicating valve, and

a check valve in automatic sprinkler systems as well as a

standpipe valve for CLASS I and CLASS III systems. Regu-

lates pressure under both flow and no-flow conditions.

Standards Compliance• �UL® Listed

• �C-UL® Listed

• �NYC MEA 325-06-E

• City of Los Angeles Approved

• SS option - California State Fire Marshall Listed

MaterialCastings/internals Cast bronze ASTM B 584

Elastomers Buna Nitrile (FDA approved)

EPDM (FDA approved)

FeaturesSizes: � 2 1/2”

Maximum inlet pressure 400 psi

End connections (FNPT) ANSI B1.20.1

(Grooved) AWWA C606

Factory Set

Tapped & plugged inlet and outlet for pressure gauge

Options(Suffixes can be combined)

�c - angle type valve

c IL - in-line (globe type) valve

�c G - with grooved inlet and outlet connections

�c SS - with integral supervisory switch, contact

rating 3 amps @ 125 VAC and tamper

resistant cover

�c MSA - with monitor switch adapter

c CAP - with capped bonnet, no handwheel assembly

c CH - with chrome finish

� � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � !" # $ % & ' ( ) * + % , -. / 0 1 1 . / 0 1 1 . / 0 1 1 . / 0 1 1 . / 0 1 1 . / 0 1 1 2 3 4 5 67 � 8 9 9 8 : ; < = > ? ; < : ; ? 9 @ A : = 8 : @ B ; ? = 8 < 9 ? ? = : A B ; ? @ = > B ; ; 9 B7 � 8 9 9 8 � � : ? : = ; ? 8 ? : ; : = ; ? : > A : = 8 : @ B ; ? = > A 9 < : = ; : B : > ? = : A ; 9 > ; 8 : :7 � 8 9 9 8 � : ? @ = : A ? ? > : ; < = : A ? : A A : = 8 : @ B ? ? = : A > : ? ? = : A > : / = C / = C : B > 0 A7 � 8 9 9 8 � � � : ? : = ; ? 8 ? : ; : = ; ? : > A : = 8 : @ B ; ? = > A 9 > ? = 8 ; ; ; / = C / = C ; 8 : :7 � 8 9 9 8 � � � B ; ; B / = C / = C / = C / = C ; ? = 8 < 9 ? ? = : A > : ? @ = > B ; : A <7 � 8 9 9 8 � � � � � < : = 8 : > 8 / = C / = C / = C / = C ; ? = > A 9 < : = ; : B : < : = 8 : > 8 ; 9 B

D E F G G F H I J K L D E F G G F M J K L

Dimensions & Weights (do not include pkg.)

B

A

D

E

D

E

B

A

D

E

C

RADIUS

OF SWINGRADIUS

OF SWING

C

A

C

A

C

D

A

C

D

ERADIUS

OF SWING

OPEN

D

E

A

ZW4004 ZW4004CAP ZW4004IL ZW4004G ZW4004ILG ZW4004ILGCAP

Residual Pressure ChartsFor Pressure-Tru® 2 1/2” Models: ZW4000, ZW4000G, ZW4004 & ZW4004G

Choosing The Correct SettingsIn designing a sprinkler system, a minimum of 20 psi pressure differential (the difference

between the inlet static pressure and the valve outlet set static pressure) is recommended

to assure a well regulated and efficient system. In choosing the correct setting for the

Pressure-Tru® valve, refer to the Residual Pressure Charts, Static Pressure Chart and the

following procedures:1. Determine the demand in gallons per minute required downstream of the valve.2. Determine the standpipe residual or “flow pressure” at the valve inlet.3. Locate the appropriate flow chart based on GPM required and body style.4. Locate the inlet residual pressure on the vertical axis of the chart and draw a horizontal line from this pressure across the chart.5. Locate the desired valve outlet residual pressure on the horizontal axis of the chart and draw a vertical line from this pressure.6. The curve nearest the intersection of the two lines drawn is the appropriate type for the valve.7. To determine the static outlet pressure, locate the static chart. Determine the valve inlet static pressure shown on the vertical axis and draw a horizontal line from that pressure to the appropriate curve determined above, then draw a vertical line down to the horizontal axis and read the static outlet pressure.

Maximum Rated Inlet PressureMaximum inlet pressure, to

assure a maximum outlet

pressure of 175 psi. Inlet side

of valves can be safely tested

up to 400 PSI during system

hydrostatic leak test.N O P P Q R S T U V P W Q R X Y Q Z Z [ Y Q\ ] ^ Q ^ Z _ ` a ^ T bc d e e ` f g h e bi d e e ` f g h e bX j k e ` f d g h bl j m e ` f m f h bn f o e ` f e e e bp f h e ` m g f h b\ f f h ` m h h e bq f e e ` m j g h b

ANGLE BODY (ALL)

50-200 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE BODY (ALL)

201-300 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE BODY (ALL)

301-400 GPM

N O

P

QR

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE BODY (ALL)

401-500 GPM

N O

P

QR

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 2 of 5

INLINE BODY (NPT)

201-300 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Residual Pressure ChartsFor Pressure-Tru® 2 1/2” Models: ZW4000IL & ZW4004IL

INLINE BODY (NPT)

50-100 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (NPT)301-400 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Inle

t R

esid

ua

l (p

si)

INLINE BODY (NPT)101-200 GPM

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

N O

P

Q

R

S

T

U

INLINE BODY (NPT)

401-500 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

ANGLE & INLINE BODIES (ALL)

STATIC CHART

N O P

Q

R

S

T

U

Inle

t S

tatic (

psi)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Static (psi)

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 3 of 5

Residual Pressure ChartsFor Pressure-Tru® 2 1/2” Models: ZW4000ILG & ZW4004ILG

INLINE BODY (GROOVED)

50-100 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ua

l (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

101-200 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ua

l (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

201-300 GPM

N O

P

Q

R

S

TU

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

301-400 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

INLINE BODY (GROOVED)

401-500 GPM

N O

P

Q

R

S

T

U

Inle

t R

esid

ual (p

si)

50

100

150

200

250

300

350

400

20 40 60 80 100 120 140 160

Outlet Residual (psi)

Proper performance is dependent upon licensed, quali-

fied personnel performing regular, periodic testing ac-

cording to ZURN WILKINS' specifications and prevailing

governmental & industry standards and codes and upon

following these installation instructions. Failure to do so re-

leases ZURN WILKINS of any liability that it might otherwise

have with respect to that device. Such failure could also

result in an improperly functioning device.

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 4 of 5

Page 5 of 5

r s t u u v w u x w yz x { | w } u ~ � � t � w � ~ w ~ � x | w � � � � � � � � u v w � t � w � ~ � u � { t � � � � � � � � � � � � � � � � �� t � u � w � � �� | u � w } u ~ � � � u u � w ~ � x | w � � � � u v w � t � w � ~ � � � � ¡ � t � ¢ x £ | � � w ~ � � �¤ ¥ ¦ § § ¨ © § ª © « ¤ ¥ ¦ § § ¨ © § ª © « ¬ © ¥ ® ¯ ° ± ¦ ² © ¯ ³ ¤ § ´ ® § ª ¯ ° « ¤ § ´ ® § ª ¯ ° «µ ¶ · ¸ ¹ º » ¼ ¶ · ¸ ¹ ½ ¾ ¿ À Á · ½  à à à à à à à à à à à à à à à à à à à � �¤ ¥ ¦ § § ¨ © § ª © « r s t u u v w u x w yz x { | w } u ~ � � t � w � ~ w ~ Ä x ~ v Å � w � � ¢ v u � � Å � ¢ � s t � � � � � � � � � � � � � � � � �Æ u x ¢ � u � Å � ¢ � s t Ç u � � x ~ � t w w | � u � { t � � �� | u � w } u ~ � � � u u � w ~ Ä x ~ v z ~ � � w � } � � s È w � � � w ~ } u x x w � � t � u � w £ | � � w ~ � � �¤ ¥ ¦ § § ¨ © § ª © « ¤ ¥ ¦ § § ¨ © § ª © « ¤ ¥ ¦ § § ¨ © § ª © § ² ª § ª © « ¤ § ´ ® § ª ¯ ° «µ ¶ · ¸ ¹ º » ¹ º ¿ À · É Ê Â » ¼ À Ê Ë ¾ Â É · ¿ ½ ¶ ¶ ·  ½ Ì Â ¶ ¾ Ë Í Í ·  º Ê Á Í ½ Ë Í · ¼ Î � �Ï ¿ » Ð ½ Á ¿ Ì Ë Ñ É · Á Ò Ê ¿ · ¼Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó ÓÓ Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó ÓÓ Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó ÓÓ Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó

ExampleÔ � Õ Ö Ô × Ø Ù Ú Û Û Ú µ ¶ Á ¹ Ì Ü ¾ · Á Ý ¾ Ê Ê Á Þ Ê Ì ¿ Á Ê ¾ ß ½ ¾ à · á Ý ½ ¸ ¿ Ê Á » µ · ¿ â r s t u u v w u x w yz x { | w } u ~ � � t � w � ~ w ~ Ä x ~ v Å � w � � ¢ v u � � Å � ¢ � s t � � � � � � � � � � � � � � � � �Æ u x ¢ � u � Å � ¢ � s t Ç u � � x ~ � t w w | � u � { t � � �� | u � w } u ~ � � � u u � w ~ Ä x ~ v z ~ � � w � } � � s È w � � � w ~ } u x x w � � t � u � w £ | � � w ~ � � �¤ ¥ ¦ § § ¨ © § ª © « ¤ ¥ ¦ § § ¨ © § ª © « ¤ ¥ ¦ § § ¨ © § ª © § ² ª § ª © « ¤ § ´ ® § ª ¯ ° «ã � � ä � å � æ ç è � é � � ä � � ç ê � � ë è ì � ê í � ë é î ì � ï ð ñ ò ò ñ ã ó ô � õ ö � � �

ZW4000 Series Fire Valve Part Number AssistantCheck off the boxes that match the choices you want. If the choice is blank, this is standard and you

add nothing to the part number. If there are letters after the check box, then you add those letters to the

part number in that order from left to right.

A bonnet setting has to be part of the part number since the ZW4000 series valves are factory set and not

field adjustable. The flow curves Must be used by the system designer to select the correct bonnet setting.

ü

ü

ü

ü

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. A

Date: 7/13

Document No. OF-ZW4000SERIES

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. C

Date: 5/15

Document No. FV-ZW4100

Product No. Model ZW4100

Model ZW4100

Pressure-Tru™ Fire Hose Valve

Page 1 of 4

ApplicationThe Pressure-Tru™ ZW4100 Series Pressure Reducing Valve

is listed as a standpipe valve for individual hose stations in

CLASS II systems. Regulates pressure under both flow and

no-flow conditions.

Standards Compliance• UL® Listed

• C-UL® Listed

MaterialsCastings/internals Cast bronze ASTM B 584

Elastomers Buna Nitrile (FDA approved)

EPDM (FDA approved)

FeaturesSizes: 1 1/2"

Maximum inlet pressure 400 psi

Inlet connection:

FNPT ANSI B1.20.1

Grooved AWWA C606

Outlet connection: Male Hose (NH) NFPA 1963

Factory Set

� � � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � !" � # $ % % & ' ( # $ ) $ & $ ( * $ + + # $ % $ , + $ , $ ( , & ' , + ( * & * - #" � # $ % % � & ' ( # $ ) $ & $ ( * $ + + # $ % $ , ' ( * & % , $ ( , & ' � ( � ( - #

A

C

DD

E

C

ZW4100 ZW4100G

BB

RADIUS

OF SWING

A

ZW4100

Options(Suffixes can be combined)

c ZW4100 - angle type valve

c G - with grooved inlet connection

c ST - with specified hose thread

c CC - with cap and chain

c CH - with rough chrome finish

Dimensions & Weights (do not include pkg.)

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 2 of 4

. / 0 1 2 2 3 4 5 6 4 37 8 9 1 : ; < = >; 21 2 21 ; 2: 2 2: ; 2? 2 2? ; 20 2 2

: 2 0 2 8 2 @ 2 1 2 2 1 : 2 1 0 2A B C D E C F E G H I B J D K L M N OPQRSTUSVPWXYRZ [\]̂

_ ` a b c c d e f g e dh i j k i l m no cp q qp i qh q qh i qr q qr i qs q q

t c s q u q v q p q q p h q p s qw x y z { y | { } ~ � x � z � � � � ��������������� ����Residual Pressure ChartsFor Pressure-Tru® 1 1/2” Models: ZW4100, ZW4100G, ZW4104 & ZW4104G

Maximum Rated Inlet PressureMaximum inlet pressure, to assure a maxi-

mum outlet pressure of 175 psi. Inlet side

of valves can be safely tested up to 400

PSI during system hydrostatic leak test.� � � � � �� � � � � � � � ¡ � � ¢ £ � ¤ ¤ ¥ £ �� ¤ ¦ § ¨ � � ©ª « ¬ ¬ ® ¯ ° ¬ ±² « ¬ ¬ ® ¯ ° ¬ ±³ « ¬ ¬ ® ¯ ° ¬ ±´ µ ¶ ¬ ® « ¯ ° ±· µ ® ° ® ® « ¬ ±¸ ® ¹ ¬ ® ¬ ¬ ¬ ±º ® « ¬ » ¶ ° ¬ ±¼ ® ¬ ¬ » µ ¯ ° ±

½ ¾¿ À Á  ÃÄ

½ ¾¿ À Á ÃÄ

Proper performance is dependent upon licensed, qualified personnel performing regular, periodic testing according to

WILKINS’ specifications and prevailing governmental & industry standards and codes and upon following these installation

instructions. Failure to do so releases WILKINS of any liability that it might otherwise have with respect to that device. Such

failure could also result in an improperly functioning device.

Choosing The Correct SettingsIn designing a sprinkler system, a minimum of 20 psi pressure differential (the

difference between the inlet static pressure and the valve outlet set static

pressure) is recommended to assure a well regulated and efficient system. In

choosing the correct setting for the Pressure-Tru® valve, refer to the Residual

Pressure Charts, Static Pressure Chart and the following procedures:1. Determine the demand in gallons per minute required downstream of the valve.2. Determine the standpipe residual or “flow pressure” at the valve inlet.3. Locate the appropriate flow chart based on GPM required and body style.4. Locate the inlet residual pressure on the vertical axis of the chart and draw a horizontal line from this pressure across the chart.5. Locate the desired valve outlet residual pressure on the horizontal axis of the chart and draw a vertical line from this pressure.6. The curve nearest the intersection of the two lines drawn is the appropriate

type for the valve.

7. To determine the static outlet pressure, locate the static chart. Determine the valve inlet static pressure shown on the vertical axis and draw a horizontal line from that pressure to the appropriate curve determined above, then draw a vertical line down to the horizontal axis and read the static outlet pressure.

Å Æ Ç È É É Ê Ë Ì Í Ë ÊÈ Î Ï Ð È Ñ É Ò Ó ÔÑ ÉÈ É ÉÈ Ñ ÉÎ É ÉÎ Ñ ÉÕ É ÉÕ Ñ ÉÇ É É

Î É Ç É Ï É Ö É È É É È Î É È Ç É× Ø Ù Ú Û Ù Ü Û Ý Þ ß Ø à Ú á â ã ä åæçèéêëéìæíîïèð ñòóô

õ ö ÷ ø ù ù ú û ü û ý þ þ ÿ ü � û� �� � �� � �� � �� � �� � �� � �� � �

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � ������������� !"#

Å Æ Ç È É É Ê Ë Ì Í Ë ÊÈ $ Ï Ð Î É É Ò Ó ÔÑ ÉÈ É ÉÈ Ñ ÉÎ É ÉÎ Ñ ÉÕ É ÉÕ Ñ ÉÇ É É

Î É Ç É Ï É Ö É È É É È Î É È Ç É× Ø Ù Ú Û Ù Ü Û Ý Þ ß Ø à Ú á â ã ä åæçèéêëéìæíîïèð ñòóô

Å Æ Ç È É É Ê Ë Ì Í Ë ÊÈ Ñ È Ð È $ Ñ Ò Ó ÔÑ ÉÈ É ÉÈ Ñ ÉÎ É ÉÎ Ñ ÉÕ É ÉÕ Ñ ÉÇ É É

Î É Ç É Ï É Ö É È É É È Î É È Ç É× Ø Ù Ú Û Ù Ü Û Ý Þ ß Ø à Ú á â ã ä åæçèéêëéìæíîïèð ñòóô

Residual Pressure ChartsFor Pressure-Tru® 1 1/2” Models: ZW4100, ZW4100G, ZW4104 & ZW4104G

% &' ( )* + ,

% &' ( ) * + ,

%&' ( ) * +,

%&' ( ) * +,

Page 3 of 4

Page 4 of 4

Example- . - / 0 1 2 3 4 - 5 4 6 7 8 9 : ; < = 8 > < ? ? 8 @ ? : A 8 ? < B C < D = ? 8 E ? F = G C H ; B C < D = I > C H A ? 8 J 6 = A K L M N O O P Q O R Q ST R U V Q W O X Y Z N [ Q \ X Q X ] R X P ^ _ ` Q [ a b P O [ Y ^ c b d M N e f g g h i j h i i k g l m n o hp O R b d O [ ^ c b d M N q O r \ R X c N Q Q V s O _ U N . . .t [ O O a Q X ] R X P T X \ ` d Q [ W [ \ M u Q d v \ ` ` Q X W O R R Q d v N [ O w Q x V \ d Q X@ E . . .y z { | | } ~ | � ~ � y z { | | } ~ | � ~ � y z { | | } ~ | � ~ | � � | � ~ � y | � � � | � � � �� g i � k � h � � � o � h i � h o � � i g � � � h � � f � � � � h � � � � � � � j � � � . .L M N O O P Q O R Q ST R U V Q W O X Y Z N [ Q \ X Q X � R V Q d � � � � � q \ d b O R \ V r O P Q d N [ Q \ X s O _ U N e f g g h i j h i i k g l m n o hv N [ O w Q . . .t [ O O a Q X � R V Q d ^ ` Q M b \ V Z N [ Q \ X c � v \ ` ¡ v N \ b R x V \ d Q X . . .y z { | | } ~ | � ~ � y z { | | } ~ | � ~ � y z { | | } ~ | � ~ � y | � � � | � � � � y | � � � | � � � �6 7 = H 9 ¢ J F 7 = H 9 C < A £ 8 = C ¤ ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥ ¥ . .¦ § ¦ ¨ © ª « ¬ ¦ ® ¯ ° ± ² ³ ´ µ ¶ ± · µ ¸ ¸ ± ¹ ¸ ³ º ± ¸ µ » ¼ µ ½ ¶ ¸ ± ¾ ¸ ¿ ¶ À ¼ Á ´ » ¼ µ ½ ¶  · ¼ Á º ¸ ± à ¯ ¶ º Ä L M N O O P Q O R Q ST R U V Q W O X Y Z N [ Q \ X Q X ] R X P ^ _ ` Q [ a b P O [ Y ^ c b d M N e f g g h i j h i i k g l m n o hp O R b d O [ ^ c b d M N q O r \ R X c N Q Q V s O _ U N . . .t [ O O a Q X ] R X P T X \ ` d Q [ W [ \ M u Q d v \ ` ` Q X W O R R Q d v N [ O w Q x V \ d Q X . . .y z { | | } ~ | � ~ � y z { | | } ~ | � ~ | � � | � ~ � y | � � � | � � � � . .Å A J Æ C 8 A : Ç È É = 8 Ê ? A = FË Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë ËË Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë ËË Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë ËË Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë Ë

ZW4100 Series Fire Valve Part Number AssistantCheck off the boxes that match the choices you want. If the choice is blank, this is standard and you

add nothing to the part number. If there are letters after the check box, then you add those letters to the

part number in that order from left to right.

A bonnet setting has to be part of the part number since the ZW4100 series valves are factory set and not

field adjustable. The flow curves Must be used by the system designer to select the correct bonnet setting.

ü ü

ü ü

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 ! Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 ! Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. A

Date: 7/13

Document No. OF-ZW4100SERIES

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. C

Date: 5/15

Document No. FV-ZW4104

Product No. Model ZW4104

Model ZW4104Pressure-Tru™ Automatic Fire Control Valve

Page 1 of 4

B B

A A

CC

DDE

ZW4104GZW4104

RADIUS

OF SWING

AA

C C

DD

E

ZW4104CAP ZW4104GCAP

RADIUS

OF SWING

OPEN OPEN

B B

� � � � � �

ApplicationThe Pressure-Tru™ ZW4104 Series Pressure Reducing Valve

is listed as a floor control valve, an indicating valve, and

a check valve in automatic sprinkler systems as well as a

standpipe valve for CLASSII systems. Regulates pressure

under both flow and no-flow conditions.

Standards Compliance• �UL® Listed

• �C-UL® Listed

• SS option - California State Fire Marshall Listed

MaterialCastings/internals Cast bronze ASTM B 584

Elastomers Buna Nitrile (FDA approved)

EPDM (FDA approved)

FeaturesSizes: 1 1/2”

Maximum inlet pressure 400 psi

End connections:

FNPT ANSI B1.20.1

Grooved AWWA C606

Factory Set

� � � � � � � � � � � � � � � � � � � � � � � �� � � � � �� � � � � � � � � � � � � � � ! � " # � $� % � & '� & ( � � � & ( � � � & ( � � � & ( � � � & ( � � � & ( � � ) * # + ', � - . / - 0 1 2 - . 3 . 0 . 2 4 . 5 5 - . / . 6 5 . 6 1 2 . 0 5 5 6 1 2 . 0 5 5 7 -, � - . / - � 0 1 2 - . 3 . 0 . 2 4 . 5 5 - . / . 6 1 2 4 0 / 6 . 2 6 0 1 & 2 � & 2 � 7 -, � - . / - � � � - 5 2 4 . . 3 & 2 � & 2 � 1 1 2 - 7 5 6 5 . 6 1 2 . 0 5 5 6 1 2 . 0 5 5 4 1 ( 5, � - . / - � � � � - 5 2 4 . . 3 & 2 � & 2 � 1 1 2 - 7 5 6 1 2 4 0 / 6 . 2 6 0 1 & 2 � & 2 � 4 1 ( 5Dimensions & Weights (do not include pkg.)

Options(Suffixes can be combined) ZW4104 - angle type valve�c G - with grooved inlet and outlet connections�c SS - with integral supervisory switch, contact rating 3 amps @ 125 VAC and tamper resistant cover�c MSA - with monitor switch adapter�c CAP - with capped bonnet, no handwheel assemblyc CH - with rough chrome finish

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 � Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 � Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com Page 2 of 4

8 9 : ; : < = = > : < ? @ : > A B B C D E F 9 G < H = I J K L B M M N J K L B M M O N J K L B M L P J K L B M L O

Choosing The Correct SettingsIn designing a sprinkler system, a minimum of 20 psi pressure differential (the difference

between the inlet static pressure and the valve outlet set static pressure) is recommended to

assure a well regulated and efficient system. In choosing the correct setting for the Pressure-

Tru® valve, refer to the Residual Pressure Charts, Static Pressure Chart and the following

procedures:

1. Determine the demand in gallons per minute required downstream of the valve.

2. Determine the standpipe residual or “flow pressure” at the valve inlet.

3. Locate the appropriate flow chart based on GPM required and body style.

4. Locate the inlet residual pressure on the vertical axis of the chart and draw a horizontal

line from this pressure across the chart.

5. Locate the desired valve outlet residual pressure on the horizontal axis of the chart

and draw a vertical line from this pressure.

6. The curve nearest the intersection of the two lines drawn is the appropriate type for

the valve.

7. To determine the static outlet pressure, locate the static chart. Determine the valve

inlet static pressure shown on the vertical axis and draw a horizontal line from that

pressure to the appropriate curve determined above, then draw a vertical line down to

the horizontal axis and read the static outlet pressure.

Maximum Rated Inlet PressureMaximum inlet pressure, to

assure a maximum outlet

pressure of 175 psi. Inlet

side of valves can be safely

tested up to 400 PSI during

system hydrostatic leak test.Q R S S T UV W X T Y Z [ \ S ] T U ^ _ T ` ` a _ TX ` b c d X Z ef g h h i j k l h mn g h h i j k l h mo g h h i j k l h mp q r h i j g k l ms q j l i j j g h mt j u h i j h h h mv j g h i w r l h mx j h h i w q k l m

y z { | } } ~ � � � � ~� � � � � � � �� }| } }| � }� } }� � }� } }� � }{ } }

� } { } � } � } | } } | � } | { }� � � � � � � � � � � � � � � � � � ������ �¡�¢£¤�¥ ¦§©̈ ª «¬ ® ¯ °±² ³ ´ µ ¶ ¶ · ¸ ¹ º ¸ ·» ¼ ½ µ ¾ ¿ À Á Â

¿ ¶µ ¶ ¶µ ¿ ¶¾ ¶ ¶¾ ¿ ¶Ã ¶ ¶Ã ¿ ¶´ ¶ ¶¾ ¶ ´ ¶ ¼ ¶ Ä ¶ µ ¶ ¶ µ ¾ ¶ µ ´ ¶Å Æ Ç È É Ç Ê É Ë Ì Í Æ Î È Ï Ð Ñ Ò ÓÔÕÖ×ØÙ×ÚÔÛÜÝÖÞ ßàáâ ª «¬ ®¯ °±

Proper performance is dependent upon licensed, qualified personnel performing regular, periodic testing according to

ZURN WILKINS’ specifications and prevailing governmental & industry standards and codes and upon following these

installation instructions. Failure to do so releases ZURN WILKINS of any liability that it might otherwise have with respect

to that device. Such failure could also result in an improperly functioning device.

ã ä å æ å ç è è é å ç ê ë å é ì í í î ï ð ñ ä ò ç ó è ô õ ö ÷ í ø ø ù õ ö ÷ í ø ø ú ù õ ö ÷ í ø ÷ û õ ö ÷ í ø ÷ úü ý þ ÿ � � � � � � � �ÿ � � � ÿ � � �� �ÿ � �ÿ � �� � �� � �� � �� � �þ � �

� � þ � � � � ÿ � � ÿ � � ÿ þ �� � � � � � � � � � � � � � � � � � ���� !" #�$%&�' ()*+

, - . / 0 0 1 2 3 2 4 5 5 6 3 7 28 9: 9 9: 8 9; < <= > ?@ ? ?@ > ?A ? ?

B 9 C 9 D 9 E < F ? ? F = ? F A ? F G ?H I J K L J M J N J O P Q R S T UVWXYZ[Z\ZV]̂ _̀ab

ü ý þ ÿ � � � � � � � �ÿ c � � � � � �� �ÿ � �ÿ � �� � �� � �� � �� � �þ � �

� � þ � � � � ÿ � � ÿ � � ÿ þ �� � � � � � � � � � � � � � � � � � ���� !" #�$%&�' ()*+

ü ý þ ÿ � � � � � � � �ÿ � ÿ � ÿ c � �� �ÿ � �ÿ � �� � �� � �� � �� � �þ � �

� � þ � � � � ÿ � � ÿ � � ÿ þ �� � � � � � � � � � � � � � � � � � ���� !" #�$%&�' ()*+d ef g hi j k

d ef g h i j k

def g h i jk

def g h i jk

Page 3 of 4

Page 4 of 4

Examplel m l n o p q r s l t s u v w x y z { | w } { ~ ~ w � ~ y � w ~ { � � { � | ~ w � ~ � | � � � z � � { � | � } � � � ~ w � u | � � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � � � � � � � ¡ � � � � � ¢ ¡ £ � � ¤ ¥ ¦ ¦ § ¨ © § ¨ ¨ ª ¦ « ¬ ® §¯ � � ¡ £ � � � ¢ ¡ £ � � ° � ± � � � ¢ � � � � ² � � � � m m m³ � � � � � � � � � � � � � £ � � � � � � ´ � £ µ � � � � � � � � � � £ µ � � � ¶ � · � � £ � �� � m m m¸ ¹ º » » ¼ ½ » ¾ ½ ¿ ¸ ¹ º » » ¼ ½ » ¾ ½ ¿ ¸ ¹ º » » ¼ ½ » ¾ ½ » À ¾ » ¾ ½ ¿ ¸ » Á  à » ¾ Ä Å ¿Æ ¦ ¨ Ç ª È § É Ê Ë ® Ì § ¨ Ç § ® Ê Í ¨ ¦ Î Ë Ï § Í Ð ¥ Î Ì Ñ Ï § Ò Ó Ô Õ Ö Ô × © Ø Ù × m m� � � � � � � � � � �� � � � � � � � � � � � � � � � � Ú � � � £ Û Ü Û Ý Þ ß ° � £ ¡ � � � � ± � � � £ � � � � � ² � � � � ¤ ¥ ¦ ¦ § ¨ © § ¨ ¨ ª ¦ « ¬ ® §µ � � � ¶ � m m m³ � � � � � Ú � � � £ � � � � ¡ � � � � � � � � ¢ Ý µ � � à µ � � ¡ � · � � £ � � m m m¸ ¹ º » » ¼ ½ » ¾ ½ ¿ ¸ ¹ º » » ¼ ½ » ¾ ½ ¿ ¸ ¹ º » » ¼ ½ » ¾ ½ ¿ ¸ » Á  à » ¾ Ä Å ¿ ¸ » Á  à » ¾ Ä Å ¿u v | � x á � � v | � x � { � â w | � ã ä ä ä ä ä ä ä ä ä ä ä ä ä m må æ å ç è é ê ë ì å í ì î ï ð ñ ò ó ô õ ð ö ô ÷ ÷ ð ø ÷ ò ù ð ÷ ô ú û ô ü õ ÷ ð ý ÷ þ õ ÿ û � ó ú û ô ü õ � ö û � ù ÷ ð � î õ ù � � � � � � � � � � � �� � � � � � � � � � � � � � � � � � � � � � � � � � ¡ � � � � � ¢ ¡ £ � � ¤ ¥ ¦ ¦ § ¨ © § ¨ ¨ ª ¦ « ¬ ® §¯ � � ¡ £ � � � ¢ ¡ £ � � ° � ± � � � ¢ � � � � ² � � � � m m m³ � � � � � � � � � � � � � £ � � � � � � ´ � £ µ � � � � � � � � � � £ µ � � � ¶ � · � � £ � � m m m¸ ¹ º » » ¼ ½ » ¾ ½ ¿ ¸ ¹ º » » ¼ ½ » ¾ ½ » À ¾ » ¾ ½ ¿ ¸ » Á  à » ¾ Ä Å ¿ m m� � � � � w � y � � � | w ~ � | �

ZW4100 Series Fire Valve Part Number AssistantCheck off the boxes that match the choices you want. If the choice is blank, this is standard and you

add nothing to the part number. If there are letters after the check box, then you add those letters to the

part number in that order from left to right.

A bonnet setting has to be part of the part number since the ZW4100 series valves are factory set and not

field adjustable. The flow curves Must be used by the system designer to select the correct bonnet setting.

ü ü

ü ü

Zurn Industries, LLC | Wilkins1747 Commerce Way, Paso Robles, CA U.S.A. 93446 ! Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited3544 Nashua Drive, Mississauga, Ontario L4V 1L2 ! Ph. 905-405-8272, Fax 905-405-1292

www.zurn.com

Rev. A

Date: 7/13

Document No. OF-ZW4100SERIES