Freon, a Refrigerant

Transcript of Freon, a Refrigerant

Freon, a Refrigerant

1 i ways lieen an essential i n inany iii- dustrics, and particu- larly in t i le ciiemiaa.1 industry. Icewasthe first and only refrig- eration medium fo r many centuries, but there were so many disadvantages con- Iiected with its u s ~ that other incans wore s o u g h t , and it iviyiis

fiiiind that a nuiiiliiir OS liquids aiid giyiisea could be used to pro- duce re f r igera t ion . There are two princi- pal m e t h o d s b y which they are em- ployed: one, gener- a l ly r e fe r r ed to as the indirect niet.hod.

K. J. 'faowsoru, Kinetic Chemicals, Irtc., Wilmington, Del.

wliidi still has proper- tics especially favor- ab le to economic operation. Freon is adaptable for use in all compn:ssion types of refrigerating sys- tems, and tests have s2ion.n that it closely approaches tlre ideal refrigerant.

T 11 e p li y s i c a I , cliemical, and the r - inodgnainic p r o per - t i es of Freon !lave liceii ca re fu l ly and fully studied, and the va lues h a v e been m a d e a v a i l a b l e throogli the publica- t i ons l i s ted a t the cud of t h i s p a p e r . These da t a furn ish

is the circulation of cooled solutiuna; the otlwr, the direct method, is the circulation and expansion of the refrigeralit itself. Refrigerat.ion, either by the direct or indirect method, was ks t employed almost entirely in industrial applications,

iiiformation that is neceasar~- to intelligently design and operate tiis plant; hoverer, a fen- outstanding properties will he discussod briefly.

hut was aft,erward extended to take the place of ice in coiii- Cr<e3lIC.&l. i'i%OPEl%'l~iES mercial uses as well, and more recently has been adapt,ed to household refrigerating equipment.

Unfortunately there were certain itrliereiit hazards in the use of the refrigerants employed; and, while the liazards could be fairly well controlled in industria1 refrigeration because suitable precautions could be enforced, their control was not practicable in commercial and liousehold refrigerating systems.

B'rcon or diehlorodifluorometlrane is a colorli:ss, almost odorless gas, boiling point -29.8" C. at 760 rnm. (-21.7' F. at 29.92 inches alxolutc). It is nontoxic, noncorrosive, notiirritating, and noninflamniable. It is generally prepared by replacing chlorine in carbon tetracbloride Kitti fluorine. Cliemically it is inert at ordi,,ary tllemallr stable up to 550" c. (low F.).

The chief lrasards mere those of fires and explosions of tlre rcfrirrertants themselves, liealtli hazards duo to the lxiei tv of the i & p r a n t s , the hazards due to clicrniw~l reuctioik resulting from the accidental introductiorr of the refrigerant Sroni the cooling system into tlrc d, and in some casrs tlie haeards

I'resaures required to IiqueSy the refrigerant vapors affect the drsign of the apparatus; the specific volume per pound of tlie refrigerant vapor from the evaporator deternlillcs the

liston displacement of the com- nrcssor: and tlie latent hcat of .. ~ ~ ~~~~ ~~~. ~ . . . ..., ,i

The properties of saturated ant-une l1either inflamn1ablc nor toric nor capable of eti- teririg into dangerous chcnii-

be ope ra t ed a t r e l a t ive ly l o w pressures a n d wliieli retical displace.ment per minute would be eiiici(:nt and suitable Sor industrial, i~~i i i i i i i~r~i i l l , tier standard tuii reiruired for a Freon-charred compressor

reactions, whiell (!auld

. . apartmcnt bouse, iind iroiisehold refrigerat,ing tystenis.

Reon, sotnetirrics known as F-12 atid Kinetic KO. is dichlorodifluoroinethaiic (CC1,Ft) and was developed i n a deliberate attempt to produce, by cliemical arrangement, a refrigerant from which these hazards are eliminated and

(.MIS i:utic feet, or 164.73 liters) Ealis t&meen &thy1 diloride (6.434 cubic feet, or 182.26 liters) a.nd propane (3.868 mLic feet, or 109.57 liters), or ammonia (3.436 cubic feet, or 97.33 Mers). The displacement figures do not provide for superheat of vapors or the subcooling of the

620

June, 1932 I N D U S T R I A L A S D E N G I N E E R I N G C H E M I S T R Y 62 1

refrigerant liquid. The standard ton conditions, which include temperatures of 86" F. (30" C.), represent conditions in large commercial installations with water-cooled con- densers, but do not represent conditions in small air-cooled compressors. Thus, the calculations must not be taken as representative for small water- and air-cooled compressors.

Freon may be used in either water-cooled or air-cooled condensers owing to low head pressures and exceedingly low compression temperatures. The low temperature of adia- batic compression requires less condensing surface for the removal of superheat than is needed for certain other common refrigerants. For standard ton conditions, the actual displacement will be approximately 15 to 25 per cent more than the theoretical value and will be dependent upon the evaporator pressure, capacity of the compressor in tonnage, compressor speed, and refinement in design.

QUANTITIES OF LIQUID REFRIGERANT. While Freon has a relatively low latent heat value, this is not considered a disadvantage, as it merely means that more of the refrigerant must be circulated to produce the desired amount of re- frigeration. Actually, it is a decided advantage in small refrigerating machines, because the larger quantity of liquid circulated will permit the use of less sensitive, more accurate, and more positive operating and regulating mechanisms.

OPERATIKG PRESSURES. Freon operates a t low but positive head and back pressures and high volumetric effi- ciency. It permits light compressor construction, sim- plicity of design, great flexibility of application, high effi- ciency, quietness of operation, low manufacturing cost, and low installation and service costs. Furthermore, the low but positive pressure prevents moisture-laden air from entering the system which might cause the following adverse con- ditions: reduction of the coefficient of performance (ratio of indicated horsepower to refrigeration per minute) ; air lodging in the condenser and resulting in high head pressure; and moisture freezing interfering with the normal operation of the regulating valve.

DEKSITY OF VAPOR. Freon vapor a t 5" F. (-15" C.) and 11.81 pounds per square inch (0.830 kg. per centimeter) gage pressure is approximately three times as dense as methyl chloride, approximately four times as dense as sulfur dioxide or isobutane, and approximately five times as dense as ammonia. Thus, all restrictions to the free circulation of vapor should be avoided as far as possible to obtain maximum operating efficiency

THEORETICAL HORSEPOWER. The theoretical horsepower

per ton of refrigeration should be substantially the same under a given set of conditions for all refrigerants, with the possible exception of carbon dioxide. In the case of carbon dioxide the horsepower is somewhat higher because of the exceedingly high operating pressures.

DETECTIKG LEAKS. A Freon leak may be detected by means of a halide lamp. This lamp may be described as a torch burning alcohol, which, under normal conditions, produces a colorless flame. A tube fastened to the base of the burner is used to conduct the air suspected of con- taining Freon vapor through the flame and over metallic copper. Owing to the breaking down of the refrigerant in the flame, a volatile copper halide is formed, and the flame color changes from the normal colorless to bright green if the air contains as much as 0.01 per cent of Freon. A leak from a refrigerating system of 0.06 pound (27.2 grams) or more per month is easily detected by means of halide lamps now available. Such a leak would be equivalent to the escape of 1 ounce per month or 0.76 pound (340 grams) per year.

CORROSIVE ACTION Test specimens of aluminum, brass, cast iron, copper,

Dural metal, bronze, galvanized iron, Babbitt metal, lead, monel metal, magnesium alloy, silver, steel, tin solder, zinc, and k' metal, after being sealed in glass tubes with Freon under its own vapor pressure for 6 months a t a temperature of 235" F. (112.8' C,), showed no visible evidences of corrosion except for a slight darkening of the surfaces of the aluminum, brass, copper, bronze, lead, and zinc. There was no per- ceptible pitting of the surfaces of any of the specimens.

Freon, saturated with water a t 80 " F. (26.7 ' C.) and heated a t 235" F. (112.8" C.) for 4 months with the above metals, corroded only Y metal and magnesium alloy. Brass, copper, and lead were somewhat discolored but not corroded.

In refrigerating equipment there may be present a small amount of free water, but there will never be a suffi- ciently high temperature under normal operating conditions (109.5" F., or 43" C. Compression temperature-standard ton conditions) to cause corrosion of any of the metals used in compressor construction. Freon is only slightly soluble in water, and the solution formed will not corrode any of the common metals used in refrigeration construction.

The addition of mineral oil to Freon has no effect upon the corrosive action, except possibly to decrease the amount of discoloration caused by the free water. Neither the tensile

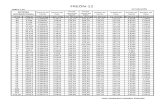

TABLE I. PROPERTIES OF SATURATED VAPORS UNDER STAXDARD TON CONDITIOSS ENGLISH T'ALUES hfETRIC \'.4LUES

Unit At 5' F. At 86" F. Unit A t -15' C. At 30' C. Absolute pressure Gage pressure Volume of liquid Volume of vapor Density of liquid Density of vapor Heat, liquid Heat, latent Heat vapor Entrhpy, liquid Entropy, evaporation Entropy vapor Sp. heat ' liquid Sp. heat: vapor C p Sp. heat, vapor C V Ratio C / C * Sp. gr., fiquid (yater 1) Sp . gr., vapor (air 1)

ritical pressure Critical temperature Critical volume Molecular weight Melting point Boiling point

Lb. per sq. in. Lb. per sq. in. Cu. ft. per lb. Cu. ft. per lb. Lb. per cu. ft. Lb. per cu. ft. B. t. u. per lb. B. t. u. per lb. B. t. u. per lb. B. t . u. per Ih. per F. B. t. u. per lb. per O F. B. t . u. per lb. per e F.

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . gb. per sq. in. abs.

Cu. f t . per lb. F.

. . . . . . . . . . . . . . . . . F. ' F.

26.51 11.81 0.0111 1.485

90.00 0.6735 9.32

107.9 93.2

0.0124 0.389

2.569 80 .63

27.72 69.47 59.65 78.79 87.37 0.02097 0.05708 0.14955 0.10932 0.17052 0.16640 0.214 0.243 0.1372 0.1476 0.1190 0.1297

1.138 (77' F.) 1.442 1,292

4.26

0,0289

580 233

120.9 -247 - 21.7

Kg. per sq. cm. Kg. per sq. cm. Liter per kg. Cu. meter per kg. Kg. per liter Kg. per cu. meter Kilocal. per kg. Kilocal. per kg. Kilocal. per kg. Kilocal. per kg. per C. Kilocal. per kg. per O C. Kilocal. per kg. per ' C.

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . , . . Ka. per sq. cm. ahs.

Liters per kg. c.

c. c. . . . . . . . . . . . . . . . . . . .

1.864 7.586 0.830 6.553 0.693 0.774 0,0927 0.0243 1.442 1.292

10.799 41.151 5.178 15.400

38.594 33.138 43.772 48,538

0.02097 0.05708 0.14955 0.10932

0.16640 0.17052 0.214 0 , 2 4 3 0.1372 0.1476 0.1190 0.1297

1.138 (25' C.) 1.442 1.292

4.26 40.7?8

1.804 111.7

120.9 -155 - 29.8

BTASDARD TON CONDITION@ Refrigerant per minute 3.916 lb. 1.776 kg. Refrigerant per minute 0.0485 cu. it. 1.374 liters Displacement per minute 5.815 cu. it. 164.73 liters Temp. of adiabatic compression 109.5 F. 43.0 ' C.

a The standard commercial ton of refrigeration is a t the rate of 200 B. t. u. (50.4 kilocalories) per minute, with an evaporator temperature of 5' F ( -15' C.) and a temperature of 86' F (30' C.) in the saturated portion of the condenser.

622 I N D U S T R I A L A K D E N G I N E E R I N G C H E M I S T R Y

strength nor the elongation of the metals exposed to Freon vapor for one year was affected.

INFLAMMABIIJTY Freon is noninflammable, and Freon-air mixtures are

nonexp1osiT.e. It has been impossible to obtain flame propagation in vapor-air mixtures when tested a t ordinary or even elevated temperatures, up to 1382' F. (750' C.), by application of either electric spark or gas flame.

A long series of tests, conducted by the Cnited States Bureau of Mines, showed that Freon has value for extin- guishing flames. It possesses specific flame-extinguishing power, the effect being almost identical with that of carbon tetrachloride (on a volumetric basis), owing largely to its heat capacity.

This refrigerant will permit installations to be made in locations where other refrigerants could not be used because of the hazard of fire.

For detailed information on inflammability, the student of this subject is referred to a United States Bureau of hlines Report ( 2 ) .

TOXICITY This subject was

carefully investigated by the United States Bureau of hlines (3).

In a room 20 x 20 x 10 feet or 4000 cubic feet (113.3 cubic meters), 250 pounds (113.4 kg.) of Freon (20 per cent by volume) can be introduced without exceeding a concen- tration that test animals have lived in for weeks without harmful physical effect, either immediate or delayed. It was possible to produce death of experimental animals only by concentrations high enough to exclude sufficient oxygen to support life. This is a striking demonstration of chemical stability and inertness. These advantages of Freon are not found in any other commonly used refrigerant, except carbon dioxide which is adaptable only to very large systems.

PRODUCTS OF DECOMPOSITION

Freon is nontoxic and nonirritating.

When Freon was fist offered as a refrigerant, and its properties were being investigated, extensive experiments were conducted to determine if a health hazard could be produced by the liberation of Freon in a confined space in the presence of open flames or other high temperatures. The products of decomposition of a refrigerant had not be- fore been given serious consideration during studies of its health hazard, because, with the exception of Freon and carbon dioxide, all commonly used refrigerants are inherently toxic or inflammable, or both.

The Underwriters Laboratories (4) made a careful investi- gation of this subject as it applies to Freon. For purposes of comparison, Kinetic Chemicals had the Jackson Laboratory of E. I. du Pont de Semours and Company (1) investigate this subject as it applies to other commonly used refrigerants.

Freon is a stable compound capable of undergoing, without decomposition, the physical changes to which a refrigerant is commonly subjected in a refrigerating system, involving repeated evaporations, compressions, condensations, and heat absorptions.

Freon and all other organic halides break down into the corresponding oxides and acids when heated to a high tempera- ture, such as an open flame, and when exposed t o the action of water vapor and oxygen. However, since Freon is non- inflammable, only the vapor which comes in actual and direct contact with flame or high temperature is decomposed. Furthermore, Freon vapors are heavy (more than four times as heavy as air) which minimizes the amount of vapor that

L'ol. 24, So. 6

would under ordinary conditions come in contact with the decomposing agent.

In comparing the toxicity of the products of decomposition of Freon with the toxicity of other commonly used refriger- ants, these facts should be taken into consideration: A pound of any of the other commonly used refrigerants, except carbon dioxide, expands into from 6.7 cubic feet (189.7 liters) to 25.4 cubic feet (719.5 liters) of gas a t 70' F. (21.1' C.), and every cubic inch of the gas is inherently toxic or inflammable. A pound of Freon expands into 3.3 cubic feet (93.4 liters) of gas, and only that portion which comes in actual contact with a flame or high temperature 1022' F. (550" C.) is decomposed into toxic gases. It should be noted that these gases of decomposition of Freon are principally halogen acids.

Freon has this additional advantage: Whereas, the other commonly used refrigerants, except carbon dioxide, are either highly inflammable or toxic, or both, Freon is itself noninflammable and nontoxic, and the conditions required to decompose it into harmful gases in normal use are very remote. But if, by reason of an unusual and remotely possible set of conditions, toxic gases (gases of decompo- sition) are formed, the odorless Freon must have been changed into decomposition products which are pungent and irritat- ing, rendering them noticeable in minute quantities. Under such conditions Freon develops its own warning agent in its gases of decomposition.

Under test conditions Freon vapor in a tightly closed room, when brought in contact with flames, such as those from gas-range burners, by means of a high velocity air- circulating fan, decomposes to form hydrogen chloride and hydrogen fluoride. Results of tests for phosgene, free chlorine, and carbon monoxide in the products of decompo- sition made by the Underwriters Laboratories were negative,

The percentage by volume of hydrogen chloride and hydrogen fluoride in the tightly closed test room indicates that a fan circulating air rapidly has a marked influence upon this percentage. When no fan is used to thoroughly diffuse the Freon into all parts of the test room, the combined halogen acids are considerably lower than when a fan is used to cause forced air circulation. The use of an air-circulating fan as employed in the tests by the Underwriters Laboratories and by Jackson Laboratory a t Deepwater Point, N. J., was most abnormal and does not represent conditions usually found in practice. If the heavy Freon vapor had not been diffused to all parts of the room or directed through the gas flames, the halogen acids would have been greatly reduced. Of course, the same comments apply to any halogenated product used as a refrigerant.

\Then only a pilot light is used a t the gas range, and where the air in the tightly closed test room has been thoroughly mixed with Freon vapor, the total acids are approximately one per cent of the amount formed if two burners are being used and the Freon and air are thoroughly mixed.

In confined spaces with the ordinary ventilation necessary to remove or dissipate the products of fuel combustion, the decomposition products of Freon do not attain a lethal concentration. Very small concentrations, as low as 10 to 20 p. p. m. of these decomposition products, are readily detected.

Under purely test conditions, when Freon vapor was directed through oil and wood fires, hydrogen chloride, hydrogen fluoride, and phosgene were formed. No free chlorine was found, probably because of the fact that water vapor was present in large quantities and any chlorine formed by decomposition reacted with water to form hydrogen chloride.

Also, under test conditions, when Freon vapor was directed

June, 1932 I N D U S T R I A L AiCD E N G

upon iron surfaces heated to a temperature of 1022' F. (550 O C.), hydrogen fluoride, hydrogen chloride, chlorine, and sometimes phosgene were found. Where small concen- trations of Freon (3 pounds per thousand cubic feet. or 2.268 kg. per 28.32 cubic meters) were used, no phosgene resulted, but when heavy concentrations (80 pounds per thousand cubic feet, or 36.29 kg. per 28.32 cubic meters) were used, phosgene could be detected.

Freon is not decomposed, except in minute traces, by electric hot plates and ranges, using Globar type (exposed and cast in) nichrome heating elements.

In case of fire where large quantities of Freon may be involved, firemen are amply protected by hose streams and automatic sprinklers, as the products of deconiposition are very soluble in water and almost instantly removed thereby.

To bring about a health hazard, it would be necessary for large quantities of Freon to leak into a small closed space containing open flames, where there was no ventilation to the outside and where the air within the space was being circulated a t a high velocity to bring the heavy vapors into contact with the flames. Even under these conditions, it would take considerable time for appreciable quantities of the vapor to decompose, because Freon is noninflammable and only the vapor brought in actual contact with the flame decomposes. If such severe and unusual conditions should ever exist in actual practice, it is almost inconceivable that any person present would not instantly recognize the presence of the pungent and irritating products of decomposition, even in minute quantities. Ample warning3 would be given which would prompt any person present to ventilate the space or to leave long before concentrations dangerous to health were reached.

COSCLUSIOK The following facts have been established and are sub-

stantiated by the data included in the published reports

I l Y E E R I N G C H E M I S T R Y 623

and papers given in the bibliography a t the end of this article:

1. It is noninflammable. 2. 3. It is nonexplosive. 4. It is nonirritating. 5 . It is nontoxic. 6. 7. 8. It is stable. 9. It is noncorrosive.

It does not support combustion.

It has no odor even in fairly high concentrations. Its products of decomposition give ample warning.

10. Leaks can be readily detected. 11. It is not absorbed by foods or materials being re-

12. It has no effect on flowers, fruits, vegetables, dairy frigerated.

products, or furs, or materials being refrigerated.

LITERATURE CITED (1) Calcott, Elec. Refrigeration News, 6, No. 17, Serial 146 (Dec. 30,

(2) Jones and Perrott, Bur. Mines, Rept. Investigations 3042 (1930). ( 3 ) Sayers, Yant, Chornyak, and Shoaf, Ibid. , 3013 (1930). (4) Underwriters Laboratories, Rept. M . H . , 2256 (1931).

1931).

BIBLIOGRAPHY Bichowsky, Refrigerating Eng., 22, 177 (1931). Bichowsky and Fleischer, Kinetic Chemicals, Inc., Tech. Paper 7

Bichowsky, Gilkey, Downing, and Benning, IND. ENG. CHEM., 23,

Buffington and Fellows, Kinetic Chemicals, Inc., Tech. Paper 5

Buffington and Fleischer, ISD. ENG. CHEY., 23, 1590 (1931). Buffington and Gilkey, Ib id . , 23, 253 (1931). Buffington and Gilkey, Ib id . , 23, 1292 (1931). Buffington and Gilkey, Am. SOC. Refrigerating Engrs., Circ. 12

Gilkey, Gerard, and Bixler, IND. ESG. CHEM., 23, 364 (1931). Midgley and Henne, Ib id . , 22, 542 (1930).

(1931).

366 (1931).

(193 1).

(1931).

RECEIVED April 2, 1932.

Methyl Chloride J. B. CHURCHILL, 52 E. 41st Street, New York, Y. Y

M ETHYL chloride, discovered and described by Peligot and Dumas in 1833, found its earliest industrial use as a methylating agent in the dye industry. It

was first commercially manufactured in Germany about the year 1874. The date of its first use by engineers as a refriger- ant is more or less in doubt, but as early as 1895 it began to be employed for this purpose in both France and Germany. Its use rapidly became general as it was recognized that its chemical and physical properties especially adapted it for fractional-ton refrigeration, and it soon became regarded as one of the safest and most practical refrigerants to be employed \\-ith compression machines of capacities up to 5 tons. In France it was officially adopted by the Kavy as the safest refrigerant for marine work, and it mas required wherever refrigeration was installed on vessels of the sub- marine type.

Although its use in Europe became widespread, the fact that it was available in this country only by importation pre- vented and delayed its being employed by the American engineer. Shortly before 1920 the Roessler and Hasslacher Chemical Company made a searching investigation of the chemical and physical properties of methyl chloride and its suitability as a refrigerant. Convinced of its undoubted es- tablishment as an important refrigerant, it started produc-

tion in 1920, and was the pioneer in the production of methyl chloride of a high degree of purity in commercial quantities. Since 1920 the process of manufacture has been continually improved until it has been brought to a high state of efficiency.

PROPERTIES OF METHYL CHLORIDE ( 2 ) Chemical formula Mol. weight Color

CHaCl 50.474 Colorless and transnerent in both

gaseous and liquid state Odor Faintly sweet chloroform-like and

ethereal: the vapors do not irritate eyes or lunga

l lelt ing point, O F. (" C . ) -144 (-97.6) Boiling point, F. (" C.) - 10.65 ( -23.7)

1.00 0.92 0.80 289 (142.8) 970

1.78 CP 1.20 = 0.24; CD = 0.20

7 I f 3 At ordinary temperatures and

atmospheric pressures, 1 volume of water will dissolve 3-4 volumes of methyl chloride; i t is readily soluble in alcohol, ether, chloroform, and hydro- carbon oils

Referred to water at 4' C.

![· sunita palmer, m.d. max shuman, m.d. chan t. nguyen, m.d. date phone address ... a anemia]bleeding a deafness a gl problem a migraines a immune ... a apt a trailer a bottle a](https://static.fdocuments.nl/doc/165x107/5f21c960faf08f627148735c/sunita-palmer-md-max-shuman-md-chan-t-nguyen-md-date-phone-address-.jpg)