E TIJDELIJKE DAKEN EN OVERBRUGGINGEN · accordance with BS EN12811-1 and or NASC:TG20 (current...

Transcript of E TIJDELIJKE DAKEN EN OVERBRUGGINGEN · accordance with BS EN12811-1 and or NASC:TG20 (current...

TIJDELIJKE DAKEN EN OVERBRUGGINGEN

NIEUWE BROCHURE

A L T R A D B E N E L U X

Beeld: Dimitri Janssens

2

TIJDELIJKE DAKEN EN OVERBRUGGINGEN

ALTRAD BENELUX

Tijdelijke daken

Aluminium tralieliggers

• Opmaak plannen voor steigers & tijdelijke daken

• Technische ondersteuning• Ontwerp op maat• Producttraining

Ingenieursbureau

• In ontwikkeling• Tot 30 meter lang• 500 kg/m2

Overbruggingssystemen

781

7998127

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

DESSA PPPPPP DESSA PPPPPP DESSAPPPPPPDESSA PPPPPP DESSA PPPPPP

DESSA PPPPPP DESSA PPPPPP DESSAPPPPPPDESSA PPPPPP DESSA PPPPPP

! Important note or detail

Physical anchorSupplementary fitting

14.0 SECURITYIt is the contractors sole responsibility to ensure allentrances to and from the completed scaffold are secureagainst un-authorised access whilst the scaffold is bothin-service and out of service.

8.0 MATERIALSAll scaffolding materials forming this structure are tocomply with the recommendations of BS EN12811-1 and orNASC:TG20 (current editions).

13.0 PERMITS AND PERMISSIONSThe contractor must obtain all permits and permissions priorto erection.

9.0 DIMENSIONSWritten dimensions shall take precedence over scaleddimensions. The contractor must verify all site dimensionsand notify DESSA Limited of any discrepancies prior toerection.

10.0 MODIFICATIONNo alteration is to be made to the structure detailed on anyworking drawing without prior written permission fromDESSA Limited.

5.0 FOUNDATIONSThe contractor must prepare all foundations prior to erectionand verify sufficient capacity to support the imposed loadsindicated on this drawing and/or detailed in Keyfacts. Wherethis foundation is another structure it is essential that thisstructures owner or owners delegated representativeprovides written verification of the structures ability tosupport the additional imposed loads. Unless specifiedotherwise sole boards and base plates in accordance withNASC TG20 / BSEN12811-1 to be used at every standardlocation.

3.0 INTERFACE LOADSThe contractor is to ensure that the existing structure, itsfabric and/or the ground will safely support the extraimposed loads imparted from the structure detailed on thisdrawing or supply new.Refer to Keyfacts for calculated principal interface loads.

2.0 BASIS OF DESIGNDesigns are been prepared from information supplied to usby, or on behalf of the contractor who should check that hisrequirements have been correctly interpreted and that allloadings, dimensions, lift heights, bay sizes, erection/strikingsequences etc. are as required and practicable.

4.0 LOADINGS ALLOWEDThe contractor must ensure that all loadings allowed for aresufficient and that all loaded areas specified are adequate.Refer to Keyfacts for loadings allowed.

7.0 SHORING WORKSWe cannot and will not pass comment on the structure beingshored, as this involves matters beyond our control andknowledge. It is the contractors responsibility to ensure thatthe existing structure will safely span between our supports,and can be safely shored in the way indicated.

6.0 ANCHORAGEUnless specifically stated to the contrary on the workingdrawing all scaffold anchorage to be installed and tested instrict compliance with manufacturers recommendations andNASC TG04. It is the contractors responsibility to ensure thateach anchor as detailed and installed remains throughout theperiod of the contract and is not interfered with in any waywithout the written consent of DESSA Limited. Refer toKeyfacts - Interface loads for calculated anchor loads.

15.0 ERECTION/DISMANTLE/PARTIAL COMPLETIONIt is not possible to use the scaffold during erection ordismantle operations or partial completion. Unlessspecifically stated otherwise, this drawing relates to thecompleted scaffold structure only. It is the contractorsresponsibility to ensure and maintain stability and structuralintegrity during erection, dismantle and partial completionphases.

16.0 CLADDINGAll cladding whether net or sheet must be installed in strictcompliance with manufacturers recommendations andNASC:TG20. Cladding should be installed so as to stay inposition at the wind loads detailed in Keyfacts. Cladding mustnot be installed during erection, dismantle and partialcompletion phases.

11.0 CONSTRUCTION NOTESUnless noted otherwise all general construction to be inaccordance with BS EN12811-1 and or NASC:TG20 (currenteditions). Unless noted otherwise all lifts and bracing shall beconstructed using EN74 load bearing couplers.

12.0 LADDER BEAMS AND LATTICE BEAMSUnless noted otherwise on this drawing or manufacturersrecommendations all ladder beams and/or lattice beamsare to be braced using load bearing couplers as follows:-Steel beams:Top chord lacing 1.2m c/cBottom chord lacing 2.4m c/cTop chord plan bracing 1 bay in each 6 Section bracing2.4m c/c 1 bay in each 6Alloy beams:Top chord lacing 1.0m c/cBottom chord lacing 2.0m c/cTop chord plan bracing 1 bay in each 5 Section bracing2.0m c/c 1 bay in each 5

1.0 DRAWING STATUSConceptual DesignIdeas and schemes presented as potential solutions to theclient's brief. Conceptual designs are not techically robust, nocalculations and no assessment of the scheme in context ofit's surroundings having been undertaken. The drawing shouldnot be used for construction.Preliminary DesignIntended to show a realisable scheme in line with the client'sbrief. Global checks may have been conducted in order toachieve this, but the overall scheme is not technicallycomplete. The drawing should not be used for construction.Working DrawingProvided in line with detailed calculations to relevantstandards and in compliance to the client's brief. Inconjunction with other notes, clauses and statutoryrequirements, the latest revision of this drawing can be usedfor construction.As BuiltScheme as constructed on site. As built drawings are forinformation only and do not infer or construe compliance torecognised standards or project calculations.

- 24/05/2018 ORIGINAL ISSUE DL

Checked

Scales

Drawn

Date

Customer

Original Size

A2(594x420)

Approved

Owner

Drawing Number

Drawing Title

Project

Drawing Details

Rev

Revision Record

DateRev Description

Drawing Status

© T

his

draw

ing

is c

onfid

entia

l and

the

excl

usiv

e pr

oper

ty o

fD

ESSA

Lim

ited.

No

unau

thor

ised

use

, cop

y or

dis

clos

ure

isto

be

mad

e, a

nd is

to b

e re

turn

ed u

pon

requ

est.

0 50 100

App

Important Notes

Key Facts

Legend

Drawing issued for information only not to be used for construction

DESSASCAFFOLD

TECHNICALSERVICES

PRODUCTS

Preliminary design

P18095D01

BORGERHOUTHAL 1

A

18/06/2018

DL - -

AS SHOWN

BORGERHOUT HAL 1

500MM CANTILEVER BAY

PLAN (1:200)

1-1 (1:100)

2-2 (1:100)

A

LOADINGS ALLOWED:

Environmental loads:-Wind EN1991-1-4, 0.792kN/m2

Snow EN1991-1-3, 0.176kN/m2

Imposed loads:-Class 2 scaffold EN12811-11 level @ 0.75kN/m2

SHEETING:Roof structure encapsulated using PVC sheetingto roof beams and gables

INTERFACE LOADS:

Maximum reactions shown on drawing.

These forces should be considered to act at everyanchor simultaneously.

- 18/06/2018 Amends for contract issue DL

2-

2-

A (1:50)

DOUBLEBRACE 2.57

X 2.0M

DOUBLEBRACE 1.09

X 2.0M

732 CONSOLEFOR

INSTALLATIONOF SHEETS

ANCHORS TOSOLID CONCRETE

LEDGERS ASINTERNAL EDGEPROTECTION

ANCHOR(1:10)

PLAN

TO WALL

SIDE-ONASTSHEAR TIEC/W RESINANCHORS

FIXEDWEDGECOUPLERFITTINGTOROSETTE

220

MAX SPACING BETWEENANCHOR SUPPORTS

FIXED WEDGE COUPLER

220STANDARD

MAX SPACINGBETWEEN ANCHORSUPPORTS

15.28kNagainst downwards

7.68kNagainst uplift

10.7kN

10.7kN

22178 2469

GABLE SHEETTENSION BAR TO EVERY BEAM LINEWITH TUBE DROPPERS (MINIMUM 2M C/C)

!

600

0

300

0

1088

COMBINATION OF MAX. 2.57M + OTHER SIZED BAYSTO SUIT

ROOF GABLESTO BE CLOSEDOFF DURINGOPERATION

ROOF 150MM HIGHER

1-

1-

FACE BRACE 1 IN 5 BAYSSECTION BRACE TO EVERY LINE

Lodewijk Dehaese, Verantwoordelijke tijdelijke daken Altrad Benelux, tel: (+32) 0474.53.17.62, mail: [email protected] of [email protected]

3w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

348

121416182122

Wie zijn we?Altrad Benelux is dé leverancier van materialen voor tijdelijke daken, overspanningen, steigers, aluminium tra-lieliggers, trappen en veiligheidstoepassingen. Daarnaast werken we samen met de ontwerpdienst en het ingeni-eursbureau van Altrad Dessa (UK). We streven steeds naar innovatieve oplossingen met de beste prijs/kwaliteitver-houding. Hierdoor zijn we de ideale partner voor stellingbouwers, aannemers en bedrijven.

Waarom kiezen voor Altrad Benelux?Door onze technische knowhow én persoonlijke aanpak kunnen wij u een uitstekende klantenservice garanderen. Heeft u technische vragen, vragen over producten of wilt u ondersteuning ter plaatse? Wij helpen u graag verder.

Hoogstaande kwaliteitAltrad Benelux biedt een up-to-date assortiment aan waarbij kwaliteit steeds voorop staat. Onze materialen hebben bovendien een groot gebruiksgemak. Dankzij het ingenieuze productieproces worden problemen die doorgaans deel uitmaken van het aluminium lasproces vermeden. Na productie worden de afgewerkte materialen steeds nauwkeurig getest. Kortom: Altrad Benelux staat voor innovatieve oplossingen én hoogstaande kwaliteit.

Vlotte verdelingAltrad Benelux garandeert een vlotte verdeling van alle materialen en toebehoren. Dankzij onze grote voorraad kunnen we snel en efficiënt afleveren. Ons filiaal in Boortmeerbeek (Industrieweg 11) staat in voor de distributie in België, Nederland en Luxemburg.

ALTRAD BENELUX

TIJDELIJKE DAKEN

PROJECTEN

ASTERIX EN ASTERIX HD

D78 EN D45 TRALIELIGGERS

L45 EN S45 TRALIELIGGERS

RANGER TRAPPEN

VERHUUR

TECHNISCHE SERVICE

INHOUD

Veilige RANGER trappen

4

TIJDELIJKE DAKENAltrad Benelux beschermt uw werf en materialen tegen ongunstige weersomstandigheden, geluidsoverlast en vervuiling.

5w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

Altrad Benelux UNI Roof UNI Roof is een erg gebruiksvriendelijk en praktisch daksys-teem om uw werf en materialen te beschermen. Door zijn aluminium structuur en PVC sheeting kan dit daksysteem onder alle klimaatomstandigheden ingezet worden.

Wat maakt dit systeem zo bijzonder?Dit lichtgewicht daksysteem kan zelfs zonder bouten en kranen gemonteerd worden. Er zijn meerdere samenstellingen mogelijk: zowel met 1 of 2 dakhellingen als met gewelfde configuraties met tralieliggers van 40, 70, 78 of 133 cm.De dakstructuur bestaat uit universele tralieliggers. Deze kunt u ook gebruiken voor andere types steigers.

Beel

d: D

imitr

i Jan

ssen

s

6

KENMERKEN• Minimum aan onderdelen.• Opbouw zonder gereedschap.• Meerdere plaatsingsmogelijkheden.• Lichtgewicht. • Makkelijk te hanteren.• Gedetailleerde gebruikshandleidingen.• Mogelijkheid om zeilen aan de

onderzijde te plaatsen.

• Tralieliggers zijn compatibel met andere systemen.

• Duurzame zeilen worden veilig vastgezet in de geleiding.

• Veilige opstellings- methode door specifieke uitroltechniek.

• Verschillende dakhellin-gen mogelijk.

• Makkelijke plaatsing van zeilgeleiding.

• Overlapping van daken mogelijk waar-door de werf toeganke-lijk blijft voor kraanwerk.

VOORDELEN

7w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

De tralieliggers en ondersteunende elementen kunnen zowel gebruikt worden voor de constructie van ondersteuningen als voor volledig overdekte platforms. De geleiders en platen worden eenvoudig gemonteerd door beugels aan de onderste drager te bevestigen. Hierdoor kan de ruimte volledig ingekap-seld worden voor maximale bescherming.

Meer dan een tijdelijk dakDe tralieliggers en verbindingsliggers (diagonalen of vak-werken) kunnen ook gebruikt worden voor overbruggingen of overdekte platformen. Onder meer publieke toegangen kunnen hiermee verwezenlijkt worden.

Andere mogelijkhedenOns daksysteem biedt een innovatieve oplossing voor uiteenlopende projecten: vrijstaande beschutting, tijdelijke loodsen, treinsporen, werfafsluitingen, podia, plateaus en bruggen, inpakken van gebouwen en archeologische opgravin-gen... Het zijn maar enkele van de vele mogelijkheden.

StockOnze materialen worden in vaste maten geproduceerd en zijn zeer snel leverbaar.

TIJDELIJKE DAKEN

18°

18°

18°

18°

18°

18°

18°

36°

36°

15°Standaard

hellingsgraden of op maat gemaakte

hellingsgraden: beiden zijn

mogelijk!

8

UNI ROOF SYSTEEM

Uitgewerkt plan in 3D van een verrijdbaar dak op een vrijstaande steiger. Volledige sterkteberekening kan verkregen worden op aanvraag.

MATEXPO

Montage van een

verrijdbaar dak: een

ideaal systeem om

materialen in de

werfzone te liften.

Projecten Benelux

9w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

781

7998127

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

RR RR

RR

DESSA PPPPPP DESSA PPPPPP DESSAPPPPPPDESSA PPPPPP DESSA PPPPPP

DESSA PPPPPP DESSA PPPPPP DESSAPPPPPPDESSA PPPPPP DESSA PPPPPP

! Important note or detail

Physical anchorSupplementary fitting

14.0 SECURITYIt is the contractors sole responsibility to ensure allentrances to and from the completed scaffold are secureagainst un-authorised access whilst the scaffold is bothin-service and out of service.

8.0 MATERIALSAll scaffolding materials forming this structure are tocomply with the recommendations of BS EN12811-1 and orNASC:TG20 (current editions).

13.0 PERMITS AND PERMISSIONSThe contractor must obtain all permits and permissions priorto erection.

9.0 DIMENSIONSWritten dimensions shall take precedence over scaleddimensions. The contractor must verify all site dimensionsand notify DESSA Limited of any discrepancies prior toerection.

10.0 MODIFICATIONNo alteration is to be made to the structure detailed on anyworking drawing without prior written permission fromDESSA Limited.

5.0 FOUNDATIONSThe contractor must prepare all foundations prior to erectionand verify sufficient capacity to support the imposed loadsindicated on this drawing and/or detailed in Keyfacts. Wherethis foundation is another structure it is essential that thisstructures owner or owners delegated representativeprovides written verification of the structures ability tosupport the additional imposed loads. Unless specifiedotherwise sole boards and base plates in accordance withNASC TG20 / BSEN12811-1 to be used at every standardlocation.

3.0 INTERFACE LOADSThe contractor is to ensure that the existing structure, itsfabric and/or the ground will safely support the extraimposed loads imparted from the structure detailed on thisdrawing or supply new.Refer to Keyfacts for calculated principal interface loads.

2.0 BASIS OF DESIGNDesigns are been prepared from information supplied to usby, or on behalf of the contractor who should check that hisrequirements have been correctly interpreted and that allloadings, dimensions, lift heights, bay sizes, erection/strikingsequences etc. are as required and practicable.

4.0 LOADINGS ALLOWEDThe contractor must ensure that all loadings allowed for aresufficient and that all loaded areas specified are adequate.Refer to Keyfacts for loadings allowed.

7.0 SHORING WORKSWe cannot and will not pass comment on the structure beingshored, as this involves matters beyond our control andknowledge. It is the contractors responsibility to ensure thatthe existing structure will safely span between our supports,and can be safely shored in the way indicated.

6.0 ANCHORAGEUnless specifically stated to the contrary on the workingdrawing all scaffold anchorage to be installed and tested instrict compliance with manufacturers recommendations andNASC TG04. It is the contractors responsibility to ensure thateach anchor as detailed and installed remains throughout theperiod of the contract and is not interfered with in any waywithout the written consent of DESSA Limited. Refer toKeyfacts - Interface loads for calculated anchor loads.

15.0 ERECTION/DISMANTLE/PARTIAL COMPLETIONIt is not possible to use the scaffold during erection ordismantle operations or partial completion. Unlessspecifically stated otherwise, this drawing relates to thecompleted scaffold structure only. It is the contractorsresponsibility to ensure and maintain stability and structuralintegrity during erection, dismantle and partial completionphases.

16.0 CLADDINGAll cladding whether net or sheet must be installed in strictcompliance with manufacturers recommendations andNASC:TG20. Cladding should be installed so as to stay inposition at the wind loads detailed in Keyfacts. Cladding mustnot be installed during erection, dismantle and partialcompletion phases.

11.0 CONSTRUCTION NOTESUnless noted otherwise all general construction to be inaccordance with BS EN12811-1 and or NASC:TG20 (currenteditions). Unless noted otherwise all lifts and bracing shall beconstructed using EN74 load bearing couplers.

12.0 LADDER BEAMS AND LATTICE BEAMSUnless noted otherwise on this drawing or manufacturersrecommendations all ladder beams and/or lattice beamsare to be braced using load bearing couplers as follows:-Steel beams:Top chord lacing 1.2m c/cBottom chord lacing 2.4m c/cTop chord plan bracing 1 bay in each 6 Section bracing2.4m c/c 1 bay in each 6Alloy beams:Top chord lacing 1.0m c/cBottom chord lacing 2.0m c/cTop chord plan bracing 1 bay in each 5 Section bracing2.0m c/c 1 bay in each 5

1.0 DRAWING STATUSConceptual DesignIdeas and schemes presented as potential solutions to theclient's brief. Conceptual designs are not techically robust, nocalculations and no assessment of the scheme in context ofit's surroundings having been undertaken. The drawing shouldnot be used for construction.Preliminary DesignIntended to show a realisable scheme in line with the client'sbrief. Global checks may have been conducted in order toachieve this, but the overall scheme is not technicallycomplete. The drawing should not be used for construction.Working DrawingProvided in line with detailed calculations to relevantstandards and in compliance to the client's brief. Inconjunction with other notes, clauses and statutoryrequirements, the latest revision of this drawing can be usedfor construction.As BuiltScheme as constructed on site. As built drawings are forinformation only and do not infer or construe compliance torecognised standards or project calculations.

- 24/05/2018 ORIGINAL ISSUE DL

Checked

Scales

Drawn

Date

Customer

Original Size

A2(594x420)

Approved

Owner

Drawing Number

Drawing Title

Project

Drawing Details

Rev

Revision Record

DateRev Description

Drawing Status

© T

his

draw

ing

is c

onfid

entia

l and

the

excl

usiv

e pr

oper

ty o

fD

ESSA

Lim

ited.

No

unau

thor

ised

use

, cop

y or

dis

clos

ure

isto

be

mad

e, a

nd is

to b

e re

turn

ed u

pon

requ

est.

0 50 100

App

Important Notes

Key Facts

Legend

Drawing issued for information only not to be used for construction

DESSASCAFFOLD

TECHNICALSERVICES

PRODUCTS

Preliminary design

P18095D01

BORGERHOUTHAL 1

A

18/06/2018

DL - -

AS SHOWN

BORGERHOUT HAL 1

500MM CANTILEVER BAY

PLAN (1:200)

1-1 (1:100)

2-2 (1:100)

A

LOADINGS ALLOWED:

Environmental loads:-Wind EN1991-1-4, 0.792kN/m2

Snow EN1991-1-3, 0.176kN/m2

Imposed loads:-Class 2 scaffold EN12811-11 level @ 0.75kN/m2

SHEETING:Roof structure encapsulated using PVC sheetingto roof beams and gables

INTERFACE LOADS:

Maximum reactions shown on drawing.

These forces should be considered to act at everyanchor simultaneously.

- 18/06/2018 Amends for contract issue DL

2-

2-

A (1:50)

DOUBLEBRACE 2.57

X 2.0M

DOUBLEBRACE 1.09

X 2.0M

732 CONSOLEFOR

INSTALLATIONOF SHEETS

ANCHORS TOSOLID CONCRETE

LEDGERS ASINTERNAL EDGEPROTECTION

ANCHOR(1:10)

PLAN

TO WALL

SIDE-ONASTSHEAR TIEC/W RESINANCHORS

FIXEDWEDGECOUPLERFITTINGTOROSETTE

220

MAX SPACING BETWEENANCHOR SUPPORTS

FIXED WEDGE COUPLER

220STANDARD

MAX SPACINGBETWEEN ANCHORSUPPORTS

15.28kNagainst downwards

7.68kNagainst uplift

10.7kN

10.7kN

22178 2469

GABLE SHEETTENSION BAR TO EVERY BEAM LINEWITH TUBE DROPPERS (MINIMUM 2M C/C)

!

600

0

300

0

1088

COMBINATION OF MAX. 2.57M + OTHER SIZED BAYSTO SUIT

ROOF GABLESTO BE CLOSEDOFF DURINGOPERATION

ROOF 150MM HIGHER

1-

1-

FACE BRACE 1 IN 5 BAYSSECTION BRACE TO EVERY LINE

Uitgewerkt plan van de werf: bij de berekening werd rekening gehouden met de locatie. Dit zorgde voor een exact en overzichtelijk resultaat.

Uni-slot voor zeilgeleiding. De druk van de compressoren zorgt voor een waterdichte afsluiting.

WATERBOUWKUNDIG LABO BORGERHOUTVolledig verrijdbare daken voor renovatie van de bestaande platte

dakstructuur. De ideale oplossing om droog te werken en materialen op de

werflocatie te liften.

10

UNI ROOF SYSTEEM

PODIUM EVENEMENT

MET TIJDELIJK DAK

Fandorp voor de Rode Duivels

in Mechelen. Wij stonden

in voor de volledige

berekening van

dit tijdelijke project.

Podium voor publieke toegang.

500 kg/m2.

Projecten Benelux

11w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

OVERBRUGGING MET ASTERIX HD

VOETGANGERSBRUGDeze publieke overbrugging van 500 kg/m2 werd volledig ondersteund door Asterix HD tralieliggers. Een ideale, maar ook een snelle en veilige oplossing! 14.0 SECURITYIt is the contractors sole responsibility to ensure allentrances to and from the completed scaffold are secureagainst un-authorised access whilst the scaffold is bothin-service and out of service.

8.0 MATERIALSAll scaffolding materials forming this structure are tocomply with the recommendations of BS EN12811-1 and orNASC:TG20 (current editions).

13.0 PERMITS AND PERMISSIONSThe contractor must obtain all permits and permissions priorto erection.

9.0 DIMENSIONSWritten dimensions shall take precedence over scaleddimensions. The contractor must verify all site dimensionsand notify DESSA Limited of any discrepancies prior toerection.

10.0 MODIFICATIONNo alteration is to be made to the structure detailed on anyworking drawing without prior written permission fromDESSA Limited.

5.0 FOUNDATIONSThe contractor must prepare all foundations prior to erectionand verify sufficient capacity to support the imposed loadsindicated on this drawing and/or detailed in Keyfacts. Wherethis foundation is another structure it is essential that thisstructures owner or owners delegated representativeprovides written verification of the structures ability tosupport the additional imposed loads. Unless specifiedotherwise sole boards and base plates in accordance withNASC TG20 / BSEN12811-1 to be used at every standardlocation.

3.0 INTERFACE LOADSThe contractor is to ensure that the existing structure, itsfabric and/or the ground will safely support the extraimposed loads imparted from the structure detailed on thisdrawing or supply new.Refer to Keyfacts for calculated principal interface loads.

2.0 BASIS OF DESIGNDesigns are been prepared from information supplied to usby, or on behalf of the contractor who should check that hisrequirements have been correctly interpreted and that allloadings, dimensions, lift heights, bay sizes, erection/strikingsequences etc. are as required and practicable.

4.0 LOADINGS ALLOWEDThe contractor must ensure that all loadings allowed for aresufficient and that all loaded areas specified are adequate.Refer to Keyfacts for loadings allowed.

7.0 SHORING WORKSWe cannot and will not pass comment on the structure beingshored, as this involves matters beyond our control andknowledge. It is the contractors responsibility to ensure thatthe existing structure will safely span between our supports,and can be safely shored in the way indicated.

6.0 ANCHORAGEUnless specifically stated to the contrary on the workingdrawing all scaffold anchorage to be installed and tested instrict compliance with manufacturers recommendations andNASC TG04. It is the contractors responsibility to ensure thateach anchor as detailed and installed remains throughout theperiod of the contract and is not interfered with in any waywithout the written consent of DESSA Limited. Refer toKeyfacts - Interface loads for calculated anchor loads.

15.0 ERECTION/DISMANTLE/PARTIAL COMPLETIONIt is not possible to use the scaffold during erection ordismantle operations or partial completion. Unlessspecifically stated otherwise, this drawing relates to thecompleted scaffold structure only. It is the contractorsresponsibility to ensure and maintain stability and structuralintegrity during erection, dismantle and partial completionphases.

16.0 CLADDINGAll cladding whether net or sheet must be installed in strictcompliance with manufacturers recommendations andNASC:TG20. Cladding should be installed so as to stay inposition at the wind loads detailed in Keyfacts. Cladding mustnot be installed during erection, dismantle and partialcompletion phases.

11.0 CONSTRUCTION NOTESUnless noted otherwise all general construction to be inaccordance with BS EN12811-1 and or NASC:TG20 (currenteditions). Unless noted otherwise all lifts and bracing shall beconstructed using EN74 load bearing couplers.

12.0 LADDER BEAMS AND LATTICE BEAMSUnless noted otherwise on this drawing or manufacturersrecommendations all ladder beams and/or lattice beamsare to be braced using load bearing couplers as follows:-Steel beams:Top chord lacing 1.2m c/cBottom chord lacing 2.4m c/cTop chord plan bracing 1 bay in each 6 Section bracing2.4m c/c 1 bay in each 6Alloy beams:Top chord lacing 1.0m c/cBottom chord lacing 2.0m c/cTop chord plan bracing 1 bay in each 5 Section bracing2.0m c/c 1 bay in each 5

1.0 DRAWING STATUSConceptual DesignIdeas and schemes presented as potential solutions to theclient's brief. Conceptual designs are not techically robust, nocalculations and no assessment of the scheme in context ofit's surroundings having been undertaken. The drawing shouldnot be used for construction.Preliminary DesignIntended to show a realisable scheme in line with the client'sbrief. Global checks may have been conducted in order toachieve this, but the overall scheme is not technicallycomplete. The drawing should not be used for construction.Working DrawingProvided in line with detailed calculations to relevantstandards and in compliance to the client's brief. Inconjunction with other notes, clauses and statutoryrequirements, the latest revision of this drawing can be usedfor construction.Working drawing status only valid if drawing markedapproved.As BuiltScheme as constructed on site. As built drawings are forinformation only and do not infer or construe compliance torecognised standards or project calculations.

Important note or detail

Physical anchorSupplementary fitting

LOADINGS ALLOWED:

Environmental loads:-Wind EN1991-1-4, 0.75kN/m2

Snow EN1991-1-3, 0.352kN/m2

SNOW TO BE CLEARED INSTANTLY PRIOR TOPUBLIC ACCESS

Imposed loads:-1 level @ 2.5kN/m2

SHEETING:

External elevations of walkway to receive singlelayer of 22mm non-slip plyboard

INTERFACE LOADS:

Maximum reaction at ground level= 28.12kN

These forces should be considered to act at everyanchor simultaneously.

- 15/10/2018 CONCEPTUAL ISSUE (EXC. ROOF COVERAGE) DL

Checked

Scales

Drawn

Date

Customer

Original Size

A1(841x594)

Approved

Owner

Drawing Number

Drawing Title

Project

Drawing Details

Rev

Revision Record

DateRev Description

Drawing Status

© T

his

draw

ing

is c

onfid

entia

l and

the

excl

usiv

e pr

oper

ty o

fD

ESSA

Lim

ited.

No

unau

thor

ised

use

, cop

y or

dis

clos

ure

isto

be

mad

e, a

nd is

to b

e re

turn

ed u

pon

requ

est.

0 50 100

App

Important Notes

Key Facts

Legend

Preliminary designDrawing issued for information only not to be used for construction

DESSASCAFFOLD

TECHNICALSERVICES

PRODUCTS

P18154D01

TRANSPORTLAAN18M BRIDGE AND STAIR FOR ACCESS

2.5kN/m2

B

23/10/2018

DL ALJ

AS SHOWN

TRANSPORTLAAN

1-

1-

PLAN (1:75) [TIMBERS EXCLUDED FOR CLARITY]

3-

3-

A 22/10/2018 PLY AND BATTENS ADDED FOR DECK DL2-

2-

150

075

015

00

150

075

015

00

150

075

015

00

150

010

8815

465

280

2072 1000

2000 2000 2000 2000 2000 2000 2000 2000 2000 2000

20721000

150

80

24144

2-2 (1:75)

18000

1-1 (1:75)

1500 1500 1500 750 1500 1500 750 1500 1500 1088

154

1088

269

100

020

00

200

020

00

150

0

2072 1000 18000 1000 2072

269

100

020

00

200

020

00

150

0

19000

3-3 (1:20)

1088 154 1088

1280

1279

422 422 398 422 422

A

A (1:20)

B

2158

C

B (1:5)C(1:5)

JOIST JOINT DETAIL (1:20)

--

--

CONTUR PUBLIC ACCESSGUARDRAIL

OR3.0M L X 2.0M H DIAGONALS

WITH PLY OUTER

FACE BRACE, BOTH SIDES SECTION BRACEEVERY LINE

ANY STEELDECKS ONPLATFORM TORECEIVE PLYOVERLAY

!

RED DIMENSIONS ON PLAN - TO GROUNDPINK DIMENSIONS ON PLAN - TO PUNCHEONS

PUBLICACCESSSTAIRFLIGHT3.0M L X2.0M H

WEDGE/WEDGE FITTINGSBETWEEN STANDARDS

JOISTS AND PLY TOBRIDGE LIFT

SECTON BRACEALL LINES

2" X 2" BATTENS AT 1M C/CVERTICALLY TO SUPPORTWALL MOUNTED PLY

180X60MMBATTENSTO SUPPORTWALKWAY PLY

DESSA ASTERIX HD BEAM SPANS2NO. AT 1.09M CTS

DESSA BRACE FRAMES AT 1M C/CDESSA PLAN BRACES AT 1M C/C

ENSURE 8 PIN TOTAL AT CONNECTIONS

5467

CLEARANCE TO UNDERSIDE OF ASTERIX HD

PLETTAC SADDLESPIGOTAT 2M C/CBETWEEN ALTERNATEVERTICAL POSTS OFASTERIX HD

STANDARD BOLTED TOPLETTAC SADDLE

SPIGOT!

374

INDICATIVE BASEJACKEXTENSION. SITECONDITIONS BAYVARY.NOT TO EXCEED400MM

!

BOLT BASE PLATETO UNDERSIDE OF

152X152X23 UKC

GRAVLOCKSOR BOLTLESS

GIRDERCLAMPS TOASTERIX HD

DESSA BRACE FRAME ON POST

DESSA PLANBRACE ONCOLLARS

!

2" X 2" BATTENREST ON TOP OF

BASE PLY. SCREWTHROUGH

UNDERSIDE USINGFORM A WASHER

PLY SCREWED TOBATTEN AT 1M C/CVERTICALLY ANDHORIZONTALLYUSINGCOUNTERSUNKSCREW FIXINGS FORA FLUSH FINISH

22MM NO SLIP PLYSCREWED TOBATTEN AT 1M C/CHORIZONTALLYUSINGCOUNTERSUNKSCREW FIXINGS FORA FLUSH FINISH

DOUBLE COUPLERFITTED TO EITHERSIDE OF BATTEN TOAVOID HORIZONTALDISPLACEMENT.EVERY 2ND LINE.

180 X 60MM TIMBER JOISTRESTING ON TUBULAR

LEDGER

100 100

INTERMEDIATE TRANSOMS, LEDGERTO LEDGER IF JOIST OVERHANG

FROM MAIN LEDGER EXCEEDS200MM

!

Puncheon

1390

28kNper line

28kNper line

FACE BRACE INDICATED THUS

ENSURE ALL STANDARDS ARE PINNED!

PLANBRACEINDICATEDTHUS

PLAN BRACING TO SCAFFOLD USING HORIZONTAL DIAGONALS PLAN BRACING TO SCAFFOLD USING HORIZONTAL DIAGONALS

8875

D

B (1:5)

2" X 2" BATTENREST ON TOP OF

ROSETTE. PLY.SCREW THROUGHUNDERSIDE USINGFORM A WASHER

PLY SCREWED TOBATTEN AT 1M C/CVERTICALLY ANDHORIZONTALLYUSINGCOUNTERSUNKSCREW FIXINGS FORA FLUSH FINISH

PLANBRACEINDICATEDTHUS

PLANBRACEINDICATEDTHUS

WEDGE/WEDGEFITTINGS TO EVERYLINE WITHADDITIONALSTANDARDS

BALLASTREQUIREMENT

3TONNE PERSIDE OR

750KG PERLOCATION

SHOWN!

BALLASTREQUIREMENT3TONNE PERSIDE OR750KG PERLOCATIONSHOWN !

BALLAST REQUIREMENT3TONNE PER SIDE OR750KG PER LOCATIONSHOWN

!

WEDGE/WEDGEFITTINGS TO EVERY

LINE WITHADDITIONALSTANDARDS

500

154 154

DOUBLESTANDARDS FOR

1.5M USINGWEDGE/WEDGE

FITTINGS

DOUBLESTANDARDS FOR

1.5M USINGWEDGE/WEDGE

FITTINGS! !

REINFORCED LEDGERSTO HOUSE BALLAST

DOUBLE STANDARDS (EXTRA1.5M WITH 0.5M OFFSET)

ON WEDGE WEDGE FITTINGS

!

DOUBLE BRACES, BASE AND 2ND LIFT ! DOUBLE BRACES, BASE AND 2ND LIFT! DOUBLE BRACES, BASE AND 2ND LIFT!

DOUBLE BRACES, THIRD LINE IN ONLY

!

DOUBLE BRACES, THIRD LINE IN ONLY

!

B 23/10/2018 REINFORCING STANDARDS ADDED DL

De Asterix tralieliggers zijn ideaal voor lange overbruggingen. De diagonalen en vakwerken klikken op de tralieliggers, wat een vlotte en snelle montage mogelijk maakt.

Lodewijk Dehaese, Verantwoordelijke tijdelijke daken Altrad Benelux, tel: (+32) 0474.53.17.62, mail: [email protected] of [email protected]

ALTRAD BENELUX werkt

momenteel aan de

ontwikkeling van een nieuw

systeem voor dergelijke

constructies. Contacteer ons

voor meer informatie!

12

ASTERIX aluminium tralieliggersDe Asterix aluminium tralieliggers wor-den geproduceerd volgens de strenge EN1090-normen. Hoogstaande kwaliteit en een uitzonderlijk hoge capaciteit zijn hierdoor gegarandeerd. Bovendien zijn ze compatibel met alle andere types van steigers. De koppeling gebeurt d.m.v. stalen tralieliggerverbinders en koppelingspennen. Standaardelementen zoals 18° en 36° nokstukken voor tijdelijke daken, koppelingen, steigerbuizen, aluminium tussenliggers, diagonalen en vakwerken zijn uit stock leverbaar.

Een ontwerpingenieur zorgt voor een exacte berekening.

10 velden 6 velden 2 velden

ZELFDE PROJECT, MINDER TRALIELIGGERS.

ASTERIX EN ASTERIX HD

Tralieliggers 450 mm Tralieliggers 750 mm Asterix HD tralieliggers

13w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

TECHNISCHE FICHE VERKRIJGBAAR OP AANVRAAG.

TECHNISCHE

FICHE

VERKRIJGBAAR

OP AANVRAAG.

ASTERIX • Beschikbare lengte: 1, 2, 3, 4, 5, 6 m• Hoogte: 702 mm • Maximum buigingsmoment: 41,31 kNm• Maximale afschuifkracht: 23,73 kN

ASTERIX HD• Beschikbare lengte: 0,55, 1, 2, 3, 4 m• Hoogte: 1280 mm • Maximum buigingsmoment: 102,20 kNm• Maximale afschuifkracht: 32,60 kN

Tralieliggerverbinders verkrijgbaar.

Tralieliggerverbinders verkrijgbaar.

Tralieliggerverbinder en borgpennen.

Tralieliggerverbinder en borgpennen.

1 m

4 m

2 m

3 m

3 m

2 m

4 m

1 m

5 m

6 m

14

D78 en D45 De D78 en D45 tralieliggers zijn compatibel met alle mogelijke steigersystemen en tijdelijke daken. De D78 tralieliggers zijn verkrijgbaar van 1 tot en met 6 meter met een hoogte van 780 mm. De D45 tralieliggers zijn verkrijgbaar van 1 tot en met 8 meter met een hoogte van 450 mm.De bovenste en onderste buizen van de tralieliggers worden geproduceerd in de traditionele steigerbuismaat van 48 mm, waardoor u ze makkelijk kunt koppelen aan andere steigersystemen. De verticale buizen zitten om de meter en op elk uiteinde. Voor het monteren van overspanningen, ondersteuningen, vloerbodems en dakconstructies zijn deze tralieliggers de beste keuze.

D78 EN D45 TRALIELIGGERS

15w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

D78 tralieliggers• Beschikbare lengte: 1 m tem 6 m• Hoogte: 780 mm • Maximum buigingsmoment: 38,84 kNm• Maximale afschuifkracht: 23,71 kN

D45 tralieliggers• Beschikbare lengte: 1 m tem 6 m• Hoogte: 450 mm • Maximum buigingsmoment: 22,20 kNm• Maximale afschuifkracht: 12,10 kN

D78 EN D45 TRALIELIGGERS

Tralieliggerverbinders verkrijgbaar.

Tralieliggerverbinders verkrijgbaar.

1 m

2 m

3 m

4 m

5 m

6 m

8 m6 m5 m4 m3 m2 m1 m

TECHNISCHE FICHE VERKRIJGBAAR OP AANVRAAG.

TECHNISCHE

FICHE

VERKRIJGBAAR

OP AANVRAAG.

16

L45 EN S45 TRALIELIGGERS

L45 en S45De L45 en S45 tralieliggers zijn compatibel met alle traditionele steigersystemen en tijdelijke daken. Bovendien zijn ze licht en zeer sterk. De L45 tralieliggers met een hoogte van 450 mm zijn verkrijgbaar in een formaat van 1 tot 6 meter. De S45 tralieliggers met een hoogte van 450 mm hoogte zijn verkrijgbaar in lengtes van 4,1 m , 6,1 m en 8,1 m. De bovenste en de onderste buizen van de tralieliggers worden geproduceerd in de standaard steigerbuismaat van 48 mm. Zo zijn ze makkelijk te koppelen aan ieder steigersysteem. De verticale buizen zitten om de meter en op elk uiteinde. Deze tralieliggers zijn de ideale oplossing voor het monteren van overspanningen, ondersteuningen, vloerbodems en dakconstructies.

17w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

L45 tralieliggers• Beschikbare lengte: 1 m tem 8 m• Hoogte: 450 mm • Maximum buigingsmoment: 21,98 kNm• Maximale afschuifkracht: 11,69 kN

S45 tralieliggers• Beschikbare lengte: 4.1 m, 6,1 m en 8,1 m• Hoogte: 450 mm• Maximum buigingsmoment: 20,19 kNm• Maximale afschuifkracht: 11,66 kNm

Tralieliggerverbinders verkrijgbaar.

2 m

3 m

4 m

5 m

6 m

8 m

8.1 m

6.1 m

4.1 m

TECHNISCHE FICHE VERKRIJGBAAR OP AANVRAAG.

TECHNISCHE

FICHE

VERKRIJGBAAR

OP AANVRAAG.

18

RANGERTM TRAP

RS0003 3 557 783 GEENRS0006 6 985 1457 2 korte leuningenRS0009 9 1412 2130 2 lange leuningenRS0012 12 1840 2804 4 korte leuningenRS0015 15 2267 3478 2 korte en 2 lange leuningen

TRAPNUMMER TREDEN MINIMALE HOOGTE (mm)

MAXIMALE HOOGTE (mm)

lEUNING VEREIST BREEDTE (mm)

TECHNISCHE SPECIFICATIES (VAN GRONDNIVEAU TOT BOVENSTE TREDE)

RS0003

RS0006

RS0009

RS0012

RS0015

19w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

GELEIDE ALUMINIUM LEUNING UIT ÉÉN STUK• Eenvoudig te installeren: het volstaat om de reling in de

bevestigingsgaten te steken.• Montage zonder linker- of

rechterkant: dit voorkomt verwarring bij het opbergen van de installatie.

• 2 lengtemodules, geschikt voor alle lengte-assortimen-ten.

• Lichtgewicht.• Plaatsing onder dezelfde hoek

als het trapelement.

INGEBOUWD LEUNINGGAT MET SCHROEFDRAAD• Voorkomt dat er onderdelen

uit de buitenrand van de trap steken, wat veiliger is op het terrein en makkelijker is voor opslag en transport.

• Ingebouwde antiliftklem: zo blijft de leuning verankerd.

• De leuning kan makkelijk los-gemaakt worden door het in-gebouwde veermechanisme.

INGEBOUWD VERGRENDELMECHANISME IN DE ONDERPLATEN• Vergrendeling van de trap

gebeurt met een steiger-sleutel.

• Kan op een veilige onder-grond of via het onderste niveau vergrendeld worden.

MEERDERE BEUGELOPTIES VOOR BOVENTREDE• Steigerbuis haakt in de inge-

bouwde antiliftklem en ligt zo vlak tegen de buis, zodat steigerplanken er overheen passen.

• De plaatverbindingsbeugels worden aan de solide platen bevestigd door de bouten in de voorgeboorde gaten te draaien.

• Plaatverbinding voor hout en beton is ook mogelijk.

PLATTE VERPAKKING• Maakt opslag en transport eenvoudiger en veiliger. • Tijds-, arbeids- en kostenbesparend.

RANGERTM TRAP

TRAPNUMMER TREDEN MINIMALE HOOGTE (mm)

MAXIMALE HOOGTE (mm)

lEUNING VEREIST BREEDTE (mm)

PLAATVERBINDING. (165mm BOVEN DE BOVENSTE TREDE)

BUISVERBINDING. (110mm BOVEN DE BOVENSTE TREDE)

• SNEL EN FLEXIBEL ALTERNATIEF.

• COMPATIBEL MET ELK TYPE STEIGER.

• LICHTGEWICHT.

• MAKKELIJK TE TRANSPORTEREN.

• VEILIGE MONTAGE VANOP DE GROND.

Functies en voordelen

VOORDEEL:PIVOTERENDE TREDEN!

De trappen kunnen voor verschillende

hoogtes en toepassingen

gebruikt worden.

5 verschillende types beschikbaar: van 0,6 m tot 3.5 m.

Lodewijk Dehaese, Verantwoordelijke tijdelijke daken Altrad Benelux, tel: (+32) 0474.53.17.62, mail: [email protected] of [email protected]

20

21w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

Altrad Benelux is de ideale partner voor uw project. Door onze jarenlange expertise hebben wij de knowhow om elk project tot een goed einde te brengen. Van ontwerp tot calculatie: wij bieden alle mogelijke diensten aan!

VERHUURProjecten van A tot Z

Altrad Benelux

VOORDELEN• Ruime voorraad.• Compatibel met

onze steigerverhuurdienst.• Kostenbesparend.• Kwalitatief hoogstaande materialen. • Voorzien van de nodige certificaten. • Technische ondersteuning van A tot Z.

TIJDELIJKE DAKEN EN OVERBRUGGINGEN

UW VEILIGHEID IS ONZE PRIORITEIT!MEER INFO OF EEN

OFFERTE OP MAAT?

www.tijdelijkedaken.be

Lodewijk Dehaese,

Verantwoordelijke tijdelijke daken

Altrad Benelux, tel: (+32) 0474.53.17.62,

mail: [email protected]

22

TECHNISCHE SERVICEAltrad Benelux biedt zijn klanten een volledige

ontwerp- en controleservice aan voor steigerprojecten en tijdelijke

dakprojecten. Deze service wordt eventueel aangevuld met werfbezoeken.

• 2D ontwerptekeningen en -controle.• 3D tekeningen.• 2D en 3D structurele frame-analyses

mét berekeningsrapporten.• Trainingsvideo's en animaties. • Risico's analyseren.• Plaatsbezoeken.

Altrad Benelux maakt gebruik van de modernste technische software:

Autodesk Product Design & Manufacturing CollectionIncludes: AutoCad, AutoCad Mechanical, Inventor, 3ds Max

Graitec visual analysis software, full frame 3D.

Adobe Creative Cloud Photoshop, InDesign,

After Effects, Premiere Pro

De mogelijkheden van onze YouTube tutorials:

Sketchup Pro

Surf naar

ALTRAD BENELUX STEIGERS

Ontdek de verschillende

plaatsings- mogelijkheden en

montages in onze tutorials

op YouTube.

23w w w.t i jde l i j kedaken.be

t i jde l i j kedaken@altrad .be

TECHNISCHE SERVICEOok andere gepatenteerde systemen en ontwerpen voor tijdelijke projecten kunnen in de berekening worden opgenomen. Dankzij onze jarenlange expertise en technische knowhow kunnen wij u steeds de beste service en advies op maat garanderen.

Innovatieve conceptontwikkeling op maat

• Volledige ondersteuning voor systeemsteigers, tralieliggers en Ranger trappen.

• Technische handleidingen met onderdelenlijst.

• Productietekeningen.• 3D tekeningen.• 2D en 3D structurele frame-analyse

mét berekeningsrapporten.• Prototypes / lancering.

• Training op maat, bij de klant of op locatie.

• Volledige service.• Werfopleidingen.• Software training.• Instructievideo's.

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

R RR R

R R

! Important note or detail

Physical anchorSupplementary fitting

14.0 SECURITYIt is the contractors sole responsibility to ensure allentrances to and from the completed scaffold are secureagainst un-authorised access whilst the scaffold is bothin-service and out of service.

8.0 MATERIALSAll scaffolding materials forming this structure are tocomply with the recommendations of BS EN12811-1 and orNASC:TG20 (current editions).

13.0 PERMITS AND PERMISSIONSThe contractor must obtain all permits and permissions priorto erection.

9.0 DIMENSIONSWritten dimensions shall take precedence over scaleddimensions. The contractor must verify all site dimensionsand notify DESSA Limited of any discrepancies prior toerection.

10.0 MODIFICATIONNo alteration is to be made to the structure detailed on anyworking drawing without prior written permission fromDESSA Limited.

5.0 FOUNDATIONSThe contractor must prepare all foundations prior to erectionand verify sufficient capacity to support the imposed loadsindicated on this drawing and/or detailed in Keyfacts. Wherethis foundation is another structure it is essential that thisstructures owner or owners delegated representativeprovides written verification of the structures ability tosupport the additional imposed loads. Unless specifiedotherwise sole boards and base plates in accordance withNASC TG20 / BSEN12811-1 to be used at every standardlocation.

3.0 INTERFACE LOADSThe contractor is to ensure that the existing structure, itsfabric and/or the ground will safely support the extraimposed loads imparted from the structure detailed on thisdrawing or supply new.Refer to Keyfacts for calculated principal interface loads.

2.0 BASIS OF DESIGNDesigns are been prepared from information supplied to usby, or on behalf of the contractor who should check that hisrequirements have been correctly interpreted and that allloadings, dimensions, lift heights, bay sizes, erection/strikingsequences etc. are as required and practicable.

4.0 LOADINGS ALLOWEDThe contractor must ensure that all loadings allowed for aresufficient and that all loaded areas specified are adequate.Refer to Keyfacts for loadings allowed.

7.0 SHORING WORKSWe cannot and will not pass comment on the structure beingshored, as this involves matters beyond our control andknowledge. It is the contractors responsibility to ensure thatthe existing structure will safely span between our supports,and can be safely shored in the way indicated.

6.0 ANCHORAGEUnless specifically stated to the contrary on the workingdrawing all scaffold anchorage to be installed and tested instrict compliance with manufacturers recommendations andNASC TG04. It is the contractors responsibility to ensure thateach anchor as detailed and installed remains throughout theperiod of the contract and is not interfered with in any waywithout the written consent of DESSA Limited. Refer toKeyfacts - Interface loads for calculated anchor loads.

15.0 ERECTION/DISMANTLE/PARTIAL COMPLETIONIt is not possible to use the scaffold during erection ordismantle operations or partial completion. Unlessspecifically stated otherwise, this drawing relates to thecompleted scaffold structure only. It is the contractorsresponsibility to ensure and maintain stability and structuralintegrity during erection, dismantle and partial completionphases.

16.0 CLADDINGAll cladding whether net or sheet must be installed in strictcompliance with manufacturers recommendations andNASC:TG20. Cladding should be installed so as to stay inposition at the wind loads detailed in Keyfacts. Cladding mustnot be installed during erection, dismantle and partialcompletion phases.

11.0 CONSTRUCTION NOTESUnless noted otherwise all general construction to be inaccordance with BS EN12811-1 and or NASC:TG20 (currenteditions). Unless noted otherwise all lifts and bracing shall beconstructed using EN74 load bearing couplers.

12.0 LADDER BEAMS AND LATTICE BEAMSUnless noted otherwise on this drawing or manufacturersrecommendations all ladder beams and/or lattice beamsare to be braced using load bearing couplers as follows:-Steel beams:Top chord lacing 1.2m c/cBottom chord lacing 2.4m c/cTop chord plan bracing 1 bay in each 6 Section bracing2.4m c/c 1 bay in each 6Alloy beams:Top chord lacing 1.0m c/cBottom chord lacing 2.0m c/cTop chord plan bracing 1 bay in each 5 Section bracing2.0m c/c 1 bay in each 5

1.0 DRAWING STATUSConceptual DesignIdeas and schemes presented as potential solutions to theclient's brief. Conceptual designs are not techically robust, nocalculations and no assessment of the scheme in context ofit's surroundings having been undertaken. The drawing shouldnot be used for construction.Preliminary DesignIntended to show a realisable scheme in line with the client'sbrief. Global checks may have been conducted in order toachieve this, but the overall scheme is not technicallycomplete. The drawing should not be used for construction.Working DrawingProvided in line with detailed calculations to relevantstandards and in compliance to the client's brief. Inconjunction with other notes, clauses and statutoryrequirements, the latest revision of this drawing can be usedfor construction.Working drawing status only valid if drawing markedapproved.As BuiltScheme as constructed on site. As built drawings are forinformation only and do not infer or construe compliance torecognised standards or project calculations.

- 18/01/2019 ORIGINAL ISSUE DL

Checked

Scales

Drawn

Date

Customer

Original Size

A2(594x420)

Approved

Owner

Drawing Number

Drawing Title

Project

Drawing Details

Rev

Revision Record

DateRev Description

Drawing Status

© T

his

draw

ing

is c

onfid

entia

l and

the

excl

usiv

e pr

oper

ty o

fD

ESSA

Lim

ited.

No

unau

thor

ised

use

, cop

y or

dis

clos

ure

isto

be

mad

e, a

nd is

to b

e re

turn

ed u

pon

requ

est.

0 50 100

App

Important Notes

Key Facts

Legend

Conceptual designDrawing issued for information only not to be used for construction

P18181D01.DWG

DESSASCAFFOLD

TECHNICALSERVICES

PRODUCTS

altr

ad-d

essa

.com

P18181D01

VICTOR BUYCK SHELTER

OUTER SHELER

-

18/01/2019

BC DL DL

AS SHOWN

VICTOR BUYCK DUAL SHETLER

7021

10982

6148

4000

200

020

00

36deg RIDGE BEAM

38628

110

21

8no. BRACED BAY 7no. UNBRACED BAY15 BAYS AT 2.57M

PRE-ATTACHED 1MSHEET FLAP TO PREVENT

WATER PENETRATION.ADD BALLAST TO

PREVENT FLAP UPLIFT

EAVES CONTINUOUS TUBE CONNECTOR

A

PLAN VIEW (1:100)1-

1-

1-1 (1:50)

A (1:8)

450mm BEAM ATTACHED VIATUBE TO BAND AND PLATE.

ATTACH VERTICAL BEAMS TOSECURE TO GROUND.

BAND AND PLATE TOPHYSICALLY SECURE

ROOF TO GROUND VIA450mm BEAM

ADJUSTABLE BASEJACK

8963

4520

FINAL ASSEMBLY(BOTH ROOFS)(1:100)

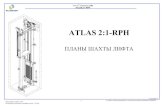

Plan voor uitvoering las- en schilderwerken aan brug.

Ver

antw

oord

elijk

e ui

tgev

er: W

esse

l Fra

nsen

24

ALTRAD BENELUX NVIndustrieweg 11 - 3190 Boortmeerbeek

T: +32 (0) 16/31.01.40 - F: +32 (0) 16/31.01.50 - [email protected]

Lodewijk Dehaese, Verantwoordelijke tijdelijke daken Altrad Benelux, tel: (+32) 0474.53.17.62, mail: [email protected] of [email protected]

Beeld: Dimitri Janssens