ADI Word

-

Upload

ashutosh-gupta -

Category

Documents

-

view

218 -

download

0

Transcript of ADI Word

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 1/8

ADI was discovered almost 50 years ago and found successful commercial

application in 1972. Today ADI as !ecome te material of coice for te designer"

as it o#ers te !est design com!inations of low cost" design $e%i!ility"

macina!ility" ig strengt to weigt ratio" good tougness" wear resistance &

fatigue strengt. ADI is more environment friendly tan many competing materials.

'verview

(aterial selection" processing" cost" product design" ease of availa!ility"

environmental impact due to its use" & performance of te )nal product are

insepara!le. ADI comes out wit ig scores on all tese counts.

(a*ing 'f ADI

(olten +ast iron wen treated wit magnesium results in nodular iron on

free,ing.

-rapite is present in a speroidal form rater tan as $a*es.

Ductile iron as superior mecanical properties as compared to cast iron & is

ceaper tan mallea!le iron.

(allea!le irons were manufactured !y su!ecting wite cast irons to very long eat

treatment cycles" and ence were very e%pensive

Ductile iron as replaced mallea!le irons entirely & steel / cast iron in many

applications.

Ductile iron wen eated to te austenitic range 900o + appro% and

uenced in te range of 230o + to 500o + gives us Austemperted Ductile

Iron ADI.

Te original inventors called te process “incomplete austempering” as

te resultant microstructure contained large uantities of RETAINED

AUSTENITE [RA]. Incomplete austempered ductile iron e%i!ited ig

elongation values as compared to normali,ed" ardened or fully !ainitic

ductile irons for similar tensile strengt levels.

Advantages

1. 4ower in cost wen compared to oter competing manufacturing metods"

suc as fa!rication" wrougt /macined" forged / macined.

2. uperior mecanical properties as compared to cast iron" weldments"

aluminum alloys" normali,ed or tougened ductile irons.

6. nergy consumption for a )nised ADI product is almost alf tat of a forged"

macined & case car!urised ardened component" for a similar application.

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 2/8

8. Ductile irons will e%i!it superior damping capacity & macina!ility as

compared to steel.

5. ADI as a very low cost to strengt ratio wen compared to oter commonly

used engineering materials.

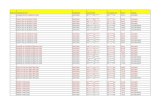

Material. Forged Al. Cast Al. Cast Steel Forged Steel H&T Steel Ductile Iron ADI.

Unit Cost /

Unit Y.S.

20 12 6 4 3 2 1

. ADI e%i!its transformation induced plasticity T:I;. <ence it as superior

wear resistance as compared to irons & steels of euivalent ardness values.

An ADI wit a ardness value of 650 =<> ?63 <:+@ will ave a wear resistance

euivalent to a case ardened steel of 0 <:+" ma*ing ADI a suita!le coice for

gears" camsafts" rollers" & oter wear parts. ear resistance of ADI is furter

enanced !y sot peening.7. Due to T:I;" ADI also as iger tougness & fatigue strengt as compared

to normali,ed / tougened ductile iron" nearing tose of steel at times"

especially for te lower tensile grades.

;roperties of Ductile IronB

Prior Metallurgical Parameters to Ensure Success with ADI…

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 3/8

1. -ood foundry practice to ensure a sound casting free from srin*age &

porosity. The austempering process cannot compensate for foundry

defects

2. (aintenance of proper and consistent cemistry. :ecommended limits for

cemical composition are as followsC Carbon: 3.5/3.9%; ilicon: !.3/!."%;#anganese: $.!5% ma; Copper $.&% ma; 'ic(el:!.$% ma;

#olybdenum: $.!5% ma only for hea)y sectioned castings.

6. 'odularity should be more than &$% * nodule count should be more

than +$$/mm!

8. #inimum 5$% pearlite in the matri * less than +% carbides prior to

austempering.

>odularityB

(icrostructure of ductile irons of varying degrees of nodularity. ?a@ 99 nodularity.

?!@ 30 nodularity. ?c@ 50 nodularity. All unetced. 6E

>odule +ountB

eries of micrograps depicting increasing nodularity in ductile irons. Fpper leftC 50

nodules per 10 mm suare. Fpper rigtC 100 nodules per 10 mm suare. 4ower leftC

150 nodules per 10 mm suare. 4ower rigtC 200 nodules per 10 mm suare. AsG

polised. 100E

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 4/8

Heat Treatment of ADI…

AFT>ITIATI'> is typically done in te temperature range of 360 to 950o +. +are

sould !e ta*en to prevent decar!uri,ation" car!on pic* up & termal soc* during

austenitisation. If salt !ats are used for eating" tey sould !e free of cyanide as

carry over of cyan salts to te >IT:IT/>IT:AT =AT< will lead to splasing of ot

salt & can cause severe inury. HF>+<I>- is normally done in a >IT:IT / >IT:AT

!at wit or witout water additions. enever water additions are done" proper

stirring is essential as te steam generated can result in splasing. Time &

Temperature for transformation are decided on te following !asisC

Austenization & Transformation…

TTT Cure…

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 5/8

Heat Treatment of ADI…

election of time & temperature are decided on te !asis ofC

1. ection tic*ness of te component

2. -rade of ADIC <iger te tensile" lower will !e te uencing temperature"

!ut never !elow te (s Temperature. Huencing temperatures are normally

!etween 250 to 825o +. Huencing time varies !etween 20 to 150 minutes.

>ormally iger te tensile strengt reuired" iger will !e te temperature.

6. ;earlite content in te matri% prior to austenitisation.

8. <iger te austenitisation temperature greater will !e te :A" greater will !e

te austenite car!on content & te ferrite will !e coarser. Te austenitisation

conditions sould !e selected" wit an aim for optimi,ing te mecanicalproperties.

Ausferrite…!"#$ Picral% Ausferrite…!"#$ Picral%

Ausferrite…"#$ ital%

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 6/8

Strain Har'ening…!

(a' o'ularit)…!

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 7/8

ADI * Showing Car+i'es 'ue to ,resence of - .!#$!!!

Post Austem,ering Processing & Ins,ection…

1. Always loo* out for an AF::IT structure & correct ardness after

austempering. Fpto 6 martensite & 10 !ainite may !e present wit te

rest !eing AF::IT. Te 750 >/mm2 grade may also ave some ferrite.

2. DonJt loo* for =AI>IT ust !ecause austempering as !een done. A !ainitic

structure of te same ardness will give lower elongation values tan an

AF::IT structure

6. Tempering or reeating ADI leads to a loss of tougness. <ence please avoid

tis practice.

/+serations & Conclusions…

ADI is used in diverse components operating under e%treme engineering conditions.

ADI is used for manufacturing cran*safts" camsafts" gears" sproc*ets" wear parts

in eartmovers" !rea*er !ody" suspension/cassis mem!ers etc. it te a!ove

mentioned advantages many more components are in te development / cange

over pase to !e converted to ADI. (any organi,ations are studying te !ene)ts of

ADI so as to reduce weigt & cost of teir )nised products. ADI o#ers a great

opportunity for value addition & cost reduction to te engineering industry. ADI as

very wide spread applications and will de)nitely !e a maor growt area in te days

to come.

THA0 1/2!

Please feel free to call on us 3

D 4u,ta Enter,rises!

7/26/2019 ADI Word

http://slidepdf.com/reader/full/adi-word 8/8

S * 567 MIDC7 (hosari7 Pune! 899.#:!

Tel!; <9=.#.=#>9#.5<67 <9=.#.=#>9#56?.!

Email! n'genter,rises3gmail!com