5007142 Syn 96289 Fracturing

Transcript of 5007142 Syn 96289 Fracturing

-

8/18/2019 5007142 Syn 96289 Fracturing

1/2

56 JPT • MARCH 2006

Natural completions in the Yegua forma-

tion have resulted in failures caused by

formation-sand production and wellbore

collapse. In the past, a popular remedy was

small fracturing treatments with gravel-pack

screens to control the production of forma-

tion material. Designing the completions

specifically for wellbore stabilization, sand

control, and maximizing the conductivity

endurance has resulted in techniques that

eliminate the need for gravel-pack screens,helping to simplify completion operations

and minimize cost.

IntroductionThe Yegua formation is a sand/shale deposi-tional system that extends from south Texasto south-central Louisiana. Historically, theYegua has been completed naturally, requir-ing periodic cleanout when formation sandaccumulates in the wellbore. The typicalsolution for preventing the production offormation sand has been some form ofmechanical remediation involving gravel

packs or vent screens. In some areas, theYegua will produce naturally without mak-ing formation sand; however, casing failuresoccur when the bottomhole flowing pres-sure is drawn down until a critical failurestress is reached and the rock fails.

The downdip Yegua, studied here, usu-ally is an overpressured gas/condensate,pressure-depletion-type reservoir. Waterproduction is relatively low in early stagesof production and can vary greatly in laterstages. The increased water production hasbeen attributed to water coning from high-er-permeability stringers.

Well 1. Well 1 production was severelyrestricted when a failure occurred. As thereservoir pressure depleted, fines migra-

tion and formation compaction reducedthe near-wellbore permeability. As a result,the drawdown pressure increased, caus-ing eventual failure of the formation rock.Formation sand filled the wellbore, haltingproduction, which required a workover toclean out the wellbore. In several cases, thenear-wellbore stresses increased to the point

at which the casing either collapsed or wassheared, thereby losing the wellbore. Well1 is an example of lost production becauseof formation failure that, eventually, led tocollapsed casing.

ObjectiveThe purpose of the work reported here was

to maximize hydrocarbon recovery whileminimizing casing failures and forma-

tion-sand production. The objective wasaccomplished by reducing the drawdownpressure near the wellbore by placing high-

ly conductive proppant packs. The packsincluded curable, resin-coated proppantor proppant coated with a conductivity-endurance modifier (CEM) to help ensurethat all perforations were packed withcoated proppant.

Well 2

Well 2 was completed with a 5-in., 18 lbm/ft,P-110 long string set at 13,730 ft measureddepth (MD) and 27 / 8-in., 6.5 lbm/ft tubingset with a packer at 13,535 ft MD. The YeguaEY3 sand was perforated in three intervals:13,588 to 13,592, 13,599 to 13,603, and13,610 to 13,613 ft MD. The perforatedzones then were fracture stimulated. The

net pay interval was approximately 35 ftlong with a porosity of 22%.

This article, written by Technology Editor Dennis

Denney, contains highlights of paper SPE

96289, “Fracturing for Sand Control: Screenless

Completions in the Yegua Formation,” by V.R.

Ellis, SPE, and G. Cormier, SPE, Halliburton;

G. Adams, SPE, Noble Energy Inc.; and F.

Santos, SPE, Sanchez Oil & Gas, prepared

for the 2005 SPE Annual Technical Conference

and Exhibition, Dallas, 9–12 October.

Fracturing for Sand Control:

Screenless Completions in the Yegua Formation

HYDRAULIC FRACTURING

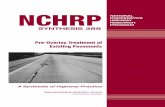

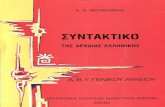

Fig. 1—Well 2 stress orientation.

For a limited time, the full-length paper is available free to SPE members at www.spe.org/jpt. The paper has not been peer reviewed.

-

8/18/2019 5007142 Syn 96289 Fracturing

2/2

JPT • MARCH 2006 57

Determining Fracture Plane. Fig. 1 shows a portion of the openhole ori-ented-dipole-sonic log run to determinethe preferred fracture-plane orientation.

The computed maximum and minimumstresses are indicated at 13,550 ft MD, withthe maximum-stress direction being north-west/southeast. There was a second maxi-mum-stress component of a lower degree,

oriented northeast/southwest. The overallstress anisotropy was low and could be anindication that there is not a strong frac-ture-orientation preference.

Completion Fluid. Cores from two repre-sentative Yegua wells were analyzed withX-ray diffraction to determine mineral con-tent, specifically clay content. The mixed-layer clay (illite and smectite) contentranged from 5 to 25 vol%, which causedconcern about swelling in the presence offresh water. To prevent the clay from swell-ing, a 7% KCl solution, which provides

protection even after ion exchange hasoccurred, was used for all completion andfracturing operations.

Perforations. Results of the oriented-dipole-sonic log indicated two possible pre-ferred fracture orientations because twomaximum stresses were logged. Orientedtubing-conveyed perforating was used toalign with the fracture plane oriented in thenorthwest/southeast direction, that of thegreater of the two stresses identified. Use ofcurable, resin-coated proppant and CEM-coated proppant improved proppant-pack-

ing efficiency and helped minimize the riskof flowing back proppant or formation sand.Because the stress anisotropy was relativelylow, subsequent wells used various perfora-tion methods to test the necessity of orient-ing the perforations. There was very little

difference between the breakdown, treating,and friction pressures of treatments thatused either nonoriented 0° or 180° phasing.Subsequent wells used nonoriented 0° and180° phasing and experienced no signifi-cant amounts of tortuosity or perforationfriction. The total number of perforationswas minimized to ensure that all perfora-

tions were packed with the proppants.

Well 2 Treatment. The fracturing treat-ment was designed for a tip screenout tomaximize proppant-pack conductivity andspread the drawdown pressure along thefracture plane. Total proppant volume was80,000 lbm of 20/40-mesh curable, resin-coated bauxite proppant.

Well 2 has produced 1.5 Bcf of gas, while Well 1 produced only 0.118 Bcf before the

production was halted because of the cas-ing failure. This incremental gain representsmore than U.S. $6,900,000, based on a gasprice of U.S. $5/Mcf.

Well 3 Well 3 was drilled directionally to intersecta fault that is normal to the strike plane.The path resulted in a 45° wellbore devia-

tion throughout the completion interval.The 27 / 8-in. tubing was set at 11,378 ftMD and 11,042 ft true vertical depth. Thiscompletion targeted the Yegua Y-3 and Y-2sands. The Yegua Y-3 perforations werefrom 11,797 to 11,799 ft MD, and theYegua Y-2 perforations were from 11,575 to11,577 ft MD.

The perforated intervals were limitedto 2 ft to minimize the risk of creatingmultiple fractures during the stimulationtreatment and to control the placement ofproppant for a more efficient pack of eachperforation. The production mechanism

for the Yegua formation in this area isdepletion drive with a constant water/gasratio (WGR). After the reservoir pres-sure declines to a critical point, the WGR

begins to increase. The increased waterproduction results in the production of for-mation fines and the need for subsequentremedial work to clean out the wellbore.Surface production equipment also mustbe cleaned routinely to maintain perfor-mance. The Yegua Y-3 was perforated withtwo 2-ft gun sections using a 21 / 8-in. gunwith 6 shots/ft phased 60° for a total of12 holes; the interval then was fracture

stimulated. This procedure was repeatedfor the Y-2 sand, and the well was cleanedout and put on production.

The two zones contained a total ofapproximately 30 ft of net pay with aporosity of 18% and a permeability of

5.5 md. After perforating the Y-3 sandand before the fracture stimulation, thestatic bottomhole pressure was measuredat 9,760 psi. The objectives of the frac-ture treatment were to increase produc-tion while minimizing the near-wellborepressure drawdown, controlling proppantflowback, and eliminating production of

formation sand. The decision was madeto use an intermediate-strength syntheticproppant coated with a CEM designed toremain tacky throughout its life. The CEMproduct was added to the proppant at theblender screws in a dry-coat process thatuses the energy of the blender screws tohelp ensure thorough coating before the

proppant reaches the blender tub. Thisparticular type of CEM is designed to pre-vent the migration of formation fines into

the proppant pack by increasing the prop-pant surface friction, allowing it to interactinstantaneously with surrounding particu-lates. The treatment schedule was identicalfor both zones and was pumped at a rate of12 bbl/min through the 27 / 8-in. tubing.

A sand plug was placed to isolate theY-3 sand from the Y-2 sand immediatelyfollowing the Y-3 treatment. The Y-2 sand

then was stimulated using the same treat-ment schedule. The well then was flowed torecover the treatment fluid and remove thesand plug isolating the lower zone.

Well 3 Production. The initial flow ratewas 10 MMcf/D of gas and 15 BWPD at aflowing tubing pressure of 7,700 psi. Thewell produced for approximately 8 monthswith a constant WGR of approximately2 BW/MMcf and a rate of 10 MMcf/D of gaswithout producing formation sand or prop-pant. During the next 12 days, water pro-duction increased until it reached 600 B/D,

with a WGR greater than 240 BW/MMcf. Aproduction log verified that the source ofthe water was the Y-2 sand, so the zone wasisolated with a cement squeeze. The combi-

nation of the CEM and a designed-for-pur-pose fracture treatment had resulted in the2-ft interval of the Y-2, with 24 perforations,flowing up to 600 BWPD for 12 days with-out producing formation sand or proppant.After isolating the watered-out Y-2 sand,the Y-3 sand was put back on production.The Y-3 sand is producing approximately4 MMcf/D of gas and 10 BWPD with nomeasurable fines or proppant.

Conclusions• Installing screenless fracture comple-

tions with a curable, resin-coated proppantor CEM-coated proppant can enable pro-duction from the Yegua formation without

formation-sand production, provided that ahigh-conductivity-fracture treatment is per-formed to reduce the drawdown pressure.

• This type of completion helps improvethe net present value of the well by allow-ing uninterrupted production rather thanhaving periodic workovers to clean forma-tion sand out of the wellbore.

• All perforations must be packed withthe curable, resin-coated proppant orCEM-coated proppant to help preventthe formation sand from having access tothe wellbore.

• The length and phasing of the perforat-ed interval play a significant role in achiev-ing high perforation-packing efficiency.

• If the stress anisotropy is low, a perfora-

tion design using either 0° or 180° phasingis recommended. JPT