Silica Fu Me

-

Upload

raed-abu-hamad -

Category

Documents

-

view

216 -

download

0

Transcript of Silica Fu Me

-

7/30/2019 Silica Fu Me

1/75

Behaviour of lightweight expanded polystyrene concretecontaining silica fumeK. Ganesh Babu*, D. Saradhi BabuStructures and Materials Laboratory, Department of Ocean Engineering, Indian Institute of Technology Madras, Chennai 600 036, IndiaReceived 17 January 2002; accepted 4 November 2002AbstractLightweight concrete can be produced by replacing the normal aggregate with lightweight aggregate, either partially or fully, dependingupon the requirements of density and strength. The present study covers the useof expanded polystyrene (EPS) beads as lightweightaggregate both in concretes and mortars containing silica fume as a supplementary cementitious material. The main aim of this project is tostudy the strength and the durability performance of EPS concretes. These mixeswere designed by using the efficiency of silica fume at thedifferent percentages. The resulting concretes were seen to have densities varying from 1500 to 2000 kg/m3, with the corresponding strengthsvarying from 10 to 21 MPa. The rate of strength gain for these concretes shows that an increase in the percentage of silica fume increases the7-day strength. This was observed to be about 75%, 85%, and 95% of the corresponding 28-day strength at the silica fume replacement levelsof 3%, 5%, and 9%, respectively. The results of absorption, at 30 min and the final absorption, show that the EPS mixes made with sand havelower levels of absorption compared to the mixes containing normal aggregates. F

urther, the absorption values were seen to be decreasingwith increasing cementitious content. The performance of these concretes, in terms of their chloride permeability and corrosion resistance,even at the minimal silica fume content level was observed to be very good.D 2002 Published by Elsevier Science Ltd.Keywords: Expanded polystyrene; Silica fume; Strength; Water absorption; Chloride permeability; Corrosion1. IntroductionThe demand for lightweight concrete in many applicationsof modern constriction is increasing, owing to theadvantage that lower density results in a significant benefitin terms of load-bearing elements of smaller cross sectionsand a corresponding reduction in the size of the foundation

[1]. Lightweight aggregates are broadly classified in to twotypesnatural (pumice, diatomite, volcanic cinders, etc.)and artificial (perlite, expanded shale, clay, slate, sinteredPFA, etc.). Expanded polystyrene (EPS) beads are a type ofartificial ultra-lightweight (density of less than 300 kg/m3),nonabsorbent aggregate [2,3]. It can be used to produce lowdensityconcretes required for building applications likecladding panels, curtain walls, composite flooring systems,and load-bearing concrete blocks [4,5]. Also, it was reportedthat it can be used for other specialized applications like thesub-base material for pavement and railway track bed; asconstruction material for floating marine structures, seabeds, and sea fences; as an energy-absorbing material for

the protection of buried military structures; and as fenders inoffshore oil platforms [610]. By incorporating the EPSbeads at different volume percentages in the concrete,mortar, or cement paste, a wide range of concrete densitiescan be achieved. The EPS aggregate replaces wholly orpartly the normal aggregate in the case of concrete, or sandin the case of mortars.Earlier researchers studied EPS mostly in mortar withOrdinary Portland Cement (OPC) as the binder. Also, toovercome its hydrophobic nature, bonding additives like

-

7/30/2019 Silica Fu Me

2/75

water-emulsified epoxies and aqueous dispersions of polyvinylpropionate were added [11], or chemically treated EPSbeads which are capable of preventing the segregation in theconcrete mixes (commercially available as BST aggregate inAustralia) were used [12]. Other investigators also reportedthat EPS tends to float and can result in a poor mixdistribution and segregation, necessitating the use of admixtures[7,8]. Apart from this, most of the studies reported to0008-8846/02/$ see front matter D 2002 Published by Elsevier Science Ltd.doi:10.1016/S0008-8846(02)01055-4* Corresponding author. Tel.: +91-44-257-8623, +91-44-445-8623;fax: +91-44-235-0509.E-mail address: [email protected] (K.G. Babu).Cement and Concrete Research 33 (2003) 755762This document has beenedited with Infix PDF Editor- free for non-commercial use.To remove this notice, visit:www.iceni.com/unlock.htm

-

7/30/2019 Silica Fu Me

3/75

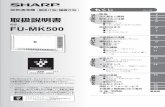

K.G.Babu,D.S.Babu/CementandConcreteResearch33(2003)755762Table1Chemicalcompositionofcementandsilicafume

ChemicalcompositionCementSilicafumeSilica(SiO2)21.7874.07Alumina(Al2O3)6.562.22

Ferricoxide(Fe2O3)4.131.57Calciumoxide(CaO)60.122.95Magnesiumoxide(MgO)

2.081.27Sodiumoxide(Na2O)0.362.89Potassiumoxide(K2O)

-

7/30/2019 Silica Fu Me

4/75

0.426.51Sulphuricanhydride(SO3)2.160.95Lossonignition(LOI)2.397.67

datewereessentiallyonconcretesoflowerdensities(below

1300kg/m3)resultinginstrengthsbelow12MPa.

Thepresentstudy

isanefforttodevelopstructurallightweightconcretesof14401850kg/m3withthe

correspondingstrengthsofabout17MPaminimum[1].Concretescontaining

-

7/30/2019 Silica Fu Me

5/75

silicafumeasthesupplementarycementitiousmaterialwithnormalcoarseaggregateandEPS,withoutaddinganybondingadditiveswereinvestigated.Also,itiswellunderstoodthat

forconcretestoqualifyasstructuralmaterials,itisimportantthatapartfrom

thestrength,durabilityandcorrosionresistanceparametersneedaspecificassessment.Inview

ofthis,theinvestigationsincludedbothparametersrelatedtostrength

-

7/30/2019 Silica Fu Me

6/75

likecompressiveandsplittensilestrengths,andthedurabilityparameterslikewaterabsorption,chloridepermeability,corrosionrate,andacceleratedcorrosioncracking.

2.

Mixproportions2.1.MaterialsCementconformingtoIS:12269(C53grade),whichwillalso

confirmtoASTMTypeI,andsilicafumewereusedas

Table2DetailsofEPSconcretemixescontainingsilicafume

-

7/30/2019 Silica Fu Me

7/75

cementitiousmaterialsintheconcretemixes.ThechemicalcharacteristicsofthecementandsilicafumearegiveninTable1.SeriesI

andIIIcontainsandfinerthan2.36mm,whileSeriesIIcontainssand

finerthan1.18mm.Themaximumsizeofthenormalcoarseaggregate(crushed

bluegranite)inSeriesIandIIwas10mm,

-

7/30/2019 Silica Fu Me

8/75

whileitwas16mmforMixes8and10and20mmforMixes9and11.Inthepresentstudy,Mixes10

and11weredesignedwiththesametotalcementitiousmaterialandw/(c+

s)ratio,aswasreportedearlierbyZhangandGjorv[13]forlightweight

concretescontainingexpandedclay-typeaggregates.Twotypesofcommerciallyavailable

-

7/30/2019 Silica Fu Me

9/75

sphericalEPSbeadsthatareessentiallysinglesized(TypesAandB)wereused.ThegradingshowsthatTypeAhasmostly6.3-mm-sizebeads

andTypeBhasmostly4.75-mm-sizebeads.Thebulkdensityandthespecific

gravityofthesebeadswere9.5kg/m3and0.014forTypeAand

20kg/m3and0.029forTypeB,respectively.Anaphthalene-based

-

7/30/2019 Silica Fu Me

10/75

superplasticizerwasusedtoproducethemixesofflowableorhighlyflexiblenaturetosuitthehandcompactionadopted.

Thedesignof

EPSmixeswithsilicafumewasbasedontheefficiencyconceptsuggestedearlier

[14].Threepercentagesofsilicafume3%,5%,and9%(byweightofthe

totalcementitiousmaterials),withthecorrespondingefficiencyvaluesof7.5,

-

7/30/2019 Silica Fu Me

11/75

5.0,and3.5wereused.Themixeswerealldesignedasconcretesconsideringtheefficiencyofsilicafume.Thereductioninthecementpastephase

resultingfromthehighefficiencyofsilicafumewascompensatedtoacertain

degreebyadditionalfines.Thecompletedetailsoftheconcretemixesarepresented

inTable2.

2.2.ProductionofEPSconcrete

-

7/30/2019 Silica Fu Me

12/75

Concretewasmixedinaplanetarymixerof100-lcapacity.EPSbeadswerewettedinitiallywithapartof

SlMixCement

SF(s)Waterw/(c+s)TotalSandaNormalCAasEPSc%

VolumeSP%Flownumbernumber(kg/m3)(%)(kg/m3)ratioaggregates(kg/m3)(kg/m3)

aggregatesb(kg/m3)TypeA(kg/m3)TypeB(kg/m3)ofEPS

-

7/30/2019 Silica Fu Me

13/75

ofTCM(mm)SeriesI135031580.440175248132572522136.40.2547236231640.4401724

48848157917629.00.2548337531700.4401691

49764842012621.00.2547433531520.4401786

77989411334.40.5048SeriesII5

-

7/30/2019 Silica Fu Me

14/75

39951850.440160649853057822.20.552639951850.4401606102857822.20.5

55739951850.440160674386333.20.5

49SeriesIII839951850.4401606337515321433

28.70.2551939951850.4401606337

-

7/30/2019 Silica Fu Me

15/75

51532143328.70.5531060591850.278145430546629139226.30.5581160591850.278

145430546629139226.00.7555

CAnormalcoarseaggregate;

SFsilicafume.

aThesizeofsandusedinSeriesII

was1mm,downgraded;andinSeriesIandIII,

-

7/30/2019 Silica Fu Me

16/75

thesizeswere2.36mm,downgraded.

bA10-mmdowngradedaggregatewasusedinSeriesIandII,16mmdowngradedin

Mixes8and10,and20mmdowngradedinMixes9and11.

TheweightofCAisconvertedtoanequivalentvolumeof

EPS(thebulkdensityofCA,EPSTypeA,and

-

7/30/2019 Silica Fu Me

17/75

TypeBwere1600,9.5,and20kg/m3respectively).

-

7/30/2019 Silica Fu Me

18/75

K.G.Babu,D.S.Babu/CementandConcreteResearch33(2003)755762themixingwaterandsuperplasticizerbeforeaddingtheremainingmaterials.Mixing

wascontinueduntilauniformandflowingmixturewasobtained.Thefreshconcrete

densitiesandflowvaluesweremeasuredimmediatelyafterthemixing.Theflowvalues

variedbetween47and58cmandfacilitatedhandcompaction.

-

7/30/2019 Silica Fu Me

19/75

Thespecimenswerecuredunderwetgunnybagsinitiallyand,afterdemolding,werestoredinwater.

3.Experimentalinvestigations3.1.Specimensand

curingconditionsStandardtestspecimensofdifferentsizeswerechosenforinvestigatingthe

variousparameters.Cubesof100mmsizewereusedforstudyingthecompressive

strengthsat1,3,7,28,and90daysand

-

7/30/2019 Silica Fu Me

20/75

alsofortheabsorptiontestsat90days.Splittensilestrengthtestwasconductedon100mmdiameter.200mmcylindersat28

days.Cylindersof50mmthicknessand100mmdiameterwereusedfor

thechloridepermeabilitystudiesat90days.Cylindersof100mmdiameter.

200mmwithan8-mm-diameter,hot-rolled,deformedsteelbarof

-

7/30/2019 Silica Fu Me

21/75

100mmofexposedlengthembeddedinthemiddlewereusedtostudythecorrosionrateandacceleratedcorrosioncracking.Thesespecimensalonewerecured

inseawateruntiltesting(90days)after3daysofnormalwatercuring.

3.2.TestprogramTheflowvaluesofthefreshconcretemixes

weremeasuredaccordingtoASTMC124-1973.Compressivestrengthtest

-

7/30/2019 Silica Fu Me

22/75

wascarriedoutinatestingmachineof2000kNcapacityataloadingrateof2.5kN/s.Thesplittensilestrengthtestwas

conductedoncylindersat28daysasperASTMC496-89.Theabsorption

testwascarriedoutasperASTMC642-82.Saturatedsurfacedrycubes

werekeptinahotairovenat60C

-

7/30/2019 Silica Fu Me

23/75

(althoughASTMsuggestsatemperaturerangeof100110C)untilaconstantweightwasattained.Thisisbecauseatthistemperaturerangeof100

110C,theEPSbeadsinitiallyshrinkandfinallyevaporate.Thesearethen

immersedinwaterandtheweightgainismeasuredatregularintervalsuntil

aconstantweightisreached.Theabsorptionat30min

-

7/30/2019 Silica Fu Me

24/75

andthefinalabsorption(atapointwhenthedifferencebetweentwoconsecutiveweightsat12-hintervalwasalmostnegligible)werereportedtoassess

theconcretequality.

Thestudiesforthedurabilityrequirementswereundertaken

onlyontheconcretesofSeriesI,asthesecontainedtheleastamount

ofsilicafumethatimprovedtheperformancesignificantly(highestefficiency

-

7/30/2019 Silica Fu Me

25/75

andacorrespondinglylowercementitiousmaterialscontent)andpresentedthelowestdurabilitythatcanbeexpected.Thesewerelimitedtochloridepermeability,potential,corrosion

rate,andacceleratedcorrosionstudies.

Thechloridepermeabilitytestwasconducted

toassesstheconcretequalityasperASTMC1202-94.Apotentialdifference

of60VDCwasmaintainedacrossthespecimen.One

-

7/30/2019 Silica Fu Me

26/75

ofthesurfaceswasimmersedinasodiumchloride(NaCl)solutionandtheotherinasodiumhydroxide(NaOH)solution.Thetotalchargepassing

in6hwasmeasured,indicatingtheresistanceofthespecimentochloride

ionpenetration.

Potentiodynamicpolarizationtechniquewasadoptedtomeasurethecorrosion

rateofthe8-mm-diameterbarsinthecylinderspecimens,by

-

7/30/2019 Silica Fu Me

27/75

usingascanningpotentiostat(EGandGPAR-Model362)andanXlogX,Yrecorder.Apotentialof250mVwasappliedoneither

sideoftheopencircuitpotential(OCP),andthecorrosioncurrent(Icorr)was

takenat100mVfromthepotentiodynamicplot.Thecorrosionratewascalculated

fromIcorrbyusingFaradaysequation.

Acceleratedcorrosion

-

7/30/2019 Silica Fu Me

28/75

-

7/30/2019 Silica Fu Me

29/75

dailyresistancewascalculated.Later,toacceleratethecorrosionprocess,acurrentof60Vwasappliedforaperiodof10daysor

untilacrackoccurred.Thecurrentpassingwasmeasuredatregularintervalsto

evaluatethechargetocracking.

4.ResultsanddiscussionsAcomprehensive

summaryofthedifferentstrengthsandabsorptioncharacteristicsofall

-

7/30/2019 Silica Fu Me

30/75

theconcretesispresentedinTable3.Theresultsofthecorrosion-relatedparametersinvestigatedforSeriesI,asalreadyproposed,aregiveninTable

4.

4.1.FreshconcreteTheworkabilityoftheconcreteinterms

oftheflowmeasurementswasreportedinTable2.Flowvaluesofthe

allthemixeswereintherangeof4758cm.

-

7/30/2019 Silica Fu Me

31/75

Theseflowvaluescorrespondtoaslumpofabout5070mminmostcases.Themixeshavingthehigherpercentagesilicafumeshowhigher

flowvalues.Alltheconcreteswereflexibleandeasytoworkwith,and

couldbeeasilycompactedusingjusthandcompactionandcouldalsobeeasily

finished.Theproblemsassociatedwiththesegregationandfinishabilityof

-

7/30/2019 Silica Fu Me

32/75

themixescontainingcoarsebeadsasreportedearlier[7]weretotallysolvedbyensuringthataminimumamountofcementitiousmaterialwasalwayspresent.

Thesilicafumeandthesuperplasticizerwereessentiallyaddedtohelpsolvethe

problemsassociatedwiththehydrophobicnatureoftheEPSbeadsandtoimprove

thecohesivenessofthemix.

-

7/30/2019 Silica Fu Me

33/75

K.G.Babu,D.S.Babu/CementandConcreteResearch33(2003)755762Table3StrengthandabsorptionofEPSconcretemixes

SlMixFreshconcreteCompressivestrength(MPa)SplittensileAbsorption(%)numbernumber

density(kg/m3)1day3days7days28days90daysstrength

(MPa)30minFinalSeriesI115524.26.6

-

7/30/2019 Silica Fu Me

34/75

7.610.210.61.530.6955.424216985.87.211.215.014.02.040.9035.3553197910.212.814.021.421.22.16

1.0494.882415034.46.88.410.212.22.100.7414.596Series

II518565.210.615.219.819.12.231.3063.52061748

5.010.417.618.518.62.201.2443.14071546

-

7/30/2019 Silica Fu Me

35/75

4.09.212.415.014.92.150.7302.570SeriesIII817626.610.211.612.011.21.831.3503.630917714.69.8

14.21717.22.021.2503.1501017939.813.415.616.216.5

2.221.2702.5401118739.816.419.820.821.22.321.0002.340

4.2.Compressivestrength4.2.1.EffectofageThe

-

7/30/2019 Silica Fu Me

36/75

variationofthecompressivestrengthwithageshowsacontinuousincreaseinalmostallthemixes.Therateofstrengthdevelopmentwasgreaterinitially

anddecreasedastheageincreased.Therateofstrengthgainat7,

28,and90daysispresentedinFig.1.Acomparisonofstrengths

at7daysrevealsthatconcreteswith3%silicafume

-

7/30/2019 Silica Fu Me

37/75

developedalmost75%ofits28-daystrength,whilethatwith5%and9%silicafumedevelopedalmost85%and95%ofthecorresponding28-day

strength.Therewasnoappreciablestrengthimprovementat90days.Fromthis,it

isclearthattherateofstrengthgainwasincreasingwithanincreasing

percentageofsilicafume.

4.2.2.Effectofdensity

-

7/30/2019 Silica Fu Me

38/75

andEPSvolumeThedensityoftheconcretewascontrolledbyvaryingtheEPSvolumeinthemix.Thevariationofcompressivestrengthwith

theplasticdensityofconcrete(andpercentvolumeofEPS)waspresentedin

Fig.2.ThestrengthofEPSconcretesappearstoincreaselinearlywithan

increaseinconcretedensity,orwithadecreaseinthe

-

7/30/2019 Silica Fu Me

39/75

EPSvolume.

4.2.3.EffectofEPSbeadsizeThestrengthofEPSconcreteincreasedwithadecreaseintheEPSbeadsize

forthesamemixproportions.Thisis

Table4Corrosionstudies

onEPSconcretes(SeriesI)

SlnumberCharge(C)90-dayOCP

(.mV)Corrosionrateat100mV(mpy)ACCstudies

-

7/30/2019 Silica Fu Me

40/75

ADR(V)Totalchargetocracking(C)Mix1Mix2Mix3Mix4676.74496.37460.71372.513303006703050.502

0.3900.4510.3645.405.605.304.1017,94220,97412,66913,176

ACCacceleratedcorrosioncracking;ADRaveragedailyresistance.

clearfromtheresultsof

theconcretesofSeriesIImadewithonlyTypeB

-

7/30/2019 Silica Fu Me

41/75

(smallerEPSbeads),whichshowedhigherstrengthvalues,thanthemixesmadewiththecombinationofTypeAandTypeBbeadsforthe

sameconcretedensities.

4.2.4.EffectofnormalaggregatesizeComparingthe

strengthresultsofMixes8and10containing16-mm,downgraded,normalcoarseaggregate

withthoseofMixes9and11containing20-mm,downgraded,

-

7/30/2019 Silica Fu Me

42/75

normalcoarseaggregate(Fig.3),itisclearthatthecompressivestrengthincreasedwithincreasingaggregatesize.Thepercentageincreaseinstrengthwithsize

wasalsoobservedtobehigherintheleanmixescomparedtothe

richmixes.

4.2.5.EffectofsandMixes1and5contain

bothsandandcoarseaggregatewhilecorrespondingMixes4and

-

7/30/2019 Silica Fu Me

43/75

6containonlysandastheaggregate(mortar).Themixproportionsofthetwomixsets(Mixes1and4,andMixes5and

6)arealsonearlythesame.Acomparisonofthestrengthresultsof

thesetwosetsofmixeshavingcomparabledensitiesclearlyshowsthattheeffect

ofsandisnegligible,bothintermsofthestrength

-

7/30/2019 Silica Fu Me

44/75

gainrateaswellasthestrengthat90days.However,itwasobservedthatthemixescontainingcoarseaggregatesalwaysshowaslight

increaseindensity(about50100kg/m3).

4.2.6.Effectoflightweightaggregate

strengthThestrengthofconcreteismainlyinfluencedbythestrengthofthe

aggregate.Thedevelopmentofhigh-strengthconcretesispossibleonlywhen

-

7/30/2019 Silica Fu Me

45/75

theaggregateshaveenoughstrength.Presently,Mixes10and11weredesignedwiththesametotalcementitiousmaterialandw/(c+s)ratioas

werereportedearlierbyZhangandGjorv[13].Theyreporteda28-daycompressive

strengthof102.4MPafortheseconcretesmadewithexpandedclayaggregate.However,

the28-daystrengthforMixes10and11containingEPS

-

7/30/2019 Silica Fu Me

46/75

wereonly16.2and20.8MPa,respectively,inthepresentstudy.

-

7/30/2019 Silica Fu Me

47/75

K.G.Babu,D.S.Babu/CementandConcreteResearch33(2003)755762Fig.1.Variationofcompressivestrengthwithage.

This

widevariationofstrengthismainlyduetothedifferenceinstrengthof

theaggregates,asEPSaggregateshavealmostzerostrength.

Moreover,the

failuremodeoftheconcretespecimenscontainingEPSaggregatesunder

-

7/30/2019 Silica Fu Me

48/75

compressiveloadingdidnotexhibitthetypicalbrittlefailurenormallyassociatedwiththeconventionalaggregateconcrete.Thefailureobservedwastobemoregradual

(morecompressible),andthespecimenswerecapableofretainingtheloadafterfailure

withoutfulldisintegration.Asimilartypeoffailurewasalsoreportedearlierfor

plasticshreddedaggregateconcretes[16].Thisclearlyshowsthehigh

-

7/30/2019 Silica Fu Me

49/75

energyabsorp

tioncapacityoftheseconcretesthatwassuggestedearlier[5,9].

4.3.SplittensilestrengthThevariationoftensile

strengthwiththecompressivestrengthisgiveninFig.4.Fromthis,it

canbeseenthatthetensilestrengthincreasedwithanincreaseincompressive

strength.Thesplittingfailuremodeoftheconcretespecimenscontaining

-

7/30/2019 Silica Fu Me

50/75

EPSaggregatesalsodidnotexhibitthetypicalbrittlefailurenormallyobservedinconventionalconcreteasincompressivestrength.Thefailureobserved

Fig.2.VariationofstrengthwithdensityandEPSvolume.

-

7/30/2019 Silica Fu Me

51/75

K.G.Babu,D.S.Babu/CementandConcreteResearch33(2003)755762Fig.3.Variationofcompressivestrengthwithage(SeriesIII).

wasmoregradual(compressible)andthespecimensdidnotseparateintwo,

aswasearlierreportedforplasticshreddedaggregateconcretes[16].

4.4.

AbsorptionThedurabilityofconcreteprimarilydependsuponitspermeability,

-

7/30/2019 Silica Fu Me

52/75

whichdefinestheresistancetotheingressofaggressiveions.Theabsorptioncharacteristicsindirectlyrepresenttheporosity,throughanunderstandingofthepermeablepore

volumeanditsconnectivity.Alimitontheinitial(30min)absorptionfor

assessingtheconcrete

qualitywasdefinedbyCEBearlier[17].The

initialabsorptionat30min,aswellasthefinal

-

7/30/2019 Silica Fu Me

53/75

(total)absorption,wereshowninFig.5.AspertheassessmentcriteriagivenbyCEB,allthemixesinthepresentstudyshoweda

lowabsorptionrating(