Pm18 Unilever Mitchell 1

-

Upload

dgek-london -

Category

Documents

-

view

218 -

download

0

Transcript of Pm18 Unilever Mitchell 1

-

8/13/2019 Pm18 Unilever Mitchell 1

1/45

Starch as a HydrocolloidWhy is starch is the mostimportant food thickener?

John Mitchell

-

8/13/2019 Pm18 Unilever Mitchell 1

2/45

The starch granule

Gelatinisation and gelation: What is the

difference?

Modified starches

What is the difference between starch and

hydrocolloid solutions at the same viscosity

-

8/13/2019 Pm18 Unilever Mitchell 1

3/45

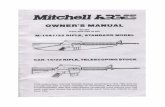

Size shape and morphology of the granules

is characteristic of the botanical source

wheat lentil

rice

ryemaize

potato

shoti

avacado

green

pea

mm

-

8/13/2019 Pm18 Unilever Mitchell 1

4/45

Amylose / amylopectin contentsAmylose / amylopectin contents

Starch Source % amylose % amylopectin

Maize 26 76

Wheat 25 75Potato 24 76

Tapioca 17 83

Rice 17 83

Waxy maize 99

High amylose 50 / 75 50 / 25

-

8/13/2019 Pm18 Unilever Mitchell 1

5/45

Amylose and Amylopectin

Starch normally contains two

polysaccharides amylose and

amylopectin

Amylose

Almost entirely linear (1-4 linked)

Molecular size ~ 5. 105 g mol-1

Amylopectin

Highly branched (1-4 and 1-4 linkages)

Molecular size ~ 108 g mol-1

-

8/13/2019 Pm18 Unilever Mitchell 1

6/45

Racemose model

Amylopectin

70-99% by weight

Mol weight ----108 g mol-1

branch chains

~20 glucose units

only one reducing end

Glucose units linked 1-4

andsome 1-6 linkage

-

8/13/2019 Pm18 Unilever Mitchell 1

7/45

Diagram of the starch polymer organisation

-

8/13/2019 Pm18 Unilever Mitchell 1

8/45

Packing of the molecules to form a starch granule

lamellae

growth ring

Jenkins and Donald, 1995

-

8/13/2019 Pm18 Unilever Mitchell 1

9/45

Gelatinisation vs Gelation

-

8/13/2019 Pm18 Unilever Mitchell 1

10/45

Gelatinisation

Description of structural transformation which occurs

when starch granules are heated in excess water

Swelling of starch granules

Increase in viscosity

Loss of birefringence (maltese cross pattern seen under

polarising microscope)

Accompanied by heat adsorption as seen by endotherm in

differential scanning calorimetry

Occurs in temperature range ~55-75 OC as measured by

loss of birefringence (high amylose starches higher)

-

8/13/2019 Pm18 Unilever Mitchell 1

11/45

Gelation

Formation of crosslinked network on cooling

as a result of formation amylose double

helices

Individual polysacchardies Amylose forms strong gels rapidly at minimum

concentrations ~2%.

Amylopectin forms weak gels slowly much higher

concentrations required (~20%)

-

8/13/2019 Pm18 Unilever Mitchell 1

12/45

Electron

Micrograph

Showing

Structure of

an Amylose

Gel

-

8/13/2019 Pm18 Unilever Mitchell 1

13/45

Modified Starches

-

8/13/2019 Pm18 Unilever Mitchell 1

14/45

Modified starch e numbersModified starch e numbers

E 1404 oxidised starch

E 1410 monostarch phosphate

E 1412 distarch phosphate

E 1413 phosphated distarch phosphate

E 1414 acetylated distarch phpsphate E 1420 acetylated starch

E 1422 acetylated distarch adipate

E 1440 hydroxypropyl starch

E 1442 hydroxypropyl distarch phosphate

E 1451 acetylated oxidised starch

E 1450 Starch sodium octenyl succinate

Acid thinned starches like unmodified starches are deemed to be ingredients NOT additives

-

8/13/2019 Pm18 Unilever Mitchell 1

15/45

Properties of native starchesProperties of native starches

Starch

Source

Granule

Size m.

Gel TempoC

Solution

Clarity

Gel

Texture

Stability to

retrogradn.

Resistance

to shear

Freeze /

thaw

stability

Maize 10 - 20 62 - 74 Opaque Short Poor Fair Poor

Wheat A 25 35

B 2 -5

52 64 Opaque Short Poor Fair Poor

Rice 3 - 8 61 78 Opaque Short Poor Fair Poor

Potato 15 - 100 56 69 Clear Very

Cohesive

Fair Poor Poor

Tapioca 20 - 60 60 - 72 Clear Soft Fair Poor Poor

Sago 15 - 25 52 64 Clear Soft Fair Poor Poor

Waxy

Maize

6 - 30 63 - 72 Clear Cohesive Good Poor Fair

-

8/13/2019 Pm18 Unilever Mitchell 1

16/45

Chemical ModificationChemical Modification

Modification Reagent Product

Acid Thinning Hydrochloric acid Acid thinned starch

Oxidation Sodium hypochlorite Oxidised starch

Cross linking Phosphorus

oxychloride

Distarch phosphate

Sod. Tri meta

phosphate

Distarch phosphate

Adipic anhydride Distarch adipate

Epichlorohydrin Distarch glycerol

Esterification Acetic anhydride Starch acetate

Etherification Propylene oxide PO starch ester

-

8/13/2019 Pm18 Unilever Mitchell 1

17/45

Effect of Cross linking on BrabenderEffect of Cross linking on Brabender

ViscosityViscosity

Viscosity

0 95 95TemperatureoC

Control

0.03% POCl3

0 05 POCl30 075 POCl3

0 15 POCl350

-

8/13/2019 Pm18 Unilever Mitchell 1

18/45

What is the difference between starchand hydrocolloid solutions at the

same viscosity?

-

8/13/2019 Pm18 Unilever Mitchell 1

19/45

Solutions can be thickened with

swollen particles or polymers in

solution

Swollen starch granules

Plant cells

Gel particles

Guar gum

Pectin

Hydroxypropylcellulose

-

8/13/2019 Pm18 Unilever Mitchell 1

20/45

The next slide shows the appearance of apredominantly paticulate suspension (wheat starch)and a polymer solution (hydroxpropylmethylcellulose(HPMC)) which have been stained with a red fooddye and gently hand mixed with water. Prior to

mixing the viscosity of the stainedsuspension/solution was 380mPa.s at ambienttemperature and a 50s-1.

In contrast to wheat, waxy maize starch whichcontains no amylose will disrupt on gelatinisation

behaving more like a polymer solution than asuspension of particles. The modified waxy maizestarch maintains the particulate structure .

-

8/13/2019 Pm18 Unilever Mitchell 1

21/45

Five Minutes After Mixing

Wheat

Starch

Modified

Waxy

MaizeStarch

Native

Waxy

Maize

Starch

HPMC

-

8/13/2019 Pm18 Unilever Mitchell 1

22/45

Consequence of Good Mixing of

Solutions Thickened by Swollen

Starches

Good taste perception

Short non-stringy texture

Longer gastric emptying time

-

8/13/2019 Pm18 Unilever Mitchell 1

23/45

1.5

1.6

1.7

1.8

1.9

2

2.1

-0.25 0.25 0.75 1.25 1.75

log (Kokini shear stress (Pa))

log(meanflavour)

w axy maize

(crosslinked)w heat

w axy maize

nativeHPMC (Anne-

Laure)HPMC (Dave

Cook)

Perceived Flavour Plotted Against Kokini

Shear Stress

-

8/13/2019 Pm18 Unilever Mitchell 1

24/45

Mouthfeel of Hydrocolloid Solutions (Szcznesniak

and Farkas (1962), Mitchell (1979))

Least Slimy

Most Slimy

Slimy material thick, coats the mouth and is difficult to swallow

-

8/13/2019 Pm18 Unilever Mitchell 1

25/45

Effects in the stomach

MRI pictures of stomach content following the ingestion of400g of water and 100g of(a)a crosslinked waxy maize starch and (b)HPMC at anequivalent viscosity of 500mPa.s at 50s-1.

(a) (b)

some remains unmixed

fully mixed longer gastric emptying time

Acknowledgements: L. Marciani

SPINE

LIVERSTOMACH CONTENTS

SPLEEN

-

8/13/2019 Pm18 Unilever Mitchell 1

26/45

Consequences of changing

microstructure of starch

Origin of Starch

Waxy maize (100% amylopectin)

Waxy maize physically treated to prevent

granule break up

Wheat

Salivary amylase

-

8/13/2019 Pm18 Unilever Mitchell 1

27/45

Heat

shear

Native

waxy maize

starch

Modified/crosslinked

waxy maize

WheatPolysaccharidereleased from

swollen granule

Granule

disruption

Swelling

Botanical

origin

Salivary

amylase

Processing

Effect of processing, origin and

amylase on microstructure of paste

-

8/13/2019 Pm18 Unilever Mitchell 1

28/45

Cooked starch CharacteristicsCooked starch CharacteristicsUndercookedUndercooked OptimalOptimal

cookingcooking

OvercookedOvercooked

Appearance Cloudy Clear Clear

Texture Thin, starchy

taste

Heavy bodied,

short textured

Cohesive, long

texture

Stability Poor Good Manyfragments, few

intact granules

Viscosity Low Good Viscosity drop

Microscope Small granules,under swollen,

birefingent

cross

Well swollen,

some

fragments

Many

fragments,few

intact granules

-

8/13/2019 Pm18 Unilever Mitchell 1

29/45

Consequences of changing

microstructure of starch

-

8/13/2019 Pm18 Unilever Mitchell 1

30/45

Starch systems impact of

origin

Wheat Modified waxy maize give higher mixing

efficiency / sodium release / taste perception than

non-modified waxy maize

100 m

Wheat

100 m

Waxy maize

100 m

Modified waxy maize

-

8/13/2019 Pm18 Unilever Mitchell 1

31/45

Starch systems impact of

salivary amylase

-amylase is an enzyme present in saliva,

can cleave 1-4bonds between glucose

residues in starch molecules

At the concentrations present in saliva it canhalve the viscosity of a starch paste in a few

seconds

Large variation in in-mouth amylase activity

between subjects

-

8/13/2019 Pm18 Unilever Mitchell 1

32/45

Starch systems impact of

salivary amylase

0 50 100 150 200Modified waxy

maize starch

0 50 100 150 200Waxy maize

starch

100 m

0 50 100

100 m

2-a 50 100

-

8/13/2019 Pm18 Unilever Mitchell 1

33/45

Thickener type Saltiness Thickness

HPMC 0.11ns 0.09ns

Waxy maize starch -0.20* -0.28***

Modified waxy maize starch -0.43*** -0.19*

Wheat starch -0.25*** -0.14ns

Correlations between perceived

saltiness and thickness and

panellists saliva amylase activity

-

8/13/2019 Pm18 Unilever Mitchell 1

34/45

Conclusions from amylase

study

Amylase activity in the mouth releases

polymeric material from swollen starch

granules reducing mixing efficiency and

salt perception

Data suggests that consumers who

have a high in-mouth amylase activity

perceive flavour/taste in starchthickened foods less well

-

8/13/2019 Pm18 Unilever Mitchell 1

35/45

Microstructure

Mixing

Rheology

Sensory/inbody

performance

The Weakest Link?

-

8/13/2019 Pm18 Unilever Mitchell 1

36/45

Observation of droplet break

up in two fluid systems

Easy break up of the viscous fluid

element will result in good mixing

Rheooptics

CaBER rheometer

-

8/13/2019 Pm18 Unilever Mitchell 1

37/45

Counter rotating shear cell

FV

G

3

1

2

1: Transparent parallel rotating

plates.

2: Observed object in suspending

fluid

3: Image acquisition unit: optical

microscope +camera+ monitor +

DVD recorder

-2 transparent plates rotating in opposite directions

- Gap (h) is 1mm, radius (r) at which the droplet sits 5-10mm

- droplet is submitted to a known shear rate calculated as follows:

with uand lthe relative velocities of upper and lower plate respectively

- Suspending fluid: high viscosity silicon oil (transparent, inert towards aqueous systems,

induces high stresses)

h

rlu

*

Observed system is static in laboratory reference

Silicon oil

Fluid droplet

-

8/13/2019 Pm18 Unilever Mitchell 1

38/45

HPMC and cross linked waxy maize starch atequivalent shear viscosities

100

m

100m

100m

HPMC

CLWM

0

1

2

3

4

5

6

7

0 50 100 150 200 250 300

Strain

L/D

o

HPMC

CLWM

HPMC overshoot, no breakup

Starch deformation and break

up

HPMC and CLWM at shear stress 640Pa. D0

=80m

Under the same conditions, HPMC and CLWM behave differently;

- HPMC reaches a steady-state deformation

- CLWM deforms and breaks up.

-

8/13/2019 Pm18 Unilever Mitchell 1

39/45

CaBER Extensional Rheometer

-

8/13/2019 Pm18 Unilever Mitchell 1

40/45

Experimental Conditions

The sample is placed between two parallel plate (6mmdiameter) separated by a 3mm gap.

The fluid is then exposed to a rapid extensional stepstrain by moving the upper plate upwards (final gap

11.3mm, linear strike, 50ms), thereby forming a fluidfilament.

A laser micrometer measures the midpoint diameter ofthe gradually thinning fluid filament, after the upperplate has reached its final position, until its break-up.

-

8/13/2019 Pm18 Unilever Mitchell 1

41/45

Processed xanthan

Wheat

Waxy maize

M odif ied waxy

maizeGelatine

0.00

0.01

0.02

0.03

0.04

0.05

0.2 0.3 0.4 0.5 0.6

Viscosity 50s -1 (Pa.s)

Break-uptime(s.)

Filament break-up times for good

mixers

-

8/13/2019 Pm18 Unilever Mitchell 1

42/45

1.5

1.6

1.7

1.8

1.9

2

2.1

-0.25 0.25 0.75 1.25 1.75

log (Kokini shear stress (Pa))

log(mean

flavour)

w axy maize

(crosslinked)w heat

w axy maize

nativeHPMC (Anne-

Laure)HPMC (Dave

Cook)

Perceived Flavour Plotted Against Kokini

Shear Stress

-

8/13/2019 Pm18 Unilever Mitchell 1

43/45

Conclusion

As a thickener for foods starch has a

fundamental advantage over most other

polysaccharide hydrocolloids due to its more

efficient mixing with bodily fluids

-

8/13/2019 Pm18 Unilever Mitchell 1

44/45

References

Murphy, P and Mitchell, J, (2009) Starch in Handbook ofHydrocolloids edited and Phillips G.O and Williams P.A,Woodhead Publishers

Ferry, A-L et al. Viscosity and flavour perception. Why is starch

different from hydrocolloids? Food Hydrocolloids (2006) 20:855

Ferry, A-L et al. In-mouth amylase activity can reduce perceptionof saltiness in starch thickened foods. J of Agricultural andFood Chemistry (2006) 54:8869

Desse, M, Wolf, B, Mitchell, J. and Budtova, T Experimental studyof the break up of starch suspension droplet in step-up shearflow . J Rheology (2009) 53: 943

-

8/13/2019 Pm18 Unilever Mitchell 1

45/45

Thanks

Ann-Laure Ferry (Nestl, DEFRA Food Link)

Melinda Desse (European Polysaccharide Network ofExcellence)

Bettina Wolf

Tatiana Budtova

Sandra Hill

Tim Foster

Luca Marciani

Andy Taylor

Dave Cook

Dave Howling Margaret Hill