mk-CM-Brochure

-

Upload

viet-nguyen -

Category

Documents

-

view

165 -

download

1

Transcript of mk-CM-Brochure

stainless steel conveyors

Sanitary.Durable.

Innovative.

mk North America, Inc.

CleanMove™, the latest conveyor innovation from mk, is a full line of sanitary conveyors designed for the specific needs of the food and pharmaceutical industries. CleanMove sanitary stainless steel conveyors provide state-of-the-art cleanability, performance, reliability and are designed to meet food and pharmaceutical industry standards.

With over 40 years of diverse industrial know-how, superb quality, constant innovation and application engineering excellence, mk North America, Inc. offers you a perfect solution for any application. With a full line of best-in-class products mk helps you increase productivity, improve quality, cut costs, and increase profits.

mk is a leader in the design and manufacture of high quality, sanitary stainless steel conveyors and low profile aluminum conveyors. Companies from almost every industry around the globe have turned to mk for solutions to their conveyor needs.

better products. better solutions.

ultra

standard

mk CleanMove Conveyor Technology 3

The CleanMove Plus is ideal for processing basic non-cultured food items like bakery goods or snack foods, as well as fruits and vegetables and canning lines. The equipment is designed for medium to high pressure washdown (up to 1,500 psi) with the use of corrosive chemicals for cleaning. It features a bolted, non-pitted continuous welded #4 polish stainless steel frame construction. The design also features food-grade, stainless steel bearings with polymer housing and epoxy painted (or stainless steel) motors.

The CleanMove Ultra is designed for high caustic and high pressure washdown processes (up to 1,500 psi), for minimizing bacteria growth. Allowing for CIP (Clean In Place) and COP (Clean Out of Place) options, this line is designed for raw meats, poultry and fish as well as dairy products. Ultra features a polished, sealed tube frame construction with non-pitted welds, and a #4 polish or bead blast finish. It also features stainless steel motors and bearings along with premium sanitary construction.

ultra

CleanMove™ Conveyors are offered in three different sanitary construction levels. This allows you to meet industry and application specific government compliance standards while minimizing equipment cost.

mk CleanMove

Advantages & Features:

• Sanitary stainless steel construction• Designed to FDA, 3-A, NSF and BISSC regulations• Easy to clean and maintain• Heavy duty construction

• High quality components and materials• Large variety of options and accessories• Full application and engineering support• Custom designs

The CleanMove Standard is an economical solution with non-corrosive benefits for handling of packaged food or pharmaceuticals in a low moisture environment. The equipment can be wiped-down or washed using mild detergents and pressure (up to 100 psi). It features a bolted, #4 polish stainless steel frame construction; and stainless steel pulleys and hardware.

standard

4 mk CleanMove Conveyor Technology

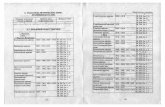

Sanitary Construction Levels - Design Specifications

CleanMove™ Standard CleanMove™ Plus CleanMove™ Ultra

EnvironmentDry to low moisture, no use of corrosive chemicals

Moderate to high moisture, moderate to high use of corrosive chemicals

High moisture, high use of caustic chemicals to minimize risk of bacterial growth

CleanabilityWipe-down and liquid spray washdown with soap and water cleaners up to 100 psi

Medium to high pressure washdown up to 1,500 psi, chlorinated cleaners

High pressure washdown, chlorinated and/or caustic cleaners up to 1,500 psi

Frame Material

304 stainless steel 304 stainless steel 304 stainless steel

Finish #4 polish outside surfaces #4 polish#4 polish or bead blast throughout

FrameConstruction

BoltedBolted, continuous non-pitted welds

Continuous non-pitted welded construction, ground and polished welds

Standoffs None1/4 inch to 1/2 inch thick bolted spacers

1/2 inch to 1 inch thick welded standoffs

BearingStainless steel sealed ball bearings or Polymer housing with steel/zinc insert

Polymer housing, stainless steel insert, FDA approved solid lubricant

Stainless steel bearing unit, FDA approved solid lubricant

Motor/Gearbox

Industrial Epoxy painted, washdown Stainless steel, washdown

Hardware Stainless steel Stainless steel Stainless steel

StandsStainless steel angle bar, #4 polish

Stainless steel square tube,#4 polish

Stainless steel square tube,#4 polish

Leveling PadPlastic, zinc plated threaded rod

Plastic, stainless steel threaded rod

3A sanitary leveling pad

Side Rail UHMW-PE or stainless steel UHMW-PE or stainless steel UHMW-PE or stainless steel

Control BoxNema 4x, IP65, industrial painted enclosure

Nema 4x, IP65,epoxy painted enclosure

Nema 4x, IP56,stainless steel enclosure

mk CleanMove Conveyor Technology 5

Recommended Applications

Packaged Processed Raw

Dairy

Pharmaceutical, Medical, Personal Care

Packaged Unpackaged

Packaged Cooked Dough

Dough Processing, Candy & Confectionary

Fruits & Vegetables

Packaged Cooked Raw

Packaged Cooked Raw

Meat & Poultry

= CleanMove Standard = CleanMove Plus = CleanMove Ultra

6 mk CleanMove Conveyor Technology

CleanMove Standard Series 200 Overview

6 mk CleanMove Conveyor Technology

standard

General Specifications

• 304 stainless steel

• #4 polish exterior surfaces

• Heavy duty bolted construction

• Full line of accessories, including stand supports and side rails

• Wipe-down and liquid spray washdown, soap and water; up to 100 psi

• Quality components

• Pharmaceuticals

• Packaged candies

• Wrapped breads

• Packaging lines

• Can and bottle lines

• Packaged snack foods

• Dry to low moisture environments

Applications

A compact and economical solution for your food and pharmaceutical packaging needs. The CleanMove Standard conveyor series offers a wide variety of conveyor platforms. With extensive belting, drive options and accessories, mk has the solution to meet your specific application.

ECONOMICAL

COMPACT

ROBUST

mk CleanMove Conveyor Technology 7

Standard industrial duty motors with

optional upgrades to washdown units

Wide selection of support stands

Stainless steeltype 304 bolted

construction

#4 polish on exterior surfaces

Transfer rollers can aid product on or off

the conveyor

Polymer housed bearings with a steel/zinc insert

Flat top chain conveyors can include curves, as shown, or be straight running

Fixed and adjustable side rails are available for all conveyor series

Available in Fabric Belt, Flat Top Chain & Plastic Modular Belt

8 mk CleanMove Conveyor Technology8 mk CleanMove Conveyor Technology

CleanMove Plus Series 400 Overview

General Specifications

• Medium to high pressure washdown, up to 1,500 psi• Chlorinated cleaners• Robust 304 stainless steel construction• #4 polish exterior surfaces• Bolted, continuous non-pitted welded construction• ¼-inch to ½-inch standoffs, welded• Polymer bearings with stainless steel insert and FDA

approved solid lubricant• Washdown duty motors and reducers• Full line of accessories including support stands and

side rails• Designed to FDA, 3-A, NSF and BISSC regulations

• Unpackaged pharmaceuticals

• Candies and confectionaries

• Dough

• Can and bottle lines

• Fruits and vegetables

• Packaged and/or cooked meat, fish and poultry

• Moderate to high moisture environments

• Moderate to high use of corrosive chemicals and cleaners

Applications

The CleanMove Plus is a very versatile conveyor series and is designed to operate in most sanitary environments. CleanMove Plus offers a wide variety of conveying platforms, belting options and accessories.

SANITARY

VERSATILE

ROBUST

mk CleanMove Conveyor Technology 9

Optional quick release handle on drip pan

for cleanability

Side mounted epoxy painted

washdown motor

Optional Clean in Place (CIP) Belt Cleaning System

Optional MicroTransfer slave driven with plastic

modular belt

No flat surfaces on stands for water to

collect

Optional Drip pan to collect water from CIP system

Bottom of the stands are closed

off to prevent water from

entering

Polymer bearings with stainless steel

insert and FDA approved solid

lubricant

Available in Fabric Belt, Flat Top Chain & Plastic Modular Belt

CleanMove Ultra Series 600 Overview

ultra

10 mk CleanMove Conveyor Technology

General Specifications

• Robust and durable 304 stainless steel construction• #4 polish throughout• Ground and polished welds• ½-inch to 1-inch thick welded standoffs• Stainless steel bearings with FDA approved

solid lubricant• Full line of accessories, including supports and

side rails• High pressure washdown (up to 1,500 psi) and

the use of caustic cleaners• Designed to FDA, 3-A, NSF and BISSC regulations

• Raw meat, poultry and fish• Dairy products: cheese, milk, yogurt• Raw dough• Unpackaged pharmaceuticals• Raw candy and confectionaries• Proofing lines for dough

Applications

The CleanMove Ultra stainless steel conveyors are designed and built to work in the highest sanitary environments. Designed to withstand the most demanding of cleaning applications as typically seen with raw proteins and dairy products.

MOST HYGIENIC

OPEN DESIGN

DURABLE

CleanMove Conveyor Technology 11

All hardware and fasteners are clear of

the belt path

Under belt scrapers are ideal for keeping product from building

up on the belt

Stainless steel motor and reducer

Optional nosebar transfer at infeed

Optional drip pans can also be used to

collect product

Open frame design allows for quick and easy belt cleaning

All surfaces featurea #4 polish

3-A stainless steel leveling pads

Available in Fabric Belt, Flat Top Chain & Plastic Modular Belt

12 mk CleanMove Conveyor Technology

All mk synthetic fabric belt conveyors feature FDA approved belt and cleat options. As shown below these conveyors are available with and without cleats. For added cleanability many of the belts can be supplied with sealed edges. A wide variety of belt splices, including endless and stainless steel lacings are available. These conveyors also feature optional v-guide belts and frames.

CFB-400 and CCB-400CFB-200 and CCB-200

Standard

• 304 stainless steel

• #4 polish finish on external surfaces

• Bolted construction

• Wipe down

• Soap and water compatible

• Washdown up to 100 psi

• Stainless steel industrial bearings

• Industrial motors

• 304 stainless steel

• #4 polish finish

• Bolted, continuous non-pitted welded construction

• Chlorinated cleaner compatible

CFB-400 Specifications:

• 2 in. drive pulley diameter

• 2 to 24 in. frame width, in 2 in. increments

• 48 ft. max. frame length

• 250 fpm max. speed

• 450 lbs. max. load capacity

• End and mid-mount drives available

• Allows for a rolling nosebar

• 3 in. drive pulley diameter

• 4 to 36 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 300 lbs. max. load capacity

• End and mid-mount drives available

• Optional tip-up tail

• Allows for a rolling nosebar

• 2 in. drive pulley diameter

• 2 to 24 in. frame width, in 2 in. increments

• 48 ft. max. frame length

• 250 fpm max. speed

• 450 lbs. max. load capacity

• End drives available

• Has cleats from 0.25 to 3 in tall, customer selected pitch

• Offers corrugated side walls on the belt

CFB-200 - CleanMove StandardFlat Belt Conveyor

CFB-400 - CleanMove PlusFlat Belt Conveyor

CCB-200 - CleanMove StandardCleated Belt Conveyor

Fabric & Cleated Belt Conveyors

Standard Features:

CFB-200 Specifications: CCB-200 Specifications:

mk CleanMove Conveyor Technology 13

0 CFB-600 and CCB-600

Standard Features: Features:

• 304 stainless steel

• #4 polish or bead blasted finish on all frame surfaces

• Non-pitted welded construction (wherever possible)

• Caustic cleaner compatible

• Washdown up to 1,500 psi

• Stainless steel bearings with FDA approved solid lubricant

• Stainless steel motors

• Washdown up to 1,500 psi

• Polymer bearings with stainless steel insert and FDA approved solid lubricant

• Epoxy painted washdown motors

CFB-600 Specifications: CCB-600 Specifications:CCB-400 Specifications:

• 4 in. drive pulley diameter

• 6 to 36 in. frame width, 2 in. increments

• 60 ft. max. length

• 250 fpm max. speed

• 450 lbs. max. load capacity

• End and mid-mount drives available

• Tip-up tail standard

• Open frame construction out of square tube stainless steel offers maximum cleanability

• Optional belt lifter available

• Allows for a rolling nosebar

• 4 in. drive pulley diameter

• 6 to 36 in. frame width, 2 in. increments

• 60 ft. max. length

• 250 fpm max. speed

• 450 lbs. max. load capacity

• End drives available

• Tip-up tail standard

• Open frame construction out of square tube stainless steel offers maximum cleanability

• Optional belt lifter available

• Cleats from 0.25 to 3 in tall, customer selected pitch

• 3 in. drive pulley diameter

• 4 to 36 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 300 lbs. max. load capacity

• End drives available

• Optional tip-up tail

• Cleats from 0.25 to 3 in. tall, customer selected pitch

CFB-600 - CleanMove UltraFlat Belt Conveyor

CCB-600 - CleanMove UltraCleated Belt Conveyor

CCB-400 - CleanMove PlusCleated Belt Conveyor

14 mk CleanMove Conveyor Technology

Plastic modular belt conveyors are offered with or without cleated belts. These conveyors allow for the belt to be quickly and easily removed. Removing the belt allows for access inside the frame for cleaning. Used in many industries, these conveyors provide a versatile solution.

CMP-400 and CCM-4CMP-200 and CCM-200

• 304 stainless steel

• #4 polish finish on external surfaces

• Bolted construction

• Wipe-down

• Soap and water compatible

• Washdown up to 100 psi

• Polymer housed bearing with zinc/steel insert

• Industrial motors

• 304 stainless steel

• #4 polish finish

• Bolted, continuous non-pitted welded construction

• Bolted spacers for hardware and accessory attachment

• 3.9 in. drive pulley diameter

• 4 to 48 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 1,000 lbs. max. load capacity

• End and mid-mount drives available

• Allows for a rolling nosebar

• 5.1 in. drive pulley diameter

• 4 to 48 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 1,000 lbs. max. load capacity

• End and mid-mount drives available

• Optional tip-up tail

• Allows for a rolling nosebar

• 3.9 in. drive pulley diameter

• 4 to 48 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 1,000 lbs. max. load capacity

• End drives available

• Cleats up to 6 in. tall, customer selected pitch

• Belt sidewalls available

CCM-200 - CleanMove StandardCleated Plastic Modular Belt Conveyor

CMP-400 - CleanMove PlusPlastic Modular Belt Conveyor

CMP-200 - CleanMove StandardPlastic Modular Belt Conveyor

Plastic Modular Belt Conveyors

Standard

CMP-400 Specifications:

Standard Features:

CMP-200 Specifications: CCM-200 Specifications:

mk CleanMove Conveyor Technology 15

400 CMP-600 and CCM-600

• 304 stainless steel

• #4 polish finish or bead-blasted on all frame surfaces

• Non-pitted welded construction (wherever possible)

• Caustic cleaner compatible

• Welded standoffs to keep hardware out of the belt path

• Washdown up to 1,500 psi

• Stainless steel bearings with FDA approved solid lubricant

• Stainless steel motors

• Chlorinated cleaner compatible

• Washdown up to 1,500 psi

• Polymer bearings with stainless steel insert & FDA approved solid lubricant

• Epoxy painted washdown motors

• 5.1 in. drive pulley diameter

• 4 to 48 in. frame width, 2 in. increments

• 50 ft. max. frame length

• 250 fpm max. speed

• 850 lbs. max. load capacity

• End and mid-mount drives available

• 3-A sanitary design guidelines

• Frame cut outs for easy cleaning

• No horizontal surfaces allow for maximum drainage

• Allows for a rolling nosebar

• 5.1 in. drive pulley diameter

• 4 to 48 in. frame width, 2 in. increments

• 50 ft. max. frame length

• 250 fpm max. speed

• 850 lbs. max. load capacity

• End drives available

• 3-A sanitary design guidelines

• Frame cut outs for easy cleaning

• No horizontal surfaces allow for maximum drainage

• Cleats up to 6 in. tall, customer selected pitch

• Belt sidewalls available

• 5.1 in. drive pulley diameter

• 4 to 48 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 1,000 lbs. max. load capacity

• End drives available

• Optional tip-up tail

• Cleats up to 6 in. tall, customer selected pitch

• Belt sidewalls available

CCM-600 - CleanMove UltraCleated Plastic Modular Belt Conveyor

CCM-400 - CleanMove PlusCleated Plastic Modular Belt Conveyor

CMP-600 - CleanMove UltraPlastic Modular Belt Conveyor

Standard Features: Features:

CMP-600 Specifications: CCM-600 Specifications:CCM-400 Specifications:

16 mk CleanMove Conveyor Technology

Incline conveyors can be configured in a variety of different ways. They are available in fabric and plastic modular belt options. A wide variety of cleats and sidewalls are available. Incline conveyors from mk are robust, durable and useful in many industries and applications.

CIC-400 and CIM-40CIC-200 and CIM-200

• 304 stainless steel

• #4 polish finish on external surfaces

• Bolted construction

• Wipe down

• Soap and water compatible

• Washdown up to 100 psi

• Polymer housed bearing with zinc/steel insert

• Industrial motors

• Angles of incline/decline are 15°, 30°, 45° and 60°

• 304 stainless steel

• #4 polish finish

• Bolted continuous non-pitted welded construction

• Bolted spacers for hardware and accessory attachment

• Chlorinated cleaner compatible

• 2 in. drive pulley diameter

• 6 to 24 in. frame width, 2 in. increments

• Usable width is 5 in. less frame width

• 48 ft. max. frame length

• 150 fpm max. speed

• 250 lbs. max. load capacity

• Available in a variety of configurations

• Customer selected lengths for each section

• Cleats from 0.25 to 3 in. tall, customer specified pitch

• 3 in. drive pulley diameter

• 6 to 24 in. frame width, 2 in. increments

• Usable width is 5 in. less frame width

• 48 ft. max. frame length

• 150 fpm max. speed

• 400 lbs. max. load capacity

• Available in a variety of configurations

• Customer selected lengths for each section

• All FDA approved components in the bend assemblies

• Cleats from 0.25 to 3 in. tall, customer specified pitch

• 3.9 in. drive pulley diameter

• 6 to 24 in. frame width, 2 in. increments

• Usable width is 4.75 in. less frame width

• 60 ft. max. frame length

• 150 fpm max. speed

• 400 lbs. max. load capacity

• Available in a variety of configurations

• Customer selected lengths for each section

• Cleats up to 6 in. tall, customer specified pitch

Incline Conveyors

CIM-200 - CleanMove StandardIncline Plastic Modular Belt Conveyor

CIC-400 - CleanMove PlusIncline Belt Conveyor

CIC-200 - CleanMove StandardIncline Belt Conveyor

Standard

CIC-400 Specifications:

Standard Features:

CIC-200 Specifications: CIM-200 Specifications:

mk CleanMove Conveyor Technology 17

0 CIC-600 and CIM-600

• 304 stainless steel

• #4 polish or bead blast finish on all frame surfaces

• Non-pitted welded construction (wherever possible)

• Welded standoffs to keep hardware out of the belt path

• Caustic cleaner compatible

• Washdown up to 1,500 psi

• Stainless steel bearings with FDA approved solid lubricant

• Stainless steel motors

• Angles of incline/decline are 15°, 30°, 45° and 60°

• Washdown up to 1,500 psi

• Polymer bearings with stainless steel insert and FDA approved solid lubricant

• Epoxy painted washdown motors

• Angles of incline/decline are 15°, 30°, 45° and 60°

• 4 in. drive pulley diameter

• 6 to 24 in. frame width, 2 in. increments

• Usable width is 8 in. less frame width

• 48 ft. max. frame length

• 150 fpm max. speed

• 400 lbs. max. load capacity

• 3-A sanitary design guidelines

• Square tube steel frame, with rounded edges, for maximum cleanability

• Cleats from 0.25 to 3 in. tall, customer specified pitch

• 5.1 in. drive pulley diameter

• 8 to 48 in. frame width, 2 in. increments

• Usable width is 5.25 in. less frame width

• 50 ft. max. frame length

• 150 fpm max. speed

• 400 lbs. max. load capacity

• 3-A sanitary design guidelines

• Square tube steel frame, with rounded edges, for maximum cleanability

• Cleats up to 6 in. tall, customer specified pitch

• 5.1 in. drive pulley diameter

• 6 to 48 in. frame width, 2 in. increments

• Usable width is 4.75 in. less frame width

• 60 ft. max. frame length

• 150 fpm max. speed

• 400 lbs. max. load capacity

• Available in a variety of configurations

• Customer selected lengths for each section

• All FDA approved components in the bend assemblies

• Cleats up to 6 in. tall, customer specified pitch

CIM-600 - CleanMove UltraCleated Belt Conveyor

CIM-400 - CleanMove PlusIncline Plastic Modular Belt Conveyor

CIC-600 - CleanMove UltraIncline Belt Conveyor

Standard Features: Features:

CIC-600 Specifications: CIM-600 Specifications:CIM-400 Specifications:

18 mk CleanMove Conveyor Technology

Flat top chain conveyors are available with or without curves. These conveyors allow for the belt to be quickly and easily removed. Removing the belt allows for access inside the frame for cleaning.

CTF-200 and CRF-200 CTF-400 and CRF-400

Standard Features: Standard Features:

• 304 stainless steel

• #4 polish finish on external surfaces

• Bolted construction

• Wipe down

• Soap and water compatible

• Washdown up to 100 psi

• Polymer housed bearing with zinc/steel insert

• Industrial motors

• All FDA approved beltings available in Acetal plastics and stainless steel

• 304 stainless steel

• #4 polish finish

• Bolted, continuous non-pitted welded construction

• Chlorinated cleaner compatible

• Washdown up to 1,500 psi

• Polymer bearings with stainless steel insert and FDA approved solid lubricant

• All FDA approved beltings available in Acetal plastics and stainless steel

• 5.09 in. drive pulley diameter

• 3.25, 4.5, 6, 7.5, 10 and 12 in. chain widths

• 60 ft. max. frame length

• 200 fpm max. speed

• 1,200 lbs. max. load capacity

• 5.09 in. drive pulley diameter

• 3.25, 4.5, 6, 7.5, 10 and 12 in. chain widths

• 60 ft. max. frame length

• 200 fpm max. speed

• 1,200 lbs. max. load capacity

• Raised belt surface for superior cleanability

• 5.09 in. drive pulley diameter

• 3.25, 4.5, 7.5, 10 and 12 in. chain widths

• 40 ft. max. frame length

• 200 fpm max. speed

• 800 lbs. max. load capacity

• Horizontal and vertical bends available

• Multiple straight and bend sections possible

• 5.09 in. drive pulley diameter

• 3.25, 4.5, 7.5, 10 and 12 in. chain widths

• 40 ft. max. frame length

• 200 fpm max. speed

• 800 lbs. max. load capacity

• Horizontal and vertical bends available

• Multiple straight and bend sections possible

Flat Top Chain Conveyors

CTF-200 - CleanMove Standard Straight FlatTop Chain Conveyor

CTF-200Specifications:

CTF-400Specifications:

CTF-400 - CleanMove Standard Straight FlatTop Chain Conveyor

CRF-200 - CleanMove Standard Curved FlatTop Chain Conveyor

CRF-200Specifications:

CRF-400Specifications:

CRF-400 - CleanMove Standard Curved FlatTop Chain Conveyor

mk CleanMove Conveyor Technology 19

Curved plastic modular belts are highly customizable. Multiple straight and curve sections per conveyor are possible. The belt is easily removable to access to inner frame for cleaning.

CRM-200 CRM-400 CRM-600

Standard Features: Standard Features: Standard Features:

• 304 stainless steel

• #4 polish finish on external surfaces

• Bolted construction

• Wipe down

• Soap and water compatible

• Washdown up to 100 psi

• Polymer housed bearing with zinc/steel insert

• Industrial motors

• 30°, 45°, 60°, 90° and 180° bend angles

• 304 stainless steel

• #4 polish finish

• Bolted continuous non-pitted welded construction

• Bolted spacers for hardware and accessory attachment

• Chlorinated cleaner compatible

• Washdown up to 1,500 psi

• Polymer bearings with stainless steel insert and FDA approved solid lubricant

• Epoxy painted washdown motors

• 30°, 45°, 60°, 90° and 180° bend angles

• 304 stainless steel

• #4 polish finish or bead-blasted on all frame surfaces

• Non-pitted welded construction (wherever possible)

• Welded standoffs to keep hardware out of the belt path

• Caustic cleaner compatible

• Washdown up to 1,500 psi

• Stainless steel bearings with FDA approved solid lubricant

• Stainless steel motors

• 30°, 45°, 60°, 90° and 180° bend angles

CRM-200 Specifications: CRM-400 Specifications: CRM-600 Specifications:

• 3.5 in. drive pulley diameter

• 6 to 24 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 500 lbs. max. load capacity

• 3.5 in. drive pulley diameter

• 6 to 36 in. frame width, 2 in. increments

• 60 ft. max. frame length

• 250 fpm max. speed

• 500 lbs. max. load capacity

• 5.1 in. drive pulley diameter

• 6 to 48 in. frame width, 2 in. increments

• 50 ft. max. frame length

• 250 fpm max. speed

• 500 lbs. max. load capacity

• 3-A sanitary design guidelines

• Frame cut outs for easy cleaning

• No horizontal surfaces allow for maximum drainage

Curved Plastic Modular Belt Conveyors

CRM-200 - CleanMove StandardCurved Plastic Modular Belt Conveyor

CRM-400 - CleanMove PlusCurved Plastic Modular Belt Conveyor

CRM-600 - CleanMove UltraCurved Plastic Modular Belt Conveyor

20 mk CleanMove Conveyor Technology

The positive drive belt is the ultimate in hygienic design. The belt is a solid thermoplastic (100% closed) material. The belt is positively driven which eliminates belt tracking issues. The conveyor features a toolless frame design, frame cut-outs and belt lifters for fast and easy belt cleaning.

Positive Drive

CPD-600

• 304 stainless steel

• #4 polish or bead blast finish on all frame surfaces

• Non-pitted welded construction (wherever possible)

• Welded standoffs to keep hardware out of the belt path

• Caustic cleaner compatible

• Washdown up to 1,500 psi

• Stainless steel bearings with FDA approved solid lubricant

• Stainless steel motors

• Toolless frame design

• 5.2 in. drive pulley diameter

• 6 to 36 in. width, 3 in. increments

• 30 ft. max. frame length

• 250 fpm max. speed

• 600 lbs. max. load capacity

• End drives available

• 3-A sanitary design guidelines

• Frame cut outs for easy cleaning

• Optional belt lifter available

CPD-600 - CleanMove Ultra Positive Drive Belt

Standard Features:

CPD-600 Specifications:

mk CleanMove Conveyor Technology 21

mk offers both fixed and adjustable side rails. For adjustable side rails, we offer three different uprights and three different horizontal rail options. Shown below are just a few examples of what we offer. Consult our full line catalog for more information.

mk offers a variety of different stands designed to meet the specific needs of the CleanMove conveyor levels. Many stands are available with leveling pads or casters. Shown below are just a few examples of what we offer. Consult our full line catalog for more information.

Support Stands

Side Rails

22 mk CleanMove Conveyor Technology

mk North America's standard offering includes motors and gearheads from various world class suppliers. They are offered in three different levels of cleanability to correspond to the three levels of CleanMove series conveyors. Customers are welcome to mix and match motor sanitation levels with different conveyor sanitation levels.

• Industrial motors, gearhead and gearmotors for CleanMove Standard series

• Epoxy painted, washdown rated motors, gearheads and gearmotors for CleanMove Plus series

• Stainless steel, washdown rated motors, gearheads and gearmotors for CleanMove Ultra series

• Motor types can be mixed and matched with any CleanMove series

• A wide variety of voltages available including; 115 AC 1 Ph, 230 and 460 AC 3 Ph

• DC motors and 115 AC speed controls are available for CleanMove Standard and Plus series

Motors

Featuring products from:

See our full catalog for more details or call mk North America and we will be happy to design a solution for you!

mk CleanMove Conveyor Technology 23

mk offers three different levels of cleanability for controllers, corresponding to the three levels of CleanMove conveyors. Customers are welcome to mix and match sanitation levels of controllers with the conveyor levels, however caution should be taken when selecting a controller of a lower sanitation level.

• mk North America offers a variety of speed controls and inverters to be used with our various motors

• All controllers are Nema 4x with either a IP65 or IP56 rating

• DC voltage motors require the use of a speed control to operate

• AC motors are inverter duty, but do not require the use of an inverter

• In all instances customers are welcome to provide their own controls

Controllers

Featuring products from:

24 mk CleanMove Conveyor Technology

All of mk’s CleanMove conveyors feature FDA approved belting. Whether your application requires a synthetic fabric belt, plastic modular belting, positive drive belting or flat top chain, mk is certain to have the right belting for your application. Shown here are a few examples of the belts we offer, and many are available with cleats. Consult the mk CleanMove Catalog for a full product listing of belts and chains. mk is also happy to use a belt that you may currently be using or if you prefer, contact our sales staff for a belting recommendation.

Fabric Belt Plastic Modular Belt

Belts & Chains

Featuring products from:

• FDA approved belting, flights and sideguards

• Damaged or worn segments of belting can be replaced, instead of replacing the entire belt; reducing costs and downtime

• Open and closed belt surfaces available

• Open belts are ideal for moist applications as well as for cooling and drainage

• Stainless steel and a variety of plastic pins available for most belt types

• Allows for use of a Clean In Place system for continuous cleaning of belting

• FDA approved belting, cleats and sidewalls

• Many belts available with sealed edges to reduce contamination of belt core

• Speciality belts for x-ray, ovens and dough processing available

• Belt splices include all FDA approved options; endless finger, endless step, stainless steel lacing or plastic lacing

• Cleats from 0.25 to 3-inches tall

• Sidewalls up to 3-inches tall

• Customer specified cleat spacing

• Belts are typically white or blue in color

mk CleanMove Conveyor Technology 25

Positive Drive Belt Flat Top Chain

Featuring products from:

• All FDA approved chains, including a variety of plastics and stainless steel

• Speciality chains featuring roller tops or friction inserts are available

• Chain industry standard widths

• USDA/FDA and 3-A cleared and approved

• A smooth, homogeneous surface without crevices which helps prevent bacteria buildup

• No ply or edge fraying

• Simple and hygenic construction

• Mechanical benefits including minimal pretension, reduced noise level, lightweight belting, easy to install, and a long operating life

26 mk CleanMove Conveyor Technology

mk North America offers two types of MicroTransfers. Designed to aid in small product transfers between large pulley diameter conveyors. Slave units are designed to be driven off either the infeed or the discharge. And motor driven units are independent of the conveyor they are mounted to.

• The transfers are designed around our CleanMove Plus and Ultra series

• For smooth product transition and product flow control through transfer

• Available in fabric and plastic modular belting

• Use in any location where a tight nose transfer is required

• Great for product singulation• Customizable to the width of the

conveyor they are transfering to or from• Transfer nose Ø = 0.78 in.

mk roller transfers are ideal when products need additional support bridging the gap between conveyors. The product is supported by three rows of food grade plastic rollers. This is a non-powered transfer and is customizable to a variety of widths, including wide conveyor widths (over 24 in.).

mk rod transfers are ideal when products need additional support bridging gaps between conveyors. This transfer features a stainless steel rod, and can be provided as non-powered or driven off the mk supplied CleanMove conveyor.

MicroTransfer

Roller Transfer

Rod Transfer

Fabric Belt

CleanMove Ultra slave driven

MicroTransfer shown.

Modular Belt

mk CleanMove Conveyor Technology 27

Accessories

Detail

Clean in Place (CIP) spray systems are designed to clean the chain of a plastic modular belt conveyor as it travels past the water spray nozzles.

Stainless steel chutes are designed to feed product onto or off of the conveyor.

Stainless steel ceiling supports can be provided with our without drop rods, ideal for conveying at high elevations.

Stainless steel drip pans can be added for a variety of uses includ-ing collecting liquids and particu-lates that fall from the product.

Hoppers are ideal in applications where large quantities of product need to be metered out, guided and moved onto the conveyor.

Covers can be provided for any of our conveyors, and come in clear polycarbonate or stainless steel versions.

Food grade urethane belt scrapers are designed to remove product build-up from the belt and help release products better.

Adjustable or non-adjustable lane dividers are used to group product into lanes, and are constructed of stainess steel or food grade plastic.

Belt lifters are designed to easily lift the belt off the conveyor surface for a fast and effective way to clean the inside of the frame.

Belt Lifter

Lane Divider

Belt Scraper

Conveyor Cover

Hopper

Drip Pan

Ceiling Support

Chute

Spray System

28 mk CleanMove Conveyor Technology

This example of a CleanMove Plus features epoxy painted motors, 3-A leveling pads, tight rolling nosebar end transfers and custom belt scrapers. This conveyor is a glaze recapturing system.

A stainless steel conveyor featuring a plastic modular belt receives small pharmaceutical vials into a rotary indexer.

Stainless steel flat belt conveyors are often used for conveying small delicate products such as these cookies. In this example cookie filling is being added as they move past the dispenser nozzles on the conveyor.

Design & Application Examples

Fixed side rails contain produce on this CleanMove Plus conveyor. Also featured are stands mounted via stand-offs keeping all hardware out of the belt path.

mk CleanMove Conveyor Technology 29

In this custom application baking pans are presented for dough filling before being transferred off the conveyor with the assistance of a stainless steel motorized driven roller.

Croissants travel on a CleanMove Plus CRM-400 conveyor to a wrapping station. This conveyor features removable side rails and casters, which make it movable.

Frozen pizzas travels to the packaging line on this CleanMove Plus CMP-400 conveyor.

Fabric belts come in a variety of different surfaces and finishes. Some belts are ideal for hot sticky goods while others, like this blue belt, are ideal in dough proofing lines.

30 mk CleanMove Conveyor Technology

CleanMove Standard flat belt conveyor, CFB-200, with adjustable side rails is ideal for transporting and containing a variety of different size products such as this pharmaceutical vial.

CleanMove Plus conveyors have many optional features which increase the cleanability of the conveyor, such as the toolless tip-up tail on this cleated fabric belt conveyor CCB-400.

Closed flat top plastic modular belt conveyor CleanMove Plus, CMP-400.

CleanMove Plus conveyor, CRM-400, with optional frame cut out for easy cleaning.

Design & Application Examples

mk CleanMove Conveyor Technology 31

CleanMove Standard flat belt conveyors, CFB-200, standard idlers feature a two bolt belt tracking and tensioning system. Also shown is a food grade UHMW side rail.

The belt has been removed to show the open and hygienic design of the internal frame of this plastic modular belt conveyor.

This CleanMove Plus flat belt conveyor features a retractable tight nosebar for small product transfer as well as a custom topside adjustable belt scraper.

A CleanMove Plus conveyor with a sanitary stainless steel chute to guide product off belt.

CleanMove is a registered trademark of mk North America, Inc. All rights reserved, information subject to change without notice. © 2015 mk North America, Inc.

mk North America, Inc.an mk Technology Group Company

105-125 Highland Park DriveBloomfield, CT 06002, USA

Phone: (860) 769-5500 Fax: (860) 769-5505