01_herres_ch01_p001-014

-

Upload

ant29539432 -

Category

Documents

-

view

216 -

download

0

Transcript of 01_herres_ch01_p001-014

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 1/14

CHAPTER 1NEC® Chapter 1,

General

Article 100

The first chapter of the National Electrical Code® (NEC®) continuesthe task started in Article 90 of laying the groundwork for the remain-der of the Code. It begins with Article 100, Definitions, which, as usual,opens with a statement of scope. At this point, it is anticipated that thereader is becoming familiar with the basic NEC article template.

Discussing scope, the article states that only Code-specific defini-tions are included and that commonly understood general and tech-

nical terms from related codes and standards are excluded; onlyterms found in two or more articles are defined herein. Terms occur-ring in a single article are defined in that article. Part II of the articledefines terms applicable to installations and equipment operating atover 600 volts nominal. The 600-volt division is found repeatedlythroughout the Code. Since it says “over 600 volts,” the commonlyused 600-volt system does not fall within the higher-voltage category.Also, in this context, these voltages are nominal. Actual voltages, asmeasured in the field, may be higher or lower depending on utilitypractice; line length; voltage drop within the service, feeder, and

branch circuits; and amount of current being drawn at the time themeasurement is made. Load current partially determines measuredvoltage. Nominal voltage is a constant, and this is what determinesCode usage.

Most of the definitions are self-explanatory. Exam questions basedon these definitions are fairly easy to answer because the terms are inalphabetical order and occur in either Part I or Part II or within thearticle in question, a location best ascertained by consulting the Index.In the discussion that follows, we will look at a few of the definitionsthat have a great impact on Code usage and understanding.

One of the really crucial definitions also comes first because ithappens to be first alphabetically. We have to understand exactlythe meanings and distinction between accessible and readily accessible

1

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 2/14

2 C h a p t e r O n e

and between inaccessible and not readily accessible. This is so becausea great many Code provisions depend on these distinctions. Accessi-ble, in regard to equipment, means “admitting close approach.” The

concept is further refined by adding “not guarded by locked doors,elevation, or other effective means.” Accessible, in regard to wiringmethods, means “capable of being removed or exposed withoutdamaging the building structure or finish or not permanently closedin by the structure or finish of a building.”

Readily accessible means “capable of being reached quickly foroperation, renewal, or inspections without requiring individuals toclimb over or remove obstacles or resort to portable ladders and soforth.” The classic example of equipment that is accessible but notreadily accessible is a junction box above a suspended ceiling.

(Junction boxes have to be accessible but not readily accessible.) Anentrance panel, by contrast, cannot be above a suspended ceiling because it needs to be readily accessible. Interestingly, a dry trans-former of 600 volts nominal or less, not exceeding 50 kVA, is per-mitted in hollow spaces of buildings not permanently closed in bystructure, provided that it meets the ventilation requirements ofSection 450.9 and separation from combustible materials require-ments of Section 450.21(A). These units are not required to be readilyaccessible and could go above a suspended ceiling.

Concealed means “rendered inaccessible by the structure or finish of

the building.” Wires in concealed raceways are considered concealed,even though they may become accessible by withdrawing them.

Approved means “acceptable to the authority having jurisdic-tion.” This may or may not be accompanied by being listed by a test-ing organization.

Authority having jurisdiction (AHJ) means “an organization, office, orindividual responsible for enforcing Code requirements.” Generally,this is the electrical inspector, but it may vary because this matter is notmandated within the Code but rather depends on state, municipal, orother legislation. Insurance companies also inspect for Code compli-

ance and so may have personnel who constitute the AHJ, and individ-ual property owners, managers, or government workers may performthis function. In any event, the AHJ has final say on a day-to-day basis,although in many instances there are appeal remedies in place.

Bonded means “connected to establish electrical continuity andconductivity.” This concept is very important within the context ofgrounding. Except in limited cases, the goal is to achieve a lowimpedance.

Bonding jumper means “a reliable conductor to ensure the requiredelectrical conductivity between metal parts required to be electrically

connected.”Equipment bonding jumper means “the connection between the

grounded circuit conductor and the equipment grounding conductorat the service.”

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 3/14

N E C® C h a p t e r 1 , G e n e r a l 3

Main bonding jumper means “the connection between the groundedcircuit conductor and the equipment grounding conductor at the ser-vice.” This introduces the distinction between grounded and ground-

ing. Both are held at the same voltage potential with respect to ground, but they perform different functions. They are connected only in onelocation, within the service enclosure by the main bonding jumper.When they leave the service enclosure, they follow parallel paths tothe power outlet, but they are emphatically not connected at anypoint, either intentionally or by defective equipment. We shall dis-cuss this in greater detail when we get to Article 250, Grounding.

Exposed (as applied to live parts) means “capable of beinginadvertently touched or approached nearer than a safe distance by a person.” It is applied to parts that are not suitably guarded,

isolated, or insulated.Exposed (as applied to wiring methods) means “on or attached to

the surface or behind panels designed to allow access.”Identified (as applied to equipment) means “recognizable as suit-

able for the specific purpose, function, use, environment, application,and so forth, where described in a particular Code requirement.” Thisis generally done by UL or another testing laboratory.

Labeled means “equipment to which has been attached a label,symbol, or other identifying mark of an organization that is accept-able to the authority having jurisdiction and concerned with product

evaluation, that maintains periodic inspection of production oflabeled equipment or materials, and by whose labeling the manufac-turer indicates compliance with appropriate standards or perfor-mance in a specified manner.”

Listed means “equipment, materials or services included in a listpublished by an organization that is acceptable to the AHJ and con-cerned with evaluation of products or services, that maintains peri-odic inspection of production of listed equipment or materials orperiodic evaluation of services, and whose listing states that eitherthe equipment, material, or service meets appropriate designated

standards or has been tested and found suitable for a specified pur-pose.” Exam questions sometimes focus on the distinctions betweenidentified, labeled, and listed, so these terms must be understood,and it must be known how the definitions can be accessed.

We have taken a look at some of the definitions that are germaneto many Code provisions. These need to be held in mind as variouslocations within the Code are accessed so that misinterpretations donot occur.

Article 110Article 110, Requirements for Electrical Installations, is very basicfor all electrical work, and authors of licensing exams see it as anabundant source for questions. Following a statement of scope, the

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 4/14

4 C h a p t e r O n e

article begins with a number of general guidelines, some intendedfor the AHJ, some applicable to the design phase, others directed atthe installer. First, a noninclusive list of eight criteria is provided for

the inspector when deciding whether to approve equipment. Theseinclude

• NEC conformity, as evidenced by product marking, listing, orlabeling

• Mechanical strength and durability

• Wire bending and connection space

• Electrical insulation

• Heating effect both under normal use and abnormal condi-

tions

• Arcing effects

• Classification by type, size, voltage, current capacity, andspecific use

• Other safety factors

While this material is for the AHJ and probably won’t be the subjectof an exam question, it nevertheless serves to put electrical equipmentquality in perspective and certainly adds to an electrician’s developing

intuitive powers. There follow a number of general comments.

• Voltages referred to throughout the entire Code are those atwhich the circuit under consideration operates. Equipmentmust be rated at not less than the circuit nominal voltage.Generally, if equipment is operated undervoltage, it will not be damaged but will operate less efficiently. A light bulb will be dimmer than it should be but actually may have a longerlife. An exception is the electric motor, which is damaged byrunning at less than rated voltage. It will run slower than

rated rpms, and a portion of the electrical energy suppliedwill be converted to heat. Direct-current (dc) motors and uni-versal motors can be run at less than rated voltage, and thisproperty, with the proper controls, may be used intentionallyto regulate speed.

• Conductor sizes throughout the Code assume that the mate-rial will be copper. Where other materials are used, notablyaluminum and copper-clad aluminum, size adjustment must be made. The ampacity tables in Article 310, Conductors forGeneral Wiring, as we shall see, give sizes for copper on the

left. The right-hand side of the tables should be disregardedunless an exam question specifically refers to aluminum orcopper-clad aluminum. In most respects, copper-clad aluminumconductor properties are the same as aluminum conductor

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 5/14

N E C® C h a p t e r 1 , G e n e r a l 5

properties. Conductor sizes are expressed American WireGauge (AWG) or in units of circular mils.

•

Wiring integrity must be preserved, meaning that installa-tions must be free from short circuits, ground faults, andconnections to ground other than as required or permitted by the NEC.

• Only suitable wiring methods are included in the Code.They are permitted indoors and outdoors except as stated inthe Code.

• Current-interrupting ratings must be observed. Available faultcurrent depends on utility parameters and properties of theservice and premises wiring impedance. Ironically, the better

the wiring, the greater is the danger of exceeding current-interrupting ratings with possible damage to equipment andpersonal injury owing to arc flash. This issue becomes moreimportant in an industrial setting, as we shall see later.

• Circuit impedance must be considered in design stages, andexam questions address this issue. Selection and coordinationof overcurrent devices are necessary to protect equipmentand confine any outage to a limited area. Faults may occureither between two conductors or between a conductor andan intentionally or unintentionally grounded object. Properuse of listed products is an important component of Codecompliance and an important step in preventing faults.

• Conductors or equipment located in damp or wet environ-ments must be identified for such use. Licensing exams usu-ally focus on such properties. Similarly, gases, fumes, vapors,liquids, or any setting that has a deteriorating effect must beconsidered.

• Many past revisions and the current version of the Code statethat electrical equipment shall be installed in a neat and

workmanlike manner. The Code references AmericanNational Standards Institute (ANSI)/National Electrical Con-tractors Association (NECA) 1-2010, Standard Practice forGood Workmanship in Electrical Construction. This is in anInformational Note, so the document is not mandatory, but itis recommended that interested individuals consult it formore information on good work practices.

• Unused openings, unless intended, are to be closed. Wheremetallic plugs are used with nonmetallic enclosures, they areto be recessed ¼ inch from the outer surface. This is so because

they are not grounded, and being recessed provides someprotection from human contact in case they become ener-gized owing to a ground fault within.

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 6/14

6 C h a p t e r O n e

• The integrity of electrical equipment and connections is to be preserved. Busbars, wiring terminals, insulators, andother surfaces within electrical equipment are not to be

damaged or contaminated by paint, plaster, cleaners, abra-sives, corrosive residues, and similar foreign materials.Damaged, broken, bent, cut, or deteriorated parts must not be in use. Deterioration may be caused by corrosion, chemi-cal action, or overheating.

• Wooden plugs driven into holes in masonry, concrete, plaster,and the like may not be used to mount equipment, which isto be secured firmly to the surface on which it is mounted.Entrance panels, junction boxes, and other enclosures havepredrilled holes. Drywall screws may be used to mount suchenclosures to wooden walls, but at least one electrical inspec-tor has stated that only galvanized drywall screws should beused, even in an indoor setting.

• Airflow for cooling purposes must not be impeded by wallsor adjacent equipment. Floor-mounted equipment must haveclearance between the top surface and adjacent surfaces todissipate rising warm air.

• Dissimilar metals must not be joined for the purpose ofconducting electricity because over a period of time, cor-

rosion will occur. This is applicable to aluminum and cop-per. Acid flux, used by plumbers when soldering pipes,will leave a residue that promotes corrosion. For electricalconnections, use resin-based flux that is marked “Suitablefor electrical connections.” Connectors and terminals forconductors more finely stranded than Class B and Class Cstranding, as shown in Chapter 9, Table 10, must be iden-tified for the specific conductor class or classes. If atightening torque is marked on equipment, it must beobserved.

• Conductors must be connected to device or equipment ter-minals for the purpose of transferring energy to them, andthe Code specifies that these connections must perform in asatisfactory manner. A thoroughly good connection must bemade without damaging the conductors. This connectionmay be made by a pressure connector (including set-screwtypes), solder lugs, or splices to flexible leads.

• Elsewhere in the Code, solder connections are prohibited incertain applications. Wire-binding screws, nuts that have

upturned lugs, or equivalent are permitted only for 10 AWGor smaller conductors.

• Terminals for more than one conductor and those used toconnect aluminum must be identified for the purpose.

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 7/14

N E C® C h a p t e r 1 , G e n e r a l 7

• A frequent cause of electrical fires is failure of an electricalconnection. To prevent this unfortunate outcome, the Codespecifies that splicing devices be identified for the purpose.

Alternatively, brazing, welding, or soldering is an option,except where prohibited. (For example, Section 250.148, Con-tinuity and Attachment of Equipment Grounding Conduc-tors to Boxes, specifies that connections depending solely onsolder may not be used.) It is further stated that all splicesand joints and the free ends of conductors must be coveredwith an insulation equivalent to that of the conductor or withan insulating device identified for the purpose. For example,when using a wire nut (solderless connector) to join two ormore wires, only enough insulation should be stripped from

the end to facilitate a good connection. After the wire nut istwisted on, no copper should be visible unless the conductoris bare. Furthermore, wire connectors or splicing means fordirect burial are to be listed for the application.

• Here is an NEC requirement that is of great importance andoften the subject of exam questions: A conductor’s tem-perature rating may not exceed the lowest temperaturerating of any connected termination, connector, or device.Notwithstanding, conductors with temperature ratingshigher than specified for terminations are permitted forampacity adjustment and correction.

• A related requirement, also likely to appear in electricians’licensing exams: Equipment terminations for circuits rated100 amperes or less or marked for 14 AWG through 1 AWGare to be used for conductors rated 60°C. Equipment termina-tions for circuits rated over 100 amperes or marked used forconductors larger than 1 AWG are to be used for conductorsrated 75°C. (In both cases, higher temperature ratings areallowed if the equipment is listed and identified for such use.

• In the case of a three-phase, delta-connected system that hasthe midpoint of one phase grounded, it will be noticed thatthe opposite phase has a higher voltage with respect toground than the other two phases. This “high leg” must bemarked orange or by some other similarly effective means.This marking is to be placed at all connections throughout thesystem where the grounded conductor is also present.

• Switchboards, panelboards, motor control centers, meter socketenclosures, and the like in other than dwelling units must befield marked to warn against arc-flash hazard. Where high fault

current is available, as in many industrial locations, severeinjury may occur to workers even when current does not passthrough the body, i.e., there is no electrical shock. Flash warningsigns are available to comply with this requirement.

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 8/14

8 C h a p t e r O n e

• Where arcs, sparks, flames, or molten metal may be gener-ated within electrical equipment in ordinary operation, suchequipment must be enclosed or separated and isolated from

combustible material. This requirement does not refer to faultcurrent, but instead, it addresses motors, generators, andsimilar equipment that may have commutators, collectorrings, or a centrifugal starting switch.

• It is a Code violation to connect light or power circuits toany system that contains trolley wires with a ground return.An exception permits such usage in the case of car houses,power houses, or passenger and freight stations operated inconjunction with electric railways.

•All electrical equipment must display the manufacturer’sname, trademark, or other descriptive identifying marking.Other markings, such as voltage, current, and wattage, arerequired elsewhere in the Code.

• Disconnecting means must be so marked unless the purposeis self-evident.

• Engineered series combination systems must be field markedto indicate that the equipment is so rated. This is to preventimproper component replacement at some time in the futurethat could compromise the engineering intent.

• Similarly, manufactured series combination systems alsomust be so marked.

• Unused current transformers associated with potentiallyenergized circuits are to be short-circuited.

• In nondwelling units, service equipment is to be marked inthe field to indicate maximum available fault current.Available fault current often runs very high in an industrialsetting.

The foregoing bulleted list contains a number of requirementsthe Code makers have grouped together and titled Requirementsfor Electrical Installations. They are important points to keep inmind in the installation phase of a project, and all of them appear onelectricians’ licensing exams. While the points made are simple(with the possible exception of the sections on temperature limita-tions and equipment provisions, which have to be looked over care-fully before they make sense), they may be a little bit elusive becauseit is not immediately evident where this content may be found. Thisis particularly true of Chapters l and 2. It is suggested that the NEC

student make outlines of these two chapters and read them overuntil they become very familiar.

Part II of Chapter 1, General, is titled 600 Volts, Nominal, or Less.Here again, this lower-voltage category includes the frequently used

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 9/14

N E C® C h a p t e r 1 , G e n e r a l 9

600-volt nominal system. The most important item in Part II isSection 110.26, Spaces about Electrical Equipment. It is importantfrom the standpoint of licensing exams, which always contain working-

space and height questions, and also because, on a design/installationlevel, if a mistake is made and the inspector picks up on it, very costlyrework may be triggered. And if the inspector does not catch it andinjury or fatality results, the implications are unthinkable. There is asimple remedy—learn Section 110.26, and do not neglect to apply it.On an exam level, the provisions are easy to grasp, and there shouldnever be a problem getting the correct answer, but it may be difficultto access this material in the first place if you do not know where tolook. One might search around in Chapter 2, Wiring and Protection,Chapter 3, Wiring Methods and Materials, or Chapter 4, Equipment

for General Use or even an annex or table.Now that we have firmly in mind that working space, dedicated

equipment space, and related rules are in Part II (for up to and includ-ing 600 volts) of Article 110, Requirements for Electrical Installations,let us take a look at the specific mandates. Section 110.26, Spacesabout Electrical Equipment, mandates two separate and discretespaces—working space and dedicated equipment space. The first ofthese requires a protective zone around electrical equipment so thatin the event of arc flash or other emergency, a worker will not betrapped and unable to escape. Dedicated equipment space, in con-

trast, serves to isolate equipment and protect it from damage. Theseare two sets of spaces with separate requirements, both of which must be observed.

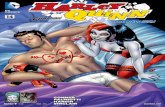

Bearing in mind that we are currently examining Part II, whichdeals with installations 600 volts nominal and less, working spacesare given in Table 110.26(A)(1) (Figure 1-1). This is the place to start.Notice that there are two voltage categories, listed in the first column.These are nominal voltages to ground, not leg-to-leg, so a 240-volt,single-phase system would be in the 150-volt category. Minimumclear distances are given for each of three conditions, and these con-

ditions are spelled out in the note appended under the table. This is allquite clear. It just remains to be ascertained how these numbers areapplied, particularly in regard to the geometric layout of these spaces,and also what must be excluded from these spaces. Moreover, there aresome exceptions. Throughout we must keep in mind that these areworking spaces. Dedicated equipment spaces are different from andin addition to working spaces.

The first thing to consider is which types of equipment requireworking spaces. In this category is equipment that is likely to requireexamination, adjustment, servicing, or maintenance. Examples are

entrance panels, load centers, motor control centers, and heating andair-conditioning controls. There may be gray areas. If in doubt, pro-vide working space. If the equipment does not fall within this cate-gory, the minimum clearances in Table 110.26(A)(1) do not apply.

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 10/14

10 C h a p t e r O n e

However, an unspecified amount of access and working space isrequired (in the first paragraph of 110.26) for all electrical equipment.

We normally think of working space as extending in front ofequipment, but the same requirements apply to the sides and back ifthese surfaces need access for examination, adjustment, servicing, ormaintenance of electrical equipment. If these surfaces require accessto work on nonelectrical equipment, the minimum clear distance forworking space is reduced, in Section 110.26(A)(1)(a), Dead-Front

Assemblies, to 30 inches. A good way to remember this is to recallthat the original working space minimum clear distances in Table110.26(A)(1) are expressed in feet and inches, whereas the relaxedrequirement for nonelectrical work is just in inches, 30 to be precise.We should discuss the geometry of working space: The width of theworking space is equal to the width of the equipment, but never lessthan 30 inches. This, of course, is so that it can be approached by aperson. Moreover, the work space must permit equipment doors orhinged panels to open at least 90 degrees, so in some cases the workspace must be increased. The 30 inches, where applicable, can extend

from either the left edge or the right edge of the equipment; it does nothave to be centered. Moreover, working spaces of adjacent pieces ofequipment may overlap. This is actually a good thing because it usu-ally means greater than minimum space is provided. In the case of

F IGURE 1-1 Water piping infringes the working space in front of this transferswitch in violation of Section 110.26, Spaces about Electrical Equipment.Also, there should be a bonding jumper around the plastic water filterhousing to provide ground continuity.

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 11/14

N E C® C h a p t e r 1 , G e n e r a l 11

overlapping working spaces, the adjacent equipment cannot be deeperor the working space minimum clearance would be compromised.

As for height, the working space is to be 6½ feet or the height of

the equipment, whichever is greater, measured from grade, floor, orplatform. Other related electrical equipment above and below theunit in question is permitted as long as it does not extend morethan 6 inches from the front surface. There are two exceptions tothese rules.

• In existing dwelling units, working spaces for service equip-ment or panelboards up to 200 amperes are permitted to haveless height (not less clear distance).

• Meters in meter sockets may extend beyond the other

equipment. (The meter can extend beyond the 6 inchespermitted in Section 110.26(A)(3), but the meter socket cannotdo so.

We have seen what is needed for working space. There are alsorelated requirements, some simple to understand and implement,some more complex. First, and this should be obvious, the workingspace is not to be used for storage. This is likely to be beyond theelectrician’s control because it may happen after the installation has been completed. In an industrial setting, it may be appropriate to out-

line the working space by painting a yellow line on the floor andappending a warning sign. In the same section, 110.26(B), ClearSpaces, it is further mandated that when normally enclosed live partsare exposed for inspection or servicing, the working space, if in a pas-sageway or general open space, is to be suitably guarded. Anothersection, 110.26(D), addresses the issue of illumination. It states thatillumination is to be provided for the working spaces about serviceequipment, switchboards, panelboards, and motor control centersthat are installed indoors and that this illumination is not to be con-trolled solely by automatic means. Automatic means, such as a motion

detector, are permitted, but a manual bypass is needed as well. Theseare the simple requirements. The others, Section 110.26(C), Entranceto and Egress from Working Space, which includes (3) PersonnelDoors, are more complex, but they need to be dealt with carefully because they appear frequently on exams.

This section requires at least one entrance of sufficient area to pro-vide access to and egress from working space about electrical equip-ment. Even though the word access is used, the main intent is workersafety, i.e., egress. In the event of an arc-flash event and possible sub-sequent fire, the object is to provide a way out for threatened and/or

injured workers. For large equipment rated 1,200 amperes or moreand over 6 feet wide that contains overcurrent, switching, or controldevices, there must two entrances to and egresses from the workingspace, and they must be at least 24 inches wide and 6½ feet high at

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 12/14

12 C h a p t e r O n e

each end—in other words, two doors. This requirement may be reducedto one entrance provided either

• There is continuous and unobstructed means of egress.• The minimum working clearance is doubled.

If there are personnel doors less than 25 feet from the nearest edgeof the working space, they must be equipped with panic hardware sothat they open under simple pressure. The idea is that an arc-flashevent or electrical fire could severely burn a worker’s hands, prevent-ing operation of a doorknob.

These are the basic working space requirements. You can expectexam questions on this and on the following material in 110.26(E),

Dedicated Equipment Space, which is less complex. You should keepin mind that both sets of requirements are in Article 110, Require-ments for Electrical Installations, and that they are two entirely dis-crete types of spaces. They serve separate purposes and have differentlocations.

Working space is concerned primarily with worker safety, whereasdedicated equipment space has to do with equipment integrity. Thelatter applies to switchboards, panelboards, and motor control cen-ters. Rather than clearance in front of equipment, it begins on grade,platform, or floor; encompasses the height and width (footprint) of

the equipment; and extends upward to a height of 6 feet above theequipment or to the structural ceiling, whichever is lower. A sus-pended ceiling is permitted within this zone. This space is for relatedelectrical equipment, but no piping, ducts, leak-protection apparatus,or other items foreign to the electrical installation may be present.Notice that the dedicated equipment space may have related electri-cal equipment, but the working space may not. This is so becauseelectrical equipment, related or not, would interfere with the clear-ances necessary for worker safety.

The area above the dedicated equipment space is allowed to con-

tain foreign systems, provided that protection against water damageis installed. Sprinkler protection is permitted for the dedicated equip-ment space, but the piping that affords this protection must be out-side that zone.

We have examined NEC requirements for working space and ded-icated equipment space. Finding the answers for the inevitable examquestions on these topics is fairly straightforward as long as you caninstantly locate the requirements in Chapter 1.

Part II of Article 110 concludes with a few simple requirementsfor electrical installations. Live parts operating at 50 volts or more

must be guarded against accidental contact by suitable means, whichare enumerated. Section 110.28 lists enclosure types in Table 110.28,Enclosure Selection. Exam questions may concern environmental

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 13/14

N E C® C h a p t e r 1 , G e n e r a l 13

conditions. Protection is afforded by various enclosure types. Envi-ronmental conditions include rain, snow, sleet, corrosive agents, andsimilar. The table has two parts, titled For Outdoor Use and For

Indoor Use. Remember the Code location!Part III, Over 600 Volts, Nominal, is like Part II, 600 Volts,

Nominal, or Less, but the requirements are more stringent for thehigher voltage. Construction specifications for transformer vaultsare supplied, augmenting those found in Article 450, Transformersand Transformer Vaults (including Secondary Ties). Table 110.31 pro-vides minimum distances from fence to live parts for various nomi-nal voltages. Table 110.34(A), Minimum Depth of Clear WorkingSpace of Electrical Equipment, parallels the table in Part II, but thereare five voltage levels, and they are higher. The three conditions are

the same.Table 110.34(E), Elevation of Unguarded Live Parts above Working

Space, addresses three voltage levels, which are between phases, notto ground. Section 110.40 states that conductors may be terminated based on the 90°C temperature rating and ampacity unless other-wise identified.

Higher voltage level requirements are rarely the subject ofelectricians’ licensing exams, but if they do appear, you will knowwhere to find the answers. Similarly, Part IV, Tunnel Installationsover 600 Volts, Nominal, is outside the scope of most exams. Part V,

Manholes and Other Electrical Enclosures Intended for PersonnelEntry, All Voltages, contains important provisions regarding size,strength, cabling work space, equipment work space, conductorinstallation, access, ventilation, and guarding. Fixed ladders must becorrosion-resistant. Exam performance will be enhanced by know-ing where this information is located, but it is not realistic to thinkthat all requirements need to be memorized.

This is the content of Article 110, Requirements for ElectricalInstallations. It is a repository for various mandates that may bedifficult to find. After all, the entire Code could be titled Require-

ments for Electrical Installations. As we have seen, the Index is anexcellent gateway, and the Contents is useful in quickly finding theanswers to exam questions. In any event, you must have an orga-nized plan for getting to the right Code location without Codehopping or getting bogged down.

8/13/2019 01_herres_ch01_p001-014

http://slidepdf.com/reader/full/01herresch01p001-014 14/14