Transactions vol ii

-

Upload

walid-salama -

Category

Engineering

-

view

283 -

download

5

description

Transcript of Transactions vol ii

1018

1015

1012

109

106

103

102

101

10-1

10-2

10-3

10-6

10-9

10-12

10-15

10-18

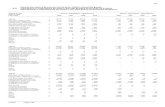

FACTOR PREFIX SYMBOL FACTOR PREFIX SYMBOL

exa

peta

tera

giga

mega

kilo

hecto

deka

E

P

T

G

M

k

h

da

deci

centi

milli

micro

nano

pico

femto

atto

d

c

m

µ

n

p

f

a

DECIMAL FACTOR PREFIXES

Black

Brown

Red

Orange

Yellow

Green

Blue

Violet

Gray

White

Gold

Silver

No Color

resistor value = (1st band)x(2nd band)x(103rd band)

resistor tolerance = 4th band (if specified)

±20%

±2%

±5%

±10%

±20%

COLOR VALUE OF (1st & 2nd bands) (3rd band) (4th band)

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

-1

-2

RESISTOR COLOR CODES

1.0

1.8

3.3

5.6

1.1

2.0

3.6

6.2

1.2

2.2

3.9

6.8

1.3

2.4

4.3

7.5

1.5

2.7

4.7

8.2

1.6

3.0

5.1

9.1

STANDARD RESISTOR VALUES

Voltage Source

Current Source

Resistor

Inductor

Capacitor

Joined Wires

Unjoined Wires

Open Circuit

Short Circuit

es appears in the circuit for i

is supplied to the circuit for all v

vR = iR

vL = L or i = vLdt

vc = idt or i = c

Connection is made at the dot

Wires cross without contact

i is zero for all v

v is zero for all i

es

is

vR

vL

+

+R

i

+L

i

vc

+c

i

v

i

v

i

didt

dvcdt

1c

SYMBOLS FOR SIMPLE ELECTRICAL CIRCUITS

A: ampere (amp) ac: alternating currentA/D: analog-to-digital ADC: analog-to-digital converterANSI: American National Standards Institute ASCII: American Standard Code for InformationInterchangeASIC: application-specific integrated circuit b: bitB: bytebps: bits per secondC: capacitanceCAN: Controller Area Network CJC: cold junction compensation CMRR: common-mode rejection ratio COM: Component Object Model CPU: central processing unitCSMA/CD: carrier sense multiple access with collisiondetection D/A: digital-to-analogDAC: digital-to-analog converterDAQ: data acquisitionDAS: data acquisition system dB: decibeldc: direct currentDCE: data communications equipmentDCOM: Distributed Component Object Model DCS: distributed control systemDDE: Dynamic Data ExchangeDIO: digital input/outputDLL: Dynamic Link Library DMA: direct memory accessDSP: digital signal processing DTE: data terminal equipmentEEPROM: electrically erasable programmable ROMEMF: electromotive force EMI: electromagnetic interference EPROM: erasable programmable ROM FIFO: first-in first-outGPIB: General Purpose Interface Bus GUI: graphical user interface

HMI: Human-machine interfacehz: hertzI/O: input/outputi: currentIEEE: Institute of Electrical and Electronic EngineersJTFA: joint time-frequency analysis L: inductanceLED: light emitting diodeLSB: least significant bitMAC: media access controlMFLOPS: million floating-point operations per second MIPS: million instructions per secondMMI: man-machine interface MUX: multiplexerODVA: Open DeviceNet Vendors AssociationOLE: Object Linking and Embedding OSI: Open Systems Interconnect PC: personal computerPCI: Peripheral Component Interconnect PCMCIA: Personal Computer Memory Card InternationalAssociation PGA: programmable gain amplifierPID: proportional-integral-derivative PLC: programmable logic controller R: resistanceRFI: radio frequency interference RMS: root-mean-square ROM: read-only memoryRTD: resistance temperature detector SCADA: supervisory control and data acquisitionSE: single-endedS/H: sample-and-hold SNR: signal-to-noise ratio SPC: statistical process control SQL: Structured Query Language SS: simultaneous samplingSTP: shielded twisted pair TCP/IP: Transmission Control Protocol/Internet Protocol TTL: transistor-to-transistor logic UTP: unshielded twisted pair V: volt

ACRONYMS AT A GLANCE

©1998 Putman Publishing Company and OMEGA Press LLC.

omega.com®

®

Data Acquisition A Technical Reference Series Brought to You by OMEGA

22

VOLUME

I N M E A S U R E M E N T A N D C O N T R O L

06 Volume 2 TRANSACTIONS

Analog I/O Functionality1 • Resolution & Aliasing

• Analog-to-Digital

• Digital-to-Analog

Figure 1-5: Analog Input Flow Diagram

Analog Input

Signals

1

2

3

4

Signal Conditioning

Digital Output

Mul

tipl

exer

Amplifier

Sample/Hold

A/D Converter

Digital I/O Functionality2

10

I N M E A S U R E M E N T A N D C O N T R O L

TABLE OF CONTENTS

VOLUME 2—DATA ACQUISITIONSection Topics Covered Page

• Digital Inputs

• Digital Outputs

• Pulse I/O

Figure 2-1: Signal Processing Requirements for Digital and Analog Signals

Signal conditioning Signal conditioning

Multiplexing

A/D-D/A conversion

Sensors & Actuators

Computer

Digital signals

Analog signals

Digital signals

17

Analog Signal Transmission3

• Analog Signal Types

• Noise & Grounding

• Wire & Cable Options

5

0

Digital Analog

VoltsVolts

Time Time

10

0

-10

Figure 3-2: Digital and Analog Signal Representations

19

Digital Signal Transmission4

• The OSI Network Model

• Physical Layer Options

• Network Topologies

• Fieldbus & Device Networks

Figure 4-9: Dual-Ring Redundant FDDI Network

Intact Broken

24

TRANSACTIONS Volume 2 07

Data Acquistion Hardware5

• Selecting a System

• Plug-in-Cards

• Standalone Components

• Communication Devices

Section Topics Covered Page

Presentation & Analysis6

36

Recording, Printing & Storage 7

• Development Considerations

• Component Architectures

• Off-the-Shelf Offerings

• Definitions and Classifications

• Trend Recorders

• Data Loggers

• Videographic Recorders

Inside Front Cover 02

Table of Contents 06

Editorial 08

About OMEGA 09

48

Figure 7-2: Typical Circular Chart Recorder Trace

Time

2

3

Hole to Accept Chart HubPrinted Line for Manual Entry Of Date

Hole to Accept Chart Positioning and Drive Pin

20 30 40 45 50 55 60 65

19 58

REFERENCE SECTIONS

68 Information Resources

72 Glossary

79 Index

82 List of Figures

08 Volume 2 TRANSACTIONS

A Commitment to StandardsSince OMEGA first opened its doors back in 1962, the practice of data acquisition has changed

at least as much as OMEGA itself. At that time, OMEGA offered a single line of fine-gauge thermocouples; now our scientific

and industrial measurement and control products number more than 68,000. In 1962, scientificand industrial data acquisition systems—if they could be called systems at all—consisted primarilyof data manually logged by technicians on clipboards and reams of analog recorder paper.And while many recorders still do record on paper, the now ubiquitous microprocessor hasrevolutionized pretty much everything else.

The PC and other microprocessor-based devices have replaced analog recording and displaytechnologies in all but the simplest data acquisition applications. And while computers havehad an undeniably positive impact on the practice of data acquisition, they have also addedunprecedented levels of complexity.

Analog-to-digital conversion and other signal conditioning functions come in a myriad ofform factors. Networked devices must be able to communicate flawlessly with

host computers at high speeds. And application programs written by aburgeoning number of independent software developers must readily

interchange ever-increasing amounts of data—and convert this firehose of raw bits into meaningful information.

The secret to success? Standards.Standards like the ISA and PCI backplane buses, RS-232

and GPIB networks, and DDE and OLE for application inte-gration. As your partner in instrumentation and control,it is our responsibility to help ease your integration andcommunication tasks using standards wherever possi-ble. You can also count on OMEGA’s commitment tostandards to preserve your freedom of choice andflexibility now and in the future. We’ll never lock youinto proprietary protocols.

Of course, the world of standards isn’t perfect andstandardization, by its very nature, lags the leading edge

of technology. But rest assured that OMEGA will be withyou every step of the way, helping to define the next gen-

eration of data acquisition standards to make your job easier,while continuing to support your ongoing requirements.

S

P.S. If you wish to submit an article of relevance for future issues of Transactions, please submit to my

attention via mail (P.O. Box 4047, Stamford, CT 06907), FAX (203-359-7700), or e-mail ([email protected]).

About OMEGA

TRANSACTIONS Volume 2 09

OMEGA’s Transactions in Measurement & Control series, as well as our legendary set of handbooks and

encyclopedias, are designed to provide at-your-fingertips access to the technical information you need

to help meet your measurement and control requirements. But when your needs exceed the printed

word—when technical assistance is required to select among alternative products, or when no “off-the-shelf”

product seems to fill the bill—we hope you’ll turn to OMEGA. There is no advertising or

promotional materials in the Transactions series. There will be none.

Our people, our facilities, and our commitment to customer service set the standard

for control and instrumentation. A sampler of our comprehensive resources and

capabilities:

• OMEGA’s commitment to leading-edge research and development and

state-of-the-art manufacturing keeps us firmly at the forefront of technology.

OMEGA’s Development and Engineering Center, located on our Stamford, Conn.,

campus, is home to OMEGA’s design and engineering laboratories. All product

designs are tested and perfected here prior to marketing. This facility houses

OMEGA’s metrology lab and other quality control facilities. The testing that takes place here assures

that you receive the best products for your applications.

• On the manufacturing side, our Bridgeport, N.J., vertically integrated manufacturing facility near

Philadelphia houses advanced thermocouple wire production equipment along with a host of other com-

puterized CNC milling machines, injection molding equipment, screw machines, braiders, extruders,

punch presses and much, much more.

• If our broad range of standard products don’t quite match your needs, OMEGA is proud to offer the most

sophisticated and extensive custom engineering capabilities in the process measurement and control industry.

Whether you need a simple modification of a standard product or complete customized system, OMEGA can

accommodate your special request. Free CAD drawings also are supplied with customized product orders or a

new design built to your specifications at no obligation.

• We believe in active versus reactive customer service. To complement our current business and

manufacturing operations, OMEGA continues to strive toward new levels of quality by pursuing ISO 9000

quality standards. This systematic approach to quality strengthens OMEGA’s competitive edge. Our

calibration services and quality control test center are trustworthy resources that help satisfy our customers’

needs for accuracy on an initial and ongoing basis.

• The company’s technical center welcomes many corporate groups of engineers and scientists who

turn to OMEGA for training. Our 140-seat auditorium, equipped with the latest in multimedia presentation

technologies, provides an ideal learning environment for training tailored to your company’s needs—from

basic refreshers to in-depth courses.

In short, it is our commitment to quality instrumentation and exceptional customer service that remains

the cornerstone of our success. OMEGA’s priority is clear: we exist to facilitate solutions to your needs.

For more information about Transactions or OMEGA Technologies, look us up on the Internet at

www.omega.com.

Exceeding Your ExpectationsO

Today, digital computers andother microprocessor-baseddevices have replaced analogrecording and display tech-

nologies in all but the simplest dataacquisition applications. And whilecomputers have had an undeniablypositive impact on the practice ofdata acquisition, they speak only abinary language of ones and zeroes.

Manufacturing processes and naturalphenomena, however, are still bytheir very nature analog. That is, nat-ural processes tend to vary smoothlyover time, not discontinuouslychanging states from black to white,from on to off.

To be meaningfully recorded ormanipulated by a computer then,analog measurements such as pres-sure, temperature, flow rate, andposition must be translated into dig-ital representations. Inherently digi-tal events, too, such as the trippingof a motor or a pulse generated by apositive displacement flowmeter,must be made interpretable as atransistor-to-transistor logic (TTL)level changes in voltage. Hence, theorigination and ongoing develop-ment of input/output (I/O) systems

(Figure 1-1) for converting analog anddigital information about real-worldprocesses and events into the lan-guage of computers.

Resolution & Aliasing Most sensors for measuring tempera-ture, pressure, and other continuousvariables provide a continuouslyvarying electrical output to repre-

sent the magnitude of the variable inquestion. To make this signal inter-pretable by a microprocessor, it mustbe converted from a smooth contin-uous value to a discrete, digital num-ber (Figure 1-2).

This analog-to-digital (A/D) con-version process poses two primarychallenges: one of quantization andone of sampling in time (Figure 1-3).Quantization refers to the uncertain-ty introduced upon conversion of ananalog voltage to a digital number.Measurement transducers or trans-mitters typically provide continuous-ly varying signals between 0-10 V dc,±5 V dc, 0-100 mV dc, or 4-20 mA dc.Thermocouples and resistance tem-perature devices (RTDs) are othercommon low voltage inputs.

When this analog value is repre-

sented as a digital number, however,this essentially continuous resolutionis limited to discrete steps. This reso-lution of an A/D conversion often isstated in terms of bits—the more bitsthe finer the resolution. The numberof bits determines the number of divi-sions into which a full-scale inputrange can be divided to approximatean analog input voltage. For example,

8-bit resolution of a 0-10 V input sig-nal means that the range is dividedinto 28 = 256 steps. This yields a step,or interval, size of 10 V/256 = 0.039 V.Thus, a 10-V input is equal to the digi-tal number 255 and a 0-V input corre-sponds to 0. Each 0.039-V change inthe input is indicated by adding orsubtracting 1 from the previous num-ber. (For example, 9.961 V is digitallyrepresented by 254.)

10 Volume 2 TRANSACTIONS

Resolution & Aliasing

Analog-to-Digital

Digital-to-Analog

DATA ACQUISITIONAnalog I/O Functionality

1

TAnalog I/O Functionality

Figure 1-1: Functional Diagram for Data Acquisition & Control

Physical World

Sensing Signal Conditioning

Analog-to-Digital Conversion

Display & Decision Making

Actuation Signal Conditioning

Digital-to-Analog Conversion

Figure 1-2: The Analog-to-Digital Interface

Waveform Numbers

V

t

0 1 0 1

0 1 1 0

1 0 1 1

1 1 1 0

0 0 0 1

Digital data acquisition systemsnot only quantize data in terms ofmagnitude; time, too, is parceled intodiscrete intervals (Figure 1-3). In gen-eral, there is no information aboutthe behavior of the process betweendata points gathered. Special precau-tions, then, must be taken to ensureno meaningful data is lost and inter-polation between recorded pointsremains a valid assumption.

The Nyquist theorem defines thenecessary relationship between thehighest frequency contained in a sig-nal and the minimum required sam-pling speed. Nyquist stated that thesample rate must be at least twicethe highest frequency componentcontained within the input signal. So,to sample a 1-Hz sine wave, the sam-ple rate should be at least 2 Hz. (Buta rate of 8-16 Hz would be much bet-ter for resolving the true shape ofthe wave.)

The primary implications of ignor-ing the Nyquist criterion include notonly missing high frequency informa-tion but of introducing aliasing; if thesample rate is not fast enough, thepresence of totally nonexistent fre-quencies may be indicated (Figure 1-4). It is aliasing that makes a heli-copter’s rotors or a car’s wheelsappear to turn slowly backwardswhen seen in a movie. Low-pass, or

anti-aliasing filters can be used tolimit the measured waveform’s fre-quency spectrum so that nodetectable component equals orexceeds half of the sampling rate.

Designing or specifying a devicefor A/D conversion consists of aseries of trade-offs. As will be amplydemonstrated in the next section,more resolution (more bits) meansmore accurate conversion but moreexpensive hardware. Similarly, slowersample rates mean cheaper A/Dconversion, but the Nyquist criterionmust still be satisfied.

A/D ConversionContinuous electrical signals areconverted to the digital language ofcomputers using analog-to-digital(A/D) converters. An A/D convertermay be housed on a PC board withassociated circuitry or in a variety ofremote or networked configurations.In addition to the converter itself,sample-and-hold circuits, an amplifi-er, a multiplexer, timing and synchro-nization circuits, and signal condi-tioning elements also may be onboard (Figure 1-5). The logic circuitsnecessary to control the transfer ofdata to computer memory or to aninternal register also are needed.

When determining what type ofA/D converter should be used in agiven application, performanceshould be closely matched to therequirements of the analog inputtransducer(s) in question. Accuracy,signal frequency content, maximumsignal level, and dynamic range allshould be considered.

Central to the performance of anA/D converter is its resolution, oftenexpressed in bits. An A/D converter

essentially divides the analog inputrange into 2N bins, where N is thenumber of bits. In other words, res-olution is a measure of the numberof levels used to represent the ana-log input range and determines theconverter’s sensitivity to a change inanalog input. This is not to be con-

Analog I/O Functionality1

TRANSACTIONS Volume 2 11

Figure 1-3: A/D Conversion Compromises

Sampling Issues

Qua

ntiz

atio

n Is

sues

v

t

Figure 1-4: Aliasing Due to Slow Sample Rate

Sample Period

Alias Actual Signal

Signal Period

Figure 1-5: Analog Input Flow Diagram

Analog Input

Signals

1

2

3

4

Signal Conditioning

Digital Output

Mul

tipl

exer

Amplifier

Sample/Hold

A/D Converter

fused with its absolute accuracy!Amplification of the signal, or inputgain, can be used to increase theapparent sensitivity if the signal’sexpected maximum range is less thanthe input range of the A/D convert-er. Because higher resolution A/Dconverters cost more, it is especiallyimportant to not buy more resolu-tion than you need—if you have 1%accurate (1 in 100) temperature trans-ducers, a 16-bit (1 in 65,536) A/D con-verter is probably more resolutionthan you need.

Absolute accuracy of the A/Dconversion is a function of the ref-erence voltage stability (the knownvoltage to which the unknown volt-age is compared) as well as thecomparator performance. Overall,it is of limited use to know theaccuracy of the A/D converteritself. Accuracy of the system,together with associated multiplex-er, amplifier, and other circuitry istypically more meaningful.

The other primary A/D converterperformance parameter that must be

considered is speed—throughput fora multi-channel device. Overall, sys-tem speed depends on the conver-sion time, acquisition time, transfertime, and the number of channelsbeing served by the system:• Acquisition is the time needed by

the front-end analog circuitry toacquire a signal. Also called aperturetime, it is the time for which the con-verter must see the analog voltage inorder to complete a conversion.

• Conversion is the time needed toproduce a digital value correspond-ing to the analog value.• Transfer is the time needed tosend the digital value to the hostcomputer’s memory.Throughput, then, equals the numberof channels being served divided bythe time required to do all threefunctions.

A/D Converter OptionsWhile all analog-to-digital convert-ers are classified by their resolutionor number of bits, how the A/D cir-

cuitry achieves this resolution variesfrom device to device. There are fourprimary types of A/D convertersused for industrial and laboratoryapplications—successive approxima-tion, flash/parallel, integrating, andramp/counting. Some are optimized

for speed, others for economy, andothers for a compromise amongcompeting priorities (Figure 1-6).Industrial and lab data acquisitiontasks typically require 12 to 16 bits—

12 is the most common. As a rule,increasing resolution results in highercosts and slower conversion speed.• Successive approximation: Themost common A/D converter designused for general industrial and labora-tory applications is successive approx-imation (Figure 1-7). This design offersan effective compromise among reso-lution, speed, and cost. In this type ofdesign, an internal digital-to-analog(D/A) converter and a single compara-tor—essentially a circuit that deter-mines which of two voltages is high-er—are used to narrow in on theunknown voltage by turning bits in theD/A converter on until the voltagesmatch to within the least significantbit. Raw sampling speed for successiveapproximation converters is in the 50kHz to 1 MHz range.

To achieve higher sampling speeds,a redundancy technique allows a fastinitial approximate conversion, fol-lowed by a correction step thatadjust the least significant bit afterallowing sufficient settling time. Theconversion is therefore completedfaster at the expense of additionalhardware. Redundancy is usefulwhen both high speed and high reso-lution are desirable.• Flash/parallel: When higher speedoperation is required, parallel, orflash-type A/D conversion is called

Analog I/O Functionality 1

12 Volume 2 TRANSACTIONS

Figure 1-7: A/D Conversion by Successive Approximation

Analog Input

Digital Output

Reference VoltageD/A Converter

Output Register

N bits

Control Register

Comparator

Gate

Successive approximation

Integrating

Ramp/counting

Flash/parallel

DESIGN SPEED RESOLUTION NOISE IMMUNITY COST

Medium

Slow

Slow

Fast

10-16 bits

12-18 bits

14-24 bits

4-8 bits

Poor

Good

Good

None

Low

Low

Medium

High

Figure 1-6: Alternative A/D Converter Designs

for. This design uses multiple com-parators in parallel to process sam-ples at more than 100 MHz with 8 to12-bit resolution. Conversion isaccomplished by a string of com-parators with appropriate referencesoperating in parallel (Figure 1-8).

The downside of this design is thelarge number of relatively expensivecomparators that are required—forexample, a 12-bit converter requires4,095 comparators.• Integrating: This type of A/D con-verter integrates an unknown inputvoltage for a specific period of time,then integrates it back down to zero.This time is compared to the amountof time taken to perform a similarintegration on a known referencevoltage. The relative times requiredand the known reference voltagethen yield the unknown input volt-age. Integrating converters with 12 to18-bit resolution are available, at rawsampling rates of 10-500 kHz.

Because this type of design effec-tively averages the input voltageover time, it also smoothes out sig-

nal noise. And, if an integration peri-od is chosen that is a multiple of theac line frequency, excellent com-mon mode noise rejection isachieved. More accurate and morelinear than successive approxima-tion converters, integrating convert-ers are a good choice for low-levelvoltage signals.• Ramp/counter: Similar to succes-sive approximation designs, countingor ramp-type A/D converters useone comparator circuit and a D/Aconverter (Figure 1-9). This designprogressively increments a digitalcounter and with each new countgenerates the corresponding analog

voltage and compares it to theunknown input voltage. When agree-ment is indicated, the counter con-tains the digital equivalent of theunknown signal.

A variation on the counter methodis the ramp method, which substi-tutes an operational amplifier orother analog ramping circuit for theD/A converter. This technique issomewhat faster.

Multiplexing & Signal ConditioningAs shown in Figure 1-5, A/D convert-ers seldom function on their own butmust be considered in a systems con-text with associated circuitry for sig-nal conditioning, multiplexing, ampli-fication, and other functions. Everyapplication will dictate a unique mixof add-ons that may be implementedin a variety of physical configura-tions—on a PC I/O board, inside aremote transmitter, or at a local ter-mination panel. • Multiplexing: In many industrialand laboratory applications, multipleanalog signals must be converted todigital form. And if speed is not thelimiting factor, a single A/D convert-er often is shared among multipleinput channels via a switching mech-anism called a multiplexer. This iscommonly done because of the rela-tively high cost of converters.Multiplexers also allow amplificationand other signal conditioning circuitry

Analog I/O Functionality1

TRANSACTIONS Volume 2 13

Figure 1-8: A/D Conversion by Flash/Parallel Technique

Analog Input

Voltage

Digital Output

Vmax

R

1N-1

02

3

2N-1-1

R

R

R

R

Vmin

Comparators

Encoder

-+

-+

-+

-+

Figure 1-9: A/D Conversion by Counting/Ramp Technique

Analog Input

Clock

Digital Output

Reference Voltage

D/A Converter

Counter

Comparator

Gate

to be time-shared among multiplechannels. Software or auxiliary hard-ware controls the switch selection. • Sample-and-hold: It is importantto acknowledge that a multiplexer

does reduce the frequency withwhich data points are acquired, andthat the Nyquist sample-rate criteri-on still must be observed. During atypical data acquisition process, indi-vidual channels are read in turnsequentially. This is called standard, ordistributed, sampling. A reading of allchannels is called a scan. Becauseeach channel is acquired and convert-ed at a slightly different time, howev-er, a skew in sample time is createdbetween data points (Figure 1-10).

If time synchronization amonginputs is important, some dataacquisition cards offer “burst”mode operation or simultaneous“sample-and-hold” circuitry. Burstmode, or pseudo-simultaneoussampling, acquires each channel atthe maximum rate of the board,then waits a user-specified amountof time before sampling again.

True simultaneous sample-and-hold systems can sample all channelswithin a few nanoseconds of eachother, eliminating phase and timediscontinuities for all but the fastestprocesses. Essentially, a switched

capacitor on each channel tracks thecorresponding input signal. Beforestarting the A/D conversion process,all switches are opened simultane-ously, leaving the last instantaneous

values on the capacitors. • Signal scaling: Because A/D con-verters work best on signals in the1-10 V range, low voltage signals mayneed to be amplified before conver-sion—either individually or aftermultiplexing on a shared circuit.Conversely, high voltage signals mayneed to be attenuated.

Amplifiers also can boost an A/Dconverter’s resolution of low-levelsignals. For example, a 12-bit A/Dconverter with a gain of 4 can digi-tize a signal with the same resolutionas a 14-bit converter with a gain of 1.It’s important to note, however, thatfixed-gain amplifiers, which essen-tially multiply all signals proportion-ately, increase sensitivity to low volt-age signals but do not extend theconverter’s dynamic range.

Programmable gain amplifiers(PGAs), on the other hand, can beconfigured to automatically increasethe gain as the signal level drops,effectively increasing the system’sdynamic range. A PGA with threegain levels set three orders of magni-tude apart can make a 12-bit convert-

er behave more like an 18-bit con-verter. This function does, however,slow down the sample rate.

From a systems perspective,amplifier performance should be onpar with that of the A/D converteritself—gain accuracy should be spec-ified as a low percentage of the totalgain. Amplifier noise and offset erroralso should be low.• Other conditioning functions:Other A/D signal conditioning func-tions required will vary widely fromapplication to application. Amongthe options:• Current-to-voltage conversion: A

4-20 mA current signal can bereadily converted to a voltage sig-nal using a simple resistor (Figure1-11). A resistor value of 250 ohmswill yield a 1-5 V output.

• Filtering: A variety of physicaldevices and circuits are availableto help separate desired signalsfrom specific frequencies of unde-sirable electrical noise such as ac

line pick-up and other electro-magnetic/radio frequency inter-ference (EMI/RFI). If the signal ofinterest is lower in frequency thanthe noise, a low-pass filter can beused. High-pass and notch-bandfilters are designed to target lowfrequency interference and specificfrequency bands, respectively.

• Excitation: Voltage supplied by thedata acquisition card or discrete sig-nal conditioner to certain types of

Analog I/O Functionality 1

14 Volume 2 TRANSACTIONS

Figure 1-11: Conversion of 4-20 mA to 1-5 V

4-20 mA Current signal

1-5 V Voltage signal

Ground

+

250 Ω

Figure 1-10: Alternative Methods for Eliminating Time Skew Among Multiplexed Channels

Distributed Sampling

1 2 3 4 1

Skew Skew

Time

Conversion Time

1 2 3 4 1 2 3 4 1 2 3 4

No Skew

Simultaneous Sample-and-Hold

Burst Mode

transducers such as strain gages.• Isolation: Used to protect person-

nel and equipment from high volt-ages. Isolators block circuit over-loads while simultaneously pass-ing the signal of interest.

Single-Ended & Differential InputsAnother important considerationwhen specifying analog data acquisi-tion hardware is whether to use sin-gle-ended or differential inputs(Figure 1-12). In short, single-endedinputs are less expensive but can beproblematic if differences in groundpotential exist.

In a single-ended configuration,the signal sources and the input tothe amplifier are referenced toground. This is adequate for highlevel signals when the difference inground potential is relatively small.A difference in ground potentials,however, will create an error-caus-ing current flow through the groundconductor otherwise known as aground loop.

Differential inputs, in contrast,connect both the positive and neg-ative inputs of the amplifier to bothends of the actual signal source.Any ground-loop induced voltageappears in both ends and is rejected

as a common-mode noise. Thedownside of differential connections

is that they are essentially twice asexpensive as single-ended inputs; aneight-channel analog input board canhandle only four differential inputs.

D/A ConversionAnalog outputs commonly are usedto operate valves and motors inindustrial environments and to gen-erate inputs for electronic devices

under test. Digital-to-analog (D/A)conversion is in many ways the con-

verse of A/D conversion, but tendsto be generally more straightforward.Similar to analog input configura-tions, a common D/A converteroften is shared among multiplexedoutput signals. Standard analog out-put ranges are essentially the sameas analog inputs: ±5 V dc, ±10 V dc,0-10 V dc, and 4-20 mA dc.

Essentially, the logic circuitry for

Analog I/O Functionality1

TRANSACTIONS Volume 2 15

Figure 1-12: Single-Ended & Differential Analog Input Configurations

High

LowJumper

Remote ground

Analog ground

0

1

2

3

4

5

6

7

High

LowJumper

Remote ground

Analog ground

0 Hi

1 Hi

2 Hi

3 Hi

0 Lo

1 Lo

2 Lo

3 Lo

Single-Ended Inputs Differential Inputs

Figure 1-13: Weighted Value & Single Value Resistor Networks for D/A Conversion

2R

2R

2R 2R 2R

R R

R

Io

-+

Voltage Output

DN-1D2D1D∅DN-1

DN-2

D∅

R

Weighted Value Resistor Single Value Resistor

2R R

Voltage Output

2N-1 R-+

an analog voltage output uses a dig-ital word, or series of bits, to dropin (or drop out, depending onwhether the bit is 1 or 0) a series ofresistors from a circuit driven by areference voltage. This ladder ofresistors can be made of eitherweighted value resistors or an R-2Rnetwork using only two resistor val-ues—one if placed in series (Figure1-13). While operation of theweighted-value network is moreintuitively obvious, the R-2Rscheme is more practical. Becauseonly one resistor value need beused, it is easier to match the tem-perature coefficients of an R-2R lad-der than a weighted network,resulting in more accurate outputs.Plus, for high resolution outputs,very high resistor values are neededin the weighted-resistor approach.

Key specifications of an analogoutput include:• Settling time: Period required for a

D/A converter to respond to afull-scale setpoint change.

• Linearity: This refers to thedevice’s ability to accuratelydivide the reference voltage intoevenly sized increments.

• Range: The reference voltage setsthe limit on the output voltageachievable.Because most unconditioned ana-

log outputs are limited to 5 mA of

current, amplifiers and signal condi-tioners often are needed to drive afinal control element. A low-pass fil-ter may also be used to smooth outthe discrete steps in output. T

Analog I/O Functionality 1

16 Volume 2 TRANSACTIONS

References & Further Reading• The Data Acquisition Systems Handbook, Omega Press LLC, 1997.• New Horizons in Data Acquisition and Computer Interfaces, Omega Press

LLC, 1997.• Omega® Universal Guide to Data Acquisition and Computer Interfaces,

Omega Press LLC, 1997. • Analog I/O Design: Acquisition, Conversion, Recovery, Patrick Garrett,

Reston Publishing Co., 1981.• Analog Signal Processing and Instrumentation, Arie F. Arbel, Cambridge

University Press, 1980.• Analog-To-Digital and Digital-To-Analog Conversion Techniques, David

Hoeschele, John Wiley & Sons, 1994.• Analog-To-Digital Conversion: A Practical Approach, Kevin M. Daughtery,

McGraw Hill, 1995.• Automation Systems for Control and Data Acquisition, Lawrence T. Amy,

ISA, 1992.• Data Acquisition and Control, Microcomputer Applications for Scientists

and Engineers, Joseph J. Carr, Tab Books Inc., 1988.• Data Acquisition and Process Control Using Personal Computers, Tarik

Ozkul, Marcel Dekker, 1996.• Instrument Engineers’ Handbook, Third Edition, Bela Liptak, Chilton Book

Co., 1995. • Process/Industrial Instruments & Controls Handbook, Fourth Edition,

Douglas M. Considine, McGraw-Hill Inc., 1993.

TRANSACTIONS Volume 2 17

In contrast to analog transduc-ers that sense continuous vari-ables such as pressure and tem-perature, many transducers pro-

vide an output that is one of twostates: high or low, open or closed.A pressure might be too high or a

temperature too low, triggering clo-sure of a switch. Outputs, too, arenot strictly analog—solenoid valvestypically are opened or closed,many pumps and heaters are simplyturned on or off. Pulse signals areanother form of digital I/O, withone rotation of a turbine flowmeteror tachometer corresponding to asingle, countable event. Digital I/Oalso can be used for parallel com-munications among plug-in expan-sion cards, and to generate clockand other timing signals.

Already in the binary language ofcomputers, these types of digital,or discrete, inputs and outputs(I/O) are much easier for micro-

processor-based data acquisitionsystems to deal with than analogsignals. Similar to analog-to-digitalconverters used for analog I/O, dig-ital I/O is designed to deal directlywith transistor-to-transistor logic(TTL) level voltage changes. TTL

typically sets the low voltage levelbetween 0 and 0.8 V and the highvoltage level between 2.0 and 5.0 V.Voltage levels between 0.8 and 2.0 Vare not allowed. A voltage change,then, from the high range to thelow range (or vice versa) represents

a digital change of state from highto low, on to off, etc.

And because acquiring an analogsignal is more complex than acquir-ing a digital one, analog I/O channelsalso are more expensive. Hence, ifdigital I/O is adequate, do not both-er with analog.

Digital InputsMany types of digital input signalsfrom switch closures, relay contacts,or TTL-compatible interfaces can beread directly by digital I/O cards(Figure 2-1). Other types of inputsmay require some signal condition-ing, most likely to reduce higher-level voltage changes to TTL levels.A variety of signal conditioningmodules are available to provideisolation and other digital condi-tioning functions.

The most common type of digitalinput is the contact closure (Figure2-2). Essentially a sensor or switch ofsome type closes or opens a set ofcontacts in accordance with someprocess change. An applied electricalsignal then determines whether thecircuit is open or closed. Current flowsif the circuit is closed, registering a “1”in a transistor at the computer inter-face. Conversely, an open circuit

Digital Inputs

Digital Outputs

Pulse I/O

DATA ACQUISITIONDigital I/O Functionality

2

IDigital I/O Functionality

Figure 2-1: Signal Processing Requirements for Digital and Analog Signals

Signal conditioning Signal conditioning

Multiplexing

A/D-D/A conversion

Sensors & Actuators

Computer

Digital signals

Analog signals

Digital signals

Figure 2-2: Digital Input Applied to a Contact Closure

Digital InputRemote Switch Remote Contact

R

+5 V

R

retains a high voltage (and no current),registering a “0” at the transistor.

Another type of digital inputuseful in data acquisition applica-tions is the hardware trigger. Thisallows an external event—a highreactor temperature, perhaps, or alow tank level—to control data col-lection. If during routine operationdata is only being acquired forarchival storage on a once-per-sec-ond basis, a hardware trigger can beused to boost the data acquisitionrate during an upset until normalconditions are restored.

Digital OutputsAt its simplest, a digital output pro-vides a means of turning somethingon or off. Applications range fromdriving a relay to turning on an indi-cator lamp to transmitting data toanother computer. For latching out-puts, a “1” typically causes the associ-ated switch or relay to latch, while a“0” causes the switch to unlatch.Devices can be turned on or off,depending on whether the externalcontacts are normally open or nor-mally closed.

Standard TTL level signals can be

used to drive 5-V relay coils; a protec-tive diode is used to protect the digi-tal output circuitry (Figure 2-3).Because data acquisition boards cantypically supply only 24 mA of drivingcurrent, they are intended primarily todrive other logic circuits, not final con-trol elements. Scaling may be neededso that logical voltage levels are suffi-cient to cause switching in largerrelays. Outputs intended to drive larg-er solenoids, contactors, motors, oralarms also may require a boost.

Pulse I/OA somewhat separate class of digitalI/O is pulse inputs and outputs,which typically is associated withfrequency, counting, or totalizationapplications. Pulse inputs might beused to count the rotations of a tur-bine flowmeter; pulse outputs mightbe used to drive a stepping motor.

Pulse inputs are handled in muchthe same way as digital logic inputs,but the output of the sensing circuitis normally connected to a counterrather than a specific bit position inthe input register. Successive pulsesincrement or decrement thecounter. Add an elapsed time mea-sure and a frequency or pulse ratecan readily be determined. Similarto an analog-to-digital converter, acounter is characterized by its num-ber of bits—an N-bit countercan accumulate up to 2N discreteevents. Thus, a 16-bit counter cancount to 216 = 65,536. T

Digital I/O Functionality 2

18 Volume 2 TRANSACTIONS

Figure 2-3: Digital Output Applied to a Relay

Digital Output

Remote Switch

Remote Relay

+5V

References & Further Reading• The Data Acquisition Systems Handbook, Omega Press LLC, 1997.• New Horizons in Data Acquisition and Computer Interfaces, Omega Press

LLC, 1997.• Omega® Universal Guide to Data Acquisition and Computer Interfaces,

Omega Press LLC, 1997. • Automation Systems for Control and Data Acquisition, Lawrence T. Amy,

ISA, 1992.• Data Acquisition and Control, Microcomputer Applications for Scientists

and Engineers, Joseph J. Carr, Tab Books Inc., 1988.• Data Acquisition and Process Control Using Personal Computers, Tarik

Ozkul, Marcel Dekker, 1996.• Instrument Engineers’ Handbook, Third Edition, Bela Liptak, Chilton Book

Co., 1995. • Process/Industrial Instruments & Controls Handbook, Fourth Edition,

Douglas M. Considine, McGraw-Hill Inc., 1993.

TRANSACTIONS Volume 2 19

Although the microprocessorand digital network tech-nologies have fundamental-ly reinvented the ways in

which today’s data acquisition sys-tems handle data, much laboratoryand manufacturing information isstill communicated the “old” way,via analog electrical signals. And afundamental understanding of howanalog signal transmission worksmust first begin with a discussion ofelectrical basics.

To understand the ways in whichan analog signal is transmitted overa circuit, it is first important tounderstand the relationships thatmake analog signal transmissionpossible. It is the fundamental rela-tionship between voltage, current,and electrical resistance (Figure 3-1)that allow either a continuouslyvarying current or voltage to repre-sent a continuous process variable.

While charge flow is electric cur-rent, voltage is the work done inmoving a unit of charge (1 coulomb)from one point to another. The unitof voltage is often called the poten-tial difference, or the volt (V). TheInternational System of Units (SI)unit for electrical flow is the

ampere (A), defined as one coulombper second (c/s).

A signal source of voltage, V, willcause a current, I, to flow through aresistor of resistance, R. Ohm’s law,which was formulated by theGerman physicist Georg Simon Ohm(1787-1854), defines the relation:

V = IR

While most single-channel ana-log signal transmissions use directcurrent (dc) variations in current orvoltage to represent a data value,frequency variations of an alternat-ing current (ac) also can be used tocommunicate information. In theearly 19th century, Jean BaptisteJoseph Fourier, a French mathe-matician and physicist, discoveredthat ac signals could be defined interms of sine waves. A sine wave isdescribed by three quantities:amplitude, period, and frequency.The amplitude is the peak value ofthe wave in either the positive ornegative direction, the period isthe time it takes to complete onecycle of the wave, and the frequen-cy is the number of complete

cycles per unit of time (the recip-rocal of the period).

Analog Signal TypesMost data acquisition signals can bedescribed as analog, digital, or pulse.While analog signals typically varysmoothly and continuously overtime, digital signals are present at dis-crete points in time (Figure 3-2). Inmost control applications, analog sig-nals range continuously over a speci-fied current or voltage range, such as4-20 mA dc or 0 to 5 V dc. While dig-ital signals are essentially on/off (thepump is on or off, the bottle is thereor isn’t), analog signals represent con-tinuously variable entities such astemperatures, pressures, or flowrates. Because computer-based con-trollers and systems understand onlydiscrete on/off information, conver-sion of analog signals to digital repre-sentations is necessary (and dis-cussed in Chapter 1).

Transduction is the process ofchanging energy from one form intoanother. Hence, a transducer is adevice that converts physical ener-gy into an electrical voltage or cur-rent signal for transmission. There

AAnalog Signal Transmission

Figure 3-1: A Basic Electric Circuit

V

I

+

-

R

5

0

Digital Analog

VoltsVolts

Time Time

10

0

-10

Figure 3-2: Digital and Analog Signal Representations

Analog Signal Types

Noise & Grounding

Wire & Cable Options

DATA ACQUISITIONAnalog Signal Transmission

3

Analog Signal Transmission 3

20 Volume 2 TRANSACTIONS

are many different forms of analogelectrical transducers. Commontransducers include load cells formeasuring strain via resistance, andthermocouples and resistance tem-perature detectors (RTDs) for mea-suring temperature via voltage andresistance measurement, respec-tively. Transmission channels may bewires or coaxial cables.

For noise-resistant transmissionover significant distances, the rawtransducer signal is often convertedto a 4-20 mA signal by a two-wire,loop-powered transmitter. The bot-tom value of a process variable’srange, for example, a temperature, istypically designated as 4 mA, makingit easy to distinguish transmitterfailure (0 mA) from a valid signal. Ifthe current source is of good quality,current loops tend to be less sensi-tive to noise pickup by electromag-netic interference than voltage-based signals.

Noise & GroundingIn transmitting analog signals acrossa process plant or factory floor, one

of the most critical requirements isthe protection of data integrity.However, when a data acquisitionsystem is transmitting low level ana-log signals over wires, some signaldegradation is unavoidable and willoccur due to noise and electricalinterference. Noise and signal degra-dation are two basic problems inanalog signal transmission.

Noise is defined as any unwantedelectrical or magnetic phenomenathat corrupt a message signal. Noisecan be categorized into two broadcategories based on the source—internal noise and external noise.While internal noise is generated bycomponents associated with the sig-nal itself, external noise results whennatural or man-made electrical ormagnetic phenomena influence thesignal as it is being transmitted.Noise limits the ability to correctlyidentify the sent message and there-fore limits information transfer.Some of the sources of internal andexternal noise include:• Electromagnetic interference (EMI);• Radio-frequency interference (RFI);

• Leakage paths at the input terminals;• Turbulent signals from other

instruments;• Electrical charge pickup from

power sources;• Switching of high-current loads in

nearby wiring;• Self-heating due to resistance

changes;• Arcs;• Lightning bolts;• Electrical motors;• High-frequency transients and

pulses passing into the equipment;• Improper wiring and installation;• Signal conversion error; and • Uncontrollable process disturbances.

Signal leads can pick up two typesof external noise—common modeand normal mode. Normal modenoise enters the signal path as a dif-ferential voltage and cannot be dis-tinguished from the transducer sig-nal. Noise picked up on both leadsfrom ground is referred to as com-mon-mode interference.

Typical ranges for data signals andnoise are shown in Figure 3-3.Whether the noise is detrimental tothe proper performance of the sys-tem depends on the ratio of the total

0 10-4 10-3 10-2 10-1 1 10 102 107

Frequency (Hz)

Figure 3-3: Signal, Noise, and Filtering Frequencies

Controllable Disturbances

Useful Information

Analog & Digital Filtering

Noise

All-Analog Filtering

Uncontrollable Disturbances

Stray Electrical Pickup

Analog Filter Rejection

Analog Filter Rejection

Control Range

Input Range

Control Range

Digital Filter Rejection

Measurement Noise

Figure 3-4: A Ground Conductor

UtilityAC LineReturn

Ground

Earth ground

Outlet (front view)

Connection between ground and return

Analog Signal Transmission3

TRANSACTIONS Volume 2 21

signal power to the total noise level.This is referred to as the signal-to-noise ratio. If the signal power islarge in comparison to the noise sig-nal, the noise can often times beignored. However, with long-distancesignals operating with limited signalpower, the noise may disrupt the sig-nal completely.

Current-driven devices have beenmost widely accepted in processingplants, with a common current rangeof 4-20 mA. Low-level current signalsare not only safe, but are not as sus-ceptible to noise as voltage signals. Ifa current is magnetically coupledinto the connecting wires in thetransmission of the signal from a cur-rent source, no significant change inthe signal current will result. If the

transducer is a voltage-driven device,the error adds directly to the signal.After current transmission, voltagesignals can be easily rederived.

Even though internal and externalinterference can be problematic insending analog signals, analog signaltransmission is widely and success-fully used in industry. The effects ofnoise can be reduced with carefulengineering design, proper installa-tion, routing techniques of wires andcables, and shielding and grounding.

One of the ways in which engineershave tried to minimize the effects ofnoise is to maximize the signal-to-noise ratio. This involves increasingthe power of the signal being sent.Although this works in some cases, ithas its limitations. By increasing the

signal, nonlinear effects becomedominant, as the signal amplitude isincreased—it enhances the signal andthe noise in the same proportion.

Proper grounding also is essentialfor effective operation of any mea-surement system. Improper ground-ing can lead to potentially dangerousground loops and susceptibility tointerference. To understand the prin-ciples involved in shielding andgrounding, some terms must first beunderstood. A ground is a conduct-ing flow path for current between anelectric circuit and the earth. Groundwires are typically made with materi-als that have very low resistance.Because current takes the path ofleast resistance, the ground wiresconnected from the system provide

Figure 3-5: Incorrect Grounding of Signal Circuit

Signal Source

Signal Ground

Signal Ground Returnee

Zw

Ground current flows in return line

System Ground

+

+-

-

V1

Figure 3-6: Correct Grounding of Signal Circuit

Signal Source

Signal Ground

Signal Return Only

(No path for current to circulate)

System Ground

+

-

V1

Analog Signal Transmission 3

22 Volume 2 TRANSACTIONS

a stable reference for making voltagemeasurements. Ground wires alsosafeguard against unwanted com-mon-mode signals and prevent acci-dental contact with dangerous volt-ages. Return lines carry power or sig-nal currents (Figure 3-4). A groundloop is a potentially dangerous loopformed when two or more points inan electrical system are grounded todifferent potentials.

There are many different ground-ing techniques designed to not onlyprotect the data being transmitted,but to protect employees andequipment. There are two ways inwhich all systems should be ground-ed. First of all, all of the measuringequipment and recording systemsshould be grounded so that mea-surements can be taken with respectto a zero voltage potential. This notonly ensures that potential is notbeing introduced at the measuringdevice, but ensures that enclosuresor cabinets around equipment donot carry a voltage. To ground anenclosure or cabinet, one or moreheavy copper conductors are runfrom the device to a stable groundrod or a designated ground grid. Thissystem ground provides a base forrejecting common-mode noise sig-nals. It is very important that thisground is kept stable.

The second ground is for the signalground. This ground is necessary toprovide a solid reference for themeasurement of all low-level signals.It is very important that this groundis grounded separate and isolatedfrom the system ground. If a signalreturn line is grounded at the signalsource and at the system ground, adifference in potential between thetwo grounds may cause a circulatingcurrent (Figure 3-5). In this case, thecirculating current will be in series

with the signal leads and will adddirectly to the signal from the mea-suring instrument. These groundloops are capable of creating noisesignals 100 times the size of the orig-inal signal. This current can also bepotentially dangerous. In a single-point ground configuration, mini-mal current can flow in the groundreference. Figure 3-6 shows that bygrounding the wire at the signal endonly, the current has no path, elimi-nating the ground loop.

For off-ground measurements, theshield or the ground lead is stabilizedwith respect to either the low-levelof the signal or at a point betweenthe two. Because the shield is at apotential above the zero-referenceground, it is necessary to have prop-er insulation.

Wire & Cable OptionsAnother important aspect to consid-er in analog signal transmission is aproper wiring system, which caneffectively reduce noise interference.Analog signal transmission typicallyconsists of two-wire signal leads orthree-wire signal leads. In systems

that require high precision and accu-racy, the third signal lead, or shield, isnecessary. In the three-wire configu-ration, the shield is grounded at thesignal source to reduce common-mode noise. However, this does noteliminate all of the possibilities ofthe introduction of noise. It is crucialto prevent the noise pickup by pro-tecting the signal lines. For example,in the case where the noise and sig-nal frequency are the same. In thisscenario, the signal cannot be isolat-

ed/filtered from the noise at thereceiving device.

Generally, two-wire transmissionmediums are used to carry an analogsignal to or from the field area. A wirecarrying an alternating current andvoltage may induce noise in a pair ofnearby signal leads. A differential volt-age/noise will be created since thetwo wires may be at different distancesfrom the disturbing signal. There aremany different wiring options that areavailable to reduce unwanted noisepickup from entering the line. Fourtypes of wires are fundamental in dataacquisition—plain pair, shielded pair,twisted pair, and coaxial cable.

Figure 3-7: Coaxial Cable Construction

Magnetic field

Wire (+)

Electric field

Cylindrical conductor (-)

Analog Signal Transmission3

TRANSACTIONS Volume 2 23

While plain wire can be used, it isgenerally not very reliable in screen-ing out noise and is not suggested. Ashielded pair is a pair of wires sur-rounded by a conductor that doesnot carry current. The shield blocksthe interfering current and directs itto the ground. When using shieldedpair, it is very important to followthe rules in grounding. Again, theshield must only be grounded at onesource, eliminating the possibility ofground-loop currents.

Twisted-pairs help in elimination ofnoise due to electromagnetic fields bytwisting the two signal leads at regularintervals. Any induced disturbance inthe wire will have the same magnitudeand result in error cancellation.

A coaxial cable is another alterna-tive for protecting data from noise. Acoaxial cable consists of a centralconducting wire separated from anouter conducting cylinder by an insu-lator. The central conductor is positivewith respect to the outer conductorand carries a current (Figure 3-7).Coaxial cables do not produce exter-nal electric and magnetic fields andare not affected by them. This makesthem ideally suited, although moreexpensive, for transmitting signals.

Although noise and interference

cannot be completely removed inthe transmission of an analog signal,with good engineering and proper

installation, many of the effects ofnoise and interference can be sub-stantially reduced. T

References & Further Reading• Analog Signal Processing and Instrumentation, Arie F. Arbel, Cambridge

University Press, 1980.• Basic Circuit Analysis, David R. Cunningham, and John A. Stuller,

Houghton Mifflin Co., 1932.• Circuits: Principles, Analysis, and Simulation, Frank P. Yatsko, and David M.

Hata, Saunders College Publishing, 1992.• Data Acquisition and Control, Microcomputer Applications for Scientists

and Engineers, Joseph J. Carr, Tab Books Inc., 1988.• Data Communications, A Beginner’s Guide to Concepts and Technology,

Scott A. Helmers, Prentice-Hall, Inc., 1989.• Digital and Analog Communication Systems, K. Sam Shanmugam, John

Wiley & Sons, 1979.• Fundamentals of Transducers, Stan Gibilisco and R. H. Warring, Tab Books

Inc., 1985.• Instrument Engineers’ Handbook, Third Edition, Bela Liptak, Chilton Book

Co., 1995. • Introduction to Signal Transmission, Electrical and Electronic Engineering

Series, William R. Bennett, McGraw-Hill, 1970.• Microprocessors in Industrial Measurement and Control, Marvin D. Weiss,

Tab Books Inc., 1987.• Modern Digital and Analog Communication Systems, B.P. Lathi, Holt,

Rinehart, & Winston, 1983.• Process/Industrial Instruments & Controls Handbook, Fourth Edition,

Douglas M. Considine, McGraw-Hill Inc., 1993.• Signals & Systems Made Ridiculously Simple, Zohey Z. Karu, Zi Zi Press,

1995.• Signals, The Telephone and Beyond, John R. Pierce, W. H. Freeman and Co., 1981.

Industrial networks that transmitdata using digital signals often arean integral part of a data acquisi-tion or process control solution.

A basic understanding of the networktechnologies that are available for var-ious applications is required to makethe best implementation decisions—decisions that can have a profoundeffect on the ability to adapt to ever-changing technologies.

For example, the type of net-work(s) or network products select-ed for a data acquisition applicationcan greatly affect cost/benefit eval-uations for future projects. Untilrecently, fiber optics were an expen-sive option that seemed like overkillfor most applications. But with theinformation load now likely to flowbetween nodes on an enterprise net-work, fiber looks attractive.

Network technologies come in abewildering array of options, andcertain segments of this technologyare changing at an incredible rate.The average user might spend weeksresearching the various ways to buildor improve a network, just to findthat once a decision is made andproducts are purchased, the nextwave of bigger, better, faster technol-ogy is now available.

A well-designed, integrated solu-tion to data transmission will yield acompetitive advantage to any indus-trial enterprise. Users in all aspects ofa business should be able to obtainplant and business data from anyphysical node, local or remote.“Gluing” pieces of new and/or exist-ing networks together is becomingmore feasible with the use of bridg-ing, routing, and media conversion

technologies that link local area,wide area, and industrial networkstogether. And with Internet and wire-less technologies, data transmissionover large geographic areas isincreasingly feasible.

The OSI Network ModelNearly all digital network descrip-tions start with the OSI (OpenSystems Interconnect) model (Figure4-1). It explains the various “layers” ofnetwork technology. To the casualuser, this model is a little abstract,but there is not a better way to beginto understand what is going on.

Sometimes it helps to understandeach layer by examining the technol-ogy it represents. The ApplicationLayer is the most intuitive because itis what the user sees. It represents

the problem the user wants the sys-tem to solve. Internet browsers ande-mail programs are good examples.They allow the user to input and readdata while connected between aclient PC and a server somewhere on

the Internet. In an industrial applica-tion, a program on a programmablelogic controller (PLC) might control asmart valve.

The Presentation Layer performsformatting on the data going to andfrom the application. This layer per-forms such services such as encryp-tion, compression, and conversion ofdata from one form to another. Forexample, an application (one layerup) might send a time stamp format-ted in 12-hour time: 01:30:48 p.m. Amore universal representation is13:30:48, in 24-hour time, which canbe accepted or presented at the nextnode’s application in the form that itneeds. One advantage to presenta-tion services is that they help elimi-nate overhead, or embedded ser-vices, in application programs.

The Session Layer establishes theconnection between applications. Italso enforces dialogue rules, whichspecify the order and speed of datatransfer between a sender and areceiver. For example, the session

24 Volume 2 TRANSACTIONS

Physical Layer Options

Network Topologies

Fieldbus & Device Networks

DATA ACQUISITIONDigital Signal Transmission

4

IDigital Signal Transmission

Figure 4-1: The Seven-Layer OSI Network Model

Application

Presentation

Session

Transport

Network

Data Link

Physical

User Programs

Data Formatting

Application Dialogue

Addressing

Routing

Bridging

Media

Application

Presentation

Session

Transport

Network

Data Link

Physical

layer would control the flow of databetween an application and a print-er with a fixed buffer, to avoid bufferoverflows. In the time stamp exam-ple, once the data is presented in24-hour time format, an identifierand length indicator are appendedto the data string.

The Transport Layer is essentiallyan interface between the processorand the outside world. It generatesaddresses for session entities andensures all blocks or packets of datahave been sent or received. In thetime stamp example, an address foreach session entity (sender andreceiver) and checksum are append-ed to the block generated by thesession layer.

The Network Layer performsaccounting, addressing, and routingfunctions on messages receivedfrom the transport layer. If the mes-sage is lengthy, this layer will breakit up and sequence it over the net-work. This layer also uses a networkrouting table to find the next nodeon the way to the destinationaddress. In the time stamp example,a node address and sequence num-ber are appended to the messagereceived from the session layer.

The Data Link Layer establishesand controls the physical path ofcommunication from one node tothe next, with error detection. Thislayer performs media access control(MAC) to decide which node can usethe media and when. The rules usedto perform these functions also areknown as protocols. Ethernet andtoken ring contention are examplesof protocols. In the time stampexample, a header and trailer areappended to the message receivedfrom the transport layer for flaggingthe beginning and end of the frame,type of frame (control or data),

checksum, and other functions.The Physical Layer is perhaps the

most conspicuous layer from a costpoint of view. It is relatively easy tounderstand the labor and material

costs of pulling cables, along with aphysical infrastructure (conduits,raceways, and duct banks) for main-taining cable integrity. This layer doesnot add anything to the messageframe. It simply converts the digitalmessage received from the data linklayer into a string of ones and zeroesrepresented by a signal on the media.One example is RS-485, where a bina-ry 1 is represented by a Mark, or Offstate, and a binary 0 is represented bya Space, or On state. A Mark is a neg-ative voltage between terminals onthe generator, while a Space is a pos-itive voltage on those terminals.

Physical Layer OptionsThere are a number of implementa-tions of the physical layer. Networkdevices allow a wide range of connec-tivity options. Some networks arewell defined using the OSI model,where cables, bridges, routers, servers,modems, and PCs are easily identified.Sometimes only a few devices arelinked together in some kind of pro-

prietary network, or where the net-work services are bundled in a black-box fashion with the device.

The most common serial dataexchange interfaces are RS-232,

RS-422, and RS-485 for connectingtwo or more devices together. Allthree interfaces use data terminalequipment (DTE) and data communi-cation equipment (DCE) terminology(Figure 4-2). The DTE is the compo-nent that wants to communicate withanother component somewhere else,such as a PC communicating withanother PC. The DCE is the compo-nent actually doing the communicat-ing, or, performing the functions ofthe generator and receiver discussedin the standards. A modem is a com-mon example of a DCE.

The interfaces between DTE andDCE can be categorized by mechan-ical, electrical, functional, and pro-cedural aspects. Mechanical specifi-cations define types of connectorsand numbers of pins. Electricalspecifications define line voltagesand waveforms, as well as failuremodes and effects. Functional spec-ifications include timing, data, con-trol and signal grounds, and whichpin(s) the functions are to use. The

Digital Signal Transmission4

TRANSACTIONS Volume 2 25

Figure 4-2: Serial Data Transmission

DCE Data Communications Equipment

Modem Modem

DTE Data Terminal

Equipment

DTE Data Terminal

Equipment

procedural interface specifies howsignals are exchanged.

RS-485 is another serial datatransmission method. Officially, it isEIA 485, or “Standard for ElectricalCharacteristics of Generators andReceivers for Use in BalancedDigital Multipoint Systems” by theElectronics Industry Association(EIA). This standard defines a methodfor generating ones and zeroes asvoltage pulses. Remember, for all thedata handling, framing, packeting,routing and addressing performed bythe upper layers, it still comes downto pushing ones and zeroes oversome physical media.

What is important to know aboutRS-485 is that it allows multiplereceivers and generators, and it speci-fies cable characteristics in terms ofsignaling speeds and lengths. A typicalcable is a shielded twisted copper pair,which is adequate for the typical sig-

naling rate of 10 million bits per sec-ond (Mbps). This standard only definesthe electrical characteristics of thewaveforms. Note that RS-485 does notspecify any media control functions—that is strictly up to the device con-nected to the generator (usually achip). RS-485 is generally good forcable lengths up to 2,000 feet.

One example of a simple serialnetwork might be a series ofrecorders connected over an RS-485link to a PC that receives dataacquired by each recorder. The man-ufacturer sells a plug-in card thatinstalls in each recorder, with wiringinstructions. Each network card isdaisy-chained to the others over aseries of shielded twisted pair cablesthat ultimately terminate on a net-work interface card in the PC. Thereis no real need to know and under-stand the network layers in thisarrangement, except to understand

the limitations on RS-485 (distance,shielding, data rate, etc.).

By title, the RS-422 standard is TIA/EIA 422 B, “Electrical Characteristicsof Balanced Voltage Digital InterfaceCircuits” by the TelecommunicationsIndustry Association (in associationwith the EIA). It is similar to RS-485;the main differences being the risetimes and voltage characteristics ofthe waveform. RS-422 generallyallows cable lengths up to 1.2 kilome-ters at up to 100 thousand bits per sec-ond (kbps). At 10 million bps (Mbps),cable lengths are limited to around 10meters (Figure 4-3). In the presence ofcable imbalance or high commonmode noise levels, cable lengths maybe further reduced in order to main-tain a desired signaling rate.

RS-232C is perhaps the most com-mon form of serial data exchange. Itis officially known as EIA/TIA 232 E,“Interface Between Data TerminalEquipment and Data Circuit-Terminating Equipment EmployingBinary Data Interchange,” again byTIA in association with the EIA. The“E” suffix denotes a later version thanthe common “C” version. Whatmakes this standard different fromRS-422 and RS-485 is that it definesthe mechanical as well as the electri-cal interfaces.

RS-232 is good for signal rates upto 20 kbps, at distances up to 50feet. A zero (space) and a one (mark)are measured in terms of a voltagedifference from signal common (+3 Vdc = 0, -3 V dc = 1). The most com-mon mechanical interfaces are theD-sub 9 and D-sub 25 connectors.

Interchange circuits (pins) in RS-232devices fall into four categories: signalcommon, data circuits (transmitteddata, received data), control circuits(i.e., request to send, clear to send, DCEready, DTE ready), and timing circuits.

Digital Signal Transmission 4

26 Volume 2 TRANSACTIONS

Figure 4-3: Cable Length vs. RS-422 Data Rate

RS-422 Data Signaling Rate (bit/s)

10k 100k 1M 10M

Cabl

e Le

ngth

(met

ers)

10k

1.2k1k

100

10

The standards described above allare used in serial communicationsschemes designed for longer dis-tances. There is one common parallelinterface, known as the GeneralPurpose Interface Bus (GPIB), or IEEE-488. Up to 15 devices can be intercon-nected, usually personal computersand scientific equipment or instru-ments. It provides a high data signalingrate, up to 1 Mbps, but it is limited inlength. The total bus length permittedis 20 meters, with no more than 4meters between devices.

The IEEE-488 bus is a multi-drop,parallel interface with 24 linesaccessed by all devices. The lines aregrouped into data lines, handshakelines, bus management lines, andground lines. Communication is digital,and messages are sent one byte at atime. The connector is a 24-pin con-nector; devices on the bus usefemale receptacles while intercon-necting cables have mating maleplugs. A typical cable will have maleand female connectors to allowdaisy-chaining between devices.

An example of an IEEE-488 imple-mentation is a measurement systemdesigned to assess the performanceof a chemistry sample sink. The sinkperforms sample conditioning (pres-sure, flow, and temperature control)and chemical analysis (pH, dissolvedoxygen, and conductivity) on watersamples. The sink is instrumentedwith pressure sensors, resistance tem-perature detectors (RTDs), thermo-couples, and reference junctions. A30-point scanner is used to multiplexdata from all of the sensors. The scan-ner is connected to a desktop or lap-top PC using the GPIB interface. Datais acquired, stored, displayed, andreduced using application programson the PC, efficiently and reliablyunder IEEE-488.

The media used to implement thephysical layer is usually a set of cop-per wires. Unshielded twisted pair(UTP) cable is the most affordable. It islightweight, easy to pull, easy to ter-minate, and uses less cable tray spacethan shielded twisted pair (STP).However, it is more susceptible toelectromagnetic interference (EMI).

STP is heavier and more difficultto manufacture, but it can greatlyimprove the signaling rate in a giventransmission scheme (Figure 4-4.).

Twisting provides cancellation ofmagnetically induced fields andcurrents on a pair of conductors.Magnetic fields arise around otherheavy current-carrying conductorsand around large electric motors.Various grades of copper cables areavailable, with Grade 5 being thebest and most expensive. Grade 5copper, appropriate for use in 100-Mbps applications, has more twistsper inch than lower grades. Moretwists per inch means more linearfeet of copper wire used to makeup a cable run, and more coppermeans more money.

Shielding provides a means toreflect or absorb electric fields thatare present around cables. Shieldingcomes in a variety of forms fromcopper braiding or copper meshes toaluminized mylar tape wrappedaround each conductor and againaround the twisted pair.

Fiber optics are being used moreoften as user applications demandhigher and higher bandwidths. Theterm “bandwidth” technically meansthe difference between the highestand lowest frequencies of a transmis-sion channel, in hertz (Hz). Morecommonly, it means the capacity oramount of data that can be sentthrough a given circuit.

A bandwidth of 100 Mbps is stan-dard using fiber optic cables. Whenfirst introduced, fiber was considered

only for special applications becauseit was expensive and difficult to workwith. In recent years, the quest forgreater bandwidth combined witheasier-to-use fiber have made itmore common. Tools and training forinstalling and troubleshooting fiberare readily available.

There are three basic fiber opticcables available: multimode stepindex, multimode graded index, andsingle mode. Multimode fibers usu-ally are driven by LEDs at each endof the cable, while single modefibers usually are driven by lasers.Single mode fibers can achievemuch higher bandwidths than multi-mode fibers, but are thinner(10 microns) and physically weakerthan multimode. Equipment costsfor transmitting and receiving singlemode fiber signals are much higher(at least four times) than for multi-mode signals.

Digital Signal Transmission4

TRANSACTIONS Volume 2 27

Figure 4-4: Shielded Twisted Pair (STP) Cable Construction

Twisting Attenuates Magnetic Fields Shield Attenuates Electrical Fields

+

-

-

+

One distinct advantage of fiberoptic cables is noise immunity. Fiberoptic cables can be routed indis-criminately through high noise areaswith impunity, although fire ratingsshould be observed. Cables thatpass through multiple spaces in aplant should be rated for heating/ventilation/air conditioning (HVAC)plenums where they can withstand

fires per National Fire ProtectionAssociation (NFPA) requirements.

Network TopologiesThe term topology refers to themethod used to connect compo-nents on a network. The most com-mon topologies are ring, bus, and startopologies (Figures 4-5, 4-6, and 4-7),but they can take on the appearancesof each other and still maintain theircharacteristics. For example, a tokenring network segment can be wired ina star configuration, where compo-nents are cabled back to a hub wherethe ring is “inside” the hub. Thisallows a common wiring closet for agiven building or area with home-run cable pulls for each component.A hub offers the advantages of cen-

tralized maintenance and configura-tion control.

• Token Buses & RingsThe MAC functions of token ringsand buses are similar. ARCnet, devel-oped by the Datapoint Corp. in the’70s, is a token passing protocol thatcan be implemented in a bus or startopology using coaxial or UTP cables.

A “token” is passed around the bus orring. Whichever node has the tokenis allowed to communicate on themedia. ARCnet runs at 2.5 Mbps, atthe following lengths:• 400 feet with 10 nodes using UTP;• 2,000 feet with a practical limit of

up to 100 nodes using RG-62 coax-ial cable in a coaxial star configu-ration (using a hub or hubs); and

• 1,000 feet with 10 nodes per 1,000foot segment using RG-62 coaxialcable.ARCnet uses active and passive

hubs in the star configuration, withnetwork cards on the devices thathave switches for setting node num-bers. The lowest numbered node isthe master controller, giving permis-sion to communicate to each node

by number. ARCnet is available in a20-Mbps version.

The IBM token ring protocol, stan-dardized via IEEE-802.5, runs at 4 or 16Mbps. Nodes on the ring connect to amulti-station access unit (MAU), atype of hub. MAUs can be connectedtogether in a main ring, with seg-ments, or lobes, from each MAU con-nected in a star configuration todevices with network interface cards.The length of the ring is limited to 770meters and the maximum number ofnodes allowed on a ring is 260 usingSTP cable. STP cable (150 ohm) is usedmost often, but UTP (100 ohm) cablecan be used if passive filtering is pro-vided for speeds up to 16 Mbps.Bridges can be used to connect rings.

Jitter is an interesting problem thatcan arise on token ring networks,where nodes that are supposed to besynchronized with the master nodereceive distorted waveforms due tocable attenuation. The result is thateach node operates at a slightly dif-ferent speed. Jitter restricts the num-ber of nodes allowed on the ring (72at 16 Mbps on UTP). Jitter suppressorsare available that can help alleviatethis problem.

Repeaters are available for extend-ing the ring. Using phase-locked-loop(PLL) technology, a repeater canextend the main ring an additional800 feet at 16 Mbps on Category 5copper UTP.

Using a media converter, or fiberoptic transceiver, conversion betweencopper and single mode or multi-mode fiber is possible, thus extendingmain ring lengths or lobe lengths upto 1.25 miles.

• Ethernet, or CSMA/CDThe most common bus topology inbusiness applications is Ethernet.Ethernet originally was developed by

Digital Signal Transmission 4

28 Volume 2 TRANSACTIONS