Para Flo

-

Upload

carlos-ramirez -

Category

Documents

-

view

216 -

download

0

Transcript of Para Flo

-

7/31/2019 Para Flo

1/2

P R O D U C T B U L L E T I N

Paraflo HorizontalCartridge Filter

Cartridges are easily and quickly

removed and loaded from outside the

collector.

A variety of filter media is available,

including cellulose/polyester,

polyester, and membrane laminate.

Features and Benefits

Parallel air flow with patented inletextends cartridge life and increases

filtration rate.

Heavy duty construction and

powder painting inside and out

provide longer service life.

High efficiency pulsing provides

highest filtration rate in tough

applications.

Modular panelized design allows

easy capacity increases. Multiple

units share common hoppers and

minimize clean air ducting.

Complete selection of cellulose,

spun bond, and membrane filter

media permits a cartridge selection

to meet the unique needs of each

application.

Filter cartridges are conveniently

serviced from outside the collector.

Cartridge changeouts are quickly

performed on the Paraflo.

Superior design increases

efficiency and improvesfilter cartridge life.

The patented Pneumafil Paraflo

horizontal cartridge process collector

is a high efficiency filter that provides

superior performance in a variety of

applications that require high

efficiency filtration.

Paraflo filters are often used in place

of baghouses because of their compact

size, quick cartridge changes, and the

fact that they do not require a confined

space entry permit.

What Sets Paraflo Apart

The Paraflo utilizes four unique

features to achieve superior

performance:

Preseparation removes denser

particles from the air stream prior to

filtration, thereby lowering the amount

of material the cartridges must collect

and raising the filtration rate.

Parallel Air Flow eliminates high

velocity impingement of the

particulate stream on the filter media,

extending cartridge life.

High Efficiency Pulsing System

provides unmatched cleaning

performance while minimizing

compressed air consumption.

(continued)

Paraflo was developed by Pneumafil

Corporation, which is affiliated with

MikroPul. Paraflo is a registered

trademark of Pneumafil Corporation.

-

7/31/2019 Para Flo

2/2

A member of Beacon Industrial Group

BIM522 9/01

MikroPul Headquarters4500 Chesapeake Dr.Charlotte, NC 28216Tel: 704-998-2600Fax: 704-998-2601Customer Service:

800-892-7278

MikroPul Pittsburgh2591 Wexford-Bayne Road, Suite 202Sewickley, PA 15143Tel: 724-934-3910Fax: [email protected]

MikroPul Canada, Inc.245 Matheson Blvd. E., Unit # 10Mississauga, Ontario L4Z 3C9CanadaTel: 905-712-0722Fax: [email protected]

MikroPul, S de RL de CVAv. Lomas Verdes No. 480-302BCol. Lomas VerdesCP 53120 NaucalpanEdo. de MexicoTel: 52-55-5343-8224Fax: 52-55-5344-5081

NORTH AMERICAN LOCATIONS Visit our web site @ www.mikropul.com for other locations worldwide.

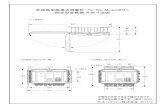

How the Paraflo WorksUnfiltered air enters the top of the

collector and is introduced into the

filter compartment through a constant

velocity, tapered flow header 1 . An

inlet flow straightener is incorporated

which minimizes turbulence, entrance

energy losses, and cartridge abrasion.

This header and flow straightenerredirects air flow 2 to be parallel to

the filter cartridges. Gravity and

inertia cause heavier particles to

continue on a downward path 3 into

the hopper.

The lighter, fine dust follows the air

stream and accumulates on the outside

of the cartridges 4 . This causes a

pressure drop (P) increase across the

cartridge media which is constantly

measured and controlled with a dual

setpoint (high-low) photohelic gauge.The cartridges are cleaned by back-

pulsing 2.75-5.5 bar (40-80 psig)

compressed air through a high

efficiency pulsing system 5 to

maintain desired P. Cartridges are Paraflos unique inlet design preseparates dust and extends cartridge life.

pulse cleaned sequentially top-to-

bottom, thereby eliminating excess

cartridge-to-cartridge reentrainment

and maximizing filtration rate. The

loosened dust falls into the hopper.

Clean air from inside the cartridges

exits into the clean air plenum 6 and

6

5

4

3

2

1

can be returned to the plant in most

applications, reducing heating and air

conditioning expense.

High efficiency pulsing system

A

B

C

D EPerformance and Utilities

1

Model Number ACFM3 Air Usage4 A B5 C D E Inlet/ WeightCartridges @ 2:1 SCFA/ Outlet (Lbs.)

A/C Pulse Dia.

PHF-4 4 1,808 1.5 2'5" 2'8" 5'0" 3'4" 7'11" 18"x34" 1,100

PHF-8 8 3,616 1.5 4'0" 2'8" 5'0" 3'4" 7'11" 18"x34" 1,650

PHF-12 12 5,424 1.5 5'7" 2'8" 5'0" 3'4" 7'11" 18"x34" 2,200

PHF-16 16 7,232 1.5 7'2" 2'8" 5'0" 3'4" 7'11" 18"x34" 2,800

PHF-20 20 9,040 1.5 8'9" 2'8" 5'0" 3'4" 7'11" 18"x34" 3,300

PHF-24 24 10,848 1.5 10'4" 2'8" 5'0" 3'4" 7'11" 18"x34" 3,800

Dimensions and Weight2

1. 115 VAC, is standard for all models2. Dimensions and weights are nominal.3. ACFM ratings based on cellulose media. Consult factory for other media types.4. Air usage based on pulsing with 80 psig compressed air.5. Hopper height based on 60 hopper.Specifications are subject to change.