Nc Milling

-

Upload

khairulakmal77 -

Category

Documents

-

view

218 -

download

0

Transcript of Nc Milling

-

8/8/2019 Nc Milling

1/15

1

NC Milling Tutorial

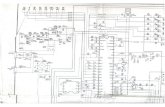

This tutorial shows how to use Pro/Engineer to generate a machine tool path for an NC

mill to manufacture a part. In this tutorial a wooden workpiece of size 7" 1.75"1.3" will have

material cut away. The first task is to use Pro/Engineer to design the part to be manufactured.

Figure 1 shows how the workpiece will be clamped to the mill tabletop. Be sure that

your part to be manufactured does not have material removed near the clamps so that the cutting

tool will not intersect with the clamps1. Figure 2 shows the cutting tool that will be used in this

exercise.

Figure 1: Workpiece Clamped to Mill Tabletop

Figure 2: Cutting Tool

1 It is possible to model the clamps in Pro/Engineer and to position them relative to the workpiece. The calculated

cutting tool path will avoid the modeled clamps. The modeling of the clamps is beyond the scope of this tutorial.

-

8/8/2019 Nc Milling

2/15

2

Step 1: Create the Part Model

Figure 3 shows the part to be manufactured. The exact dimensions are not important for

this exercise, but it should be apparent that the workpiece can be clamped from the sides and the

machining operation completed without the cutting tool intersecting the clamps. The part was

created in Pro/Engineer and was namedpinewood.prt. Pro/Engineer will create several new files

that will be associated with the manufacturing process and it is recommended that a new empty

directory be created and the filepinewood.prtmoved to this directory.

Figure 3: Part to be Machined

Step 2: Assemble the Part and Workpiece

Start Pro/Engineer and set your working directory

to the location of your part file. Select File, New from

the pull down menu. The dialog box shown in Figure 4

will appear. Check Manufacturing and NC Part and

give your manufacturing process a name. For this

tutorial, the namepinewoodwas chosen.

Select OK and the dialog box shown in Figure 5

will appear. Select your part file (pinewood.prt for this

example) and select Open. Your part will now appear

on the screen as shown in Figure 6.

Figure 4

-

8/8/2019 Nc Milling

3/15

3

Figure 5

Figure 6

-

8/8/2019 Nc Milling

4/15

4

The next step is to create the workpiece material that the part will be machined from

using our part as a guide. On the right hand menu, select Mfg Model, then Create, then

Workpiece. You are now prompted to enter a name for your workpiece. The name

pinewood_wkpiece was selected for this tutorial.

We will now enter the Sketcher to model the workpiece. To do this, on the right hand

menu, select Protrusion, then Solid/Done, then One Side/Done. You now are asked to

pick the sketching plane. Pick the bottom surface of the part. We want the workpiece to envelop

the part so make sure that the direction of the extrusion arrow is pointing upward towards the top

of the part and select Okay. You are now prompted for the reference planes. Select Right

and pick the front side of your pinewood vehicle. The References dialog box now appears.

Select the left and bottom references and then press Close. You are now in the Sketcher.

Draw a rectangular box that is the shape of your workpiece. For this exercise, the

workpiece material is 7"1.75" and is 1.3" tall. Exit the Sketcher as is normally done by clicking

on the check mark icon. It remains to enter the depth of the extrusion. Perform a blind extrusion

of 1.3". All elements of the protrusion are now defined. Select OK and then Done/Return.

The workpiece is now defined and you can rotate the view as desired to view the workpiece and

the part as is shown in Figure 7.

Figure 7

-

8/8/2019 Nc Milling

5/15

5

Step 3: Manufacturing Setup

We will now specify a 3 axis milling application. Selectc Mfg Setup from the menu on

the right. The Operation Setup dialog box appears (see Figure 8).

Figure 8

Click on the mill icon . The Machine Tool Setup dialog box opens as shown in

Figure 9.

mill icon

-

8/8/2019 Nc Milling

6/15

6

Figure 9

Make sure that the Machine Type is mill and the Number of Axes is 3 Axis. Click OK.

You are now back at the Operation Setup dialog box (see Figure 8).

We will now be establishing the coordinate system that the tool path commands will be

referenced to. Select the arrow to the right of the text Machine Zero. Click on Create on the

right side menu and then pick on the workpiece (the block from which material will be cut).

Next select 2 Axes and Done from the right side menu. You are now prompted to pick two

edges. We will be placing the origin of the coordinate system at the upper left corner when

looking down on the part. Select the two edges that pass through this point. Figure 10 shows the

screen after selecting these two edges (your screen may appear differently depending on the

order you picked the edges). A coordinate system is shown in the upper left corner. It remains

to define the directions of the X, Y, and Z axes. We will specify the direction of two of these

and the third will be defined in a right-hand sense.

The Z axis will be pointing upward, i.e. from the bottom towards the top of the part. The

X axis will point to the right. Figure 10 shows one of the coordinate axes colored as red. For

-

8/8/2019 Nc Milling

7/15

7

this case, this is pointing in the negative X axis direction. Select Reverse from the right side

menu. The red arrow now points in the direction of the X axis. Select X-Axis to define the X-

axis as being in the direction of the red arrow.

Figure 11 shows the current status of the model. The red arrow is pointing along the

direction of the negative Y axis. We could reverse the direction and then define the Y axis, but

instead we will work to define the Z axis.

Figure 11

Select Next to change which of the coordinate axes is highlighted as red (see Figure

12). This is the direction of the Z axis so select Z-Axis to define this axis. The coordinate

system is now completely defined. Select OK to return to the manufacturing setup menu (see

Figure 13).

Figure 10

-

8/8/2019 Nc Milling

8/15

8

Figure 12

To complete the manufacturing setup, we need to specify the

volume of the material to be removed. We will select the entireworkpiece and then remove the part to get the volume of material to be

removed. Select Mfg Geometry from the right side menu followed by

Mill Volume. Next select Create. You are prompted to enter a

name for the milling volume (the material to be removed). The name

pinewood_mill_volwas used in this tutorial.

You are now prompted to pick a plane that is perpendicular to

the Z axis. Select the top surface of the workpiece. A red arrow should

appear that points in the positive Z direction (if not select flip). Press

Okay.

The sketch command will now be used to create the volume of

material to be removed. Select Sketch from the right side menu. This

is followed by Extrude/Solid/Done and One Side/Done. Now

pick the top surface of your workpiece. The red arrow should now point

downward along the negative Z axis. Select Okay. You are now

prompted to select a reference so the sketcher can orient the part. Select

Right and then pick the front of the pinewood car. Now pick two

edges to serve as your reference lines in the sketcher (the bottom and left edges were chosen in

this tutorial) and then select Close. Figure 14 shows the current screen image.

Figure 13

-

8/8/2019 Nc Milling

9/15

9

Figure 14

-

8/8/2019 Nc Milling

10/15

10

Select Sketch from the top menu (see

Figure 15) and then Edge/Use. Now select

the four outer edges of the workpiece and then

Close. Now exit the sketcher by selecting the

check box . To complete the protrusion that

will define the mill volume, select UpTo

Surface, and rotate the model as needed to select

the bottom surface of the workpiece. Then select

Done.

We have selected our entire workpiece as

the mill volume, but still need to trim away the

part. Select Trim from the right side menu

followed by Done/Return, Done/Return,Done/Return. This returns us to the main

manufacturing menu. This completes the

manufacturing setup process.

Figure 15

-

8/8/2019 Nc Milling

11/15

11

Step 4: Machining Sequence

In this step, the tool and machining parameters (tool size,

cutting speed, etc.) and a retraction plane will be specified. Select

Machining from the manufacture main menu, followed by NC

Sequence. Next select Volume/Done. The sequence setup menu

will appear as shown in Figure 16. Make sure that the Tool,

Parameters, Retract, and Volume boxes are checked. Select

Done.

The Tools Setup dialog box appears as shown in Figure 17.

Set the cutter diameter to 0.375" and the length to 1". Select Apply

then File, Done.

Select Set from the MGF PARAMS menu. The Parameter

Tree dialog box appears (See Figure 18). We will have to set values

for all the parameters that have a current value of -1. Set the

following values:

Cut_Feed 60

Step_Depth 0.02

Step_Over 0.18

Scan_type Type_Spiral

Spindle Speed 1000

Clear_Dist 0.5

The cut feed parameter is the feed rate during cutting in units of xxx.

The step depth is the depth of cut in inches. The step over parameter has been set to slightly less

than half the tool diameter in units of inches. The spindle speed is in units of revolutions per

minute. The clear distance is xxx. The cut feed and spindle speed values are ignored by the

Minitech mill. The feedrate for the Minitech mill is set at 6 seconds per inch and is not

overridden by values set here. The spindle speed for the Minitech mill is set manually and is not

under computer control. After setting the parameters, select File and Exit. Next selectDone.

The Retract Surface Options dialog box appears as shown in Figure 19. We will specify

a plane that is 0.5" above the top of the workpiece. Click on Along Z Axis and enter a value of

0.5". The retraction plane is now displayed.

Figure 16

-

8/8/2019 Nc Milling

12/15

12

Figure 17

-

8/8/2019 Nc Milling

13/15

13

Figure 18

-

8/8/2019 Nc Milling

14/15

14

The volume of material to be removed must now be specified. Click on Select Vol on

the right side menu. A dialog box will be displayed that shows the mill volume that we

previously defined (see Figure 20). Click on your mill volume name and then press Select.

The machining sequence is now complete.

Figure 19

Figure 20

-

8/8/2019 Nc Milling

15/15

15

Step 5: Viewing and Outputting the Results

To view the tool path, select Play Path from the right side menu (Machining/NC

Sequence menu). Then press Screen Play. A VCR type dialog box appears that will allow you

to select the display speed and play back the tool path. When done viewing the tool path, close

the VCR dialog box and select Done Seq to return to the Machining menu.

To output a CL data file, select CL Data from the right side menu. From the Select

Feature submenu, select Operation. From the SEL MENU submenu, select the name of your

operation (OP010 was used in the tutorial). Select File from the PATH submenu and make

sure that the CL FILE and Interactive boxes are checked. Select Done. You are now

prompted for a name for your CL file. The filenamepinewoodwas used in this tutorial. You

should have a message printed at the top of the Pro/Engineer screen that says that the file

pinewood.ncl.1 was created successfully.

The last step is to convert the CL data file to a tape file that has G-code commands. Thisfeature is built into Pro/Engineer, but is not working properly at this time. The teaching assistant

will use a separate software program (Ideas) to convert your CL file to a G-code tape file.