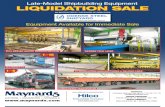

IT in Service Ind.

Transcript of IT in Service Ind.

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 1/13

138 THE McKINSEY QUARTERLY 1998 NUMBER 1

INFORMATION TECHNOLOGY/SYSTEMS

Research indicates the greatest potential for IT lies in product

development and sales

Moving from laggard to star will take two to three years

Seven highly eƒfective habits

MANUFACTURING’S

Rolf-Dieter Kempis and Jürgen Ringbeck

Rolf-Dieter Kempis is a director and Jürgen Ringbeck is a principal in McKinsey’sDusseldorf oƒfice. Copyright © 1998 McKinsey & Company. All rights reserved.

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 2/13

THE McKINSEY QUARTERLY 1998 NUMBER 1 139

IN SERVICE INDUSTRIES such as banking and airlines, informationtechnology has established itself as a vital strategic tool. Yet in manu-facturing, it has largely failed to live up to its promise. Widespread early

euphoria – visions of productivity gains from reengineering and theintegration of IT into every facet of manufacturing operations – hadevaporated by the beginning of the decade. The introduction of so-calledintegrated standard soƒtware had proven time-consuming and risky. Not onlydid implementation costs quickly outstrip initial estimates, but anticipatedbenefits failed to materialize in all but a few cases.

Plant managers complained that production planning systems were not up tothe job. Sales managers unable to reorganize order processing condemnedtheir sales information systems as inflexible. Only in handling basic admin-istrative tasks concerned with accounting and personnel, it seemed, could ITdemonstrate clear eƒficiency gains.

Bio

USE AND ABUSE OF IT

MICHAEL ROSENFELDER/TONY STONE IMAGES

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 3/13

Companies now recognize that the use of a particular soƒtware applicationcannot guarantee business success; strategic benefits, they have learned,rarely emerge from a simple increase in IT resources. In response, somemanufacturing companies are managing IT purely on the basis of cost,eschewing strategic considerations. In Germany, auto maker Porsche andwire manufacturer Continental have gone so far as to outsource their entiredata processing function. Fueled by such developments, the IT outsourcingbusiness is now valued at more than $32 billion worldwide.

None the less, IT can still serve as a powerful driver of process innovation.Technologies such as the Internet and multimedia-supported simulationshold enormous commercial potential.

How, then, can a manufacturing company harness superior IT to gaincompetitive advantage in strategic business processes? What can IT contri-bute to corporate success? To answer these questions, McKinsey and theUniversity of Darmstadt conducted a survey of some 70 companies inEurope, the United States, and Asia.

We found that strong performance in IT does make a real diƒference: betterinformation managers are also better at core processes such as R&D, orderprocessing, sales, and service. In turn, excellence in core processes produces

tangible payoƒfs: solid competencies in core operational processes improveprofitability, and superior product development promotes growth.

MANUFACTURING’S USE AND ABUSE OF IT

140 THE McKINSEY QUARTERLY 1998 NUMBER 1

As part of the survey, interviews were

conducted with top managers from

many relevant manufacturing sectors, f rom

machine manufacturers, automobile suppliers,

component producers, and electronics firmsto companies in the process industry. The

sample included companies from Europe, the

United States, and Asia. Operating units with

revenues of $0.2 to $1 billion were the focus

of the research. More than 3,000 items of

data were gathered on each organization.

On average, the companies that took part

spent about 2.2 percent of their revenues

on IT. Most employed standard software,

especially in administration. Over 60 percentused functionally integrated standard

software, and more than 40 percent used

SAP software in at least some areas. More

than 40 percent stil l used a mainframe

as a system platform.

Information management performance wasmeasured in terms of both efficiency (IT cost

as a percentage of revenues, plus project

management performance against schedule

and budget) and effectiveness (the availability,

functionality, and utilization rates of IT

applications for each core business process).

Management performance was judged by a

company’s return on sales, revenue growth

rate, profitability, and market share. We also

developed indicators to assess performance

in specific core processes such as productdevelopment, sales, order processing,

and service.

ABOUT THE RESEARCH

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 4/13

But there were also some surprises. Sales, where IT penetration hashistorically been weak, presented a major opportunity. On the other hand,production control at shop floor level is oƒten best managed with traditionalmethods.

Few companies, it emerged, are good at IT. Exhibit 1 illustrates the distri-bution of four IT cultures – stars, big spenders, cautious spenders, andlaggards – among the companies surveyed. Exhibit 2 correlates these cultureswith the four business measures used in the survey. It suggests that, whileeƒficiency is important, eƒfectiveness makes a particularly powerful contri-bution to business success: big spenders are about as successful as stars, whilecautious spenders fare little better than laggards.

Analysis of the survey results reveals that highly eƒfective IT organizationsshare seven habits. While no manufacturing operation can guarantee totransform itself simply by following a set of guidelines, there is ample evidenceto suggest that the journey from IT laggard to IT star will make a strikingdiƒference to a company’s bottom line.

Rule 1: IT is a top management aƒfair

Informationmanagementmust receive the attentionof top management. Onaverage, the top managers at IT stars together spendabout45hours permonth

on IT, compared with 20 hours for laggards. The stars also charge on averagethree senior executives with IT management tasks, who each devote about 15

MANUFACTURING’S USE AND ABUSE OF IT

THE McKINSEY QUARTERLY 1998 NUMBER 1 141

Exhibit 1

Four IT cultures

% of companies surveyed

E f f e c t i v

e n e s s

o f I T *

Efficiency of IT†

13

27

49

11

*Defined as IT support of core business processes(availability, functionality, utilization rate)

†Defined as IT costs as a share of sales (adjusted byindustry segment) and IT project processing (meetingdeadlines and budgets)

Big spenders Stars

Laggards Cautiousspenders

Exhibit 2

How the four cultures perform

E f f e c t i v e n e s s

o f I T

Efficiency of IT

Big spenders Stars

Laggards Cautious spenders

1993–96

Average annual return on sales

Rate of change in return on sales

(percentage points per annum)Rate of change in sales (% per annum)

Rate of change in market share (% per annum)

7.8

0.1

7.3

2.94.7

1.8

7.4

4.8

1.84.9 3.8

0.5

4.6

–0.9

–4.0

–1.1

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 5/13

hours a month to them, about three times as much as their peers at laggardcompanies, where four or five top managers typically share this responsibility.

Not surprisingly, top managers at low-performing companies, who spend anaverage of just 4.5 hours on IT per month, tend to have vague and unrealisticexpectations. These range from the over-ambitious (“halving IT costs throughoutsourcing,” wrote one) to the gloomy (“new media and IT tools are unsuit-able in heavy engineering,” said another). At such companies, businessprocesses are seldom linked with IT goals, and even major IT projects receivescant top management participation.

At IT stars, by contrast, top managers devote time and energy to developingan IT strategy, and get actively involved in the introduction of new systems.In particular, they play a critical role in defining projects and agreeingmeasurable goals in specific business processes and technologies (for example,reducing the time spent preparing products for specific customers byexpanding intranet connections between sales centers and plants). In majorreengineering projects, each sub-project has a set of concrete goals and isbroken down into work packages for individual employees. Executivemanagement and users keep in touch with the progress of new projects via IT

training sessions. Indeed, managersat star companies spend more thantwice as much time on IT training(for example, courses introducingnew technologiessuch asdigitalchan-nel products) as those at laggards.

Without the intimate involvement of top management in critical IT issues,information management rarelyperforms well.

Rule 2: Make IT a priority inproduct development

Companies with superior IT manage-ment tend to be better at developingproducts (Exhibit 3); they achievebetter results with smaller budgets.

As best practice moves beyond heavy investment in CAD soƒtware andengineering databases, two areas are emerging as the future focus of first-class product development.

Simulation and calculation soƒtware.The use of soƒtware to performsimulations and calculations in product development is nothing new. But

MANUFACTURING’S USE AND ABUSE OF IT

142 THE McKINSEY QUARTERLY 1998 NUMBER 1

Exhibit 3

Product development performance

E f f e c t i v e

n e s s

o f I T

Efficiency of IT

Big spenders IT stars

IT laggards Cautious spenders

% of companies surveyed

Companies with good development performance

Companies with poor development performance

60

40

100

0

40

60

29

71

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 6/13

successful developers boost development output by using them earlier andmore intensively. In our survey, approximately 50 percent of stars claimed tobe able to identify development errors such as design misspecificationsquickly and reliably, compared to only 25 percent of laggards.

The application of simulation soƒtware to modeling is already cutting develop-ment time and cost, but its future holds even greater promise. Through rapid“virtual” prototyping rather than conventional tooling up, one auto partsmanufacturer managed to reduce manufacturing costs on rear lights by 60percent, and shorten its delivery time by 12 weeks.

The use of simulation in assembly and production enables the productionprocess to be adapted to the product much earlier in development, thusreducing manufacturing costs.

Electronic integration of engineering data

and tasks. The integration of data (such asCAD data, simulation results, work sched-ules, and project status information) withtasks in the development process has muchto oƒfer. Key challenges in R& D manage-ment, such as reducing development time and broadening technical expertise,are forcing companies to integrate both their own core processes and theirdevelopment partnerships with other companies.

Successful developers are ahead in integrating engineering data manage-ment (EDM) with other applications: 50 to 70 percent of these companieshave integrated calculation and simulation results and work plans into theirEDM systems, while for poor developers the figure is only 13 to 31 percent.Successful developers also use EDM earlier in product development toestimate product costs.

The integration of CAD and simulation databases can serve as a springboardto faster, simpler communication with engineering partners. A 3D CADsystem with spatial geometric representation of objects is usually requiredfor this purpose.

Seeking to encourage superior “design to manufacture” – the design of products to optimize quality/cost tradeoƒfs – more than 75 percent of successful developers have built up interfaces between direct numericalcontrol (DNC) machinery management in the production area and CADdatabases, more than half of them with integrated functionality (allowingthe transfer not just of raw data but also of DNC programs). Among

less successful developers, only 40 percent have achieved this degree of integration. The story is much the same in relation to the integration of CAD

MANUFACTURING’S USE AND ABUSE OF IT

THE McKINSEY QUARTERLY 1998 NUMBER 1 143

The application of simulationsoƒtware to modeling is

already cutting developmenttime and cost, but its futureholds even greater promise

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 7/13

and simulation applications in manufacturing and assembly, and withdevelopment partners.

A comparison of companies’ goals for product development and the appli-cation of new technologies in the coming years reveals that the gap betweenmore successful and less successful developers in the application of IT willcontinue to widen.

Rule 3: Integrate IT into sales and customer service to boostperformance

Sales is traditionally an area of low IT penetration. Management attemptsto use management information systems to make the sales process moretransparent have been met with skepticism from sales staƒf. Even so, masterdatabases for customer files have become standard, as have order processingsystems that permit faster and more consistent order transfers. In addition,over 60 percent of the sales staƒf surveyed are now equipped with laptopcomputers and mobile phones, and many companies provide product andprice information in CD-ROM catalogs and other digital formats.

Companies whose sales performance is above average tend to use integratedstandard soƒtware more intensively, allowing them to integrate sales data toa greater extent. Their sales information systems also provide direct access to

data on capacity and production scheduling,so that the feasibility of any customer requestcan be checked before an order is placed.

Some companies have gone further, allowingregular customers to enter their ordersdirectly into EDI systems. Manufacturers of standardized industrial products that carry

out more than 50 percent of their business transactions by EDI spend only0.7 percent of revenues on back-oƒfice sales work. Those processing less than50 percent of their orders via EDI spend twice as much. Companies withmore complex product ranges currently process fewer orders via EDI;however, those processing more than 10 percent of orders via EDI achieveda cost advantage of about 50 percent over companies that did not use EDI.

Most important, the survey suggests that the use of product configurators –electronic tools that simulate the putting together of a product from thou-sands of possible features – will make an important contribution to businesssuccess in the future. During a sales pitch, staƒf will be able to show customersthe full range of products, variants, and types, calculate the price of the

product chosen, and agree a realistic delivery date.

MANUFACTURING’S USE AND ABUSE OF IT

144 THE McKINSEY QUARTERLY 1998 NUMBER 1

By using configurators, one

manufacturer was able toreplace a full 90 percent of

special customer requests witha set of pre-costed variants

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 8/13

The advantages are obvious. Contracts for products that a company cannotmanufacture would become a thing of the past, as would most delivery delays.Jobs could be scheduled on the spot, and products engineered at estimatedcost. By using configurators, one manufacturer was able to replace a full 90percent of special customer requests with a set of pre-costed variants.

Rule 4: Use IT selectively to integrate order management across

the companyPurchasing, materials management, and production planning have long beenkey areas for IT applications. By monitoring materials and comparing stocklevels against production requirements, IT can help organize orders eƒficiently.Information systems are also indispensable for planning production jobsdown to the calculation of daily job lists for individual production areas.

Despite these advances, the “factory of the future” has yet to become a reality.Many companies feel their production planning and control systems areineƒfective, inappropriate, and brittle. Companies with complex productionprograms and small batch sizes complain that their production planningsoƒtware doesn’t cater for their needs. Even manufacturers of standardproducts find their systems inflexible when orders are changed.

So how do successful manufacturers cope? The answer is that they knowwhen IT works and when it doesn’t. Surprisingly, while IT plays an importantrole in other core operating processes, it seldom oƒfers much help withproduction control at a detailed level. Almost eighty percent of companiesthat excel at order processing dispense with IT-supported control at theshop floor level, instead using simpleorganizational processes such as Kanban (Exhibit 4). Their impor-tance as a substitute for IT increaseswith the complexity of the produc-tion process. Successful developersalso limit their customers’ flexibilityover scheduling orders: their “freezepoint” for placing orders in theirMRP system is much earlier, andonce it is reached, they change ordersless oƒten to avoid disrupting pro-duction schedules.

IT has an important contribution tomake to purchasing and logistics. IT-

supported inventory management is

MANUFACTURING’S USE AND ABUSE OF IT

THE McKINSEY QUARTERLY 1998 NUMBER 1 145

Exhibit 4

Methods of shop-floor control

Companieswith excellent

orderprocessing

Companies with poororderprocessing

Users of multiplelogics and systems

Users of dedicatedsystems for shop-floor control

MRP II users; shop-floor control without IT(Kanban, etc)

22

0

78

34

55

11

Percent

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 9/13

standard; what makes the diƒference is the monitoring of orders between acompany and its customers and suppliers via EDI. Although EDI is notwidespread on the supply side – suppliers of standardized goods are the mainusers thus far – more intense use of EDI for customer order calls leads tomuch lower logistical costs (Exhibit 5).

When it comes to service, companies with excellent performance stand outnot so much because of the IT equipment they use in the field but because of the data and applications (such as diagnostic systems) they employ. Partly asa result of this broader range of applications, companies with the best serviceperformance use their IT systems twice as intensively in the field (at 25 hoursper week) as companies with poor service performance.

Rule 5: IT applications in administration have reacheddiminishing returns

Historically, administration – finance, accounting and control, and personnel – was the first part of a company to apply IT. All businesses now use ITextensively in this area, to the point that standard soƒtware seems to havelargely exhausted its potential for eƒficiency gains.

True distinction can be achieved, however, in the intelligent deployment of executive information systems (EIS), which give senior executives daily,weekly, or monthly updates on key dimensions of business performance.High-performing companies have integrated EIS systems twice as flexibleas those of their low-performing peers, whose data and analysis capacitiesare so poor that many of them could not even assess their systems’eƒfectiveness for our survey.

In addition, the more advanced players use IT extensively in human resources

for staƒf development and assignment planning, and place greater emphasis

MANUFACTURING’S USE AND ABUSE OF IT

146 THE McKINSEY QUARTERLY 1998 NUMBER 1

Exhibit 5

Use of EDI by customers for order calls

Share of customers with EDI link% of customers

Share of orders transmitted by EDI%

IT-based monitoring of overall process% of companies surveyed

Work in process% of sales

Finished goods inventory% of sales

76

8.0

Companies with excellent order processing

Companies with poor order processing

3.8

2.7 5.8

44

35

44

72

59

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 10/13

on generating employee profiles and job descriptions. Emerging workflowmanagement systems may even create fresh administrative roles in IT tomanage and organize knowledge within the organization.

Rule 6: Create a customer-oriented IT service network to fit theneeds of the business

The transition from mainframe computers to distributed client-serverarchitectures is well under way. Though traditional mainframe and midrangesystems still control most operational applications at over 80 percent of manufacturers, conversion continues to gain ground. About 20 percent of companies surveyed have already migrated from a mainframe to a client-server architecture; in coming years, many more plan to follow them.

Unfortunately, some IT departments are failing to keep up. Many staƒf preferthe mainframe systems they grew up with, and are out of touch with thepossibilities of current systems. Worse, many of those trained as computerspecialists have spent their entire career cloistered in the IT department, andsimply do not understand what the business side wants out of applications.

Leading-edge companies have reinvented their IT service structure. First,they create a network distributing IT service tasks throughout the companyin dedicated units, committees, and project teams, rather than assigning themto a single department. They set up an information management group toconcentrate on IT planning and consulting,including process redesign. Its head chairs asteering committee – comprising top man-agement, IT department heads, and membersof a core user team – that makes decisions onkey corporate IT issues. The core user teambrings together leading users from all areasof the business, and defines user require-ments in collaboration with the revamped IT department, which now con-centrates on providing infrastructure and operating the system. Users alsoplay a critical role in adding pivotal resources to soƒtware implementationprojects, and sometimes even have their own soƒtware development staƒf.

Second, although third-party providers are a central part of IT service net-works, IT stars are much more careful about what they outsource. Only 24percent outsource core operational IT services such as running the computercenter; laggards do so at twice that rate. And when they do outsource, ITstars rigorously monitor providers, assessing their performance throughexternal benchmarks and meticulous goal-setting, and paying close attention

to the negotiation of contract extensions.

MANUFACTURING’S USE AND ABUSE OF IT

THE McKINSEY QUARTERLY 1998 NUMBER 1 147

Many computer specialists havespent their entire career

cloistered in the IT department,and simply do not understandwhat the business side wants

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 11/13

Third, IT stars are much more professional about their planning and controlprocesses, relying on their information management group with its close linksto top management. They understand their costs in greater detail; 53 percentof stars were able to produce detailed cost structure analyses, compared with

just 7 percent of laggards. Poor players oƒten set IT budgets purely on thebasis of historical data, while stars conductzero-based budgeting, reassessing projectedand current tasks every year.

Most IT stars study the market systemati-cally to identify important innovations: 88percent regularly invite vendors to make

product presentations, as against 46 percent of laggards; 36 percent assignstaƒf to watch the market, compared with 13 percent of laggards. Armed withup-to-date information, they plan for the long term: 65 percent formulatethree- to five-year plans for hardware, soƒtware, and netware projects, asagainst 37 percent of laggards. Similarly, 50 percent of stars are planningmajor IT projects in the next three to five years, while only 25 percent of laggards have such projects planned that far ahead. Such detailed planningallows top performers to develop their IT capabilities deliberately andsystematically, instead of wasting energy on fire-fighting.

Rule 7: Introduce integrated standard soƒtware on a “fastfollower” basis (but redesign the business first)

In most situations, it is better to use functionally integrated standard soƒtwarethan invest in proprietary solutions. Seventy-five percent of the implemen-tation costs of the IT stars are devoted to integrated standard soƒtware,compared to 42 percent for laggards. Pioneering proprietary soƒtware is theright strategy only when it produces a clear competitive advantage, as withsome product-specific simulation soƒtware.

When to introduce integrated standard soƒtware is a key decision. A “fastfollower” strategy is the best bet: companies should wait until early soƒtwarebugs have been fixed and external consulting knowhow has become availablebefore making a commitment. But once new releases can oƒfer greaterfunctionality and user-friendliness, companies should act fast.

Over 60 percent of IT stars follow this approach; laggards tend to adopt morereactive strategies. Because they also continue to use large parts of the oldsoƒtware aƒter new systems are introduced, they experience many moreproblems with compatibility.

The survey confirmed the importance of redesigning business processesbefore new systems are introduced, rather than at the same time. The

MANUFACTURING’S USE AND ABUSE OF IT

148 THE McKINSEY QUARTERLY 1998 NUMBER 1

Detailed planning allows

top performers to develop theirIT capabilities deliberately

and systematically

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 12/13

sequential approach followed by over 41 percent of stars (but just 24 percentof laggards) reduces both project duration and costs by more than 50 percent.It enables stars to refine their selection criteria for soƒtware and gain a betterunderstanding of how standard packages could be adapted to their needs,thus avoiding the need for expensive custom programming.

IT stars apply to these projects the same planning and project control thatdistinguishes them in other areas. Although they resort to external imple-mentation partners twice as oƒten as do laggards, they tend to focus theirpartners’ eƒforts on implementation and early pilots, and strive to involvetheir own staƒf – users as well as IT managers – more closely in the roll-out.

Because they monitor IT milestones rigorously, stars stray from plannedcost far less than do laggards. Aƒter new systems have been introduced,they monitor degree of use, evolution of users’ knowledge, ongoingexpenses, and improvements in business performance in order to pursuecontinuous improvement.

By contrast, laggards oƒten fall into a downward spiral. Frequent failuresto meet objectives, combined with dissatisfaction among users, make it hardto win support for follow-up projects. Problems are swept under the carpet.Control over outsourcing lapses. The result is excessive spending for onlymediocre results.

The future

As ever, the future holds both opportunity and threat. On the one hand, newtechnology will continue to enable IT stars to make quantum leaps in eƒfec-tiveness. On the other, poor management of IT can result in a cost explosion.

One systems manufacturer saw its ITspending soar from 2.7 to 3.9 percent of salesin just three years, an increase of 44 percent.Yet nothing in its applications portfolio hadchanged. The reason for the rise? Soƒtwarecosts more than doubled as standard soƒt-ware was introduced, then heavily modified(especially in production and sales); as aresult, interfaces (70 percent of which werespecific to the company) had to be speciallyprogrammed.

The road to improvement takes a diƒferent course for each of the four ITcultures we identified (Exhibit 6). We believe that a laggard can become an

MANUFACTURING’S USE AND ABUSE OF IT

THE McKINSEY QUARTERLY 1998 NUMBER 1 149

Exhibit 6

Routes to improvement

E f f e c t i v e n e s s

o f I T

Efficiency of IT

Big spenders

Standardizationof IT

IT cost control

Intelligent IT

outsourcing

Stars

Review IT supportfor businessprocesses

Laggards

Top managementinvolvement

Standardizationof IT

Planning/controlof IT projects

Cautious spenders

Top managementinvolvement

IT as internalservice provider

IT support forbusiness processes

8/6/2019 IT in Service Ind.

http://slidepdf.com/reader/full/it-in-service-ind 13/13

star in two to three years, but only if it rethinks its notion of IT. Instead of being regarded as a limited specialist task, IT must become a key concern of top management. No longer simply a means of reducing manufacturing coststhrough automation, it must be seen as a tool for optimizing almost anybusiness process. From an all-powerful, centralized data processing depart-ment, a lean, customer-oriented IT network must emerge.

MANUFACTURING’S USE AND ABUSE OF IT

150 THE McKINSEY QUARTERLY 1998 NUMBER 1