'Milieueffectrapport structuurvisie buisleidingen' PDF document

Inleiding Offshore Buisleidingen -...

Transcript of Inleiding Offshore Buisleidingen -...

DNV GL © 2013 SAFER, SMARTER, GREENER DNV GL © 2013

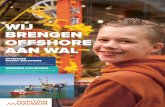

Inleiding Offshore Buisleidingen

Pipeliner Offshore dag

Stichting Pipeliner

Rotterdam, 1 Mei 2015

DNV GL

Jan Spiekhout

DNV GL © 2013

Inhoud

Inleiding

Aanleg

Lassen en NDT

Ontwerp issues

Geohazards

Complexiteit

Normen en standaards

Reparatie

Materiaal aspecten

2

DNV GL © 2013

Inleiding

Offshore platform

– riser

Zone rond platform

Offshore

Near shore

Landfall

Onshore

Behandelingsinstallatie

Compressor station

Onshore

Landfall

Near shore

Offshore

Near shore

Landfall

Onshore

Reception Facility

(Compressor station)

Onshore

Intake

3

Satellite subsea

(diep water)

DNV GL © 2013

Case NL - UK

NL UK

NEN 3650 BS EN 14161 +

BS PD 8010-2 BS EN 1594

plus IGE/TD/1

NEN 3651 ASME B31.3

BS PD 5500

RTOD

NEN 3653, NEN/BS EN 12732, NEN/BS EN

10208-2

NEN EN 1594

plus NEN

3650

20.9 mm 20.9 mm 24.9 mm 25.4 mm

25.4 mm

36 in. X65

- Ketelformule (D0 versus Dg)

- Risk evaluation offshore (10-6/km/jaar)

- Risk evaluation onshore (PR en GR, Cas. Risk)

- Testdruk

- Incidentele druk

- w.d. > 0.75 in. warmtebehandeling

DNV GL © 2013

Aanleg

Landfall

–Tunnel and shaft

–Bottom tow

–HDD

–Direct Pipe

Near shore – ondiep

Offshore

–Shallow water

–Deep water

5

DNV GL © 2013

Ontwerp issues offshore buisleidingen

Every detail is important starting with pipe out of roundness limitations

Deviations certainly lead to claims, extra costs and exceeding the project planning

Interfaces are always important

Reduction in engineering, survey and study costs may results in costs overruns with a 10 fold

potential savings cost overrun in construction

Slope (> 30 degr. angle) pipeline route on the slope, pipeline strength aspects (max. diam?)

Stability of sediments on the slope – possibility mud flow etc.

Subsidence zones to be crossed

Sea bottom roughness

Pressure (internal/external)

Free spans

Uplift (currents)

Installation methodology and landfall approach

Linepipe and cable crossings

Seabed intervention and diverless hot-tap and repair technology

10

DNV GL © 2013

G R O U P

•Steep slopes • Canyons • Seabed “rugosity”, boulders and rocks

• Slope stability aspects • Steep slope

Typical deep water pipeline topography

Landfall 1 Landfall 2

DNV GL © 2013

Vortex Induced Vibrations (VIV)

The vortex shedding frequency caused by a flow normal to a free span is

governed by the Strouhal’s number, the pipe outer diameter and the flow velocity.

As the flow velocity and thereby the shedding frequency reach one of the natural

frequencies of the span, the span starts to vibrate and the vortex shedding along

the span get correlated by the vibration of the span. In this way the vortex

shedding frequency and the VIV get locked-in with the natural frequencies of the

span over a certain range of flow velocities.

Multi-mode behavior of free spans in model tests

12

DNV GL © 2013

Deepwater pipeline free span limitation

14

FREE SPANS MUST BE LIMITED DUE TO RISK OF – OVERSTRESSING

– FATIGUE

DNV GL © 2013

Scouring - Free Span Development

Span develop in length / increased deflection

Single span / small deflection

Span develop in length / further deflection / span divided into two

DNV GL © 2013

Slide 17 02 May 2015

Deepwater Pipeline Projects are complex !

Verification of Design

Implementation

and Follow-up

Design

Fabrication

Installation

Installation possibilities,

Testing possibilities,

etc

Weldability

Welding

Procedures

Feasibility

Study

Maintenance

Operating Parameters

Operation

Start

operation

Inspection &

maintenance

De-

commissioning

Inspection points,

Maintenance frequency

Owners

objectives and

requirements

Material Selection

Design parameters

Design solutions

Etc

DNV GL © 2013

18

Normen en standaards

DNV-OS-F101:201

2 - General

improvement - Aligned with ISO

3183 (linepipe)

DNV-OS-F101:20

07 - General

Improvement

- Aligned with ISO

3183 (linepipe)

DNV-OS-F101:200

0 - Converted

to pure technical standard

DNV Rules, 1996

- Completely new version

- Limit state format with

calibrated safety factors based on the SUPERB JIP

work

DNV Rules, 1981 – Update of 1976 version, became a widely spread code

DNV Rules, 1976 – First complete code for offshore pipelines - Based on allowable stress format

DNV-OSS-301:2000

- First publically available detailed offshore pipeline

Certification Scheme

DNV-OSS-301:2013

- General improvement and

restructuring

DNV-OS-F101:2013

- “Quick fix” of Appendix A

5/2/2015

Mijnbouwregelgeving

NEN 3650/3651

NEN 3656

DNV GL © 2013

Materiaal aspecten

Rondheid

Wanddikte (tolerantie)

Chemische samenstelling (Ceq. etc.)

Re, Rm (Ramberg-Osgood parameters), breukrek

Charpy-V

DWTT

Coating

Field joint coating

Concrete

Etc.

20

DNV GL © 2013

SAFER, SMARTER, GREENER

www.dnvgl.com

CONTACTS

Private and confidential

22

Jan Spiekhout

+31-(0)507009865