Human hair-derived hollow carbon microfibers for...

Transcript of Human hair-derived hollow carbon microfibers for...

lable at ScienceDirect

Carbon 107 (2016) 872e877

Contents lists avai

Carbon

journal homepage: www.elsevier .com/locate /carbon

Human hair-derived hollow carbon microfibers for electrochemicalsensing

Bidhan Pramanick a, 1, Lorena Berr�on Cadenas a, 1, Dong-Min Kim b, Wonchul Lee b,Yoon-Bo Shim b, Sergio O. Martinez-Chapa a, Marc J. Madou a, c, Hyundoo Hwang a, *

a Tecnologico de Monterrey, Ave. Eugenio Garza Sada 2501, Monterrey, NL, 64849, Mexicob Department of Chemistry, Pusan National University, Busan, 609-735, South Koreac Department of Mechanical and Aerospace Engineering, University of California, Irvine, CA, USA

a r t i c l e i n f o

Article history:Received 22 April 2016Received in revised form21 June 2016Accepted 22 June 2016Available online 24 June 2016

* Corresponding author.E-mail address: [email protected] (H. Hwang).

1 B.P. and L.B.C. contributed equally to this work.

http://dx.doi.org/10.1016/j.carbon.2016.06.0950008-6223/© 2016 Elsevier Ltd. All rights reserved.

a b s t r a c t

Glassy carbon has been widely used for various applications including electrochemical sensors andenergy storage devices. Here we introduce a novel way to fabricate glassy carbon microfibers based onhuman hairs. The coaxial structure of hair shafts results in long hollow glassy carbon structures uponpyrolysis at 900 �C in a N2 atmosphere. The morphology of human hair samples before and after pyrolysiswas characterized using scanning electron microscopy. The chemical composition of natural and pyro-lyzed human hairs was also characterized using Raman spectroscopy and energy-dispersive X-rayspectroscopy. Screen printed carbon electrodes were modified with the hair-derived carbons and appliedfor electrochemical sensing of dopamine and ascorbic acid. The hair-derived carbons significantlyimproved the performance of the electrochemical sensors compared to the unmodified sensors. Thismethod provides an easy, simple, and inexpensive way to fabricate hollow 3D glassy carbonmicroelectrodes.

© 2016 Elsevier Ltd. All rights reserved.

1. Introduction

Carbon is one of the most abundant materials in nature and hasbeenwidely used in various applications for many decades. Carbonhasmany allotropeswith very different physicochemical propertiesenabling its usage in a variety of applications [1e4]. Depending onthe particular application one can choose from one of the followingallotropes: diamond, graphite, coke, amorphous carbon, carbonnanotubes (CNTs), and glassy carbon. Among those allotropes,glassy carbon is one of the most promising candidates for appli-cations where the following physical properties are required: highisotropy, good electrical conductivity, impermeability to gases, andlow coefficient of thermal expansion. Its high corrosion resistanceand inertness make glassy carbon ideal for applications inextremely corrosive environments, such as crucibles for decom-position of ores. It has also been widely used as an electrode ma-terial for electrochemical applications as it resists both strong acids

and bases [5,6]. Microfabrication of carbon devices is a relativelynew field. Use of focused ion beam [7,8] or reactive ion etching [9],is an expensive and time-consuming process to that end. Incontrast Schueller et al. first demonstrated a more practical carbonmicrofabrication technique using organic polymer precursors [10].They applied standard soft lithography based on poly-dimethylsiloxane (PDMS) to pattern and transfer a precursorpolymer structures to a substrate, followed by pyrolysis of themicrostructures at high temperature [11]. UV photolithography hasalso been utilized to fabricate glassy carbon microelectrodes [12].UV curable polymer precursors such as SU8 photoresists werepatterned and the polymer structures were carbonized at hightemperature (900e1100 �C) in an oxygen-free environment. At theelevated temperature in vacuum or a N2 atmosphere, all the non-carbon elements are removed and only carbon remains. Thistechnique, developed by some of the current team, is called carbon-based microelectromechanical systems (C-MEMS) technology andhas received much attention due to its simplicity and its cost-effectiveness to implement many applications such as electro-chemical sensing [13], energy storage [14], and electrokinetic par-ticle manipulation [15]. Fabrication of three-dimensional (3D)microstructures with very high aspect ratios is easy and has led to a

B. Pramanick et al. / Carbon 107 (2016) 872e877 873

wide variety of C-MEMS-derived carbon electrodes to replace noblemetal electrodes in a variety of applications [13,14,16e18].

Natural and waste hydrocarbon precursors have been appliedfor the synthesis of carbon-based nanomaterials [19]. Plant-derivedprecursors and wastes such as seeds, fibers, oils, and bagasse haveyielded different forms of carbon via pyrolysis. It has been knownthat high-quality graphene, single-walled CNTs, multi-walled CNTs,and carbon dots can be produced by thermal decomposition ofturpentine oil, sesame oil, neem oil (Azadirachta indica), eucalyptusoil, palm oil, jatropha oil, camphor, tea-tree extract, waste food,insects, agro waste, and food products [20e23]. Liang et al. found acost-effective way to prepare porous carbon microfibers by utiliz-ing a silk cocoon as a precursor material [24]. They obtained thebiopolymers from a silkworm Bombyx mori that spins silk micro-fibers to form a cocoon around itself. The one dimensional (1D) silkmicrofibers were collected and carbonized at 900 �C under N2 flowto generate carbon microfibers.

Human hair is a rather interesting waste material. Waste hairhas plenty of applications in industry and academic research. It hasa unique chemical composition and comes with several interestingproperties, such as very slow degradation, high tensile strength,high thermal insulation, high elastic recovery, and it has a scalysurface. These listed properties lead to diverse applications. Humanhair is made up of approximately 91% polypeptides, which containmore than 50% carbon, and the rest are elements such as oxygen,hydrogen, nitrogen, and sulphur [25]. Waste hair has been used inagriculture as fertilizer because it is one of the highest nitrogencontaining organic materials in nature [26]. Hair has also been usedfor reinforcing clay-based constructions due to its high tensilestrength and high friction coefficient [27]. It has also been used intraditional medicine in several cultures; i.e. carbonized human hairhas been used in traditional Chinese medicine [28]. Recently, hu-man hair has been utilized to prepare carbon flakes employed forsupercapacitors [29].

The shaft of human hair is composed of three major compo-nents: the cuticle, the cortex, and the medulla. The outermost part,the cuticle, is made of tightly arranged compact cells that protectsand anchors the inner hair structures. The cortex forms the bulk ofthe hair shaft and is composed of keratinized cells forming longfibers. Pigment granules, mainlymelanin, are found in this part. Themedulla, if present, comprises only a small percentage of mass inhuman hair. The medullar cells are loosely packed, but they shrivelup leaving a series of vacuoles along the fiber axis during dehy-dration [30]. The medulla may either be completely absent,continuous along the fiber axis, or discontinuous, and in some in-stances, a double medulla may also be present. The medulla has anegligible contribution to the mechanical and chemical propertiesof human hair [31].

In this research, we propose a simple and cost-effective way tofabricate hollow carbon microfibers based on human hair. Wedemonstrate that the unique anatomy of human hair leads toelectrically-conductive glassy hollow fibers upon pyrolysis. Thechange in chemical composition of hair before and after pyrolysiswas characterized by Raman spectroscopy and energy-dispersiveX-ray spectroscopy (EDS). The hair-derived carbon was appliedfor electrochemical sensing of ascorbic acid and dopamine.

2. Experimental

2.1. Fabrication of hollow carbon microfibers

Some hair strands from a healthy donor were used as a startingmaterial for the fabrication of hollow carbon microfibers. The hairwas pyrolyzed in a furnace (PEO 601, ATV Technologie GmbH,Germany) at 900 �C. The furnace was filled with a continuous flow

of ultrapure grade N2 gas (6 l/min) to ensure that the furnace tubeenvironment was completely free of oxygen. The temperature wasincreased from room temperature to 900 �C at a 5 �C/min ramp rateand kept constant at that temperature for 1 h. After that, thetemperature was lowered to the room temperature at a 10 �C/minrate.

2.2. Characterization

The physical structure of hair and hair-derived carbon hollowfibers were visualized by using a scanning electron microscopy(SEM; EVOMA25, Zeiss, Germany). The hair samples were attachedon a Si/SiO2 substrate using SU-8 2002 for SEM imaging. Thechemical composition of samples was examined by Raman spec-troscopy (inVia Qontor, Renishaw plc, UK) with a 514 nm Ar lasersource, and EDS (XFlash 6, Bruker Corporation, Billerica, MA, USA)with a 20 kV accelerating voltage.

2.3. Electrochemical sensing

For electrochemical sensing, screen printed carbon electrodeswere first prepared. Carbon and silver inks (Jujo Chemical, Japan)were printed on a polystyrene-base film using a screen printer(BANDO Industrial, South Korea). Ag/AgCl was used as the referenceelectrode and carbon as the working and the counter electrodes.The surface of the working electrode (area ¼ 0.07 cm2) wasmodified with hair-derived carbon and CNTs (Hanwha ChemicalCorp., South Korea), respectively, using a simple drop coatingmethod. A 5 mL of hair-derived carbon or CNTs solution was drop-ped onto the electrode surface and then the solvent was allowed toevaporate at 30e35 �C by putting the screen printed carbon elec-trodes in an oven for 30 min. The voltammetric experiments wereconducted with a potentiostat/galvanostat (PT-1, Kosentech, SouthKorea). A drop of dopamine or ascorbic acid solution was placed onthe screen printed carbon electrodes, and a linear potential sweepfrom �200 mV to 600 mV were applied to the working electrodewith a scan rate of 100 mV/s.

3. Results and discussion

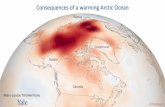

Human hair was utilized to fabricate hollow carbon fibers viapyrolysis at 900 �C in N2 environment (See Fig. 1). The hair samplesare collected and used for pyrolysis without performing any pre-treatment. During the pyrolysis, the hair shrank significantly froma diameter of 82.88 ± 0.003 mm to 31.42 ± 0.003 mm, since non-carbon atoms were removed and only CeC chains remained. Afterpyrolysis the imbricated pattern of hair disappeared and the sur-face became rough (See Fig. 2a and b). Interestingly, the carbonfibers derived from the human hair had a hollow structurewith a 2-to 4-mm-thick wall (Fig. 2c and d). The unique coaxial structure ofhuman hair, composed of medulla, cortex, and cuticle, resulted in ahollow structure of carbon fibers through pyrolysis. While themedulla, in the middle of the hair fibers, is loosely packed andcontains no keratins, the cortex and cuticle are composed of morecarbon rich precursors and have a relatively high mechanicalstiffness. After the pyrolysis, the medulla disappears whereas thecuticle and the cortex combine to make long hollow carbon fibers.

The chemical composition of the hair and the hair-derived car-bon fibers was determined using Raman spectroscopy and EDS.Raman spectra of the hair before and after the pyrolysis are shownin Fig. 3. The Raman spectrum of natural human hair before thepyrolysis showed many peaks, representing lipid and amino acids[32]. On the other hand, after pyrolysis, only two broad peaks werefound at around 1366 cm�1 and 1586 cm�1, corresponding to the D-and G-bands, respectively. The D-band is attributed to defects,

Fig. 1. Schematic diagram showing the manufacturing process for hollow carbon microfibers from human hair samples. (A colour version of this figure can be viewed online.)

Fig. 2. Scanning electron microscopic (SEM) images of hair-derived hollow carbon fibers. SEM images of the surface of human hair samples (a) before and (b) after the pyrolysis.The cross-sectional images of human hair samples (c) before and (d) after the pyrolysis are also shown. Scale bar ¼ 5 mm.

Fig. 3. Raman spectra of human hair samples before and after the pyrolysis. (A colourversion of this figure can be viewed online.)

Fig. 4. Energy dispersive X-ray spectra of human hair samples before and after thepyrolysis. (A colour version of this figure can be viewed online.)

B. Pramanick et al. / Carbon 107 (2016) 872e877874

while the G-band is characteristic of graphite. The intensity ratio ofthe D-band to G-band (ID/IG) marks the degree of structural orderwith respect to a perfect graphitic structure. The ID/IG of hair-derived hollow carbon fibers was 0.99, which indicates that the

structure is mostly glassy carbon [33]. This value is similar to theone (ID/IG ¼ 1.1) in previous research that human hair-derivedcarbon flake was used for fabricating supercapacitors [29].

According to the EDS data, the natural human hair that we usedin this research was composed of carbon (66.57 atom%), oxygen

B. Pramanick et al. / Carbon 107 (2016) 872e877 875

(16.19 atom%), nitrogen (7.94 Atom%), sulphur (9.14 atom%), and alittle amount of minerals such as calcium (0.16 Atom%) (See Fig. 4and Table 1). After the pyrolysis, most of the nitrogen andsulphur was removed whereas the percentage of carbon signifi-cantly increased to 80.84 atom%. Additionally, 14.83 atom% of ox-ygen and a small amount of calcium (0.21 atom%) were found.Considering the amount of removed elements (nitrogen andsulphur), the little increase in relative amount of calcium isreasonable. It is likely that most of the oxygen in the hair isremoved during the pyrolysis, because the amount of oxygendetected from the sample after the pyrolysis (14.83 atom%) isalmost consistent with that from the Si/SiO2 wafer substrate [34].The presence of inorganic elements such as sodium (0.21 atom%)

Table 1Chemical composition determined by EDS for human hair before and after pyrolysis.

Element Before pyrolysis After pyrolysis

Atomic % Atomic %

Carbon 66.57 80.84Oxygen 16.19 14.83Nitrogen 7.94 0Sulphur 9.14 0.21Calcium 0.16 0.21Sodium 0 0.22Silicon 1.82 3.69

Fig. 5. Scanning electron microscopic images of various patterns of hair-derived hollowcoiled carbon fiber. Scale bars ¼ 20 and 100 mm, respectively. (e, f) A broken carbon fiber. Sonline.)

and calcium is consistent with the results reported in the literature,that show varied distribution of inorganic elements in human hairsamples collected from several scalp regions of different people[35]. We also measured 1.82 atom% and 3.69 atom% of silicon fromthe hair samples before and after the pyrolysis, respectively, due tothe Si/SiO2 substrate on which the samples were attached [34].These results showed that the hair samples were successfullytransformed into glassy carbon in the pyrolysis process.

By pre-arranging the hairs before the pyrolysis, various patternsof carbonmicrofibers were created as shown in Fig. 5a and b. Coiledstructures could be obtained by applying a torsion to the hair beforethe pyrolysis (See Fig. 5c and d). The hollow carbon microfiberswere sometimes broken or collapsed due to the high tensile stressduring the pyrolysis process (See Fig. 5e and f). These results showthat desired patterns of carbon microfibers can be achieved byprecise positioning and patterning of human hair samples beforethe pyrolysis. Combining this method with the well-established C-MEMS technology, a variety of carbon microelectrode structurescould be fabricated from human hair for diverse applicationsincluding electrochemical sensors and energy storage devices.

In this research, we applied the hair-derived carbon fibers toelectrochemical sensing of ascorbic acid and dopamine. We pre-pared screen printed carbon electrodes and coated the surface ofthe working electrode with ground hair-derived carbon (SeeFig. 6a). The surface morphology of the working electrode before

carbon microfibers. (a, b) Aligned straight carbon fibers. Scale bar ¼ 50 mm. (c, d) Acale bars ¼ 50 and 10 mm, respectively. (A colour version of this figure can be viewed

B. Pramanick et al. / Carbon 107 (2016) 872e877876

and after placing hair-derived carbons was characterized by SEM.The SEM images of unmodified and modified working electrodesare shown in Fig. 6b and c. The electrochemical sensing perfor-mance of the sensors coated with the hair-derived carbons wascompared with the bareworking electrodes or CNT-coated working

Fig. 6. Electrochemical sensing based on hair-derived carbon microfibers. (a)Schematic diagram of screen printed carbon electrodes for electrochemical sensing.Scanning electron microscopic images of the screen-printed carbon electrode surface(b) without and (c) with hair-derived carbons. Cyclic voltammograms of (d) 100 mMdopamine and (e) 100 mM ascorbic acid. (A colour version of this figure can be viewedonline.)

electrodes. Cyclic voltammograms were recorded for 100 mMdopamine and 100 mM ascorbic acid in 0.1 M phosphate buffersolution of pH 7.4 using a scan rate of 100 mV/s (See Fig. 6d and e).The oxidation peaks for dopamine were measured at 333 mV,266 mV, and 96 mV, for the unmodified carbon electrode, theelectrode modified with the hair-derived carbon, and the electrodemodified with the CNTs, respectively (See Fig. 6d). The peaksattributed to oxidation of ascorbic acid were observed at 414 mV,455 mV and 297 mV with the screen printed carbon electrodesunmodified, modified with the hair-derived carbon, and modifiedwith the CNTs, respectively (See Fig. 6e). No reduction peaksappeared for ascorbic acid since the oxidation of ascorbic acid is anirreversible process, as previously reported [36].

When the working electrode was coated with the hair-derivedcarbons or the CNTs, the peak potential for dopamine was shiftedtowards more negative and its peak current increased, while thepeak potential for ascorbic acid was shifted positively and its peakcurrent decreased. This might be because the surface of the hair-derived carbon is slightly negatively charged, attracting positivelycharged dopamine [37,38]. These results imply that the electrodemodified with human hair-derived hollow carbon microfibers issuitable for dopamine sensing in the presence of ascorbic acid,which is the main interferent. The electrochemical sensing per-formance of the electrode modified with the hair-derived carbonwas better than the unmodified electrode, although the CNTs-coated electrode showed the best performance in our experi-mental conditions. Although the hair-derived carbon microfibershave less surface-area-to-volume ratio than CNTs, the extremelylow cost and ease of fabrication are the main advantages of usinghuman hair-derived carbon microfibers over CNTs. The electro-chemical sensing performance would be enhanced with furthertreatment or functionalization of the human hair samples beforeand after pyrolysis.

4. Conclusions

In this research, hollow carbon microfibers in various patternswere fabricated by the pyrolysis of human hairs. The unique coaxialstructure of human hair leads to long hollow carbon fibers fabri-cated with a simple pyrolysis process. The chemical composition ofpyrolyzed hair was mostly glassy carbon according to the Ramanscattering and EDS analyses. Various patterns of glassy carbon fi-bers could be fabricated by pre-arranging human hair samples. Theglassy carbon derived from human hair was successfully applied forelectrochemical sensing of dopamine and ascorbic acid.

The extremely low cost and ease of fabrication of our methodwould suggest a newway of using hair waste for manufacturing 3Dcarbon microelectrodes for diverse applications. The hair-derivedglassy carbons could be modified to achieve yet better perfor-mance for electrochemical sensing or in energy storage devices.Different types of hairs from nature could also be utilized forobtaining a variety of carbon nano- and microstructures.

Acknowledgements

This work was supported by Tecnol�ogico de Monterrey(002EICII01).

References

[1] C. Wang, G. Jia, L.H. Taherabadi, M.J. Madou, A novel method for the fabrica-tion of high-aspect ratio C-MEMS structures, J. Microelectromech Syst. 14 (2)(2005) 348e358.

[2] K.P.D. Jong, J.W. Geus, Carbon nanofibers: catalytic synthesis and applications,Catal. Rev. Sci. Eng. 42 (2000) 481e510.

[3] M. Elrouby, Electrochemical applications of carbon nanotube, J. Nano Adv.

B. Pramanick et al. / Carbon 107 (2016) 872e877 877

Mat. 1 (1) (2013) 23e38.[4] R.H. Baughman, A.A. Zakhidov, W.A.D. Heer, Carbon nanotubes-the route to-

ward applications, Science 297 (2002) 787e792.[5] L. Chen, Y. Tang, K. Wang, C. Liu, S. Luo, Direct electrodeposition of reduced

graphene oxide on glassy carbon electrode and its electrochemical applica-tion, Electrochem. Comm. 13 (2) (2011) 133e137.

[6] N.L. Pocard, D.C. AIsmeyer, R.L. McCreery, T.X. Neenan, M.R. Callstrom, Dopedglassy carbon: a new material for electrocatalysis, J. Mater. Chem. 2 (8) (1992)771e784.

[7] N. Miura, T. Numaguchi, A. Yamada, M. Konagai, J. Shirakashi, Room tem-perature operation of amorphous carbon-based single-electron transistorsfabricated by beam-induced deposition techniques, Jpn. J. Appl. Phys. 37 (2)(1998) L423eL425.

[8] M. Irie, S. Endo, C.L. Wang, T. Ito, Fabrication and properties of lateral p-i-pstructures using single crystalline CVD diamond layers for high electric fieldapplications, Diam. Rel Mater. 12 (2003) 1563e1568.

[9] B.K. Tay, D. Sheeja, L.J. Yu, On stress reduction of tetrahedral amorphouscarbon films for moving mechanical assemblies, Diam. Rel. Mater. 12 (2003)185e194.

[10] O.J.A. Schueller, S.T. Brittain, C. Marzolin, G.M. Whitesides, Fabrication andcharacterization of glassy carbon MEMS, Chem. Mater. 9 (1997) 1399e1406.

[11] O.J.A. Schueller, S.T. Brittain, G.M. Whitesides, Fabrication of glassy carbonmicrostructures by soft lithography, Sens. Actuators A 72 (1999) 125e139.

[12] S. Ranganathan, R. McCreery, S.M. Majji, M. Madou, Photoresist-derived car-bon for microelectromechanical systems and electrochemical applications,J. Electrochem 147 (1) (2000) 277e282.

[13] R.R. Kamath, M.J. Madou, Three-dimensional carbon interdigitated electrodearrays for redox-amplification, Anal. Chem. 86 (6) (2014) 2963e2971.

[14] S. Sharma, A. Khalajhedayati, T.J. Rupert, M.J. Madou, SU8 derived glassycarbon for lithium ion batteries, ECS Trans. 61 (7) (2014) 75e84.

[15] R.M. Duarte, R.A. Gorkin, K.B. Samra, M.J. Madou, The integration of 3Dcarbon-electrode dielectrophoresis on a CD-like centrifugal microfluidicplatform, Lab. Chip 10 (2010) 1030e1043.

[16] K. Mund, G. Richter, E. Weidlich, U. Fahlstrom, Electrochemical properties ofplatinum, glassy carbon, and pyrographite as stimulating electrodes, PacingClin. Electrophysiol. 9 (6) (1986) 1225e1229.

[17] H. Xua, K. Malladi, C. Wang, L. Kulinsky, M. Song, M. Madou, Carbon post-microarrays for glucose sensors, Biosens. Bioelectron. 23 (2008) 1637e1644.

[18] S. Sharma, M. Madou, Micro and nano patterning of carbon electrodes forbioMEMS, Bioinspired Biomim. Nanobiomater. 1 (BBN4) (2012) 252e265.

[19] R. Kumar, R.K. Singh, D.P. Singh, Natural and waste hydrocarbon precursorsfor the synthesis of carbon based nanomaterials: graphene and CNTs, Renew.Sustain Energy Rev. 58 (2016) 976e1006.

[20] R.A. Afre, T. Soga, T. Jimbo, M. Kumar, Y. Ando, M. Sharon, Carbon nanotubesby spray pyrolysis of turpentine oil at different temperatures and theirstudies, Micropor Mesopor Mater. 96 (1e3) (2006) 184e190.

[21] S. Sharma, G. Kalita, R. Hirano, Y. Hayashi, M. Tanemura, Influence of gascomposition on the formation of graphene domain synthesized from

camphor, Mater. Lett. 93 (0) (2013) 258e262.[22] P. Ghosh, R.A. Afre, T. Soga, T. Jimbo, A simple method of producing single-

walled carbon nanotubes from a natural precursor: eucalyptus oil, Mater.Lett. 61 (17) (2007) 3768e3770.

[23] R. Kumar, R. Tiwari, O. Srivastava, Scalable synthesis of aligned carbonnanotubes bundles using green natural precursor: neem oil, Nanoscale Res.Lett. 6 (1) (2011) 92e97.

[24] Y. Liang, D. Wu, R. Fu, Carbon microfibers with hierarchical porous structurefrom electrospun fiber-like natural biopolymer, Sci. Rep. 3 (2013) 1e5.

[25] A. Gupta, Human hair ‘‘waste’’ and its utilization: gaps and possibilities,J. Waste Manag. Hindawi Publ. Corp. 2014 (2014) 1e17.

[26] V.D. Zheljazkov, J.L. Silva, M. Patel, J. Stojanovic, Y. Lu, T. Kim, T. Horgan,Human hair as a nutrient source for horticultural crops, HortTechnology 18(4) (2008) 592e596.

[27] S. Ahmad, Preparation of eco-friendly natural hair fiber reinforced polymericcomposite (FRPC) material by using of polypropylene and fly ash: a review,Int. J. Sci. Eng. Res. 5 (11) (2014) 969e972.

[28] B. Eric, N. Wiseman, Concise Chinese Materia Medica, Paradigm Publications,2008.

[29] W. Qian, F. Sun, Y. Xu, L. Qiu, C. Liu, S. Wang, F. Yan, Human hair-derivedcarbon flakes for electrochemical supercapacitors, Energy Environ. Sci. 7(2014) 379e386.

[30] J.M. Yousof, Analysis of Hair Segments for Drugs by Electrospray High Per-formance Liquid Chromatography/mass Spectrometry, The American Uni-versity, Washington DC, 1996. Master Thesis.

[31] C.R. Robbins, Chemical and Physical Behaviour of Human Hair, fifth ed.,Springer-Verlag, Berlin Heidelberg, 2013.

[32] W. Akhtar, H.G.M. Edwards, D.W. Farwell, M. Nutbrown, Fourier-transformRaman spectroscopic study of human hair, Spectrochim. Acta A 53 (1997)1021e1031.

[33] O.A. Maslova, M.R. Ammar, G. Guimbreti�ere, J.N. Rouzaud, P. Simon, Deter-mination of crystallite size in polished graphitized carbon by Raman spec-troscopy, Phys. Rev. B 86 (2012) 134205.

[34] L. Domigan, K.B. Andersen, L. Sasso, M. Dimaki, W.E. Svendsen, J.A. Gerrad,J. Castillo-Le�on, Dielectrophoretic manipulation and solubility of proteinnanofibrils formed from crude crystallins, Electrophoresis 34 (2013)1105e1112.

[35] S. Seta, H. Sato, M. Yoshino, S. Miyasaka, SEM/EDX analysis of inorganic ele-ments in human scalp hairs with special reference to the variation withdifferent locations on the head, Scan Electron Microsc. Pt 1 (1982) 127e140.

[36] R.N. Adams, Probing brain chemistry with electroanalytical techniques, Anal.Chem. 48 (1976) 1126Ae1138A.

[37] F. Crepi, C. M€obius, In vivo selective monitoring of basal levels of cerebraldopamine using voltammetry with Nation modified (NA-CRO) carbon fibremicro-electrodes, J. Neurosci. Methods 42 (1992) 149e161.

[38] S. Hou, M.L. Kasner, S. Su, K. Patel, R. Cuellari, Highly sensitive and selectivedopamine biosensor fabricated with silanized graphene, J. Phys. Chem. C 114(2010) 14915e14921.