DCE - SMW Autoblok DCE.pdfSMW-AUTOBLOK 2318 P F2 O K2G2K1 S1 T P P2 P2 O D 56 F1G1 B C E L S2 X1W1 O...

Transcript of DCE - SMW Autoblok DCE.pdfSMW-AUTOBLOK 2318 P F2 O K2G2K1 S1 T P P2 P2 O D 56 F1G1 B C E L S2 X1W1 O...

-

230 SMW-AUTOBLOK

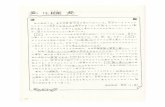

DCE 64-64/30-40 DCE 140-140/50-50 DCE 240-240/60-60

33705212 33705217 33705221mm 30-40 50-50 60-60cm² 66 140 238cm² 63 211 235cm² 63 138 238cm² 66 150 254kn 46 98 118kn 44 147 118kn 44 97 118kn 46 105 127

5000 4000 3200kg 28.6 42.5 116

kg·m² 0.074 0.18 1bar 70 70 50bar 8 8 8

dm3/min 3 3 3

■double piston rotating hydraulic cylinder■up to 70 bar■central bore for air/coolant/oil■stroke control via proximity switch or linear positioning system

DCEEqual piston area and stroke2 independent pistons

Application/customer benefits• Actuationof2+2powerchuckstypeTPTwith2pistonactuation• Actuationofpowerchuckwithpartejector• Actuationofpowerchuckswithretractableaxialstop/fingerchuckswithpower operated centering fixture

Technical features• Doublepistoncylinderwith4wayoilmanifoldforseparateactuationofthe2cylinders• Pressurerange8–70bar• Horizontalorverticalinstallation• Strokecontroloneachcylinder,safetyvalves• Centralboreforair,coolantoroilwiththreadforrotaryunion• Mountingfromtherearsidewithbolts• A10µmfilterinpressurelineisrequested• UseoilHM32ISO3448

Standard equipment Ordering exampleDouble piston cylinder Double piston cylinder Dce 64-64Mounting screws orStroke control on each cylinder Double piston cylinder Dce 64-64Proximity bracket (without proximity switch) with rotary union (optional)

Technical data

Piston 2 foractuation ofthe centeringjaws (2+4) drive 2

Piston 1 forthe actuation of thecentering/grippingjaws (1+3)drive 1

Cylinder DCE for 2 + 2 chucks type TPT

SMW-AUTOBLOK TypeId. No.Piston strokesPiston area APiston area BPiston area CPiston area DA piston force maxB piston force maxC piston force maxD piston force maxMax. speed r.p.m.WeightMoment of inertiaOperating pressure max.Operating pressure min.Oil leakage (*)

* Total at 30 bar / 50 °c ** at max. speed/ oil hM32 iSO 3448Important: On higher pressure the leakage increases proportionally. On higher oil temperature the leakage increases over proportionally (the use of an oil cooler is recommended). when designing/checking the hydraulic unit please ask for our data sheets.

-

SMW-AUTOBLOK 231

8

P

F2

O

K1G2K2

S1

T

P

P2

P2

O

D

56

F1 CBG1 E

S2L

W1X1

O

I

A1

U1

A2

RH

100Q

MU2

3

DCE 64-64/30-40 DCE 140-140/50-50 DCE 240-240/60-60A1 mm 125 170 215A2 mm 95 140 183

h6 B mm 105 125 160C mm 145 195 250D mm 6 x M10 6 x M12 6 x M16E mm 174 220 280F1 mm M45 x 1.5 M60 x 1.5 M75 x 2F2 mm M20 x 1.5 M30 M36G1 mm 85 105 125G2 mm 30 45 55H mm 362 394 451I mm 5 5 5K1 mm 42 57 70K2 mm 20.5 31 37L mm 164 174 213

min. M mm 31 24 28O g 3/8” g 3/8” g 1/2”P mm 55 55 62P1 mm 55 55 63P2 mm 53 53 63Q mm 77 77 97R mm 262 294 326

max. S1 mm 40 60 70 max. S2 mm 76 81 110

T mm 151 160 197U1 mm 30 50 60U2 mm 40 50 60W1 mm 25 25 35W2 mm 30 45 50X1 mm 10 8 9X2 mm 10 10 10

■double piston rotating hydraulic cylinder■up to 70 bar■central bore for air/coolant/oil■stroke control via proximity switch or linear positioning system

DCEEqual piston area and stroke2 independent pistons

Subject to technical changesFor more detailed information please ask for customer drawing

DCE cylinder withoptional LPS-Xlinear stroke control

SMW-AUTOBLOK TypePiston diameter 1Piston diameter 2centering rimFixing bolt circleFixing bolts

Piston rod thread 1Piston rod thread 2

inch

Piston stroke cyl. 1Piston stroke cyl. 2

Chapter 00Chapter 01Chapter 02Chapter 03Chapter 04Chapter 05Chapter 06Chapter 07Chapter 08Chapter 09Chapter 10Chapter 11Chapter 12