Ahmad 2004

-

Upload

eduardo-fernandez-sanchez -

Category

Documents

-

view

231 -

download

0

Transcript of Ahmad 2004

Analytical evaluation of the two-rail shear test method forcomposite materials

Ahmad K. Hussain1, Donald F. Adams*,2

Composite Materials Research Group, University of Wyoming, Laramie, WY 82071, USA

Received 16 November 2002; received in revised form 4 June 2003; accepted 5 June 2003

Abstract

Linear three-dimensional finite element analyses were conducted to evaluate various rail and specimen configurations of the two-rail shear test procedure. Additional analytical evaluations were performed to investigate the effects of specimen aspect ratio,

material orientation, loading direction, and the rigidity of the rails on stress distributions. Shear stresses were found to be dis-tributed uniformly over a large region in the specimen gage section for most of the models analyzed, but normally accompanied bysignificant transverse and axial normal stresses. The results indicated that an axial loading applied to a test fixture of uniform steel

rails and a test specimen with aspect ratio of 6 was the preferred test procedure. Simple test specimens of trapezoidal and rect-angular geometries, and specimens with tabs, were chosen for further evaluation. Also, the new Wyoming-Modified Two-Rail Sheartest fixture was established based on these analyses.

# 2003 Elsevier Ltd. All rights reserved.

Keywords: A. Polymer matrix composites; C. Finite element analysis; B. Mechanical properties; C. Stress concentrations; Shear test methods;

B. Modelling

1. Introduction

The finite element method is a powerful technique forthe numerical solution of a variety of engineering pro-blems, and has frequently been used in the evaluation oftest methods. The finite element method is capable ofquickly and efficiently predicting the response of a vari-ety of test specimen configurations and material orien-tations. In contrast, the fabrication and experimentalevaluation of such test specimens is expensive and timeconsuming, and hence less practical, during an initialevaluation of candidate configurations. Apart fromconsiderable savings of cost and time, finite elementanalyses require only minimal amounts of input data,and the resulting stress and strain distributions can bedetermined throughout the entire specimen.In the present study, linear three-dimensional finite

element analyses were conducted to predict the perfor-

mance of the two-rail shear test method. The effects ofvarious rail and test specimen configurations, materialorientations, and loading directions on stress distribu-tions were evaluated. These analytical results were thenused to select preferred specimen configurations and toobtain design criteria for the new Wyoming-ModifiedTwo-Rail Shear test fixture, a proposed alternative tothe ASTM Standard D 4255 (Method A) Two-RailShear test procedure [1]. The present study was part of alarger research program to re-evaluate the presentASTM Standard D 4255 two-rail shear test procedure.This existing standard incorporates features that are notadequately understood, as summarized in Ref. [2]. Theseinclude specimen aspect ratio, the use of diagonal load-ing, and the off-center location of the clamping bolts.In the ASTM standard test method, a 76�152 mm

(3�6 in) rectangular test specimen is sandwichedbetween two pairs of rails by bolting through sixoversized holes in the specimen. An off-axis (diagonal)tensile load is introduced at the ends of the rails. Ashearing load is thus transmitted into the test specimenvia the rails, and the shear strain response can bemeasured by strain gages mounted in the gage section.A slightly different version of this test procedure was

proposed earlier [3]. As outlined by Boller [3], the test

0266-3538/$ - see front matter # 2003 Elsevier Ltd. All rights reserved.

doi:10.1016/S0266-3538(03)00254-9

Composites Science and Technology 64 (2004) 221–238

www.elsevier.com/locate/compscitech

* Corresponding author. Tel.: +1-307-742-8641; fax: +1-307-742-

8682.

E-mail address: [email protected] (D.F. Adams).1 Currently Instructor, the MARA Institute of Technology (ITM),

Malasia.2 Emeritus Professor; President, Wyoming Test Fixtures, Inc.,

Laramie, WY, USA.

specimen was 76 mm (3 in) wide and 152 mm (6 in) longwith 12.7 mm (0.5 in) wide unconstrained central (gage)region. At free edges of the gage region, 12.7-mm (0.5-in) radius curves were cut. Specimens with this geometryprovided satisfactory results with greater uniformity instress distribution than a rectangular specimen [3]. Twopairs of rail guides were attached to the rails for lateralsupport. A diagonal compressive load was applied to aball and socket or spherical seat at each end of the rails.The reason why a diagonal load was applied was notgiven but the self-aligning spherical seat ensured thateach rail transmitted equal proportions of the totalload.There are several other rail shear versions that have

been introduced as alternatives. Rather than the con-ventional bolted-uniform-rail, a bonded-tapered-rail hasbeen used [4,5]. Rail shear test fixtures with low frictionrail guides, roller spacers, or knife-edge spacers havebeen also cited [2,6–8]. These mechanisms, which arenormally utilized with the compression loaded two-railfixture, can increase buckling stability and also improvealignment [3].Conventional flat specimens of rectangular shape

have been widely used. Specimens with 12.7 mm (0.50in) radius fillets at the edges [3] have been designed tominimize end effects. A trapezoidal-shaped specimenhas also been suggested [5,9,10], to reduce the magni-tude of the combined stresses in each corner whilemaintaining a large region of uniform shear stress in themiddle. Other specimen geometries may also be ana-lyzed, such as a rectangular specimen with V-notches atthe free edges (analogous to the Iosipescu shear testspecimen [11]), and ‘‘flat-bottom notched’’ specimens[12], to name a few. Modification of the existing ASTMstandard rectangular specimen by adding bondedtabs extending into the transition region, may also beconsidered.Several earlier analytical evaluations of the two-rail

shear test method with fiber-reinforced composite lami-nates have been reported [4,5,7,13,14]. Two-dimensionallinear finite element analyses of the two-rail shear testmethod were performed by Garcia et al. [4], to assessthe effects of aspect ratio, axial versus diagonal loadintroduction, and uniform versus thickness-tapered railconfigurations. Results indicated an influence of loadingdirection and rail configuration. However, aspect ratiohad a major effect on stress distributions, which alsovaried with laminate orientation.A group of investigators at the Virginia Polytechnic

Institute [7,13] compared four shear test methods,including the two-rail shear method, using the sameanalytical techniques. Their finite element results indi-cated that several factors influence the stress distribu-tions in the gage section of the rail shear test specimen.Uniform shear stress distributions were produced over alarge area in the gage section, but were often

accompanied by significant in-plane normal stressesdepending on the stiffness of the rails, the method ofload application, and the laminate properties [7,13].Black and Hart-Smith [5] presented their linear finiteelement analysis results for the bonded tapered rail spe-cimen with [�45] angle-ply and [0/�45/90]2S quasi-iso-tropic laminates. They approximated a three-dimensional effect in the three layers (rail, adhesive, andlaminate) using two-dimensional elements, emphasizingthe nonlinear behavior of the adhesive. From their ana-lysis, they predicted that the existence of stress con-centrations in the bonded tapered rail specimen wouldnot be sufficient to cause premature failures. Howeveran earlier analytical investigation [15] of a uniformthickness two-rail shear fixture with [�45]ns angle-plylaminates found that the shear stress distribution wasvery non-uniform and highly irregular, which wouldlead to unacceptably low values of experimental shearstrength [15]. It is apparent from these works [5,15] thatshear testing of laminates such as [�45]ns angle-ply and[0/�45/90]ns quasi-isotropic lay-ups are considered tobe difficult. This difficulty is generally associated withinadequate gripping, as well as a highly nonuniformstress distribution in the test area. In addition, sub-stantial local stress concentrations are normally presentand can cause premature failures in specimens of thesematerial orientations.Chang and Chen [14] used a three-dimensional analy-

sis with an eight-node isoparametric element to studythe effects of ply orientation on the in-plane shearstrength distribution in laminates. Laminates with var-ious cross-ply orientations were analyzed and a stronginfluence of the interlaminar stress in lowering thelaminate strength relative to lay-up sequence wasobserved.The definition of the material direction of a unidirec-

tional composite shear specimen, particularly the railshear specimen, has been inconsistent in the literature.For composites in general, the definition mainlydepends on the type of test method, direction of loadintroduction, and how the test fixture is oriented, e.g.,the rails in the case of the rail shear test. Some priorinvestigators considered the [0] orientation of the railshear test specimen to be in the loading direction (par-allel to the rails), but then this is unlike the Iosipescushear specimen where the 0� direction is perpendicularto the loading direction. Others simply assigned the [0]and [90] rail shear orientations corresponding to con-ventional x and y Cartesian coordinates, horizontallyand vertically, respectively. These mixed definitionssometimes cause confusion, especially when compara-tive studies between different test methods are carriedout.In the present work, the definition of the rail shear

specimen material orientation will follow the conventionof the Iosipescu shear test method [11]. Thus, a 0�

222 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

unidirectional composite has fibers oriented in the xdirection, perpendicular to the rails, and a 90� unidirec-tional composite has fibers oriented in the y direction,parallel to the rails.

2. Finite element models

Models of 13 basic two-rail shear specimen geometriesand a number of variations (varying the aspect ratio ornotch radius of the specimen, altering the loadingdirection, varying the rail thickness, adding a tab mate-rial, or changing completely the materials of the rails orthe specimen) were generated using MSC/PATRANsoftware [16], and analyzed using a previously-devel-oped finite element package known as WYO3D [17].These models are listed in Table 1. The basic geometriesare sketched in Fig. 1. Complete model details are givenin Ref. [10].

Two loading directions, axial and off-axis (diagonal)tension, were simulated. Two composite laminateorientations, [0]16 unidirectional, and [90]16 unidirec-tional were studied. In addition, a [04/904]S cross-plylaminate was modeled as a special case. Steel wasemployed for the rails and carbon/epoxy was the mate-rial utilized for the test specimen in most of the casesanalyzed.The steel rails and the composite specimen were

modeled as three-dimensional solids, such as shown inFig. 2. For the models incorporating tabs, an additionalsolid layer was used. Each individual solid layer repre-senting the rails, the unidirectional composite specimen,and the tabs was modeled as a single layer of elements.For the cross-ply specimen, two layers of elements weregenerated; each layer represented one of the orthogonalmaterial orientations. For simplicity, it was assumedthat the solids were perfectly bonded to each other.Furthermore, the symmetry of the rail shear specimen

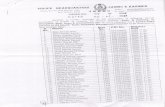

Table 1

Summary of cases for the finite element analysis

Model Geometry

Laminate orientation Loading type Anglea (�) Aspect ratiob R1. Rectangular:

(a) Rectangular A

[0],[90] Axial, diag. 90 6.0/0.75=8(b) Rectangular B

[0],[90] Axial, diag. 90 6.0/0.5=122. Rectangular with 0.5 in fillets

[0],[90] Axial – 5.13/0.75=6.853. Rectangular with V-notches

[0],[90] Axial 45 5.25/0.75=74. Rectangular with rounded notches

[0],[90] Axial 45 5.47/0.75=7.35. Rectangular A with tabs on two sides

[0],[90] Axial 90 6.0/0.75=86. Rectangular A with tabs on four sides

[0],[90] Axial 90 6.0/0.75=87. Flat-bottomed notches:

(a) FBN A

[0],[90] Axial 30 3.375/0.75=4.5(b) FBN B

[0],[90] Axial 45 4.5/1.0=4.58. Flat-bottomed notches with radii:

(a) FBN Radius A (r=0.265 in)

[0],[90] Axial 45 6.11/0.75=8.15(b) FBN Radius B (r=0.354 in)

[0],[90] Axial 45 4.65/1.0=4.659. Flat-bottomed notches extended

to the rails (FBN Extended)

[0],[90]

Axial 45 4.65/1.0=4.6510. Trapezoidal:

(a) Trapezoidal A

[0],[90] Axial, diag. 45 4.5/0.75=6(b) Trapezoidal B

[0/90] Axial 45 4.5/0.75=6(c) Trapezoidal C

[0],[90] Axial 45 4.5/1.0=4.5(d) Trapezoidal D

[0],[90] Axial 45 4.5/0.5=9(e) Trapezoidal E

[0],[90] Axial 60 4.5/0.5=9(f) Trapezoidal F

[0],[90] Axial 30 4.5/0.5=9(g) Trapezoidal G

[0],[90] Axial 30 4.5/0.75=6(h) Trapezoidal H

[0],[90] Axial 30 6.0/0.75=8(i) Trapezoidal A with titanium rails

[0],[90] Axial 45 4.5/0.75=6(j) Trapezoidal A with ‘rigid’ rails

[0],[90] Axial 45 4.5/0.75=6(k) Trapezoidal A with glass/epoxy specimen

[0],[90] Axial 45 4.5/0.75=611. Trapezoidal with thickness-tapered rails

[0],[90] Axial 45 4.5/0.5=912. Trapezoidal with width-tapered rails

[0],[90] Axial 45 4.5/1.5=313. Trapezoidal thickness ratios:

(a) Trapezoidal (2:1)

[90] Axial 45 4.5/1.0=4.5(b) Trapezoidal (3:1)

[90] Axial 45 4.5/1.0=4.5(c) Trapezoidal (13:1)

[90] Axial 45 4.5/1.0=4.5a Angle of the specimen free edges (at top and bottom) measured from vertical.b R is the specimen aspect ratio (length of the plate along the gage section/width of the plate between the rails).

A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 223

was exploited; hence, only one half was modeled. Themid-thickness of the specimen was a plane of symmetry.Unless otherwise specified, the thickness of the uni-

form rails and one-half the thickness of the compositespecimen were 12.7 mm (0.50 in) and 1.02 mm (0.040in), respectively, noting that the unidirectional compo-site specimen was actually modeled as one-half of a 16-ply laminate, assuming each ply to have a thickness of0.13 mm (0.005 in). Similarly, as a special case, a [04/904]S cross-ply laminate, having a total of 16 plies, wasmodeled as a four-ply laminate due to the symmetryabout the mid-thickness. The thickness of the tab layerin the models was 1.50 mm (0.060 in). To model thethickness-tapered rails, the rail thickness was variedfrom 12.7 mm (0.50 in) to 3.20 mm (0.125 in), and forthe width-tapered rails, the width was varied from 25.4mm (1.00 in) to 6.4 mm (0.25 in). For the trapezoidalthickness ratio models (model geometry #13), the steelrails were replaced by specimen material. As an exam-ple, for trapezoidal (2:1), the ratio 2:1 was based on thethickness of the ‘rails’ (0.080 in) relative to the (con-stant) thickness of the test specimen (0.040 in).

Fig. 1. FEA model geometries.

Fig. 2. Typical finite element grids of (a) the model geometry #1 rec-

tangular A (plan view) and (b) the model geometry #10, trapezoidal A

(isometric view).

224 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

In MSC/PATRAN, after the solids were generated,they were meshed using HEX-8, an eight-node isopara-metric element. Finer meshes were formed in the regionsbetween the rails and the specimen and also in theregions of the specimen free ends where high gradientsof stresses were expected. In WYO3D, boundary andloading conditions were imposed on each model. Tosimulate the actual boundary and loading conditions ofthe two-rail shear test, the nodes in the plane ofthrough-thickness symmetry of the model were con-strained in the z direction. In addition, for the axialloading case, nodal forces were applied in the y direc-tion (parallel to the rails) to a pair of nodes (Nodes A1and A2, see Fig. 2) while constraining them in the xdirection. For the diagonal loading case (7� off-axis forthe rectangular A and B models, and 5� for the trape-zoidal A model), the loaded nodes (Nodes D1 and D2,see Fig. 2) were given the x and y components of theload. In both loading cases the corresponding nodes atthe opposite end of the other rail (A10 and A20 for axialloading, or D10 and D20 for diagonal loading, see Fig. 2)were fixed in the x and y directions.There are two different ways the load can be intro-

duced to the rail shear specimen, viz., a tensile or com-pressive loading. Tensile loading, which was used in thepresent analyses, induces negative shear stresses. Thenormal stresses could be either tensile or compressiveaxial and transverse stresses, however. This resulted inthe normalized shear stress having negative values inmost cases, with mixed signs for the normal stresses,since the stress normalization was done by dividing theinduced stresses by the absolute value of the averageapplied shear. If compressive loading is used, all theresults obtained and presented in the present study willstill be valid, but with reversed signs.The total number of nodes in each model geometry

with two element layers was between 3000 and 4000.For models with three element layers, i.e., rectangularwith tab material (rails and composite specimen plus tabmaterial) and trapezoidal B (rails and two different

lamina orientations for cross-ply) required a total of4000–5500 nodes.Material properties were also specified in WYO3D.

Materials for the rails and the composite plate specimenwere steel and Hercules AS4/3501-6 carbon/epoxy,respectively. When tabs were modeled, aluminum wasused as the tab material. Three additional runs wereconducted using; (i) titanium rails and an AS4/3501-6carbon/epoxy composite specimen, (ii) ‘rigid’ rails andan AS4/3501-6 carbon/epoxy composite specimen, and(iii) steel rails and an S-2/3501-6 glass/epoxy compositespecimen. All three cases were analyzed using the Tra-pezoidal A model (see Table 1). The ‘rigid’ rails weremodeled by increasing the modulus of steel 2-fold. Thematerial properties for the steel, unidirectional carbon/epoxy, and unidirectional glass/epoxy [17], the titaniumalloy (Ti–6A1–4V) [4], and the aluminum tabs areshown in Table 2.All the results that will be presented later are based on

normalized stresses. Stress normalization was done bydividing the induced stresses by the absolute value ofthe average applied shear stress in the gage section. Thisabsolute value of applied shear stress was defined by�A= P=A

��

��, where P was the total applied load and A

the cross-sectional area (thickness�gage length) of thetest specimen across the gage section. The x- and y-coordinates were normalized with respect to one-halfthe specimen gage width (distance between two oppositerails) and specimen gage length, respectively.

3. Finite element analysis results

Only in-plane stress components, i.e., the shear stress�12, the axial stress �1 (the stress component parallel tothe fiber direction) and the transverse stress �2 (thestress component normal to the fiber direction) will befully presented and discussed here. The out-of-plane(interlaminar) stress components, i.e., �13, �23, and �3,were also available from the WYO3D outputs, but their

Table 2

Material properties of the rails, tabs, and composite laminates used in the present finite element analysis

Property

Rails Tabs Unidirectional laminatesSteel

Titanium Ti–6A1–4V [4] Aluminum Carbon/epoxy AS4/3501-6 [17] Glass/epoxy S-2/3501-6 [17]E11 (GPa) (Msi)

208 (30.0) 114 (16.5) 69.3 (10.0) 142 (20.5) 53.4 (7.74)E22 (GPa) (Msi)

208 (30.0) 114 (16.5) 69.3 (10.0) 9.2 (1.33) 16.4 (2.37)E33 (GPa) (Msi)

208 (30.0) 114 (16.5) 69.3 (10.0) 9.2 (1.33) 16.4 (2.37)G23 (GPa) (Msi)

78.3 (11.3) 42.1 (6.10) 26.1 (3.75) 3.6 (0.52) 5.5 (0.80)G13 (GPa) (Msi)

78.3 (11.3) 42.1 (6.10) 26.1 (3.75) 6.1 (0.88) 6.1 (0.88)G12 (GPa) (Msi)

78.3 (11.3) 42.1 (6.10) 26.1 (3.75) 6.1 (0.88) 6.1 (0.88)n23

0.333 0.342 0.333 0.29 0.32n13

0.333 0.342 0.333 0.25 0.27n12

0.333 0.342 0.333 0.25 0.27A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 225

magnitudes were small and their presence incon-sequentially affected the in-plane stress response of theunidirectional composites.In general, for all cases analyzed, the in-plane shear

stress was fairly uniformly distributed, and close to theaverage applied shear stress, throughout entire test sec-tion except near the free edges. However, undesirableaxial and transverse normal stresses, both tensile andcompressive, were also present in the gage section, withthe axial stresses being very much higher than thetransverse stresses. The presence of these axial stresseswas not a major concern, however, since the reinforcingfibers were oriented in this direction and thus this com-ponent of composite strength was high. On the con-trary, the existence of the transverse stresses can cause aproblem since the transverse strength of unidirectionalcomposites is typically very much lower than the long-itudinal strength. Furthermore, a transverse tensilestress could combine with the shear stress to promotefailure. The existence of a compressive transverse stress�2(�) could induce failure by out-of-plane buckling.The transverse tensile stress was significantly higher in[90] specimens than in [0] specimens for the various rec-tangular models, especially for rectangular A and B.The transverse tensile strength �2(+), being the low-

est of all the strengths, [i.e., axial tensile �1(+) andcompressive �1(�) strengths, transverse tensile �2(+)and compressive �2(�) strengths, and in-plane shear �12strength], is normally responsible for the so-called ‘‘firstply failure’’ in the specimen. As a comparison, typicalunidirectional composite strength properties for awidely used carbon/epoxy system [18], with (+) and (�)signs indicating tensile and compressive strengths,respectively, are:

�1(+)=1890 MPa (274 ksi)�1(�)=1930 MPa (280 ksi)�2(+)=65.5 MPa (9.5 ksi)s2(�)=269 MPa (39.0 ksi)�12=119 MPa (17.3 ksi)

Localized stress concentrations were usually predictedto be present at the following locations; near the top leftand bottom right hand corners (‘‘loaded’’ corners), andthe bottom left and top right hand corners (‘‘unloaded’’corners) of the full gage section, and at the roots of thenotches, if present. These stress concentrations gave anindication that premature failure might occur at thatparticular location rather than in the desired gage sec-tion region. However, the actual seriousness of theselocal effects was difficult to predict since it is possiblethat premature localized cracks might give stress relief,and thus be beneficial. This phenomenon has beenobserved in 0� Iosipescu shear specimens. Prematurecracks in the Iosipescu specimen often initiate near thenotch tips due to transverse tensile stresses [12]. This

cracking, however, does not propagate continuously,and was found in Ref. [12] to not affect the measure-ment of shear modulus or strength.The typical stress states in the test specimens of the

variousModel Geometries can be summarized as follows:

1. Only the in-plane stress components, i.e., shear

stress �12, axial stress �1, transverse stress �2,were significant, generally over the entire gagesection (also see items 5 and 6), and up to adistance of one-quarter of the rail width into thegripped region (under the rails). The out-of-plane(interlaminar) stress components, i.e., �13, �23,and �3, although present, were small in magni-tude.2. The shear stress �12 was fairly uniformly dis-

tributed, and close in magnitude to the averageapplied shear stress, throughout the entire gagesection, except in small areas near the free edgesfor the [0] and [90] orientations.3. High in-plane stress gradients (especially the

shear stress �12) occurred in the transition region,that is, between the one-quarter distance underthe rails from the inside edges of the grippedregion to a distance of two to three specimenthicknesses into the gage section, for the [0] and[90] orientations.4. Local shear stresses �12 were significantly larger

than the average applied shear stress �A over asmall area in one or the other of the followinglocations, depending on the particular model andspecimen orientation: (i) in the transition regionsand close to the specimen corners (loaded cornersor unloaded corners), (ii) in the proximity of notchroots and curved edges, or (iii) near free edges.5. The normalized tensile and compressive axial

stresses were very low (�1< 1:0j j), over a largeregion (more than three-fourths of the total areaof the gage section) in the center of the gagesection for all [0] orientation models, and over aneven larger region throughout the gage sectionfor the [90] orientation, except for the Trapezoi-dal Thickness Ratio Models. The normalizedaxial stress for the [90] orientations was verymuch lower than for the [0] orientation.6. The normalized tensile and compressive trans-

verse stresses were small (�2< 0:5j j) throughoutthe entire gage section, except in the vicinity ofthe local stress concentrations, typically for boththe [0] and [90] orientations for all models,excluding the [0] orientation trapezoidal withwidth-tapered rails geometry.7. The largest shear stress �12 occurred at the loaded

corners or the unloaded corners for [0] and [90]orientations, and at the notch roots of thenotched specimens (particularly for [0]).226 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

8. The largest tensile axial stress �1(+) occurred at

the loaded corners (particularly for [90]) and atthe notch roots of the notched specimens.9. The largest compressive axial stress �1(�)

occurred at the unloaded corners (particularlyfor [90]).10. The largest tensile transverse stress �2(+)

occurred at the loaded corners (particularly for[90]) or at the unloaded corners for some of the[0] trapezoidal geometries.11. The largest compressive transverse stress �2(�)

occurred at the loaded corners.The deformed shapes of the model geometries #1,rectangular A and #10, trapezoidal A for [0] specimenorientations are shown in Fig. 3. It will be noted thatthe specimens were not deformed into perfect trape-zoids, as would be expected for the ideal case. The fix-ture and the test specimen rotated significantly underload, which suggested that excellent gripping is essentialin actual experiments. Moreover, the rails were slightlybent elastically in-plane, which might imply that a fix-ture with stiffer rails could provide a better result thanone with less stiff rails.

In the following subsections the analytical results forselected model geometries are presented. In addition,the results of varying specific parameters, such as aspectratio, loading direction, and rail configuration will bediscussed. Parameters used as the basis for makingcomparisons were:

� uniformity of the normalized shear stress dis-tribution in the gage section.

� magnitudes of the normalized axial and trans-verse stresses.

� magnitudes of the stress concentrations.

Several selected individual cases are shown in Figs. 4–10. Each figure shows the predicted normalized stressdistributions through the center of the specimen gagesection parallel to the rails. Table 3 shows the predictednormalized stress concentrations and their locations forselected model geometries. These stresses were normal-ized with respect to the absolute value of the appliedshear stress and the x- and y-coordinates defining theirlocations were normalized with respect to one-half thegage width and gage length, respectively. Detailedresults for each individual case as summarized in Table 1can be found in Ref. [10].

3.1. Model comparison

The normalized shear stress distribution was fairlyuniform throughout the gage section in the rectangularA and B model geometries, varying by not more than�10% across the center of the gage section. Otherinvestigators [4,7,13] have obtained similar trends. Thetransverse stress distribution in the vicinity of the gagesection was also very low, smaller by a factor of 10 thanfor all other models. The largest normalized shear stressconcentrations for all cases (rectangular A, rectangularB, [0], [90], and axial and diagonal loadings) variedbetween �1.22 and �1.38, lower than for almost allother models. However, the transverse tensile normalstress concentration for the [90] laminate was among thelargest of all models.The specimen with 12.7-mm (0.5-in) fillets had been

shown to provide a greater uniformity in stress dis-tribution [3]. However, the results of the present studyindicated that there was no significant improvement inthe shear stress distributions for all three model geome-tries, for either the [0] or [90] orientations. In fact, themagnitudes of the shear stress became very large at thefree ends for the [0] orientation. Nevertheless, the axialtensile, transverse tensile, and transverse compressivestress concentrations were much lower than those of theconventional rectangular models.Notch rounding did not affect any of the three stress

distributions at the center of the gage section. Howeverall three stresses were decreased notably at the notch

Fig. 3. Finite element analysis output showing the deformed shapes of

0� orientation for (a) the model geometry #1, rectangular A and (b)

the model geometry #10, trapezoidal A.

A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 227

roots. Due to the sharp notches, the rectangular with V-notches model exhibited the largest magnitudes of thethree stress concentrations, for both the [0] and [90]orientations, compared to those with the roundedshapes.The stress distributions for the rectangular specimens

with tabs on two sides were uniformly distributed over asmaller region in the test specimen than for the untab-bed rectangular model. This could be due to the tabs

acting as secondary rails. Hence, the stresses were shif-ted into the transition regions between the tab layer andthe plate specimen, rather than in the regions betweenthe rails and the specimen of the untabbed rectangularmodel. The stress concentrations in this model geometrywere among the lowest of all the models, however. Thisis very favorable, since premature failures caused byunwanted peak stresses may not take place during test-ing. Thus, the specimen may achieve its true strength

Fig. 4. Normalized stress distributions along the center of gage section for various model geometries: axially loaded [0] laminate (model comparison).

228 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

prior to failure. It was probably for this reason that thetabbed specimens gave consistently high results in theASTM round-robin rail shear tests [19].The trapezoidal A configuration was found to be the

optimum configuration for the two-rail shear specimenfrom the present analyses, although the results were notexceptionally impressive relative to the rectangular

models. By way of comparison, the axially loaded tra-pezoidal A model provided a more uniform shear stressdistribution across the gage section than any of therectangular models. The normalized transverse stressfor the axially loaded [0] and [90] orientations of trape-zoidal A only varied within �0.10 over a large area(over more than 50% of the gage section) in the

Fig. 5. Normalized stress distributions along the center of gage section for model geometry #1, rectangular A: axially and diagonally loaded [0] and

[90] laminates (loading comparison).

A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 229

specimen center. Although the transverse stress washigher by a factor of 10 than that of the rectangularmodels, it was still too low to cause detrimental effects.The presence of a tensile transverse stress concen-

tration (1.19) near the unloaded corners for the [0]orientation, and (1.08) near the loaded corners for the[90] orientation, could initiate premature cracks. These

cracks would be acceptable if they were in the form ofmany microcracks, or could be constrained locally(without extending into the grip area). Otherwise theycould cause a lower shear strength measurement. Thenormalized shear stress concentrations for the axiallyloaded [0] and [90] orientations were �2.69 and �1.11,respectively. Since these peak shear stresses developed in

Fig. 6. Normalized stress distributions along the center of gage section for model geometry #10, trapezoidal A, axially and diagonally loaded [0] and

[90] laminates (loading comparison).

230 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

the same small area as the highest tensile transversestresses, the combined stress effect could speed up theformation of the cracks.

3.2. Axial versus diagonal loading comparison

Two directions of load introduction were applied torectangular A and B model geometries, a 7� off-axis(diagonal) loading and an axial loading, with both load

lines passing through the center of the specimen. The 7�

off-axis (diagonal) loading followed ASTM Standard D4255 [1] for a specimen with an aspect ratio, R=8, viz.,the rectangular A geometry. It should be noted that the7� line load nearly passed through the corners of thespecimen gage section. The axial versus diagonal load-ing was found to insignificantly affect the shear stressdistributions across the center of the gage section forboth rectangular models (see Fig. 5). Various other

Fig. 7. Normalized stress distributions along the center of gage section for model geometries rectangular and trapezoidal, axially loaded [0] laminate

(aspect ratio comparison).

A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 231

researchers [4,12] have also verified this. Nevertheless,the diagonal loading did slightly reduce the axial stressin the [0] and [90] laminates and the transverse stress inthe [90] laminate in the center of the gage section ofboth rectangular models. As mentioned, the transversestress was very low for the [0] laminate. The diagonalloading slightly reduced the magnitudes for nearly all ofthe stress concentrations.

The effects of the off-axis (diagonal) loading onthe shear stress distribution in the trapezoidal A modelwere insignificant (see Fig. 7), although the axial andtransverse stresses were very slightly reduced for bothfiber orientations. The stress concentrations werevery slightly reduced for the [0] laminate, but slightlyworsened for the [90] laminate. No statement as topreferred loading direction can be made, but the axial

Fig. 8. Normalized stress distributions along the center of gage section for model geometries trapezoidal A and trapezoidal thickness ratio axially

loaded [90] laminate (rail rigidity and thickness comparisons).

232 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

loading fixture will likely be more readily acceptedwithout having to provide any justification, unlike theoff-axis loading configuration.

3.3. Aspect ratio comparison

An analytical study by Garcia et al. [4], stated thatthere might be an optimum aspect ratio for a particular

test material. Comparing stress states between the rec-tangular A and rectangular B models for the aspectratio study (see Fig. 7), the former is very slightlyfavored, i.e., the lower aspect ratio resulted in slightlylower stresses. Comparing the results for the trapezoidalA, C, and D geometries (see Fig. 7), all with the sameacute angle of 45� but having different aspect ratios of 6,4.5, and 9, respectively, the overall stress distributions

Fig. 9. Normalized stress distributions along the center of gage section for model geometries #10, trapezoidal A, axially loaded [0] laminate

(composite specimen and orientation comparisons).

A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 233

did not differ much. However, the stress concentrationsof the trapezoidal A were generally lower than for theother two model geometries.

3.4. Rail rigidity and thickness comparison

The stress concentrations at the unloaded cornerswere probably induced by the rails. Factors that mightbe involved include the dissimilar thicknesses and dif-ferent material properties between the rails and the test

specimen. This led to tapering the rails. Tapering therails (thinner towards the unloaded ends) had been pre-viously studied [4,5]. The trapezoidal thickness-taperedand trapezoidal width-tapered models were comparedwith the trapezoidal D model ( having the same aspectratio). Neither the overall stress states nor the stressconcentrations of either the [0] or [90] orientations weresignificantly affected by tapering the rail thickness.Garcia, et al. [4], obtained the same outcome from theiranalysis.

Fig. 10. Normalized stress distributions along the center of gage section for model geometries #10, trapezoidal A, axially loaded [90] laminate

(composite specimen and orientation comparisons).

234 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

Both changing the steel rails to composite (AS4/3501-6) rails, and varying the rail thickness were consideredto reduce the stress concentrations at the unloaded cor-ners. Stress states for the trapezoidal (13:1) model werecompared with the [90] orientation trapezoidal C model.Both models were identical except that the material ofthe rails for the former was carbon/epoxy. The stressstates in the gage section did not differ significantly.Since the effect of two different material properties waseliminated by giving the rails the same material proper-ties as the specimen, the high stress concentrations nearthe corners were expected to decrease in the trapezoidal(13:1). However, the results (Table 3) indicate otherwise.The effect of reducing rail thickness on the stress

concentrations was also found to be very unfavorable.The stress distributions in the gage section of the three

trapezoidal thickness ratio models did not indicate anyimprovement with thinner rails (Fig. 8). The local stressconcentrations for the thickest rails, i.e., trapezoidal(13:1), were the lowest of the three (see Table 3).Based on these results, it can be concluded that the

rigidity of the rails affects the stress states and the localstress concentrations, with more rigid rails being super-ior. In addition, the dissimilar material propertiesbetween the test specimen and metal rails do notamplify the local stress concentrations at the corners.

3.5. Additional analyses

Additional analyses were performed to verify thatincreasing the rigidity of the rails did improve the stressstates. Trapezoidal A, with steel rails, titanium rails and

Table 3

Predicted stress concentrations of selected model geometries (normalized by the absolute value of the applied shear stress) and their locations

(nondimensionalized)

Model geometry

Load, lam. orientation Normalized�12

x y �1(+) x y �2(+) x yRectangular A

Axial, [0] �1.25 �0.96 0.89 14.81 1.14 1.00 1.62 �0.99 1.007�, [0]

�1.22 0.96 0.79 13.52 1.14 1.00 1.08 �0.99 1.00Axial, [90]

�1.38 �0.96 0.97 2.67 1.13 0.99 4.28 �0.96 1.007�, [90]

�1.24 �0.96 0.94 1.92 1.13 0.99 4.09 �0.96 1.00Rectangular B

Axial, [0] �1.31 �0.94 0.94 13.73 1.14 1.00 1.45 �0.98 1.007�, [0]

�1.26 0.94 0.83 12.14 1.14 1.00 0.92 �0.98 1.00Rectangular with

Axial, [0] �1.31 0.91 0.90 4.77 1.58 0.99 1.21 �1.00 1.170.5-in fillets

Axial, [90] �1.21 �0.48 1.07 2.48 1.28 1.10 1.27 �0.92 1.17Rectangular with

Axial, [0] �2.03 0.00 1.00 7.61 1.50 1.00 1.26 �0.71 1.00V-notches

Axial, [90] �1.41 �0.96 1.14 2.17 1.13 1.13 1.39 �0.71 0.99Rectangular with

Axial, [0] �1.37 �0.19 1.00 5.82 1.43 1.00 1.25 �1.00 1.10rounded notches

Axial, [90] �1.29 �0.91 1.09 2.04 1.13 1.10 1.41 �0.51 1.03Rectangular A with

Axial, [0] �1.14 �0.43 0.90 4.55 1.26 1.00 0.13 �0.56 0.86tabs on 2 sides

Axial, [90] �1.18 �0.43 0.86 1.13 1.26 0.71 1.60 �0.48 1.00Flat Bottomed Notch Extended

Axial, [0] �2.93 0.96 0.79 2.34 1.96 0.80 1.50 0.92 0.80Axial, [90]

�1.39 �0.96 1.21 2.08 1.00 1.18 1.35 �0.96 1.21Trapezoidal A

Axial, [0] �2.69 0.94 0.84 2.84 1.73 0.84 1.19 0.87 0.855�, [0]

�2.65 0.95 0.84 2.54 1.73 0.84 1.16 0.87 0.86Axial, [90]

�1.11 �0.87 1.14 1.54 1.00 1.02 1.08 �0.79 1.135�, [90]

�1.19 �0.95 1.16 1.50 1.00 1.10 1.20 �0.94 1.16Trapezoidal B

Axial, [0] �1.77 0.95 0.84 2.69 1.02 0.97 1.27 �1.00 1.17(Cross-Ply)

Axial, [90] �1.24 0.87 0.78 1.89 1.57 0.84 0.43 0.79 0.87Trapezoidal C

Axial, [0] �2.93 0.96 0.79 2.10 1.93 0.81 1.48 0.92 0.80Axial, [90]

�1.46 �0.96 1.21 2.30 1.00 1.18 1.41 �0.96 1.21Trapezoidal D

Axial, [90] �3.20 0.96 0.90 4.09 1.44 0.90 1.25 0.87 0.91Axial, [0]

�1.36 �0.96 1.10 1.69 1.00 1.06 1.33 �0.96 1.10Trapezoidal A with

Axial, [0] �2.87 0.95 0.84 4.33 1.73 0.84 1.30 0.87 0.86Titanium rails

Axial, [90] �1.66 �0.95 1.16 2.47 1.00 1.13 1.56 �0.95 1.16Trapezoidal A with

Axial, [0] �2.55 0.95 0.84 1.91 1.02 0.92 1.10 0.79 0.87‘rigid’ rails

Axial, [90] �1.23 0.95 0.56 1.46 1.00 1.17 1.06 �0.94 1.16Trapezoidal A with

Axial, [0] �2.21 0.95 0.84 1.59 1.64 0.88 1.23 0.79 0.87glass/epoxy

Axial, [90] �1.39 0.95 0.78 1.39 1.00 1.17 1.10 �0.94 1.05Trapezoidal with

Axial, [0] �2.97 0.96 0.90 4.14 1.44 0.90 1.03 �1.00 1.10thickness-tapered rails

Axial, [90] �1.42 �0.96 1.10 1.78 1.00 1.05 1.44 �0.96 1.10Trapezoidal 2:1

Axial, [90] �7.92 �0.96 1.21 22.66 1.00 1.20 6.37 �0.96 1.21Trapezoidal 3:1

Axial, [90] �5.87 �0.96 1.21 15.41 1.00 1.20 4.87 �0.96 1.21Trapezoidal 13:1

Axial, [90] �2.12 �0.96 1.21 3.57 1.00 1.18 1.97 �0.96 1.21A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 235

‘rigid’ rails were compared (Fig. 8), where the ‘rigid’rails were modeled as having a modulus twice as high assteel. It was found that for the [0] and [90] orientations,the ‘rigid’ rails provided slightly more uniform shearstress distributions and the lowest normalized axial andtransverse stresses across the center of the gage section.Most of the stress concentrations were the lowest for therigid rails, while the titanium rails gave the highest stressconcentrations in all cases.A glass/epoxy unidirectional composite specimen with

[0] and [90] orientations, and a carbon/epoxy [04/904]Scross-ply laminate, were analyzed using the trapezoidalA geometry. In brief, the analytical results indicatedthat the trapezoidal specimen should work well withboth glass/epoxy and carbon/epoxy (Figs. 9 and 10),and with both unidirectional and cross-ply orientations.The stress distribution in the cross-ply laminate did dif-fer somewhat from that in the unidirectional laminates.This could be due to the interply effects between the 0and 90� fibers in the cross-ply laminate.The cross-ply may be the more practical orientation.

Reinforcement in both directions, especially in the gripsection, better confines the crack formation to the gageregion. The [90] orientation may not be suitable due tothe severity of the transverse stress. In addition, sincethe fibers are parallel to the rails, a thin specimen maybe relatively easily broken while the test fixture is beinginstalled in the testing machine.

4. Summary of results

The finite element analysis results discussed in theprevious subsections were primarily for 0 and 90� uni-directional carbon/epoxy test specimens. Two addi-tional analyses were also performed, for a carbon/epoxycross-ply laminate and for a unidirectional glass/epoxylaminate. Although other factors such as stackingsequence, type of composite (chopped, woven, con-tinuous fiber, etc.), and type of fiber and matrix mate-rial, are expected to have some influence also, thefollowing summary of results and conclusions of thepresent analysis is expected to be generally applicable.That is, the present results can be summarized asfollows:

1. The shear stress states were fairly uniform

throughout the test specimen for most of themodel geometries, especially for the trapezoidalA model, except in small areas near the free edgesand in the transition region close to the rails.2. Stress concentrations exist at corners and

notch roots, and may cause premature failure.These stresses are influenced by geometricdiscontinuities.3. Free edges and the complex stresses at the

interface between the rails and the specimen giverise to stress concentrations near the corners ofthe gage section. However, the dissimilar mate-rial properties of the specimen and the rails do not.Although varying the specimen configuration andrail stiffness can minimize these stress concentra-tions, they have not been totally eliminated.4. The presence of compressive transverse stresses

may cause out-of-plane buckling failures, andhigh tensile transverse stresses may combine withthe shear stresses to cause premature failure. Theseverity of these stresses was particularly notice-able in [90] rectangular specimens, which maymake this material orientation unsuitable fortesting. It is also relatively easy to accidentallybreak a [90] specimen while installing it in thefixture.5. The trapezoidal A model has been chosen as the

optimum test specimen configuration because thenormalized shear stress distribution is uniformthroughout almost 80% of the gage section.Furthermore, the normalized transverse stress isquite small in the vicinity of the gage section. Therectangular A and the rectangular with tabs ontwo sides models are worthy of considerationalso. The trapezoidal and the rectangular speci-mens have an advantage of being easier to fab-ricate than those with notches, and the tabbedspecimen provides reinforcement in the grip sec-tion to resist possible crushing failure from thefixture.6. The angle of the trapezoidal geometry does affect

the stress states. The shear stress distribution ismore uniform for a trapezoid with a smalleracute angle, but the local stress concentrationsare larger.7. There may be an optimum aspect ratio for each

type of specimen geometry, which could alsodepend on the laminate orientation. Governingfactors in selecting an aspect ratio include thestress states produced, the accessibility of thegage section, and the overall size of the testspecimen.8. Off-axis (diagonal) loading very slightly improves

the overall stress states in the rectangular modelsand in the trapezoidal A model. However, due toa lack of detailed study to predict the optimumloading angle, there is not yet enough justifica-tion for it to be considered as the preferredloading method.9. The material stiffness and thickness of the rails

influence the stress states, with more rigid railsbeing superior. Tapering the rails does notfavorably influence the stress distributions orreduce the stress concentrations.236 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

In most of the finite element analysis cases, the railcomponents were modeled as matching the rails used inthe standard ASTM D 4255 fixture, but without bolts.The test specimen was also modeled without holes. Asignificant simplification was made by assuming a per-fect bond between a specimen and the rails, whichexplains the absence of the bolts and the holes. In anactual ASTM D 4255 test however, bolting rather thanbonding is used. Close examination of the present finiteelement analyses will reveal that they did in fact closelyrepresent the actual test condition imposed by the newlydesigned Wyoming-modified test fixture and its testspecimen, shown in Fig. 11 [2]. Thus, most of the ana-lytical results should predict the actual response moreaccurately for the newly designed fixture than the exist-ing ASTM fixture.Having analyzed various specimen and rail configur-

ations using the finite element analysis, trapezoidal A (atrapezoidal specimen) was predicted to be the optimumconfiguration. Rectangular A (a simple rectangular spe-cimen) and rectangular with tabs on two sides (a tabbedrectangular specimen) were also considered favorablefor potential experimental evaluation.Thus the finite element analysis did serve its purpose,

in predicting the responses of a variety of test specimenconfigurations and material orientations, and the effectsof several other parameters. The results also helped theauthors better understand the complexities of the stressdistributions near specimen edges and stress transitionregions. The large region of uniform shear stressaccompanied by insignificant transverse normal stressesstrongly indicated the presence of a pure shear state inthe gage section for almost all of the models. In addi-tion, by knowing that the shear stress in the center ofthe test area was close to the applied shear stress, theauthors became confident that the shear modulus mea-

surements obtained experimentally should be correct,and correction factors unnecessary.

5. Conclusion

Criteria for use in the design of a new shear test fix-ture were obtained from the detailed finite element ana-lysis study presented here. A variety of specimen andrail configurations were analyzed. In addition, severalother parameters that were expected to affect the resultswere also studied. Significant amounts of informationwere obtained through this analytical evaluation, andconsiderable amounts of time were saved by utilizingthis approach for the initial evaluation of candidate testspecimen geometries.After several candidate configurations have been

chosen, a nonlinear three-dimensional analysis usingWYO3D [17], or a failure initiation and propagationanalysis using the recently modified WYO2D program[20], can be performed. As an alternative, experimentalevaluation can now be conducted using only a smallnumber of different configurations. In fact, a concludingexperimental evaluation is often the best approach sinceanalytical methods do not always accurately predict theresponse in an actual test environment.A large central region of uniform shear stress, along

with a low transverse tensile stress, was obtained formost of the finite element analysis models. Therefore, itis strongly believed that the [90] and [0] specimens arecapable of providing reliable shear modulus values.However, a [0/90] cross-ply specimen should provide anaccurate measure of both the shear modulus and shearstrength of a composite material.

Acknowledgements

The authors express their sincere appreciation to theirfellow members of the Composite Materials ResearchGroup at the University of Wyoming for their invalu-able advice and assistance. Special thanks are alsoextended to the MARA Institute of Technology (ITM),Malaysia, and the Federal Aviation Administration,Washington, DC, for funding this study.

References

[1] ASTM Standard D 4255-83. Standard guide for testing in-plane

shear properties of composite laminates. West Conshohocken

(PA): American Society for Testing and Materials; 1995.

[2] Hussain AK, Adams DF. The Wyoming-modified two-rail shear

test fixture for composite materials. Journal of Composites

Technology and Research 1999;21(4):215–23.

[3] Boller KH. A method to measure intralaminar shear properties

of composite laminates. Technical report AFML-TR-69-311.

Dayton (OH): Air Force Materials Laboratory; December 1969.

Fig. 11. Sketch of the Wyoming-modified two-rail shear test fixture.A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238 237

[4] Garcia R, Weisshaar TA, McWithey RR. An experimental and

analytical investigation of the rail shear-test method as applied to

composite materials. Experimental Mechanics 1980;20:273–9.

[5] Black JB Jr., Hart-Smith LJ. The Douglas bonded tapered rail-

shear test specimen for fibrous composite laminates. In: Proceed-

ings of the 32nd International SAMPE Symposium, April 1987.

p. 360–71.

[6] Whitney JM, Daniel IM, Pipes RB. Experimental mechanics of

fiber reinforced composite materials. Society for Experimental

Stress Analysis monograph no. 4. Englewood Cliffs (NJ): Pre-

ntice-Hall; 1982.

[7] Bergner HW, Davis JG, Herakovich CT. Analysis of shear test

methods for composite laminates. Report VPI-E-77-14, Blacks-

burg (VA): Virginia Polytechnic Institute and State University.

April 1977.

[8] Advanced composites design guide; 3rd ed. Wright Patterson Air

Force Base (OH): Air Force Systems Command; 1977. vol. IV.

[9] Chatterjee SN, Adams DF, Oplinger DW. Test methods for

composites—a status report, vol. III. Shear test methods. Report

DOT/FAA/CT-93/17, III. FAA Technical Center, Atlantic City

International Airport (NJ): Federal Aviation Administration;

June 1993.

[10] Hussain AK, Adams DF. An analytical and experimental eval-

uation of the two-rail shear test for composite materials. Report

no. UW-CMRG-R-98-105. Laramie (WY): Composite Materials

Research Group, University of Wyoming; February 1998.

[11] ASTM Standard D 5379-93. Standard test method for shear

properties of composite materials by the V-notched beam

method. West Conshohocken (PA): American Society for Testing

and Materials.

[12] Lewis EQ, Adams DF. An evaluation of composite material

shear test methods. Report no. UW-CMRG-R-91-103, Laramie

(WY): Composite Materials Research Group, University of

Wyoming; May 1991.

[13] Herakovich CT, Bergner HW, Bowles DE. A comparative study

of composite shear specimens using the finite element method. In:

Chamis CC, editor. Test methods and design allowables for

fibrous composites [ASTM STP 734]. Philadelphia (PA): Amer-

ican Society for Testing and Materials; 1981. p. 129–51.

[14] Chang F-K, Chen M-H. The in situ ply shear strength distribu-

tions in graphite/epoxy laminated composite. Journal of Compo-

site Materials 1987;21:708–33.

[15] Whitney JM, Stansbarger DL, Howell HB. Analysis of the rail

shear test—applications and limitations. Journal of Composite

Materials 1971;5:24–34.

[16] MSC/PATRAN version 6.0. Los Angeles (CA): The Macneal-

Schwendler Corporation; August 1996.

[17] Xie M, Adams DF. A study of compression and shear test methods

for composite materials using a nonlinear finite element analysis.

Report no. UW-CMRG-R-94-102. Laramie (WY): Composite

Materials Research Group, University of Wyoming; June 1994.

[18] Engineers’ guide to composite materials. Metals Park (OH):

American Society for Metals; 1987.

[19] Lockwood PA. Results of the ASTM round-robin on the rail

shear test for composites. Composite Technology Review 1981;3:

83–6.

[20] Kotha S, Adams DF. Analytical investigation of crack initiation

and propagation in composite materials. Report no. UW-

CMRG-R-98-119. Laramie (WY): Composite Materials Research

Group, University of Wyoming; December 1997.

238 A.K. Hussain, D.F. Adams /Composites Science and Technology 64 (2004) 221–238

![Jurnal Ahmad Faza Riwidyanto [10050724226] - unesa.ac.id](https://static.fdocuments.nl/doc/165x107/626d982671e0f7662f33562f/jurnal-ahmad-faza-riwidyanto-10050724226-unesaacid.jpg)